Elgo P40T-002 Series User manual

Operating Manual

SERIES P40T-002

Programmable Touch Screen Controller for Guillotine Shears

TFT-Display with touch operation

Manual inching, single and program mode

Integrated program memory and auto-cutting machine

Material depending calculation of gap, angle & pressure

Sheet support and return to the front function

Analog inputs and outputs

Digital outputs up to 2 A

799000681 / Rev. 7 / 2019-05-13

Translation of the original operating manual

Contents

- 3 -

1Contents

1Contents ............................................................................................. 3

2List of Figures..................................................................................... 5

3List of Tables ...................................................................................... 6

4General, Safety, Transport and Storage ........................................... 7

4.1 Information Operating Manual ........................................................................................... 7

4.2 Explanation of Symbols...................................................................................................... 7

4.3 Statement of Warranties..................................................................................................... 8

4.4 Demounting and Disposal.................................................................................................. 8

4.5 General Causes of Risk ..................................................................................................... 8

4.6 Personal Protective Equipment ............................................................................................ 8

4.7 Conventional Use ............................................................................................................. 9

4.8 Safety Instructions for Transport, Unpacking and Loading ....................................................... 9

4.9 Handling of Packaging Material.......................................................................................... 9

4.10 Inspection of Transport ...................................................................................................... 9

4.11 Storage ........................................................................................................................... 9

5Product Features .............................................................................. 10

6Technical Data ................................................................................. 11

6.1 Identification .................................................................................................................. 11

6.2 Dimensions .................................................................................................................... 11

6.3 Technical Data ............................................................................................................... 12

7Installation and First Start-Up......................................................... 13

7.1 Operating Area .............................................................................................................. 13

7.2 Mounting of the Controller ............................................................................................... 14

7.3 Activation of the Device ................................................................................................... 14

8Design und Function ........................................................................ 15

8.1 Menu Structure ............................................................................................................... 15

9Main Menu ....................................................................................... 16

9.1 Language Selection......................................................................................................... 16

10 Operation Modes............................................................................. 17

10.1 Single Mode................................................................................................................... 17

10.2 Manual Mode ................................................................................................................ 20

10.3 Program Mode ............................................................................................................... 21

10.4 Reference an Axis............................................................................................................ 24

11 Service Mode / Parameter Level ..................................................... 25

11.1 Service Menu ................................................................................................................. 25

11.2 Password Login............................................................................................................... 25

11.3 Sub Menu Axis................................................................................................................ 26

11.4 Settings Axis ................................................................................................................... 27

Contents

- 4 -

11.5 Distances Axis ................................................................................................................ 32

11.6 Times Axis...................................................................................................................... 37

11.7 Analog Axis.................................................................................................................... 39

11.8 Calibrate Axis................................................................................................................. 43

11.9 Sub Menu Cutting........................................................................................................... 45

11.10 Sub Menu Setting System ................................................................................................. 47

11.11 Sub Menu Times System................................................................................................... 49

11.12 Additional Functions........................................................................................................ 52

11.13 Pump Control................................................................................................................. 53

11.14 Calibrate (Touch Screen).................................................................................................. 54

11.15 Soft Keys........................................................................................................................ 55

11.16 Material Table................................................................................................................ 57

11.17 Functional and Logical Assignment of Input-/Output Functions.............................................. 59

11.18 Load and Save OEM Data ............................................................................................... 60

11.19 Reset to Factory Defaults.................................................................................................. 60

11.20 Touchscreen Design / Program Version / Backup ID ............................................................ 61

11.21 PC Interface ................................................................................................................... 61

12 Connections...................................................................................... 62

12.1 Connector Arrangement - 16 IO Version............................................................................ 62

12.2 Pin Assignment - 16 IO Version ........................................................................................ 63

12.3 Connector Arrangement - 8 IO Version.............................................................................. 64

12.4 Pin Assignment - 8 IO Version .......................................................................................... 65

13 Parameter Tables ............................................................................ 66

13.1 Parameter Setting System ................................................................................................. 66

13.2 Parameter Times System................................................................................................... 66

13.3 Parameter Sub Menu Axes................................................................................................ 66

