Elife SR Series User manual

Low Profile Drive

Size 1 - Size 2 - Size 3

Elife-Drive SR Series

Application

Reference Manual

Elife International S.r.l.

Via del Giglio, 4 - 57037 Portoferraio - LI

Elba Island - Tuscany - Italy

Tel: +39 0565 944121

Fax: +39 0565 945726

email: [email protected]

This manual is copyrighted of Elife International. All rights are reserved. This manual must not be

copied in whole or in part, nor transferred to any other media or language, without express written

permission of Elife International.

Technical Manual Version: 1.0 r04.02

Release Data: 09 May 2021

Contents

1 Overview 1

2 Installation and Wiring 5

2.1 Mounting Elife-Drive on-board . . . . . . . . . . . . . . . . . . . . . 5

2.2 Connections................................ 7

2.2.1 High Power Connections . . . . . . . . . . . . . . . . . . . . . 8

2.2.2 Low Power Connections . . . . . . . . . . . . . . . . . . . . . 10

2.3 Standard Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.1 StandaloneMode......................... 18

2.3.2 CANopen®Mode ......................... 21

2.3.3 RS232Mode ........................... 22

2.3.4 EVCarMode ........................... 23

2.3.5 EVBikeMode........................... 25

3 Monitoring Elife Drive 27

3.1 LEDDiagnostics.............................. 27

3.2 Telemetry - Monitoring and Setting of Data . . . . . . . . . . . . . . 28

3.2.1 MotorSetting........................... 29

3.2.2 FeedbackSetting ......................... 30

3.2.3 System Parameters . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2.4 Configuration - Connection . . . . . . . . . . . . . . . . . . . 32

3.2.5 Configuration - Standalone . . . . . . . . . . . . . . . . . . . 33

3.2.6 Configuration - CANopen®.................... 34

3.2.7 Configuration - RS232 . . . . . . . . . . . . . . . . . . . . . . 35

3.2.8 Configuration - EV BIKE . . . . . . . . . . . . . . . . . . . . . 36

3.2.9 Configuration - EV CAR . . . . . . . . . . . . . . . . . . . . . 37

3.2.10IDDrive.............................. 38

3.2.11Adjustments............................ 39

3.2.12LogStatus............................. 40

i

List of Tables

2.1 Fuse size in accordance with the Elife-Drive SR Series . . . . . . . . . . 8

2.2 A summary table of high-power connections . . . . . . . . . . . . . . . 8

2.3 Elife-Drive SR I/O definitions for Standalone Traction Mode . . . . . 19

2.4 Elife-Drive SR I/O definitions for Standalone Steering Mode . . . . . 20

2.5 Elife-Drive I/O definitions for CANopen®Mode............. 21

2.6 Elife-Drive I/O definitions for RS232 Mode ............... 22

2.7 Elife-Drive SR I/O definitions for Ev Car Mode.............. 23

2.8 Elife-Drive SR I/O definitions for Ev Bike Mode ............. 25

ii

1

Overview

SR Elife-Drive

is the family of drivers designed to drive the various types of

low-voltage servomotors, specifically for use in battery powered devices.

The compact form was made possible thanks to the high efficiency of the design,

manufactured with state-of-art electronic components.

Elife-Drive is highly configurable, a wide range of programmable parameters allow

you to customize your system for your needs.

The main key features include:

•

Designed to drive from 12 V to 96 V Brushless, Brushed and AC ServoMotors.

•

The different types of feedback are supported:

Resolver

,SinCos,Hall Sensors,

Incremental Encoder,Fa-Coder,SSI,Sensorless.

•Advanced algorithms for predictive speed and torque control.

•

CANopen

®

modes of operation:

1

: Profile Velocity Mode, Torque Profile Mode,

Profile Position Mode, Homing Mode and Cycilic Sync Position Mode

•

Electromagnetic Holding Brake Output with DPR System (Dynamic Power

Reduction)

•Dedicated Safe Torque Off (STO) input

•Telemetry of the Internal functions

•

European Conformity

C

, and designed and tested in accordance with the

EMC

emission (EN 61000-6-4) and immunity (EN 61000-6-2) standards.

