Elitech FreezePoint 6000 Series User manual

FreezePoint®

Freezing Point Osmometer

USER’S

MANUAL

MODEL 6000, 6000P, 6000S, 6000SP

3

FREEZEPOINT®

Freezing Point Osmometer

MODEL 6000, 6000P, 6000S, 6000SP

USER’S MANUAL

57-0022-01-C

(Last update 02/01/21)

4

©2021 ELITechGroup Inc. All rights reserved.

Printed in the United States of America. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language (human or computer) in any form,

or by any means whatsoever, without the prior express written permission of ELITechGroup Inc.

FreezePoint®is a trademark of ELITechGroup Inc.

Other trade names used in this manual are trademarks of their respective owners, used here for

information only.

ELITechGroup Inc. makes no express or implied warranty regarding this manual, its quality, performance,

or appropriate use regarding any type of specic procedure. ELITechGroup Inc. may modify this manual

without notice and without implying any obligation or liability on the part of the company.

ELITechGroup Inc.

370 West 1700 South

Logan, Utah 84321-8212 USA

5

This manual allows for the safe and ecient operation of the FreezePoint®Model 6000 Freezing Point

Osmometer (hereafter “device”). This manual is part of the device and must be stored in the immediate

vicinity of the device and be easily accessible to personnel at any time.

Personnel must carefully read and understand this manual before beginning any kind of work. Compliance

with the safety notices and instructions in this manual is the basis for a safe work environment. In addition,

local accident prevention regulations and general safety provisions for the intended use of the device must

be followed.

Figures in this manual are included for basic understanding and may dier from the actual application.

Other applicable documents

In addition to this manual, the documents included with the device documentation apply. The warnings – in

particular safety notices – in this documentation must be observed!

Copyright

The contents of this manual are protected by copyright. Their use is permitted in connection with the

use of this device. Any use beyond this scope is not permitted without prior written authorization from

ELITechGroup Inc.

Manufacturer contact information

Address ELITechGroup Inc.

370 West 1700 South

Logan, UT 84321-8212

USA

Phone +1 (435) 752 6011

Toll-free support hotline: 1 (800) 435 2725

Fax +1 (435) 213 2108

E-mail [email protected]

Web http://www.elitechgroup.com/

European Authorized Representative:

MT Promedt Consulting GmbH

Altenhofstrasse 80

D-66386 St. Ingbert

Germany

Telephone: +49(0)68 94-58 10 20

Fax: +49(0)68 94-58 10 21

Email: [email protected]