13.4 Parameter Sub Menu Cutting............................................................................................ 70

13.5 Parameter Sub Menu Additional Functions.......................................................................... 70

13.6 Parameter Sub Menu Soft Keys ......................................................................................... 71

13.7 Parameter Material Table................................................................................................. 71

13.8 Parameter Digitale In-/Output .......................................................................................... 71

14 Disturbances, Maintenance, Cleaning............................................. 73

14.1 Fault Clearance.............................................................................................................. 73

14.2 Possible Errors and their Clearance ................................................................................... 74

14.3 Re-start after Fault Clearance ........................................................................................... 75

14.4 Maintenance .................................................................................................................. 75

14.5 Cleaning ....................................................................................................................... 75

15 Type Designation ............................................................................. 76

15.1 Accessories .................................................................................................................... 77

16 Appendix.......................................................................................... 78

17 Index ................................................................................................ 86

List of Figures

- 5 -

2List of Figures

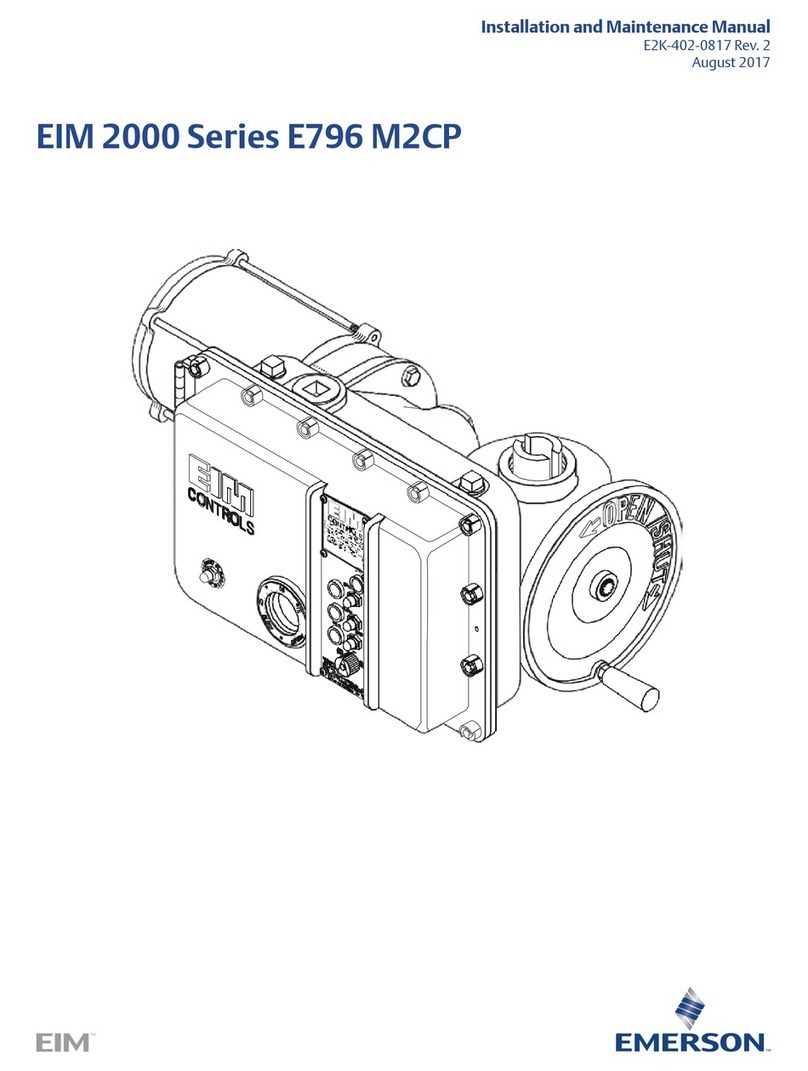

Figure 1: P40T - Touch Panel .................................................................................................................. 10

Figure 2: Type label ................................................................................................................................ 11

Figure 3: Dimensions P40T...................................................................................................................... 11

Figure 4: Mounting into panel cut-out ...................................................................................................... 14

Figure 5: Menu Structure ......................................................................................................................... 15