Elife-Drive is compliant with EN 60950-1 safety requirements.

1Elife International is a Member of CiA®- CAN in Automation

1

Specification:

Four Quadrant Regenerative Operation

Space Vector Modulation Technology

Sinusoidal and Trapezoidal Commutation Methods

Programmable Gain Setting

Fully Configurable Velocity and Position Limits

On-the-fly Mode and Gain Set Switching

Emergency Deceleration Ramp (Emergency) Input

Safe Torque Off (STO) Input

Programmable Input/Output:

Six Digital Inputs Single Ended

One 12-bit Analog Input 0÷10 V

Four Digital Outputs Singled Ended

One High Powered Brake Output

One Programmable 5 or 10V - 100mA Throttle Output

SIZE 1 NOMINAL BATTERY VOLTAGE - MAX MOTOR POWER

120x85x38 mm 12V - 400W 24V - 800W 48V - 1.6kW

PHASE CURRENT *10V ÷ 22V 16V ÷ 34V 28V ÷ 70V

up to 35 Arms SR12-35-040-x SR24-35-080-x SR48-35-1.6-x

up to 70 Arms SR12-70-040-x SR24-70-080-x SR48-70-1.6-x

SIZE 2 NOMINAL BATTERY VOLTAGE - MAX MOTOR POWER

195x95x32 mm 12V - 2.5kW 24V - 5kW 48V - 10kW 72V - 15kW

PHASE CURRENT *10V ÷ 22V 16V ÷ 34V 28V ÷ 75V 46V ÷ 100V

up to 100 Arms SR12-100-2.5-x SR24-100-5-x SR48-100-10-x SR72-100-15-x

up to 200 Arms SR12-200-2.5-x SR24-200-5-x SR48-200-10-x SR72-200-15-x

SIZE 3 NOMINAL BATTERY VOLTAGE - MAX MOTOR POWER

220x120x32 mm 12V - 7kW 24V - 14kW 48V - 28kW 72V - 43kW 96V - 56kW

PHASE CURRENT *10V ÷ 22V 16V ÷ 34V 28V ÷ 75V 46V ÷ 100V 65V to 150V

up to 400 Arms SR12-400-7-x SR24-400-14-x SR48-400-28-x SR72-400-43-x SR96-400-56-x

up to 600 Arms SR12-600-7-x SR24-600-14-x SR48-600-28-x SR72-600-43-x - - - - - -

* The value of the maximum continuous (60 min) RMS phase current is ensured with an appropriate heat sink.

