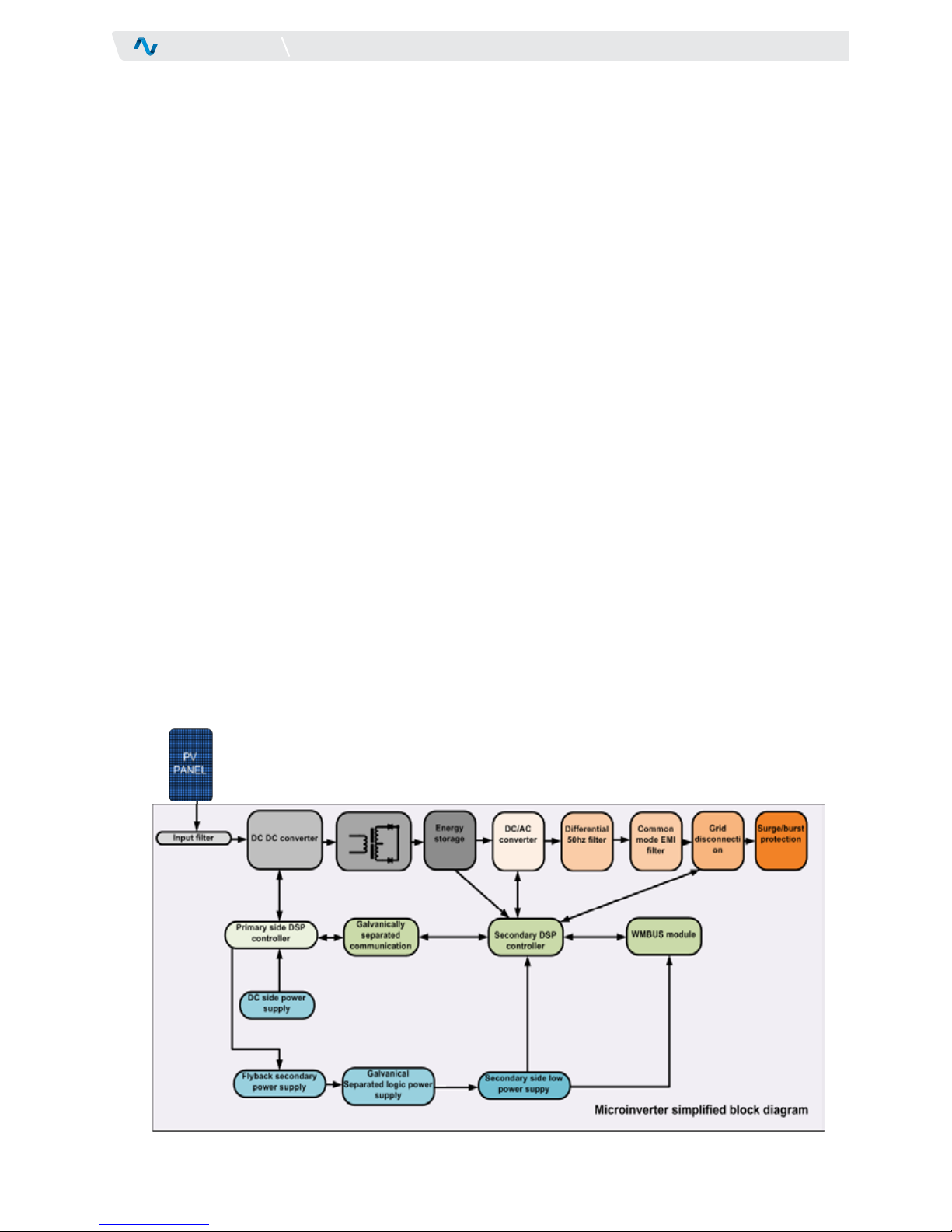

Solar Micro inverter converts direct current (DC) generated from a single PV module to alternating current (AC).

Each micro inverter use Maximum Power Point Tracking (MPPT) to maximize production of single PV module.

Micro inverter has several functional units:

Input filter on DC side decouples PV panel from high

frequency transients during DCDC converter switching.

DC side power supply of the primary (DCDC) logic is active

until minimum panel voltage is reached.

Primary DSP controller (16bit , 70MIPS, high performance

DSP) calibrates analog system, then starts to sample

PV panel open circuit voltage. After PV voltage reaches

sufficient voltage for reliable start of main flyback power

supply, secondary(AC) side logic is turned on.

At this point, power supply to both power sections is

activated, secondary DSP (32bit,60Mips controller) is

started.

After successful connection with primary DSP controller,

secondary controller will execute auto calibration and

after 10 seconds activate WMBUS RF module. This delay

is necessary for WMBUS module to stabilize operating

parameters and also to avoid unnecessary power ON/OFF

INTRODUCTION

1.3 Hardware Structure of Solar Micro Inverter 260

cycling in case of low irradiation. WMBUS module converts

inverter serial data into 868Mhz data stream according to

WMBUS standard. Data from micro inverter can be received

by Letrika data gateway or by any device compatible with

WMBUS standard.

The power DCDC converter is started in constant current

mode and high voltage. Energy storage capacitor is charged

up to minimum voltage needed for reliable start. Voltage

level in energy storage capacitor changes with grid voltage,

optimizing switching losses on power section. Foiled

capacitors are use because they have lower aging compared

with electrolytic capacitors.

Concurrently DSP2 algorithms are synchronized with grid

and operating limits are checked. Once DC voltage reaches

minimum level, AC inverter power stage is enabled, grid

disconnection relay (if present) is turned on and grid current

is gradually (according to standards limits) increased.

DCDC converter switches to MPPT tracker mode and begins

to track PV panel maximum power point. A high speed