Figure 6: Start Screen / Main Menu.......................................................................................................... 16

Figure 7: Language selection ................................................................................................................... 16

Figure 8: Single Mode............................................................................................................................. 17

Figure 9: Numerical input fields of Axis Parameters.................................................................................... 17

Figure 10: Select material from list ........................................................................................................... 18

Figure 11: Piece counter selection mask ................................................................................................... 18

Figure 12: Downwards piece counter ....................................................................................................... 19

Figure 13: Upwards piece counter ........................................................................................................... 19

Figure 14: Piece counter disabled ............................................................................................................ 20

Figure 15: Manual inching mode ............................................................................................................. 20

Figure 16: Program Mode and Program List.............................................................................................. 21

Figure 17: Numeric and alphanumeric input field...................................................................................... 22

Figure 18: Define the “End of Program” ................................................................................................... 23

Figure 19: Main Page Service .................................................................................................................. 25

Figure 20: Password login ....................................................................................................................... 25

Figure 21: Sub Menu Axis ....................................................................................................................... 26

Figure 22: Settings Axis (general) ............................................................................................................ 27

Figure 23: Axis Distances ........................................................................................................................ 32

Figure 24: Creep speed (1 speed) ............................................................................................................ 33

Figure 25: Creep speed (2 speeds).......................................................................................................... 34

Figure 26: Creep and Slow speed (3 speeds) ............................................................................................ 34

Figure 27: Axis Times.............................................................................................................................. 37

Figure 28: Axis Analog............................................................................................................................ 39

Figure 29: Axis calibration with axis angle................................................................................................. 43

Figure 30: Calibration without axis angle.................................................................................................. 44

Figure 31: Sub Menu Cutting................................................................................................................... 45

Figure 32: System General ...................................................................................................................... 47

Figure 33: System Times.......................................................................................................................... 49

Figure 34: Additional Functions ............................................................................................................... 52

Figure 35: Main Menu - pump is OFF...................................................................................................... 53

Figure 36: Main Menu - pump is ON....................................................................................................... 53

Figure 37: Example Singe Mode - pump status in the info line .................................................................... 53

Figure 38: Calibration Touch Screen ........................................................................................................ 54

Figure 39: Soft-Keys................................................................................................................................ 55

Figure 40: Material table / list ................................................................................................................. 57

Figure 41: Logic assignment of Input / Output functions ............................................................................ 59

Figure 42: Load and save OEM data ....................................................................................................... 60

Figure 43: Load default parameters.......................................................................................................... 60

Figure 44: Touchscreen Design................................................................................................................ 61

Figure 45: Activate PC interface ............................................................................................................... 61

Figure 46: Connector arrangement - 16 IO .............................................................................................. 62

Figure 47: Connector arrangement - 8 IO ................................................................................................ 64

List of Tables

- 6 -

3List of Tables

Table 1: Define Type of Axes ................................................................................................................... 28

Table 2: Soft Keys ................................................................................................................................... 55

Table 3: Interpolation Procedure .............................................................................................................. 58

Table 4: Parameter list - Setting System..................................................................................................... 66

Table 5: Parameter list - Time System ....................................................................................................... 66

Table 6: Parameter list - Axis Backgauge .................................................................................................. 66

Table 7: Parameter list - Axis Gap ............................................................................................................ 67

Table 8: Parameter list - Setting Angle ...................................................................................................... 67

Table 9: Parameter list - Distance Axis Backgauge ..................................................................................... 68

Table 10: Parameter list - Distance Axis Gap............................................................................................. 68

Table 11: Parameter list - Distance Axis Angle........................................................................................... 68

Table 12: Parameter list - Time axis backgauge......................................................................................... 69

Table 13: Parameter list - Time axis gap ................................................................................................... 69

Table 14: Parameter list - Time axis angle................................................................................................. 69

Table 15: Parameter list - Analog axis ...................................................................................................... 70

Table 16: Parameter list - Sub Menu cutting.............................................................................................. 70

Table 17: Parameter list - Sub Menu Additional Functions .......................................................................... 70

Table 18: Parameter list - Sub Menu Soft Keys........................................................................................... 71

Table 19: Parameter list - Material Table .................................................................................................. 71