Table of Contents

Section 1: Safety

1.1 Explanation of symbols 9

Safety notices 9

Special safety notices 10

Safety notices in instructions 10

Additional identiers 10

1.2 Intended use 11

Intended use 11

Attention when using device 11

1.3 Additional hazards 12

Hazards due to electrical current 12

Risk of infection 12

Risk of injury 12

Risks of device damage 13

Repeatability of the measurement 14

1.4 Personal requirements 15

1.5 Personal safety gear 16

1.6 Environmental Information 17

Section 2: Design and Function

2.1 Device Overview 18

Standard Consumables 20

Standard Items 21

2.2 Measuring Method Basics 22

2.3 Measurement Equipment 23

Upper Cooling System 24

Thermistor probe 24

Lower Cooling System 24

2.4 Touchscreen 25

Enter values 26

2.5 Printer (Model 6000 P/SP) 27

2.6 Connections and interfaces 28

Interface conguration 29

Log formats 30

CSV format 31

XML format 32

Section 3: Delivery, packaging, and storage

3.1 Packaging 37

About the packaging 37

Handling of packaging materials 37

Symbols on packaging 37

3.2 Unpacking and Device Storage 39

Unpacking device 39

Device Storage 39

Section 4: Installation

4.1 Transport device inside lab 40

4.2 Install device 41

Connect device 42

Section 5: Setup

5.1 Check printer (Models 6000P/SP) 43

5.2 Check free movement of steel needle 44

5.3 Set calibration defaults 45

Select calibration procedure 45

Congure calibration interval 45

Select calibration standards 46

Set up calibration method 46

5.4 Date Time 47

Set date and time 47

Set date format 47

5.5 Measurement series name 48

Set measurement series name 48

5.6 Result Unit 48

Set result unit 48

Section 6: Operation

6.1 Information before operation 49

Electrical current 49

Risk of infection 49

6.2 Power up device 50

6.3 Modify user preferences 51

6.4 Measure individual/batch samples 54

6.5 Calibrate device 58

Calibration methods 58

Calibrate device 58

Perform zero point calibration 60

Calibrate device using calibration standard 61

6.6 Power down device 64

Section 7: Troubleshooting

7.1 Safety notices 65

Electrical current 65

Risk of infection 65

Risk of injury 65

7.2 Notes regarding errors 66

7.3 Error table 67

7.4 Resolve Errors 71

Replace Initiation needle 71

Replace the thermistor probe 75

Align the Thermistor probe 80

Replace micro-fuses 83

Clean cooling clamp 84

Replace printer paper (Models 6000P / 6000SP only) 84

Replace printer ribbon (Models 6000P / 6000SP only) 86

7.5 Reset device to default settings 88

Section 8: Servicing

8.1 Safety notices 89

8.2 Routine maintenance 90

8.3 Remove device front panel 91

8.4 Install device front panel 94

8.5 Lubricate elevator 95

8.6 Perform visual inspection of device 96

8.7 Check repeatability of measurements 97

Sample test protocol measurement check 97

Section 9: Disposal

Section 10: Specications

10.1 Dimensions 99

10.2 Performance parameters 99

Precision (within run repeatability) 99

Accuracy (Linearity)* 100

10.3 Operating Conditions 101

10.4 Nameplate 102

10.5 Repeatability vs Reproducibility 102

Appendix A: Shipping the device 103

Appendix B: Consumables, Accessories, and Replacement Parts 105

Accessories 105

Supplies 105

Replacement Parts 105

Distilled Water 105

Appendix C: Contacting ELITechGroup 106

Appendix D: Theory of Operation 107

Appendix E: Operational Use 108

General operating conditions 108

Operational use 108

Operation 108

Defrosting procedure 110

Safety Testing 110

Installation, Operation, and Performance Qualication 111

Product Information 111

Table of Contents 111

Urgent Safety Information 112

Scope 113

Instructions 113

Installation Qualication (IQ) Verication 114

Installation of the Instrument 117

Ancillary Information 118

Device Environment 119

Operation (OQ) & Performance Qualication (PQ) 120

Calibrators / Reference solutions 128

Calibration / Verication Workow 131

Performance Check: Calibration / Verication 132

Calibrating Table 135

Revalidation Schedule 136

9

1.1 Explanation of symbols

Safety notices

The safety notices in this manual are identied by symbols. The safety notices are preceded by signal

words indicating the degree of hazard.

DANGER!

This combination of symbol and signal word indicates an immediate dangerous situation that will

result in death or serious injury if not avoided.

WARNING!

This combination of symbol and signal word indicates a potentially dangerous situation that may

result in death or serious injury if not avoided.

CAUTION!

This combination of symbol and signal word indicates a potentially dangerous situation that may

result in minor or light injury if not avoided.

NOTE!

This combination of symbol and signal word indicates important information about the device and/

or the operations of the device.

Section 1: Safety

10

Section 1: Safety

Special safety notices

Safety notices use the following symbols to indicate special hazards:

WARNING!

This combination of symbol and signal word indicates a potentially dangerous situation that may

result in contamination with bio-hazardous materials.

Observe the current Ordinance on Biological Substances and refer to the lab protocol.

DANGER!

This combination of symbol and signal word indicates an immediate dangerous situation due to

electrical current. Failure to observe a warning identied this way may result in serious or deadly

injury.

Safety notices in instructions

Safety notices can apply to specic, individual instructions. These safety notices are embedded in the

instruction to avoid interrupting the ow of reading while performing the operation. They use the signal

words described above.

Example:

1. Loosen screw.

CAUTION!

Pinch hazard on cover!

Use care when closing cover.

2. Tighten screw.

Additional identiers

To highlight instructions, results, lists, references, and other elements, the following identiers are used in

this manual:

Identication Explanation

1, 2, 3 ...

