Elisa Emilie User manual

Emilie™and Rosa™

Installation, User and Care Guide

Emilie™und Rosa™

Installations-, Gebrauchs- und Pflegeanleitung

Emilie™et Rosa™

Guide d’installation, d’utilisation et d’entretien

Emilie™i Rosa™

Instrukcja instalacji, obsługi i pielęgnacji

Emilie™& Rosa™

Handleiding voor installatie, gebruik enonderhoud

UK

DE

FR

PL

NL

2 | ElisaTM EmilieTM and RosaTM Installation Guide

UK Installation Stages

Thank you for choosing an ElisaTM product to enhance your bathroom design.

This booklet provides information for Stages 2 and 3, please refer to the separate

installation guides for Stage 1 and outlet accessories.

The outlet accessories guides will provide helpful information so you can plan the

pipe runs and terminate in the required fittings/connectors.

Installation and user guides are packed with all of our products and for your

convenience they are also available by visiting www.aqualisainternational.co.uk

The installation of this product is a 3 stage process:

Stage 2

Fitting the valve

assembly

Stage 3

Fitting the compression

plate and fascia

Stage 1

Fitting the AquahubTM

and preparation for

outlet accessories

This guide covers the installation

of Stages 2 and 3

ElisaTM EmilieTM and RosaTM Installation Guide | 3

UK

Contents

Important Information

This product must be installed by a competent person in

accordance with the relevant Water Supply Regulations. Prior

to installation, ensure all literature supplied with this product is

read and understood. We have taken great care to ensure that

this product reaches you in perfect condition, however, should

any parts be damaged or missing please contact your point of

purchase. If you require assistance, please contact the Customer

Helpline. The AquahubTM is supplied with universal fixings intended

to secure it to a suitable surface.

