Operation

Fastening and adjustment of drill bits

The reversible pris has a sharpening range fro 2 to 20 .

Fixing and align ent of the drill bits is achieved in the si plest

way. The pris is opened by eans of the knurled screw provided

for this purpose. Once opened, insert the drill bit to be sharpened.

Hold the drill bit so that the tip protrudes 15 to 20 . In front of

the cla p. Close the cla p gently with the knurled screw so that

you can still turn the drill bit by hand.

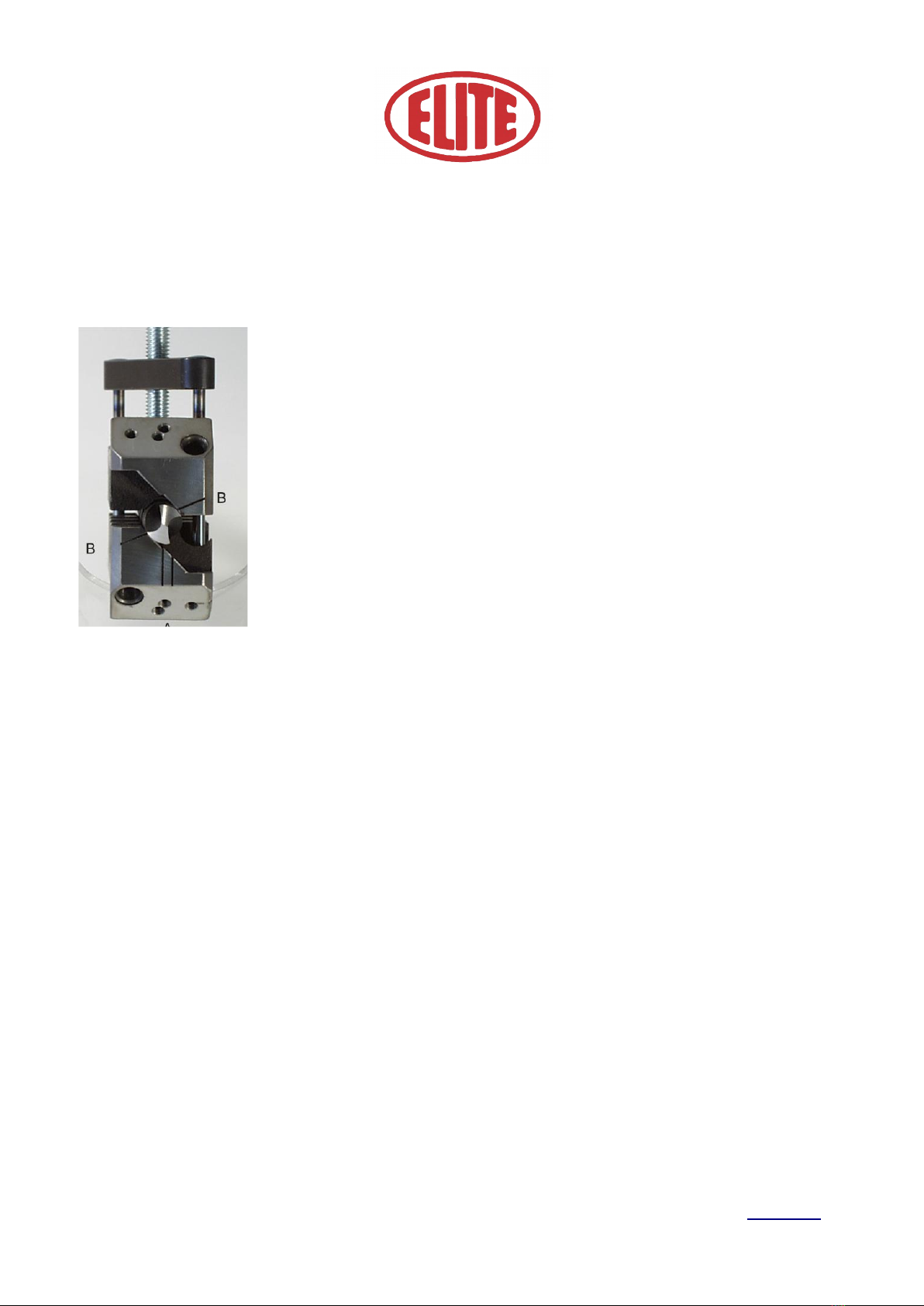

The only thing to do now is to align the cutting edge of the drill bit

so that it is parallel to the two arks shown.

Mark A: for right-hand drills Mark B: for left-hand drills

Once adjusted, we finish cla ping the cla p by hand and we can

now proceed to sharpening.

In addition to the basic settings, the rake angles can be adjusted depending on the

aterial to be cut.

If you want a higher rake angle - ore cutting capacity, you should ove the bit a little

to the left (less angle on the pris ). If you want less rake - less cutting capacity, just

ove it a little to the right.

In this way we can adjust to the angles required for each aterial.

In the case of sharpening a broken drill bit, as it has no cutting edge to adjust, we ust

cut so that it lies flat. Then we can adjust the ends of the cutting edge as close as

possible to the adjust ent arks and resharpen until a new cut appears, and we can

adjust as above.

Cutting angle adjustment.

In order to always work according to the aterial properties, we can infinitely adjust the

cutting angle.

The ost co on cutting angles are 118°, 130° and 80°.

These angles are arked on the base and can be quickly adjusted by opening the cla ping

ca (pos. 6 on page 7) and oving the pris base (pos. 4 on page 7).

Joan Oró, 27. Pol. Ind. Sesrovires, St. Esteve Sesrovires, BCN, Spain– Tel: + 4 9 2 9 5 178 – info@elite.es

10