Table 20: Parameter list - Digital Inputs at ST3.......................................................................................... 71

Table 21: Parameter list - Digital Inputs at ST4.......................................................................................... 71

Table 22: Parameter list - Digital Output at ST5 ........................................................................................ 72

Table 23: Parameter list - Digital Outputs ST6........................................................................................... 72

Table 24: Possible Errors and their Clearance ........................................................................................... 74

Table 25: Accessories ............................................................................................................................. 77

General, Safety, Transport and Storage

- 7 -

4General, Safety, Transport and Storage

4.1 Information Operating Manual

This manual contains important information regarding the handling of the device. For your own safety and operational safety, please ob-

serve all safety warnings and instructions. Precondition for safe operation is the compliance with the specified safety and handling instruc-

tions. Moreover, the existing local accident prevention regulations and the general safety rules at the site of operation have to be observed.

Please read the operating manual carefully before starting to work with the device! It is part of the product and should be kept close to the

device and accessible for the staff at any time. The illustrations in the manual are for better demonstration of the facts. They are not neces-

sarily to scale and can slightly differ from the actual design.

4.2 Explanation of Symbols

Special notes in this manual are characterized by symbols. The notes are introduced by signal words which express the magnitude of danger.

Please follow this advice and act carefully in order to avoid accidents, damage, and injuries.

Warning notes:

DANGER!

This symbol in connection with the signal word “Danger” indicates an immediate danger for the life and health of

persons. Failure to heed these instructions can result in serious damage to health and even fatal injury.

WARNING!

This symbol in connection with the word „Warning” means a possibly impending danger for the life and health of

persons. Failure to heed these instructions can result in serious damage to health and even fatal injury.

CAUTION!

This symbol in connection with the signal word “Caution” indicates a possibly dangerous situation. Failure to heed

these instructions can lead to minor injuries or damage of property.

Special safety instructions:

DANGER!

This symbol in connection with the signal word “Danger” indicates an immediate danger for the life and health of

persons due to voltage.

Failure to heed these instructions can result in serious damage to health and even fatal injury. The operations may

only be carried out by a professional electrician.

Tips and recommendations:

NOTE!

…points out useful tips and recommendations as well as information for an efficient and trouble-free operation.

Reference marks:

Marks a reference to another chapter of this manual.

Marks a reference to another chapter of another document.

General, Safety, Transport and Storage

- 8 -

4.3 Statement of Warranties

The producer guarantees the functional capability of the process engineering and the selected parameters.

4.4 Demounting and Disposal

Unless acceptance and disposal of returned goods are agreed upon, demount the device considering the safety instructions of this manual

and dispose it with respect to the environment.

Before demounting, disconnect the power supply and secure against re-start. Then disconnect the supply lines physically and discharge

remaining energy. Remove operational supplies and other material.

Disposal: Recycle the decomposed elements: Metal components in scrap metal, Electronic components in electronic scrap, Recycle plastic

components, dispose the remaining components according to their material consistence.

CAUTION!

Wrong disposal causes environmental damages!

Electronic scrap, electronic components, lubricants and other auxiliary materials are subject to special refuse and can

only be disposed by authorized specialists!

Local authorities and waste management facilities provide information about environmentally sound disposal.

Safety

CAUTION!

Please read the operating manual carefully, before using the device! Observe the installation instructions!

Only start up the device if you have understood the operating manual.

The operating company is obliged to take appropriate safety measure.

The initial operation may only be performed by qualified and trained staff.

Selection and installation of the devices as well as their embedding into the controlling system require qualified

knowledge of the applicable laws and normative requirements on the part of the machine manufacturer.

4.5 General Causes of Risk

This chapter gives an overview of all important safety aspects to guarantee an optimal protection of employees and a safe and trouble-free

operation. Non-observance of the instructions mentioned in this operating manual can result in hazardous situations.

4.6 Personal Protective Equipment

Employees have to wear protective clothing during the installation of the device to minimize danger of health.

Therefore:

Change into protective clothing before performing the works and wear them throughout the process.

Additionally observe the labels regarding protective clothing in the operating area.

