TECHNICAL SPECIFICATIONS

TXL-200 5S

The TXL200-5S is a transaxle gearbox design for use in single seat / mid engine rear wheel

drive race cars. The gearbox has 5 forward gears and 1 reverse gear which are selected by

the use of a sequential mechanism.

The gear pattern is:

5/R . R . N . 1 . 2 . 3 . 4 . 5

The 5/R position is only used to aid the tightening of the pinion shaft and layshaft nuts. This

position must NOT be used whist the gearbox is in operation as it will cause a catastrophic

failure.

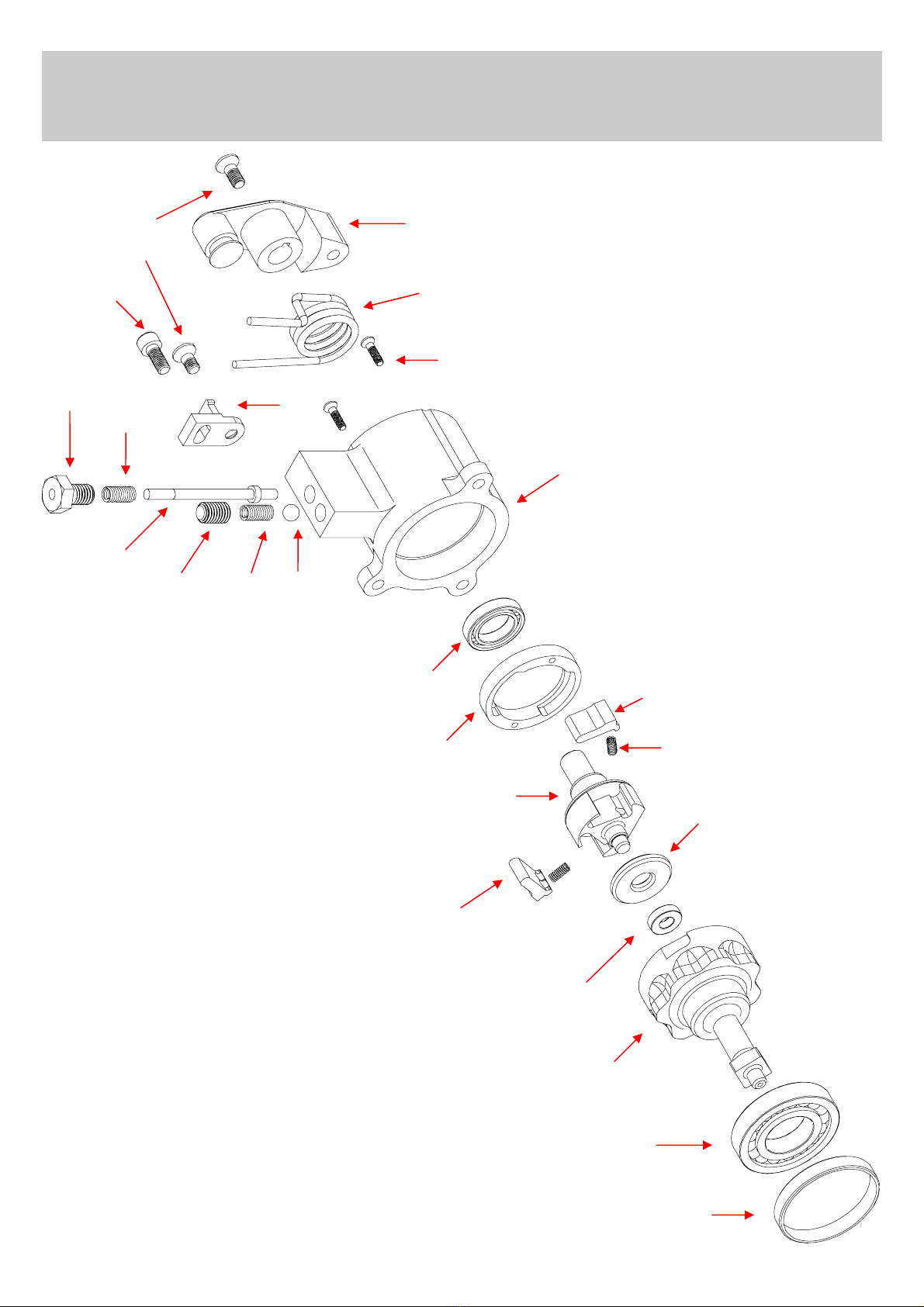

The drive from the power plant is transmitted to the gearbox layshaft via a custom input

shaft (varied to application). This is then transmitted via gears to the pinion shaft and into

the differential. Various differentials are available for the TXL200-5S including LSD, Cam

and Pawl and Free Diff.

Gear change is carried out through the actuator assembly to the sequential drum which then

moves a dog ring to engage each gear in turn in the above sequence. Reverse uses a sliding

gear to select in replacement of the dog ring system.

When coming down the gearbox a manually operated lock-out exists to stop the gearbox

hitting neutral and spiking the engine.

The gearbox case is manufactured from high grade cast aluminum. All gears in the gearbox

are manufactured from case hardening high grade material.

Lubrication in the gearbox is achieved by a simple splash system and retained within the

gearbox using oil seals

FOR ANY GUIDANCE OR QUESTIONS CALL US ON 01782 280136

The TXL200-5S gearbox is designed to be a fully stressed integral component within the

vehicles chassis with points provided for mounting of rear suspension.

Maximum Gearbox Operating Torque 200 lbs/ft

(This is application dependant; advice is

available by contacting Elite)

Gearbox Oil Type Fully synthetic gear oil

(Millers 75W90 is recommended)

Oil Quantity 1.5ltrs normal road tracks & 1.75ltrs oval tracks

(Capacity to filler on gearbox = 1.75litres)

CWP Backlash Setting 0.10 / 0.15 mm

Gearbox Dry Weight 36kg (including input shaft)