4

5

6

6

7

8

9

10

11

12

13

13

14

15

16

17

18

21

22

23

Water supply requirements

Installation requirements

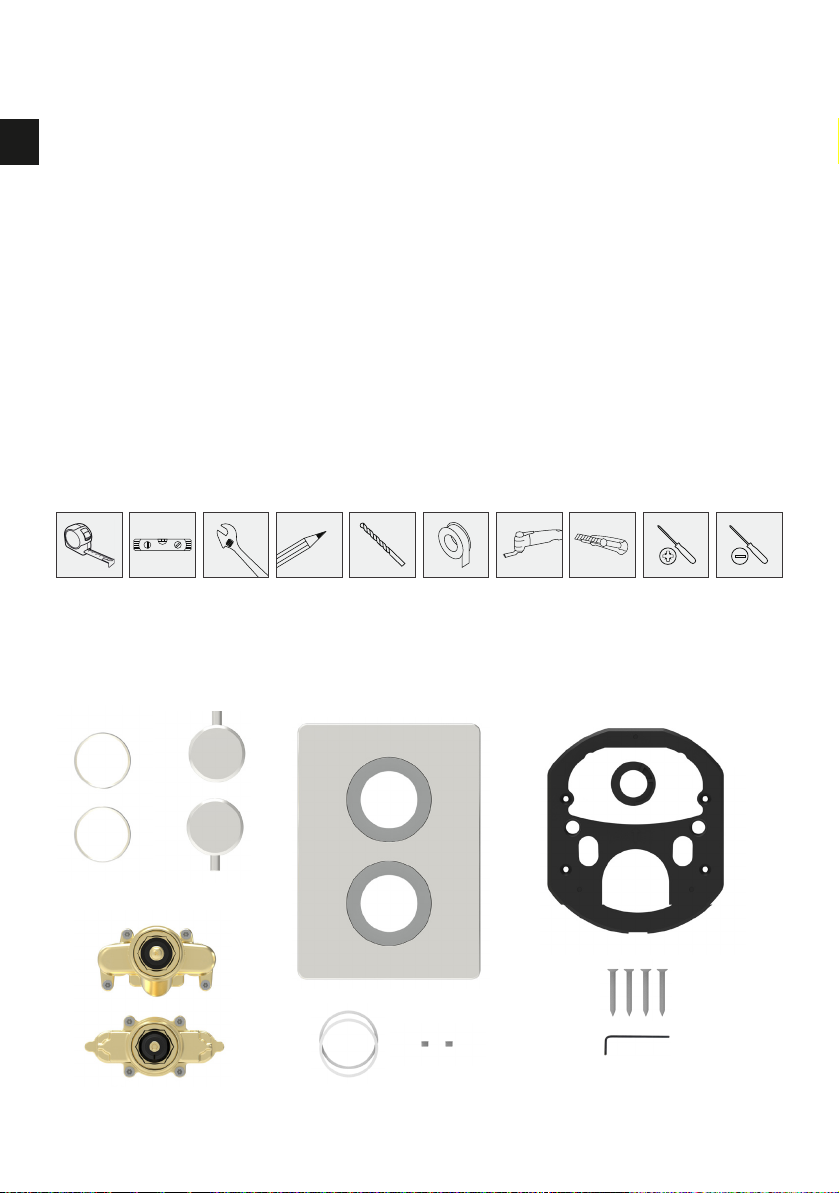

Tools required

Components RosaTM

Components EmileTM

Preparation

Fitting the thermostatic valve assembly

Fitting the headworks (Push button)

Commissioning the headworks and fitting the cover plate (Push button models)

Fitting the control dial (Push button models)

Changing cover buttons (Dual outlet (push button) models only)

Fitting the headworks (Dial models)

Commissioning and fitting the cover plate (Dial models)

Fitting the control dials (Dial models)

Commissioning – in service testing

Cartridge temperature adjustment

Troubleshooting

Caring for your shower

Maintenance

User instructions

4 | ElisaTM EmilieTM and RosaTM Installation Guide

UK Water supply requirements

This product has been designed and tested to comply with BS EN1287:1999 (LP-S)

and BS EN 1111:1999 (HP-S) Thermostatic Mixing Valves Standards.

Valves operating outside of the below conditions of use cannot be guaranteed as

type 2 valves.

Hot Water Maximum: 65˚C Cold Water Minimum: 10˚C

Recommended 60-65˚C Recommended 10-15˚C

Always maintain a 10˚C difference between hot system temperature and maximum

hot setting of valve.

Operating Pressure Range: Min. 1.0 bar, Max. 5 bar

When water pressure is higher than 5 bar a pressure reducing valve (not supplied)

must be fitted before the mixer. A setting of 3 bar is recommended.

This valve is suitable for gravity boosted, balanced high pressure and combination

boiler systems.

For gravity pumped systems use 22mm supply pipes and reduce to 15mm to

protrude through the finished wall.

Pump Installation:

PUMPS MUST NOT BE FITTED DIRECTLY TO A WATER MAIN.

REFER TO PUMP MANUFACTURERS INSTALLATION GUIDELINES.

Ensure there is adequate flow through the pump to activate the flow switches.

Combination boiler:

MUST have a minimum rating of 24kW (80,000 Btu) and be of the type fitted with

a fully modulating gas valve.

Boiler performance may affect outlet temperature.

Operating pressures:

Hot and cold supplies should be kept as even as possible in order to ensure the

maximum efficiency of the mixer.

ElisaTM EmilieTM and RosaTM Installation Guide | 5

UK

Installation requirements

Conditions of use for Type 2 (Thermostatic mixer) valves

High Pressure Low Pressure

Maximum Static

Pressure – Bar

10 10

Flow Pressure, Hot &

Cold - Bar

0.5 to 5 0.1 to 1

Hot Supply

Temperature - °C

55 to 65 55 to 65

Cold Supply

Temperature - °C

Equal to or

Less than 25

Equal to or

less than 25

Note: Valves operating outside these conditions cannot be guaranteed by the

Scheme to operate as Type 2 valves.

If a water supply is fed by gravity, then the supply pressure should be verified to

ensure the conditions of use are appropriate for the valve.

Recommended Outlet temperatures

The BuildCert TMV scheme recommends the following set maximum mixed water

outlet temperatures for use in all premises is 41°C for showers.

The mixed water temperatures must never exceed 46°C.

The maximum mixed water temperature can be 2°C above the recommended

maximum set outlet temperatures.