2Chapter 1 Overview

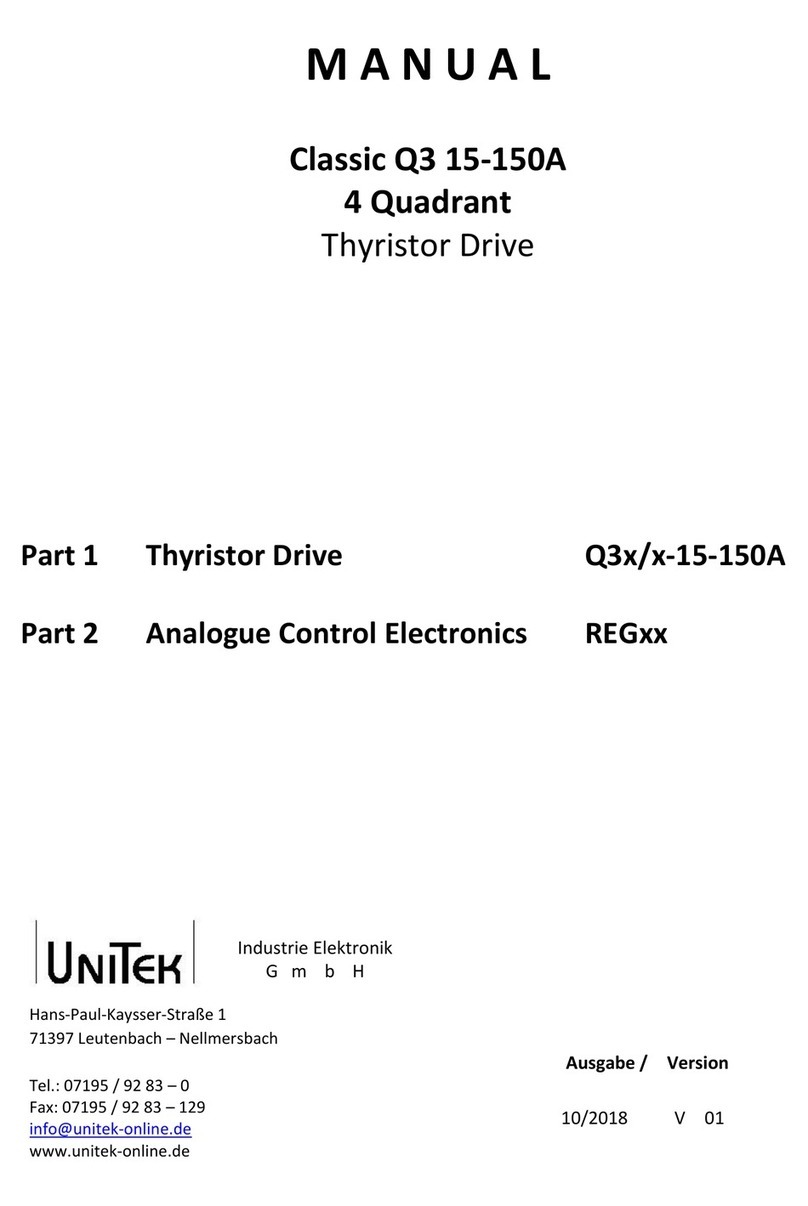

Product Identification Label

Most of information about your Elife-Drive - such as serial number, model, customer

information, etc - can be found on a label located on the front of the Elife-Drive (see

figure below). Some of these information might be requested when you contact the

technical assistance.

Compliance with the EU regulatory requirement for electrical and electronic equipment.

When your Elife-Drive is no more usable, can’t be treated as generic garbage, but

must be disposed of at a collection point for recycling of electrical and electronic

equipment, in compliance with the

WEEE

regulation (Waste of Electrical and

Electronic Equipment).

3

4

2

Installation and Wiring

2.1 Mounting Elife-Drive on-board

The Elife-Drive can be mounted in any orientation, but you must choose a location

in order to keep the controller

clean

and

dry

, aways from sunlight, water and ice.

When you mount the Elife-Drive on-board you should

ensure an effective heat

dissipation between the Elife-Drive and the vehicle surface.

Elife-Drive has a LED light on the front of the device that visually explains what

the driver is doing (see Section 3.1), if you want it to be visible you should take

this into consideration before choosing the location where your Elife-Drive will be

mounted.

In order to ensure the proper functioning of the Elife-Drive you must keep the

controller clean and dry and ensure an effective heat exchange between the

Elife-Drive and the vehicle surface.

Warning

The installation must be performed with an adequate heat exchange between the

Elife-Drive and the surface on which it will be placed. In Figure 2.1 is shown

a suggested installation method in order to ensure an effective heat dissipation

between the Elife-Drive and the surface on which it will be placed.

A thermal grease should be used on the rear side of the Elife-Drive heatsink to

improve the heat exchange between Elife-Drive and the surface on which it

will be placed.

Tips and Advice

If the installation method shown in Figure 2.1 is not sufficient to ensure an effective

heat dissipation from the Elife-Drive, you should install a Fan Cooler or a Liquid

Cooler on your Elife-Drive.

5

Figure 2.1:

A recommended installation method in order to ensure an effective heat

dissipation between the Elife-Drive and the surface on which it will be placed. A thermal

grease should be used between the Elife-Drive and the surface on which it will be placed.

6Chapter 2 Installation and Wiring

2.2 Connections

Elife-Drive on the front has different types of connectors:

High Power Connections

The three-phase alternating-current generated by Elife-Drive is supplied

through the U,V,Wterminals.

The

B+

and

B-

are the positive and negative terminals to connect to your

battery.