Protective clothing:

PROTECTIVE CLOTHING

… is close-fitting working clothing with light tear strength, tight sleeves and without distant parts. It serves preliminari-

ly for protection against being gripped by flexible machine parts.

Do not wear rings, necklaces or other jewelry.

PROTECTIVE GLOVES

…for protecting the hands against abrasion, wear and other injury of the skin.

PROTECTIVE HELMET

…for protection against injuries of the head.

General, Safety, Transport and Storage

- 9 -

4.7 Conventional Use

The device is only conceived for the conventional use described in this manual.

The ELGO device type P40T-002 serves exclusively for positioning and automatic cutting on guillotine shears.

CAUTION!

Danger through non-conventional use!

Non-intended use and non-observance of this operating manual can lead to dangerous situations.

Therefore:

Only use the device as described

Strictly follow the instructions of this manual

Avoid in particular:

Remodeling, refitting or changing of the construction or single components with the intention to alter the

functionality or scope of the device.

Claims resulting from damages due to non-conventional use are not possible.

Only the operator is liable for damages caused by non-conventional use.

4.8 Safety Instructions for Transport, Unpacking and Loading

CAUTION!

Transport the package (box, palette etc.) professionally.

Do not throw, hit or fold it.

4.9 Handling of Packaging Material

Notes for proper disposal: 4.4

4.10 Inspection of Transport

Check the delivery immediately after the receipt for completeness and transport damage.

In case of externally recognizable transport damages:

Do not accept the delivery or only accept under reserve.

Note the extent of damages on the transportation documents or delivery note.

File complaint immediately.

NOTE!

Claim any damage immediately after recognizing it.

The claims for damage must be filed in the lawful reclaim periods.

4.11 Storage

Store the device only under the following conditions:

Do not store outside

Keep dry and dust-free

Do not expose to aggressive media

Protect from direct sun light

Avoid mechanical shocks

Storage temperature (6) needs to be observed

Relative humidity (6) must not be exceeded

Inspect packages regularly if stored for an extensive period of time (>3 months)

Product Features

- 10 -

5Product Features

P40T-002 is a compact, programmable multi-axis positioning controller with touchscreen panel, designed for

axis positioning and cutting automation on guillotine shears.

Overview of features:

16 free programmable digital in-/outputs.

Analog or digital outputs for 1 - 3 speed operation.

Program memory (1000 blocks).

Angle control / gap control / backgauge.

Cut length and cut offset calculation by angle measurement system or time.

Material list for angle, gap and pressure.

Automatic cutting machine

Sheet support

Sheet return (RTO)

Serial interface for data exchange with a PC

Figure 1: P40T - Touch Panel

Basic Operation Modes:

The P40T-002 controller consists of three general operation modes:

Manual: The manual Inching operation allows axis movements via touchscreen.

Single: A single data block can be worked off.

Program: Several data sets can be lined up or programmed individually in program mode.

This series of program blocks is then processed sequentially.

Technical Data

- 11 -

6Technical Data

6.1 Identification

The type label of the P40T-002 serves for the identification of the unit. It is located on the housing of the device

and indicates the exact type designation (=order reference 15) with the corresponding part number. Further-

more, the type label contains a unique, traceable device number. When corresponding with ELGO please al-

ways indicate this data.

Figure 2: Type label

6.2 Dimensions

Figure 3: Dimensions P40T

P40TW-002-024-xx-xx-CXXX

xxxxxxx Consecutive Unit Number

Device Desigantion

144

136

180

136

48

Installation depth incl. connectors = 83 mm

Panel cut-out = 138 x 138 mm

Front plate thickness = 4 mm

52

Technical Data

- 12 -

6.3 Technical Data

P40T-002 (version for guillotine shears)

Mechanical Data

Housing

panel housing

Housing material

front plate: aluminium| housing: galvanized steel sheet

Front plate dimensions

W x H = 180 x 144 mm

Housing dimensions

W x H = 136 x 136 mm

Panel cut out

W x H = 138 x 138 mm

Keyboard

Touchscreen

Installation depth

48 mm (without connectors)| 83 mm (with connectors)