Note: 46ºC is the maximum mixed water temperature from the bath tap. The

maximum temperature takes account of the allowable temperature tolerances

inherent in thermostatic mixing valves and temperature losses in metal baths.

Warning: It is not a safe bathing temperature for adults or children.

The British Burns Association recommends 37 to 37.5ºC as a comfortable bathing

temperature for children. In premises covered by the Care Standards Act 2000, the

maximum mixed water outlet temperature is 43ºC.

6 | ElisaTM EmilieTM and RosaTM Installation Guide

UK

Tools required

Components - RosaTM

Installation requirements

The thermostatic mixing valve (TMV) will be installed in such a position that

maintenance of the TMV and its valves and the commissioning and testing of the

TMV can be undertaken.

The fitting of isolation valves is required as close as is practical to the water supply

inlets of the thermostatic mixing valve. Filtered inlet washers are supplied with

the product, if not used then the fitting of strainers is recommended as close as is

practicable to the water supply inlets of the thermostatic mixing valve.

ElisaTM EmilieTM and RosaTM Installation Guide | 7

UK

Components - EmilieTM Dual Outlet

Components - EmilieTM Triple Outlet

8 | ElisaTM EmilieTM and RosaTM Installation Guide

UK

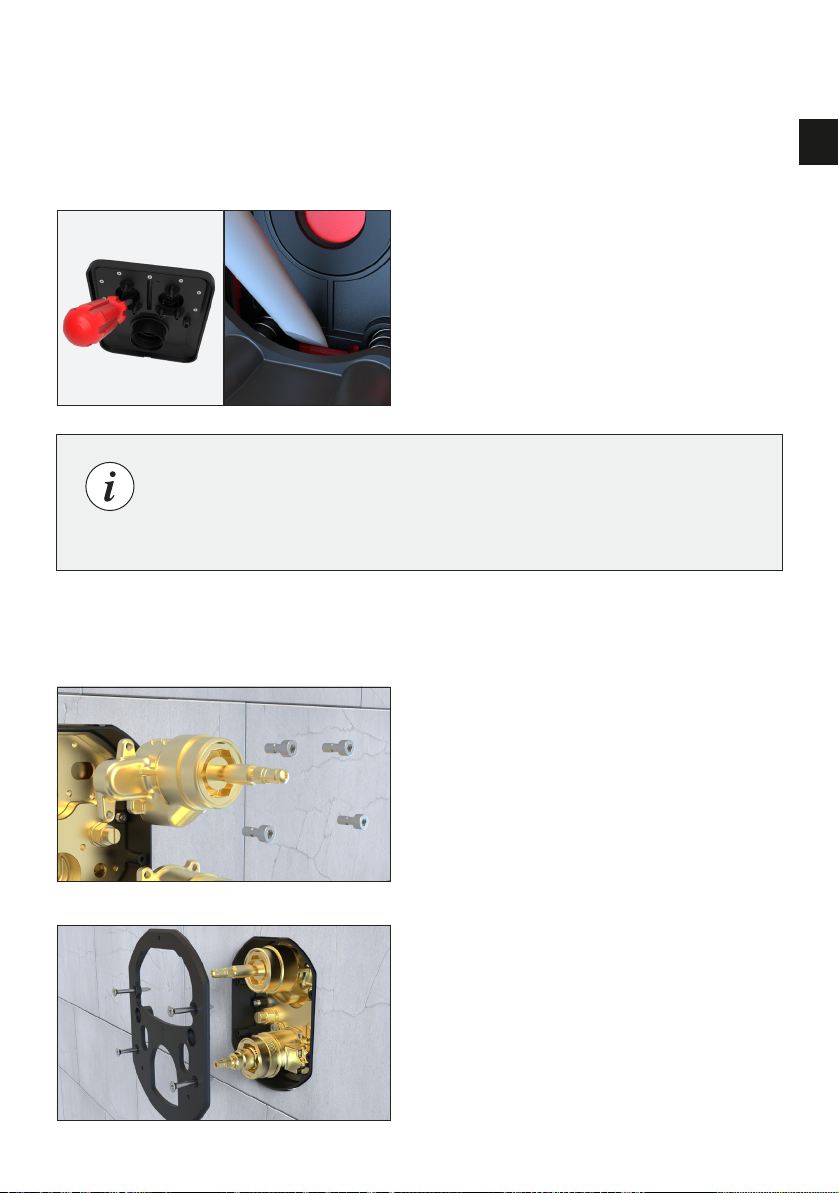

Blank headworks

70-80mm depth

60-70mm depth

Preparation

1. Once all stage 1 leak and pressure

tests have been carried out; before

proceeding with the following

instructions, ensure that the built-in

servicing valves are in the closed

position (screwed down).

2. Remove the pressure testing plates

by unscrewing the bolts with the

long allen key provided.

Ensure all O’rings are installed

and within the grooves of the

valve assembly.

For push button models. Screw

the black extension caps onto the

headworks. (Use the shorter ones

for 60-70mm installation depths

OR the longer ones for 70-80mm

installation depths.)

ElisaTM EmilieTM and RosaTM Installation Guide | 9

UK

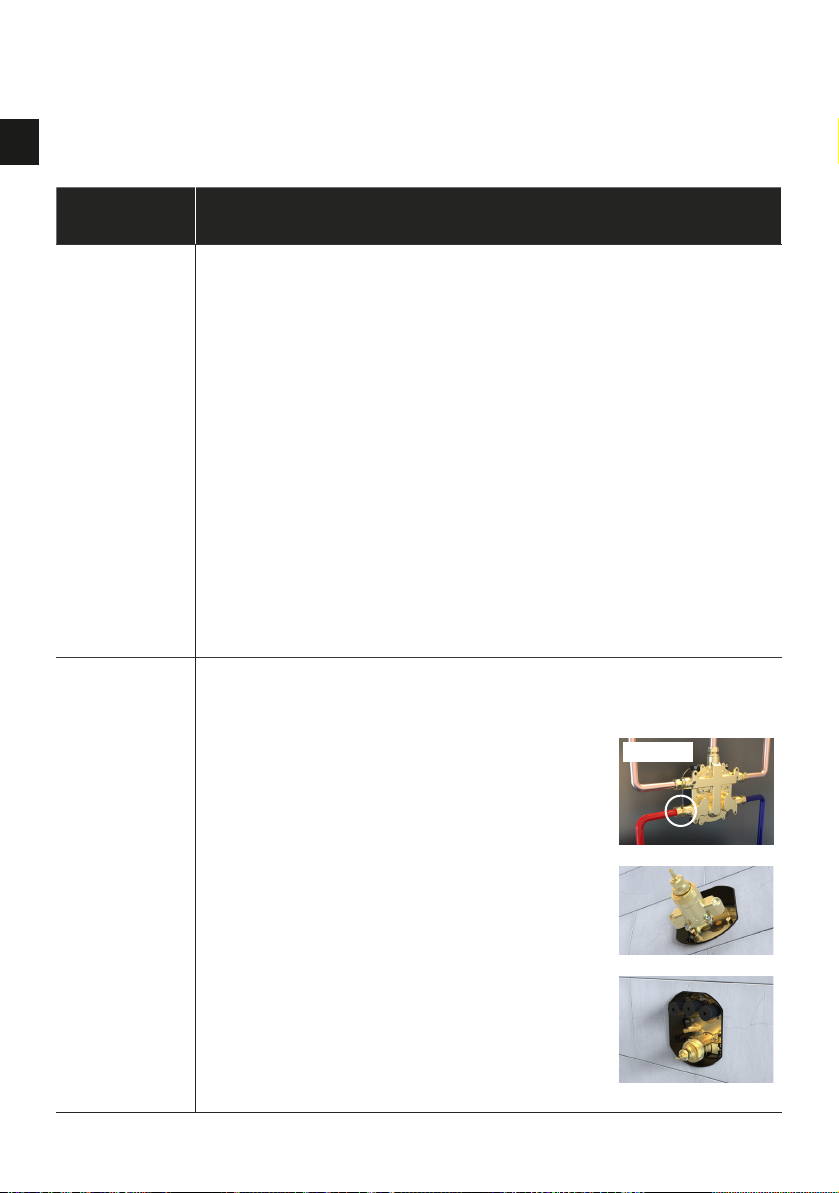

Fitting the thermostatic valve assembly

Offer the thermostatic assembly up to

the AquahubTM body and secure into

place using the long allen key provided

and the bolts.