You must connect an external fuse between the

B+

terminal and the positive

battery terminal. (see Section 2.2.1)

Low Power Connections

14 pins female connector for Digital, Analog Input and Command Signal

6 pins female connector for Output Signal

8 pins female connector for Digital Communications CANopen®and RS232

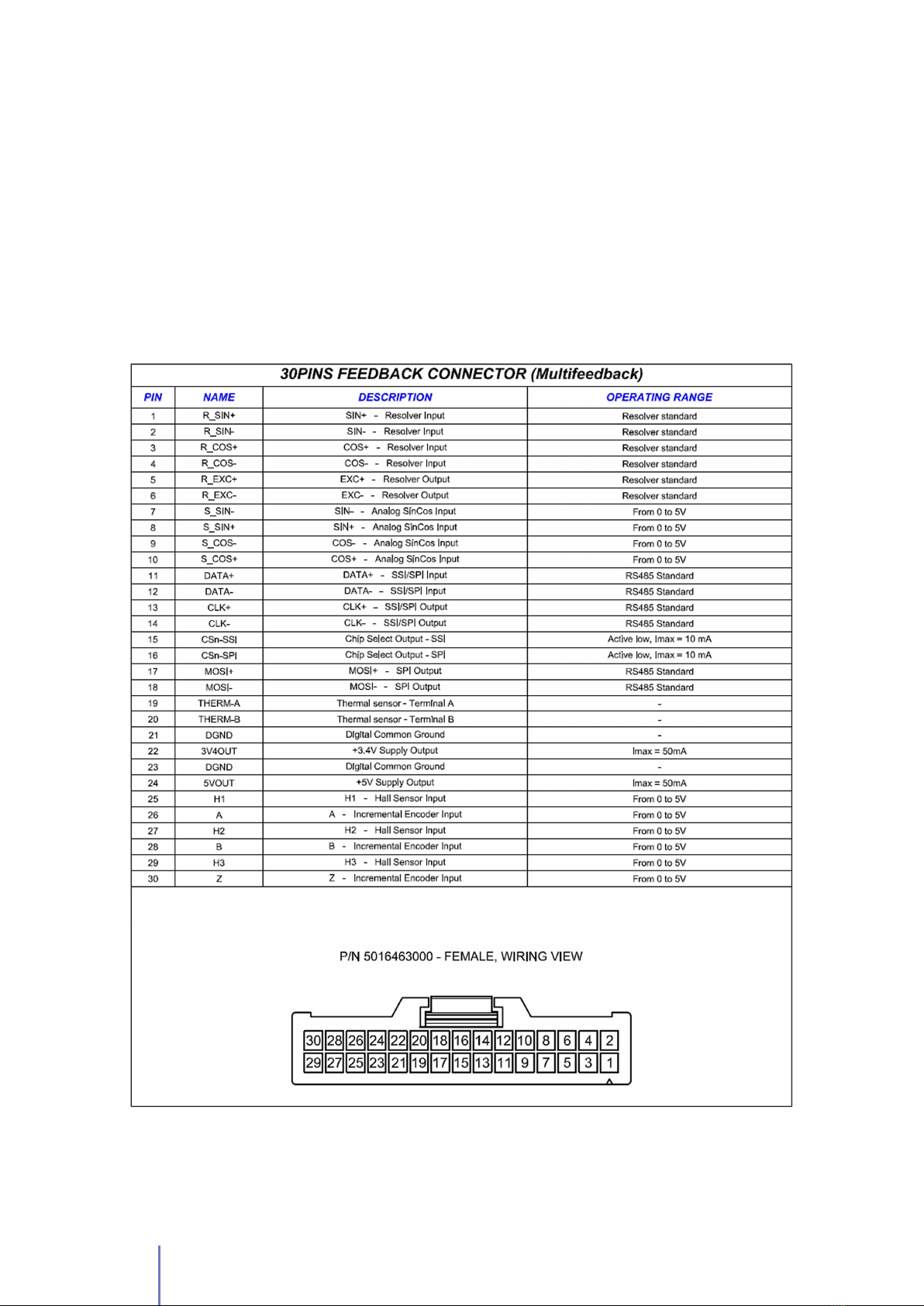

30 pins female connector for Universal Feedback Interface

Details of the 30 pins female connector

- Resolver Differential Input

- SinCos Differential Input (also works in Single Ended mode)