Electrical Data

Display

TFT touch screen monitor

Hardware

32 bit Microcontroller with 1 MByte Flash and 128 KByte RAM

Software

real time operating system: www.FreeRTOS.org

Program memory

up to 1.000 blocks (more on request)

System accuracy

± 1 increment

Power supply voltage

24 VDC +10/−20 %

Current consumption

24 VDC: max. 200 mA (unloaded);

permitted total current (without outputs): 1 A

Encoder supply voltage

24 VDC or 5 VDC

Load by measuring system

max. 130 mA

Input signals (measuring system)

HTL, TTL, analog in (order information)

Signal channels

A, B, Z resp. A, A', B, B', Z, Z' or analog 0 ... 3.3 V (order information)

External inputs

16 digital PNP inputs, assignment and logic are freely programmable

Input current / pin

max. 10 mA

Min. pulse time for inputs

300 ms

Max. input frequency

100 kHz (higher on request)

Analog inputs (option)

1 ... 3 1 ... 3 analog inputs (12 bit) at 3.3 VDC measuring system supply

Output signals

16 digital PNP outputs with freely programmable assignment

and switching logic (active HIGH / LOW)

Output current

max. 2 A per output / 8 A total current across all outputs; the

outputs are durable short circuit proof (no multiple short circuits)

Freewheel clutch / outputs

for inductive loads integrated (clamping voltage at the output max. −36 V)

Analog outputs (option)

± 10 V PID (12 bit) or ± 10 V unregulated (11 bit)

Interfaces (option)

RS232

Connections

industry standard connectors (3.81 mm grid, lockable)

and additional RJ45 sockets (depending on version)

Power down memory

E²Prom (service life: 1.000.000, switching on / off cycles or 40 years)

Further options

8 = only 8 instead of 16 digital in- and outputs

N = digital inputs as NPN version

Accessories

see 16

Environment Conditions

Operating temperature

0 ... +45° C

Storage temperature

−20 ... +50° C

Humidity

max. 80 %, non-condensing

Protection class

front: IP43 (installed state) | rear: IP00

Installation and First Start-Up

- 13 -

7Installation and First Start-Up

CAUTION

Please read the operating manual carefully before using the device! Strictly observe the Installation instructions!

In case of damage caused by failure to observe this operating manual, the warranty expires.

ELGO is not liable for any secondary damage and for damage to persons, property or assets.

The operator is obliged to take appropriate safety measures.

The first start-up may only be performed by qualified staff that has been trained and authorized by the operator.

7.1 Operating Area

WARNING!

Do not use the device in explosive or corrosive environments!

The device must not be installed close to sources of strong inductive or capacitive interference or strong electrostatic

fields!

CAUTION!

The electrical connections must be made by suitably qualified personnel in accordance with local regulations.

The device may be designed for switchboard mounting. During work on the switchboard, all components must be de-

energized if there is a danger of touching the energized parts!

(protection against contacts)

Wiring works may only be performed in the de-energized state!

Thin cable strands have to be equipped with end sleeves!

Before switching on the device, connections and plug connectors have to be checked!

The device must be mounted in a way that it is protected against harmful environmental influences such as splashing

water, solvents, vibration, shock and severe pollution and the operating temperature must not be exceeded.

Installation and First Start-Up

- 14 -

7.2 Mounting of the Controller

The P40T-002 controller is intended for installation into a 138 x 138 mm panel cut-out.

Required tools: 1 slotted screwdriver and 1 Phillips screwdriver.

Figure 4: Mounting into panel cut-out

1. Insert the positioning control into a suitable panel cut-out.

2. Then loosen the two Phillips screws of the mounting brackets attached to the rear panel. Turn the two

mounting brackets so that the free threaded holes point outwards and then retighten the Phillips screws.

3. Now insert the provided grub screws into the threaded holes of the mounting brackets and turn clock-

wise until the device is firmly seated in the cut-out.

7.3 Activation of the Device

After applying the 24 VDC power supply voltage (and automatic initialization), the device is ready for operation.

Panel rear

Panel Panel

Grub

screw (2 x)

1. 2. 3.

Mounting

bracket (2 x)

Phillips-

head screw

Design und Function

- 15 -

8Design und Function

The device is operated via touch screen. The selection is made by touching the corresponding buttons.