Tighten all bolts incrementally in a

clockwise manner until tight.

(All models)

This can be easily corrected by

installing the assembly upside-down

(so the ‘H’ and ‘C’ is on the bottom)

- as shown.

Ensure ‘H’ (as circled)

is on the hot water inlet

side (normally left-hand

side as viewed from

the front).

If the water supplies

are reversed or have

been plumbed incorrectly,

the shower will not blend

the water correctly as

the supplies do not

correspond with

the inlets of the

thermostatic assembly.

10 | ElisaTM EmilieTM and RosaTM Installation Guide

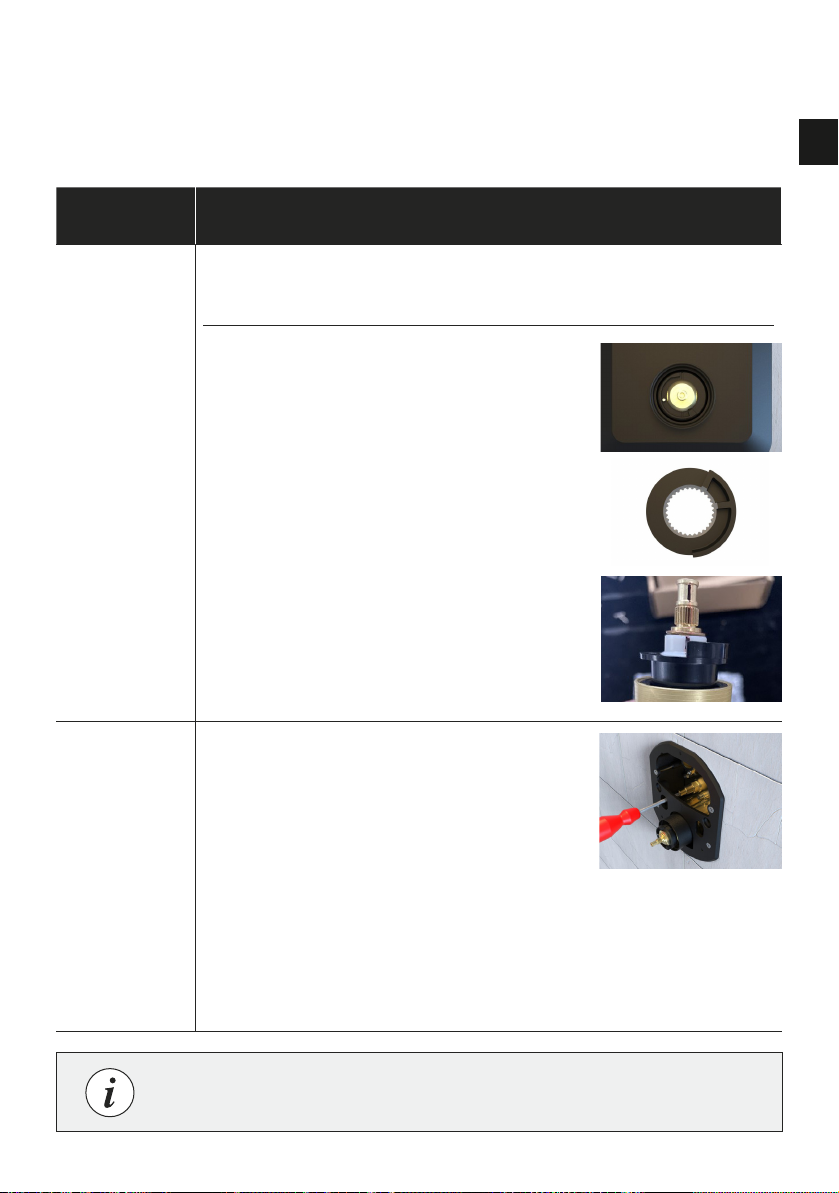

UK Fitting the headworks (Push button)

1. Offer the headworks up to the

AquahubTM body and secure into

place using the long allen key

provided and the bolts.

