Pre-Installation Notes

This RO system is designed for installation under the sink, usually in the kitchen or bathroom. It can be mounted on a wall

surface or on the cabinet floor next to the storage tank. The RO faucet installs on the sink or into the counter next to the

sink. You can also install the system in any remote location from the faucet, observing the safety guides below. You will

need a nearby water supply and drain point.

Water Supply: To provide supply water to the RO system, use the included feed supply fittings as described on page 7.

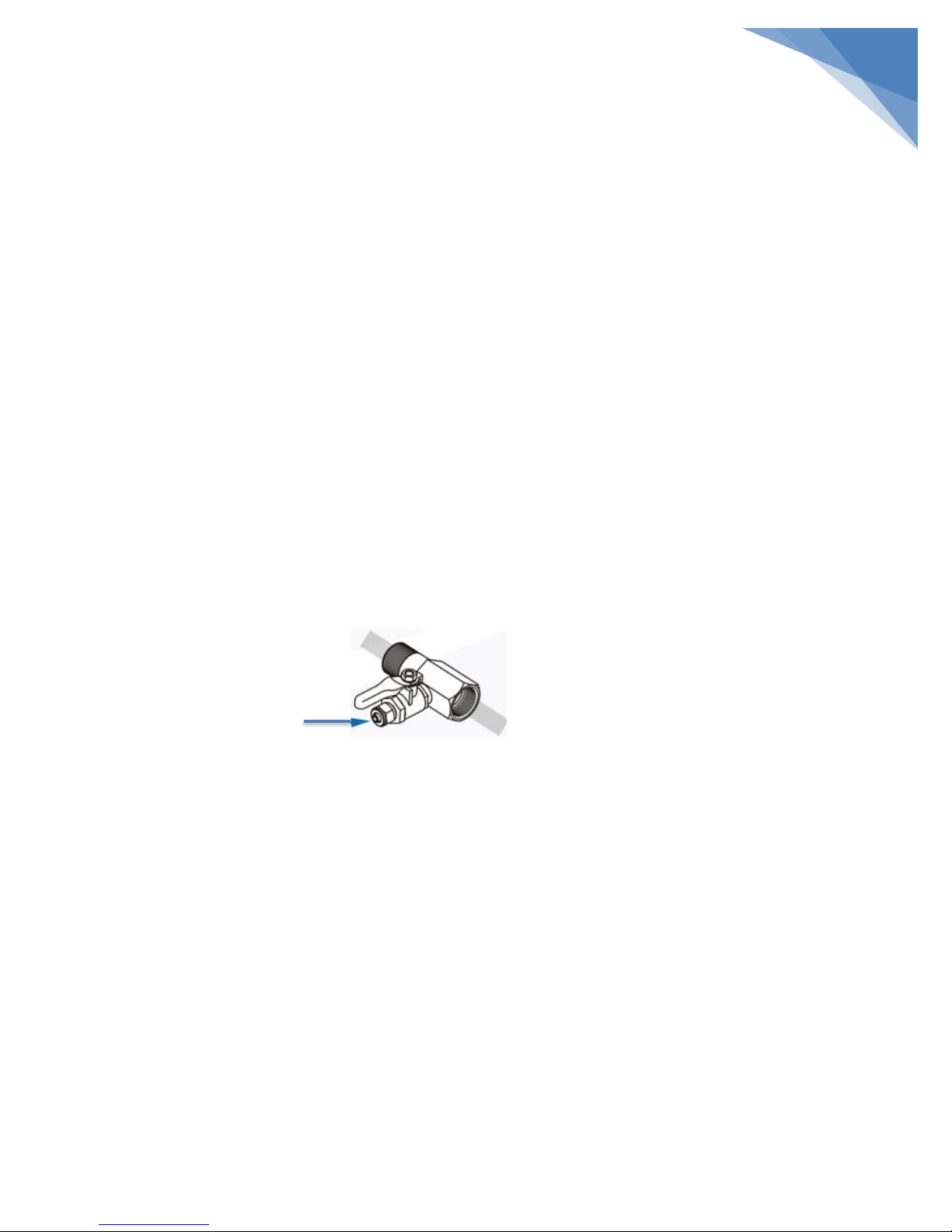

Drain Point: A suitable drain point is needed for the reject water from the RO membrane. A floor drain, laundry tub,

standpipe, sump, etc., is preferred for remote installations. A saddle drain adapter is included to install the system under

the sink where codes permit it as an optional drain point.