- Multifunction Differential Input

. Digital SinCos

. Digital Endat

. Generic SSI Encoders

. Generic SPI Encoders

. The communication protocols installed are constantly updated as needed

- Multifunction Single Ended Input

. Hall Sensor

. Incremental Encoder

. Fa-Coder

- Motor Thermal Sensor Input

- Power Supply Output

15 pins VGA connector as an alternative to the 30 pins female connector

- Multifunction Differential Input

. Hall Sensor

. Incremental Encoder

. Fa-Coder

2.2 Connections 7

2.2.1 High Power Connections

High power connections are provided by: 3-phase supply terminals (

U

,

V

,

W

) and

two terminals for battery connections (B+,B-).

In order to connect correctly Elife-Drive, you should use the following instructions:

1. Connect the the battery negative cable to the B- terminal.

2.

An external fuse (See Table 2.1) must be fitted from the

battery positive

to

terminal B+ to avoid damage to the controller.

Elife-Drive models haven’t any fuse already installed.

Note

Table 2.1: Fuse size in accordance with the Elife-Drive SR Series

ELIFE-DRIVE TYPE FUSE RATING

SR Size 1 63 A

SR Size 2 250 A

SR Size 3 700 A

* All models of SR Series require an external fuse.

3.

Connect the U, V, and W motor phases to the 3-phase supply terminals

(U,V,W).

The tightening torque must be:

for SR Size 1 =5.5 Nm for all five Power Connections

for SR Size 2 =11 Nm for all five Power Connections

for SR Size 3 =14 Nm for all five Power Connections

Note

Table 2.2: A summary table of high-power connections

TERMINAL CONNECT TO

B+ Battery positive terminal

B - Battery negative terminal

U,V,W U, V, and W motor phases

8Chapter 2 Installation and Wiring

When connecting the high power cables, make sure that the feedback cable

passes as far as possible from the power cables, possibly with a different path,

this to avoid electromagnetic interference.

Warning

Figure 2.2: Elife-Drive SR1 Series - High-power connections.

Figure 2.3: Elife-Drive SR2 Series - High-power connections.

Figure 2.4: Elife-Drive SR3 Series - High-power connections.