Tighten all bolts incrementally in

a clockwise manner until tight.

2. Install the dial shroud by rotating it

onto the threaded headwork.

3. Install the compression plate using

the screws provided.

ElisaTM EmilieTM and RosaTM Installation Guide | 11

UK

Commissioning the headworks

and fitting the cover plate (Push button models)

2. Unscrew the buttons until they touch

the bracket. Ensure all buttons are

level and remove the bracket.

3. Open both built-in servicing valves

(unwind – counter clock-wise).

4. Press the cover plate into position.

1. Ensuring the buttons are not

depressed, (in their fully extended

position) place the button

adjustment bracket on top.

12 | ElisaTM EmilieTM and RosaTM Installation Guide

UK

5. Fit the white spacer ring and flow

control dial before placing the

temperature override cam onto the

shaft. Ensuring it is in the correct

orientation(vertical – as shown).

7. Using the small allen key provided,

tighten the grub screw to secure the

dial, then press in the silicone cap.

Open the water isolation valves

and test.

Note: Silicone can be applied

around the wall plate apart from the

drainage hole at the bottom. This

must be left uncovered.

6. Place the second white spacer and

the temperature dial onto the shaft,

with the pin vertically aligned.

Fitting the control dial (Push button models)

ElisaTM EmilieTM and RosaTM Installation Guide | 13

UK

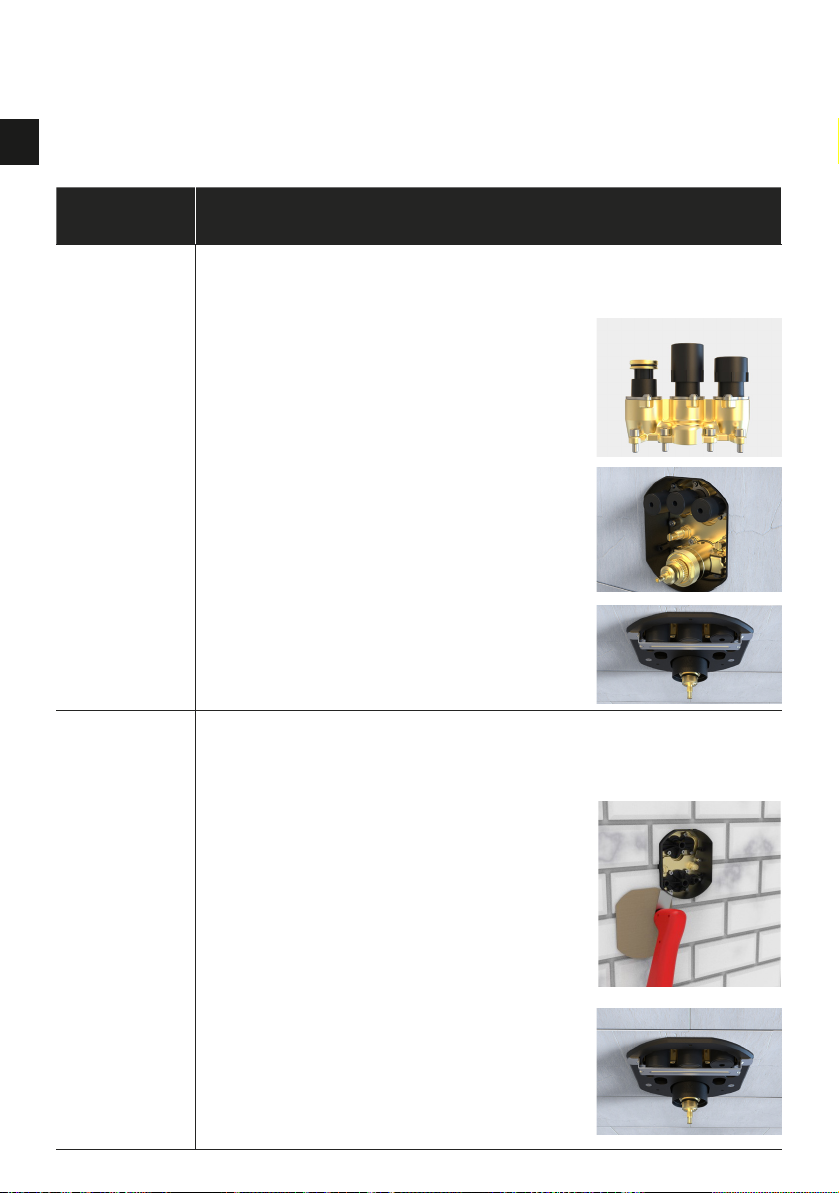

1. Offer the on/off headworks up

to the AquahubTM body and secure

into place using the long allen

key provided and the bolts.

Tighten all bolts incrementally in

a clockwise manner until tight.

2. Install the compression plate

using the screws provided.

Changing cover buttons (Dual outlet (push button) models only)

Fitting the headworks (Dial models)

The buttons can be swapped to

correlate to your specific outlets if

they do not match. At the rear of the

cover, use a flat bladed screwdriver

to pry off the buttons then press the

new ones in place. (Press against

the areas highlighted in red in the

picture opposite)

Note: Spare alternative buttons are available should the outlets

be plumbed incorrectly, according to the button graphics.

Please contact customer services.

14 | ElisaTM EmilieTM and RosaTM Installation Guide

UK

4. Open both built-in servicing valves

(unwind – counter clock-wise).

5. Press the cover plate into position.

6. Fit the temperature override cam

onto the large spline ensuring

that it is in the correct orientation

(as shown).

3. Install the dial shrouds by rotating

them onto the threaded headworks.

Commissioning and fitting the cover plate (Dial models)

ElisaTM EmilieTM and RosaTM Installation Guide | 15