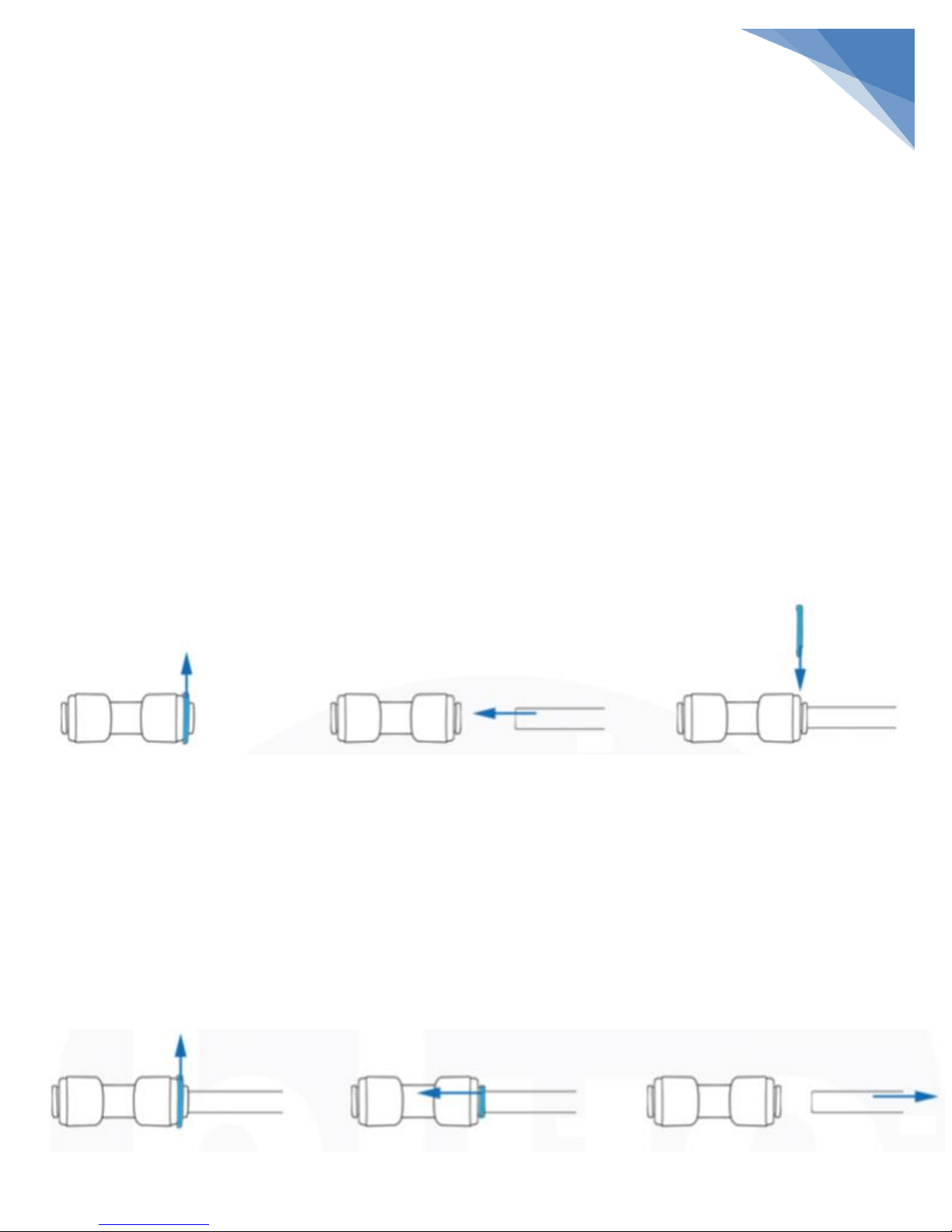

NOTE: Tubing lengths supplied with the system allow for easy moving of the filter assembly for servicing. If tubing

lengths are shortened for a neater appearance, it may be necessary to keep the filter assembly in its installed

location for service. Please keep connecting tubes as long as possible for convenient usage.

CAUTION: A refrigerator icemaker may not operate properly when connected to an RO system that has been

installed on a water system operating outside of the specified pressures listed on the Performance Data Sheet.

CHECK YOUR WATER SUPPLY: The COLD water supply to the RO system must be within certain quality limits. See

the Performance Data Sheet. If the supply water is not within the limits defined, the RO system will not filter

water as it should and will substantially reduce the filter and membrane life.

CAUTION: Chlorine in water will destroy the RO membrane. Most municipalities add chlorine to the water supply

to kill water-borne infectious organisms. The pre-filters will remove the chlorine up to the limits shown in the

Performance Data Sheet before it enters the RO membrane. It is important to replace the pre-filter cartridges at

the recommended time intervals. See the filter change-out procedures and the Performance Data Sheet.

CAUTION: Before consuming any water from the RO system you must purge the RO membrane cartridge. The RO

cartridge contains a food grade preservative that should be removed before consuming the water from the

system. This procedure is explained on page 11.

DO NOT attempt to use this product to make safe drinking water from non-potable water sources. Do not use the

system on microbiologically unsafe water, or water of unknown quality without adequate disinfection before or after the

system. This system is suitable for cyst reduction and may be used on disinfected water that may contain filterable cysts

per the Performance Data Sheet.

Check with your local public works department for applicable plumbing and sanitation codes. You must follow their

guides as you install the system. Follow your local codes if they differ with guidance in this manual.

This reverse osmosis system works on water pressure of 40 psi minimum to 87 psi maximum. You must install a

pressure reducing valve in the water supply pipe to the reverse osmosis system if the water pressure exceeds 87 psi.

DO NOT install this reverse osmosis system outdoors or in extreme hot or cold environments. Temperature of the feed

water supply to the RO system must be between 39⁰ F to 100⁰ F. Do not install on hot water.