Step-by-step instructions

Results of action steps

References to sections in this manual and

other applicable documents

• Unordered lists

[Button] Controls (such as buttons or switches), display

elements (such as indicator lamps)

Display Screen elements (such as buttons, function key assignments)

11

Section 1: Safety

1.2 Intended use

Intended use

FreezePoint® 6000 series osmometers are intended for laboratory use by qualied personnel for the

determination of total osmolality of aqueous solutions.

Attention when using device

• Only use the device to measure aqueous solutions.

• Never measure organic, saturated, or highly viscous solutions.

• Never administer measured samples to humans by infusion or injection.

• Never use calibration standards as cleaning solutions.

• Only use accessories and consumables supplied by ELITechGroup for measurements.

”Consumables, Accessories, and Replacement Parts” on page 106.

12

Section 1: Safety

1.3 Additional hazards

Hazards due to electrical current

DANGER!

Risk of death due to electrical current on device!

• Class I devices must be connected to a power socket with protective ground wire.

• If the power or device connector is used as a separation device, the connector must be easily

accessible at all times.

• Remove the power plug from the power socket to safely disconnect the device from voltage source.

• Contact with energized parts of the device results in immediate risk of death due to electric shock.

• Damage to the insulation of individual components can cause risk of death.

• Only have qualied personnel perform repair and maintenance work on the device.

• If the insulation is damaged, immediately disconnect the power plug and contact ELITechGroup

Service Department for repairs.

• Always route the power cable so it is not subject to stress and cannot be bent, pinched, or rolled over

and is not exposed to liquids or heat.

• Keep energized parts away from liquids. Otherwise, short circuit may occur.

Risk of infection

WARNING!

Risk of infection due to sample residue and in case of inadequate hygiene, disinfection, and

sterilization procedures!

• Exposure to sample residue in non-cleaned, non-sterilized, or non-disinfected components results in

an elevated risk of infection.

• Wear lab gloves during any kind of work.

• Observe all local regulations regarding hygiene, disinfection, and sterilization.

• We recommend using alcohol based disinfectants commonly found in clinical-chemical labs to clean

and decontaminate the device.

Risk of injury

CAUTION!

Risk of injury from initiation needle!

When installing and removing the initiation needle and the thermistor probe, the tip of the initiation needle

is exposed. Movement of the initiation needle can cause needle puncture injuries.

• Always keep your hands and ngers clear from the area underneath the initiation needle.

13

Section 1: Safety

Risks of device damage

Exposure to liquids and moisture

WARNING!

Device damage due to exposure to liquids and moisture!

Exposure to liquids and moisture can cause damage to the electrical components of the device, e.g. due to

a short circuit.

• Install the device on a dry workplace.

• Always use a moistened wipe to disinfect the device, but never a wet wipe.

• Never use the device outdoors.

Fan

WARNING!

Device damage due to insucient air circulation!

Obstruction of the fan outlet at the rear of the device can cause damage to the device.

• Always keep the fan outlet clear.

Impact/vibration

WARNING!

Risk of property damage due to exposure of the device to strong impact/vibration!

The device includes precision-engineered components which can be decalibrated and/or damaged in case

of exposure of the device to strong impact/vibration.

• Always install the device on a non-vibrating surface.

ESD

WARNING!

Risk of property damage due to electrostatic discharge!

Electrostatic discharge (ESD) can occur when working on the open device and cause damage to the

touchscreen and/or communication ports.

• Take ESD precautions.

14

Section 1: Safety

Repeatability of the measurement

Incorrect measurement vessels

NOTE!

Impaired repeatability of measurement due to incorrect measurement vessels!

Repeated use of the measurement vessels and use of incorrect consumables cannot guarantee

reproducible measurement results.

• Always use a clean and unused measurement vessel for every measurement.

• Only use measurement vessels supplied by ELITechGroup.

• Never use centrifuge tubes or reaction vessels.

Improper handling of the calibration standard

NOTE!

Impaired repeatability of measurement due to improper handling of calibration standards!

Improper handling and storage of the calibration standards included with the delivery negatively aects the

measurement accuracy of the device.

• Always observe the stability of the calibration standards after opening the ampule (max. 30 minutes at

72°F (22°C) ambient temperature).

• Never use opened ampules twice or mix them together.