8.1 Menu Structure

Figure 5: Menu Structure

8.1.1 Password

NOTE!

The service mode / parameter level is protected by password.

After login the parameters can be set.

PIN CODE 250565

Main Menu

Manual Service (Parameters)Single Program

Operation Modes

Main Menu

- 16 -

9Main Menu

After switching on the positioning control, the main menu opens. This contains the selection for the operating

modes, menu languages, parameter settings in service mode (password input required 8.1.1) and the clean-

ing function.

Figure 6: Start Screen / Main Menu

9.1 Language Selection

To select the language, click on the flag icons at the bottom right (see Figure 6 above). A mask appears where

you can select the desired language by tapping on the corresponding flag symbol:

Figure 7: Language selection

Countdown

Cleaning

Cleaning

Service / Parameters

Operation

Modes

Language

Selection

Operation Modes

- 17 -

10 Operation Modes

10.1 Single Mode

In single mode, a single block can be processed. Each entered target position must be confirmed with “OK”.

In single mode it is also possible to load the target position for the axis “Angle”and “Gap”from a material

table. The fields “Material selection”and “Material thickness”are located on the left side of the menu.

After one of the two fields has been changed and the new value has been confirmed, the corresponding target

positions for axis “Angle”and “Gap are displayed. It is also possible to assign a value each for the "Cut Length"

and "Cut Offset".

The material properties can be changed via the material table. This is loaded by pressing the material selection

key for longer than 5 seconds. After releasing the key, the material table opens. Either the password 2505 for

the material table or the service password (250565) is required for access.

Figure 8: Single Mode

Figure 9: Numerical input fields of Axis Parameters

Activated Soft Key

Gap Width

Angle

Soft Key

StartEscape / Back

Cut Offset

Cut Length

Quantity

Pressure

Material Thickness

Backgauge

Material Selection

Single Mode

Cancel / Exit

Sub Menu

Change sign

Selected Axis

Clear Input

Enter

Target Value

Allowed Range

Referencing

Operation Modes

- 18 -

Figure 10: Select material from list

10.1.1 Piece Counter

The piece counter can be configured in 3 modes:

Downwards counter

Upwards counter

Counter disabled

The active mode in each case is displayed in the “Single Mode” operating mask for the piece counter

(10.1.1.1, 10.1.1.2, 10.1.1.3)

The mode is set resp. selected in the piece pre-selection window.

Figure 11: Piece counter selection mask

When you exit the single mode or switch off the controller, the current quantity is stored in the single-block.

Scroll

Exit list

Consecutive

material number

Short Name

Plain text field for

material description

Scroll

Operation Modes

- 19 -

10.1.1.1 Downwards Piece Counter

The piece counter is decremented after each complete cut until the number 0 is reached.

Figure 12: Downwards piece counter

10.1.1.2 Upwards Piece Counter

The piece counter is incremented after each complete cut. A value can be specified at which counting is started.

Figure 13: Upwards piece counter

Counts downwards

(negative sign)

Counts upwards

(positive sign)

Operation Modes

- 20 -

10.1.1.3 Piece Counter disabled

The cuts are not counted when the piece counter is disabled.

Figure 14: Piece counter disabled

10.2 Manual Mode

In the manual inching mode, the axes can be moved manually. Simply activate the corresponding axis and

move to the demanded position by using the buttons “+”and “−“. The active axis is highlighted in color.

Figure 15: Manual inching mode

Does not count

(empty field)

Manual Mode

Back gauge

Gap 1 (left)

Axis movement in

negative direction

Angle

Cancel

Move cutter bar

Gap 2 (right)

Axis movement in

positive direction

Table of contents

Popular Controllers manuals by other brands

Spa-Quip

Spa-Quip SP601 Installation & service manual

DEVI

DEVI DEVIreg 850 Installation and user manual

Spirax Sarco

Spirax Sarco PLC Installation, operation and maintenance manual

Micronix

Micronix MMC-110 Series quick start guide

L&S

L&S WIRED MODULE 2.0 C quick start guide

Keysight

Keysight M9536A Startup guide