2.2 Connections 9

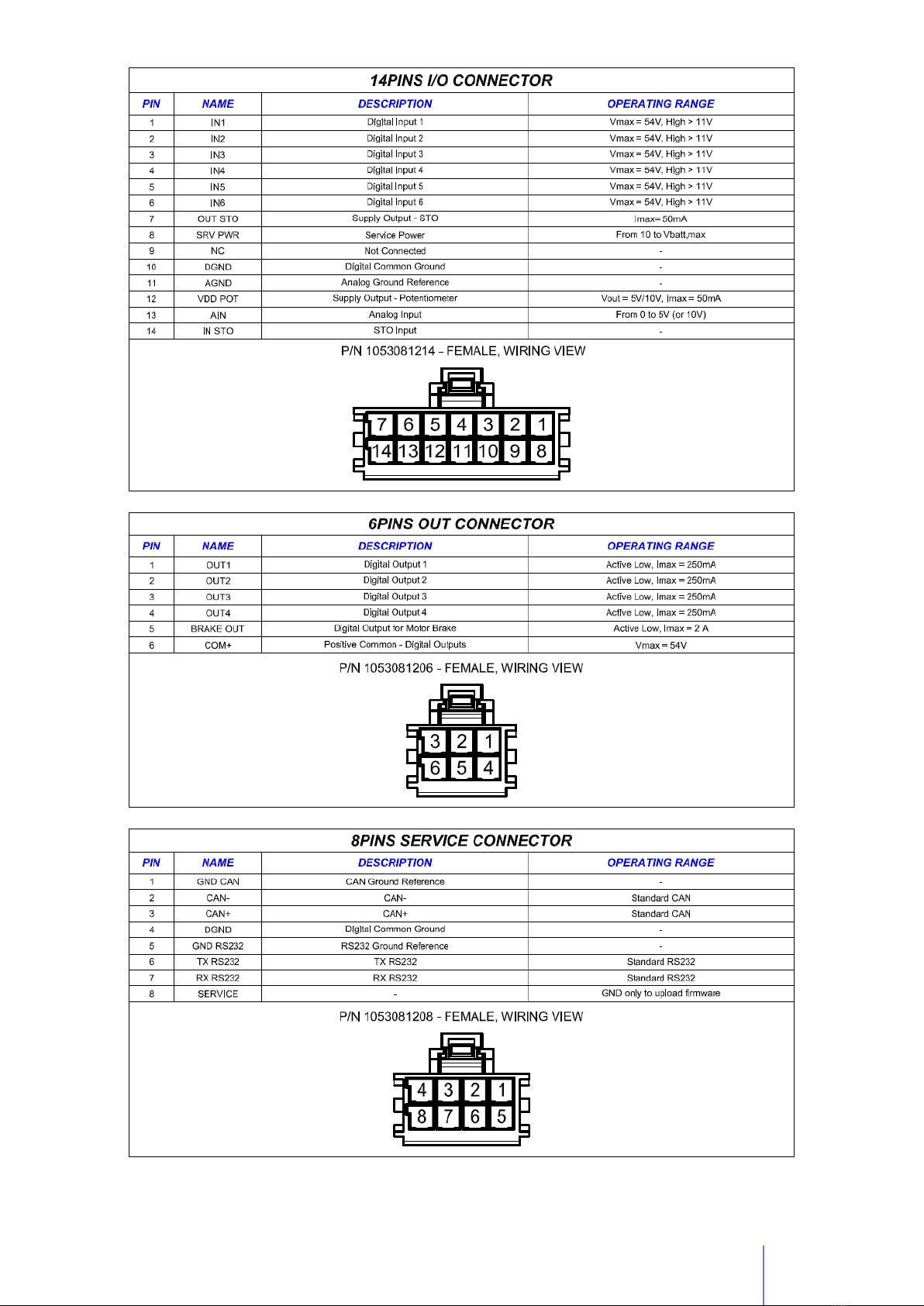

2.2.2 Low Power Connections

The low power logic control connections are provided by 4 female connectors.

- The feedback interface connector

- The Input/General Purpose connector

- The Output connector

- The Communications interface connector

The pin’s description is given in Table below:

Figure 2.5: Feedback Sensor Connections

10 Chapter 2 Installation and Wiring

Figure 2.6: Signal Command Connections

2.2 Connections 11

Figure 2.7: Alternative Feedback Sensor Connections

12 Chapter 2 Installation and Wiring

The programming connections is provided by an 8 pins male connector and a DB9

female connector. The cable description is given in Table below:

Figure 2.8: Program Connections

2.2 Connections 13

14 Chapter 2 Installation and Wiring

2.3 Standard Wiring Diagrams

Figure 2.9:

Standard wiring diagram to connect the

Elife-Drive SR Series

to your system -

Multifeedback

2.3 Standard Wiring Diagrams 15

Figure 2.10:

Standard wiring diagram to connect the

Elife-Drive SR Series

to your system

- Differential Fa-Coder Feedback

16 Chapter 2 Installation and Wiring

This manual suits for next models

23

Table of contents

Popular DC Drive manuals by other brands

Eaton

Eaton DA1-32030-20 Series Instruction leaflet

Danaher Motion

Danaher Motion Superior SLO-SYN SS2000MD4-M installation instructions

Automationdirect.com

Automationdirect.com DURApulse GS10 quick start guide

Rhymebus

Rhymebus RM6 Series Operation manual

ABB

ABB ACQ550-U1-015A-4 Series user manual

Danfoss

Danfoss VLT HVAC Drive FC 102 operating instructions

Danfoss

Danfoss 176F6636 installation instructions

Lenze

Lenze 931M Series Mounting instructions

ABB

ABB ACS355 series Quick installation and start-up guide

ABB

ABB ACS880 Series Quick start up guide

Motion

Motion SMD 4.0 Series Operation and installation manual

ITOH DENKI

ITOH DENKI POWER MOLLER HBM-604BN manual