• Never freeze opened ampules.

• Do not use the calibration standards past their expiration date.

Impact/vibration

NOTE!

Increased risk of incorrect measurements!

The device includes precision-engineered components which can be decalibrated and/or damaged

in case of exposure of the device to strong impact/vibration. This can cause a higher risk of incorrect

measurements (spontaneous crystallization).

• Always install the device on a non-vibrating surface.

15

Section 1: Safety

1.4 Personal requirements

WARNING!

Risk of injury due to inadequately qualied personnel!

Work performed on the device by unqualied personnel or the presence of unqualied personnel in the

hazard zone of the device creates risks that can result in serious injury and substantial property damage.

• Only have qualied personnel perform any kind of activity.

This manual species the following personnel qualications for the dierent task areas:

User

Based on his or her expert medical and/or pharmaceutical training, knowledge, and experience, the user is

capable of safely executing the tasks assigned to him or her.

The user is not authorized to perform any start-up activities.

The user is capable of independently detecting, evaluating, and avoiding possible risks.

The user has the expert knowledge for the intended use of the device and observes all hygiene regulations

for rooms used for medical purposes and the use of medical products.

The user knows the contents of all applicable regulations, guidelines, and standards required by law for the

safe use of the device and is capable of meeting the requirements stipulated therein.

Lab supervisor

The lab supervisor coordinates and monitors the technical procedures at the installation site of the device.

Based on his or her professional training and many years of professional experience with medical devices,

the lab supervisor is capable of performing the start-up tasks delegated to him or her by the manufacturer.

Service technician

Based on his or her professional training in the area of mechanical and electrical engineering, the service

technician is capable of performing the tasks related to troubleshooting and servicing delegated to him or

her by the manufacturer.

16

Section 1: Safety

1.5 Personal safety gear

While performing the dierent tasks on and with the device, personnel must wear the personal safety gear

referenced explicitly in the various sections of this manual.

Description of personal safety gear

The personal safety gear is explained below:

Disposable lab gloves

Disposable lab gloves protect the hands from touching sample residue.

17

Section 1: Safety

1.6 Environmental Information

NOTE!

Danger to environment due to incorrect handling of handling of environmentally hazardous substances!

Incorrect handling of environmentally hazardous substances, in particular incorrect disposal, can result in

signicant harm to the environment.

• Always observe the warnings regarding the handling of environmentally hazardous substances and

their disposal below.

• If environmentally hazardous substances are inadvertently released into the environment, immediately

initiate suitable actions. If in doubt, notify the responsible local authority about the damage and inquire

about suitable actions to be initiated.

The following environmentally hazardous substances are used:

Electronic components

Electrical components can contain poisonous substances. These must not be released into the

environment. Therefore, a specialist disposal rm must be tasked with disposal.

Sodium chloride

The calibration standards contain sodium chloride. Sodium chloride is mildly hazardous and may cause

eye, skin, and respiratory irritation.

Solutions are traceable to standards prepared from NIST Standard Reference material (SRM 919b Sodium

Chloride)

