10

INSTALLATION MANUAL

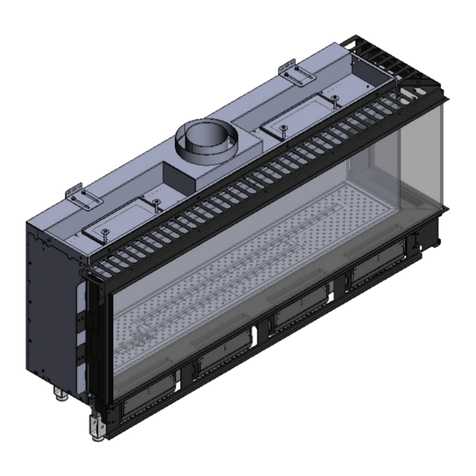

Make sure the cables of the ignition are hanging loosely under

the device, to ensure a good ignition. Remove any tie wraps or

other cable binders.

Check the pilot and second thermocouple for obstructions and

check the air tightness of the system.

Ensure that the lineset (which includes the gas valve, electrical

wiring and gas lines) does not impede the full operation of the

relief doors.

Ensure the safety of these critical components throughout the

installation process. Remove and dispose of all wraps and ties.

5.4 Installing the gas line

In accordance with the latest edition of the National Fuel Gas

Code, NFPA 54 (USA) or CAN/CSA-B149.1 (Canada,) correctly size

and route the gas supply line from the supply regulator to the

area where the appliance is to be installed.

Never use galvanized or plastic pipe unless it is rated for use with

gas. Gas supply pipes must be designed, routed, constructed and

made of materials that are in strict accordance with local codes

and regulations. A qualified plumber or gas fitter should be hired

to correctly size and route the gas supply line to the appliance in

accordance with all applicable codes and regulations.

Installing a gas supply line from the fuel supply to the appliance

involves numerous considerations of materials, protection,

sizing, locations, controls, pressure, sediment trap, and other

criteria. The sizing and/or installing of gas piping should only be

performed by a qualified plumber or gasfitter.

The gas control inlet accepts a 3/8” (9,525 mm) NPT fitting. The

gas supply piping should have a separate gas shuto valve and

a capped, 1/8” (0,375mm) pipe tapping upstream of the valve for

the purpose of reading pressure. A service shuto valve must be

placed within six feet of the fireplace gas control valve.

The gas supply pressure at the gas control valve must not exceed

the Maximum Supply Pressure as shown in the Specifications

and Dimensions section of this manual.

The gas supply line must be properly connected and bled by a

certified gasfitter or plumber.

Do not modify or substitute any part of this appliance.

The appliance and its main gas valve must be disconnected

from the gas supply piping system during any pressure testing

of that system at test pressures in excess of 1/2 psi (3.5 kPa). The

appliance must be isolated from the gas supply piping system by

closing its equipment shuto valve during any pressure testing

of the gas supply piping system at test pressures equal to or less

than 1/2 psi (3.5 kPa).

5 GAS INSTALLATION

The device is developed, tested and approved to conform the

applicable standards for the usage, the performance and safety

of the product. The installation of your device must apply to the

current building prescriptions.

We advise to make use of a qualified gas installer for the

installation of your device. The installer can provide you with all

information regarding the safety regulations of the installation.

This appliance is only for use with the type of gas indicated on

the rating plate. These appliances are not convertible for use

with other gases unless a certified kit is used and the conversion

is performed by an authorized qualified technician.

5.1 Attention points gas fireplace

This device can be place in a new or existing situation. The device

can be installed in a fully enclosed or mechanically ventilated

room without extra ventilation.

Before installation of these appliances, the area into which the

fire is to be fitted must be cleared of all debris (including dust), in

particular combustible material.

5.2 Attention points gas connection

The gas connection should apply to the local norms in force.

Applicable standards are ANSI Z21.50/CSA 2.22 (Vented Gas

Fireplaces) and CAN/CGA 2.17-M91 (Gas-fired Appliances for Use

at High Altitudes.)

If your installation is at an elevation greater than 2000 feet (600

meter) in the US or 4500 feet (1370 meter) in Canada, consult

with the local authority having jurisdiction for gas product

installations to determine their specific requirements for high

altitude installations. Calculate the diamater of the gas flue,

such that no pressure loss is occuring in the pipes. Place a

shut-o valve in the near vicinity of the device. Position the

gas connection, such that it is always accessible for service

purposes.

Before construction of the enclosure, carefully cut the black tie

wraps which hold the line set to the bottom of the fireplace.

Then carefully unwrap the line set. Lay the line set out towards

the location of the access door. Do not kink the lineset and do

not bend to a radius of less than 2"/ 50 mm. Make sure that the

line set is always accessible for service purposes.

5.3 Checking the gas lines

To be able to check on the gas lines, it is necessary to have the

right equipment. If necessary take out the glass of the device

and use the measuring point (see Figure 15.4), to check the

supply pressure on the gas pipes.

A = Supply pressure

B= Burner pressure