UK

8. Using the allen key supplied,

tighten the grub screw to secure

the control dial.

9. Insert the silicone cover cap, then

open the water isolation valves

and test.

7. Fit the white spacer rings

and control dials.

Override button needs to be

pressed in when fitting the

temperature control knob/dial.

Fitting the control dials (Dial models)

Note: Silicone can be applied

around the wall plate apart from the

drainage hole at the bottom. This

must be left uncovered.

16 | ElisaTM EmilieTM and RosaTM Installation Guide

UK

1. The designation of the thermostatic mixing valve matches the application.

2. The supply pressures are within the valves operating range.

3. The supply temperatures are within the valves operating range.

4. Isolating valves and strainers (filtered washers) are fitted.

If all these conditions are met, proceed to set the temperature as stipulated in the

Cartridge Temperature Adjustment section.

The mixed water temperature at the terminal fitting must never exceed 46ºC.

It is a requirement that all TMV2 approved valves shall be verified against the

original set temperature results once a year.

When commissioning / testing is due the following performance checks

shall be carried out:

• Measure the mixed water temperature at the outlet.

• Carry out the cold water supply isolation test by isolating the cold water supply

to the TMV, wait for five seconds, if the water is still flowing check that the

temperature is below 46ºC.

If there is no significant change to the set outlet temperature (+/-)2ºC or less

change from the original setting) and the fail – safe shut off is functioning, then the

valve is working correctly and no further service work is required.

Note: If there is a residual flow during the commissioning or the annual verification

(cold water supply isolation test), then this is acceptable providing the temperature

of the water seeping from the valve is no more than 2ºC above the designated

maximum mixed water outlet temperature setting of the valve.

Temperature readings should be taken at the normal flow rate after allowing for

the system to stabilise.

The first step in commissioning and in service testing of a thermostatic mixing

valve is to check the following:

Commissioning – in service testing

ElisaTM EmilieTM and RosaTM Installation Guide | 17

UK

The sensing part of the thermometer probe must be fully submerged in the water

that is to be tested.

Any TMV that has been adjusted or serviced must be re-commissioned and re-

tested in accordance with the instructions in the setting section.

The installation of thermostatic mixing valves must comply with the requirements of

the Water Supply (Water Fittings) Regulations 1999.