18

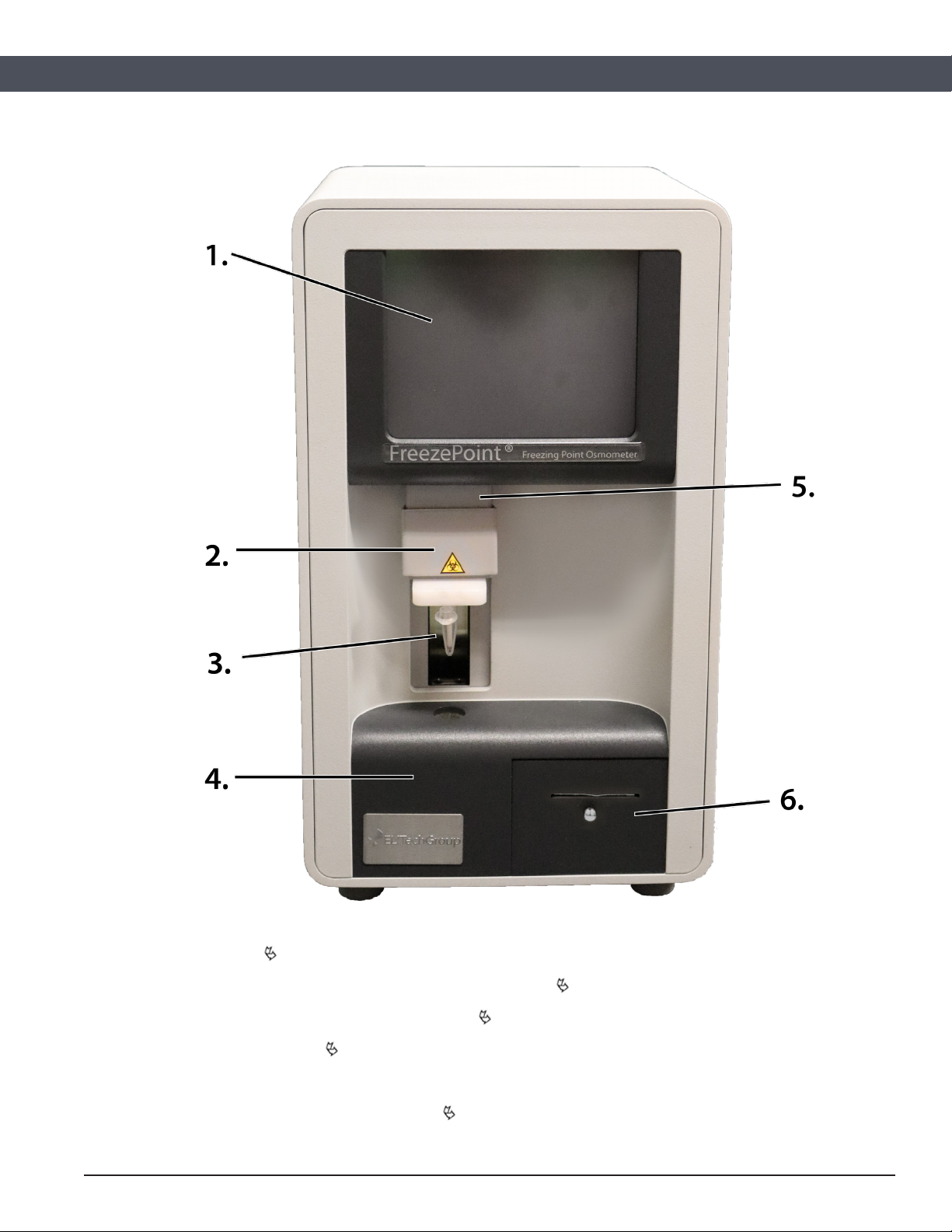

2.1 Device Overview

Figure 1 Device overview—front

1. Touchscreen page 25

2. Upper cooling system (behind movable elevator cover), page 24

3. Thermistor probe with measurement vessel, page 24

4. Lower cooling system page 24

5. Elevator

6. Printer (Model 6000P / Model 6000SP)

Section 2: Design and Function

19

Section 2: Design and Function

Figure 2 Device overview-rear

1. Interfaces

2. Micro-Fuse compartment

3. On/O switch

4. Power cable connection

5. Fan outlet

20

Section 2: Design and Function

Standard Consumables

NOTE: Risk of falsied measurement results!

When using accessories and/or consumables provided by manufacturers other than ELITechGroup, the

repeatability of the measurement results cannot be guaranteed.

• Always use the accessories and consumables supplied by ELITechGroup.

• Reorder consumables, in particular measurement vessels and calibration standards, from

ELITechGroup (see “Manufacturer contact information” on page 5 for contact information).

Figure 3: Overview of Consumables

1. SS-036 Pipettor Tips (1000 ea)

2. SS-275 / SS-279 Measurement Vessels, 1000 ea./100 ea., FreezePoint

3. SS-276 Calibration Standard, 300 mOsmol/kg, FreezePoint

4. SS-277 Calibration Standard, 850 mOsmol/kg, FreezePoint

5. SS-281 Printer paper, 8 rolls (Model 6000 P/SP)

”Consumables, Accessories, and Replacement Parts” on page 106.

This manual suits for next models

4

Table of contents

Other Elitech Laboratory Equipment manuals