• N.B. Where water supplies vary significantly from the stated requirements

and /or the valve is not commissioned as instructed this product can reach

temperatures in excess of 50°C.

Cartridge temperature adjustment

18 | ElisaTM EmilieTM and RosaTM Installation Guide

UK

Problem Solution

Water

Leaks

If the AquahubTM or headworks have been incorrectly installed,

leaks could occur down or within the wall.

*Turn off the mains water supply*

Fully close the built in service valves, make sure the servicing valves are

tightened securely into the aquahubTM.

Check all inlets and outlets have been fitted with ptfe tape.

Check all headwork O’Rings are installed correctly and not perished.

Check blanking plugs have been applied to the correct/un-used outlets

Check the thermostatic cartridge and diverter

cartridge/valves are secure.

Check outlet plumbing.

Perform pressure and leak testing - refer to AquahubTM installation

guide (stage 1 installation).

Water is

only fully

hot OR fully

cold

If the inlets have been plumbed in incorrectly, the shower will only

dispense fully hot OR fully cold water. Despite turning the temperature

dial, the water will not blend to a showering temperature.

You have probably plumbed the water

supplies into the wrong inlets.

This can be easily corrected by installing

the headworks upside-down (so the ‘H’

and ‘C’ are on the bottom) see page 9.

Now the inlets have been switched and

your thermostatic cartridge should work

correctly.

Troubleshooting

Incorrect

ElisaTM EmilieTM and RosaTM Installation Guide | 19

UK

Troubleshooting

Dial

not fully

rotating

Remember to depress the pin in order to allow full rotation and

achieve temperatures over 38 degrees.

If depressing the pin is not helping,

its possible you have installed the

temperature override cam incorrectly

(see page 12 or 14).

Or your dial may not be aligned with

the cartridge. In this case, make sure the

markings on the teeth are aligned and

then place your dial on so the pin

is vertical.

Shower is

not working

You may have forgotten to open the

service valves within the aquahub /on the

incoming pipework or left your stop cock

(mains water supply valve) closed.

Remove the faceplate and fully loosen the

isolation valves. (The valves will unscrew

and protrude out when loosened). see

page 11 or 14.

If this has not solved the issue, check your

mains supply valve and external isolation

valves on your incoming pipework.

Problem Solution

Contact customer services for information on replacement parts.

20 | ElisaTM EmilieTM and RosaTM Installation Guide

UK

Problem Solution

Buttons not

working

If the wrong extension bosses have been screwed on, the buttons will

not fully depress or disengage the valves behind.

Remove the faceplate and

compression plate.

Unscrew the black extension bosses and

replace with the longer spare set.

(see page 8).

Readjust them to the correct depth using

the metal bracket. (see page 11).

Faceplate

not sitting

flush with

the wall

You may have incorrectly installed the AquahubTM shroud, button

extension bosses or compression plate, which will prevent the

faceplate from sitting flush with the wall.

Check the compression plate is sitting flush

with the tiles. If not, remove it and check the

plastic shroud behind has been trimmed

flush to the wall ( It should not protrude

more than 2-3mm past the finished wall

surface). If the shroud seems ok, make sure

the compression plate is located on the

shroud correctly and is screwed down tight

against the wall.

Lastly, if this has not corrected the problem,

it is likely that you have installed the wrong

button extension bosses. Unscrew them

and replace with the shorter set. Then

readjust using the metal bracket supplied.

(see page 11).

Troubleshooting

Blank headworks

70-80mm depth

60-70mm depth

This manual suits for next models

1

Table of contents

Languages:

Other Elisa Bathroom Fixture manuals

Popular Bathroom Fixture manuals by other brands

Kohler

Kohler Mira Sport Max J03G Installation and user guide

Moen

Moen 186117 Series installation guide

Hans Grohe

Hans Grohe Raindance Showerpipe 27235000 Instructions for use/assembly instructions

Signature Hardware

Signature Hardware ROUND SWIVEL BODY SPRAY 948942 Install

fine fixtures

fine fixtures AC3TH installation manual

LIXIL

LIXIL HP50 Series quick start guide