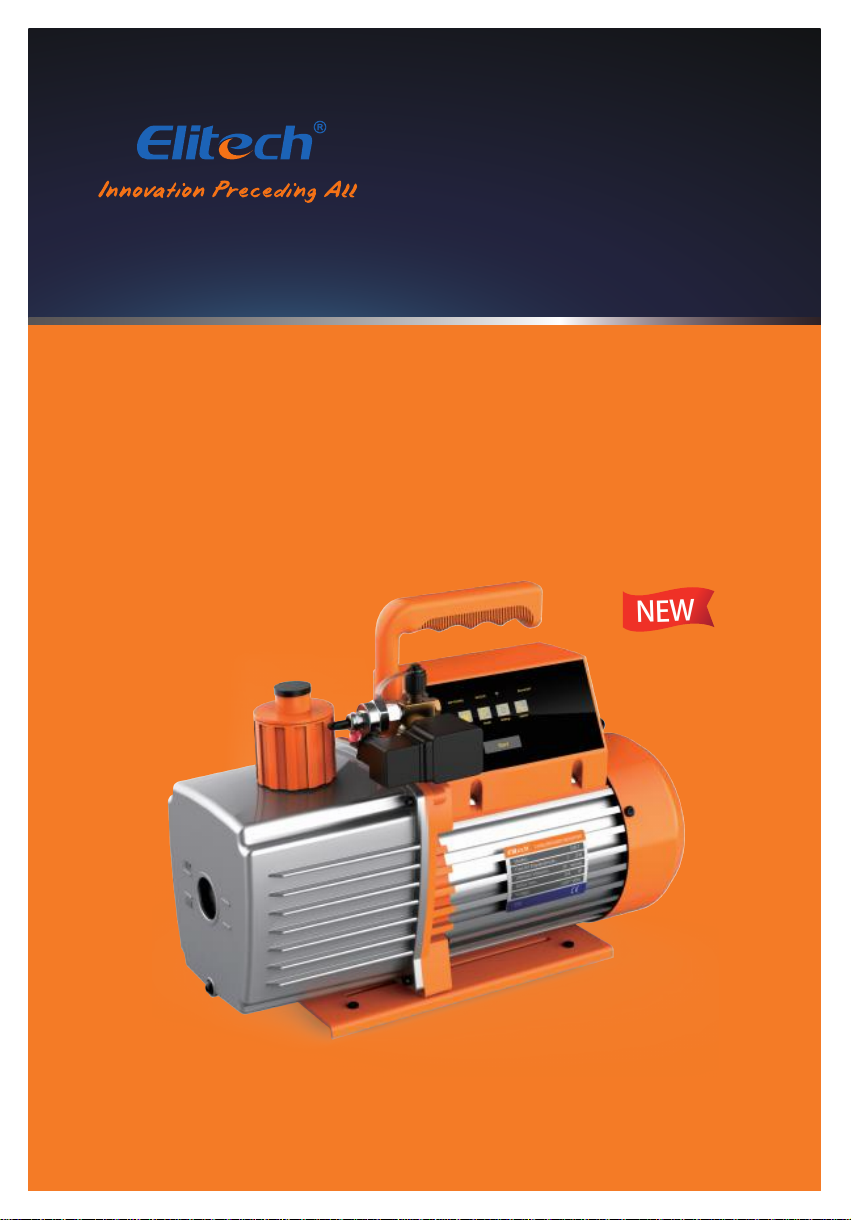

Elitech SVP-7 User manual

IntelligentVacuumPump

UserManual

SVP-7/SVP-9/SVP-12

NEW

Contents

Disclaimer ···························································································1

Product Features ···············································································2

Technical Parameters ·········································································2

Service Parts ······················································································3

Operation Guide ···············································································4

Care and Maintenance ·······································································9

App Operating Instructions ······························································11

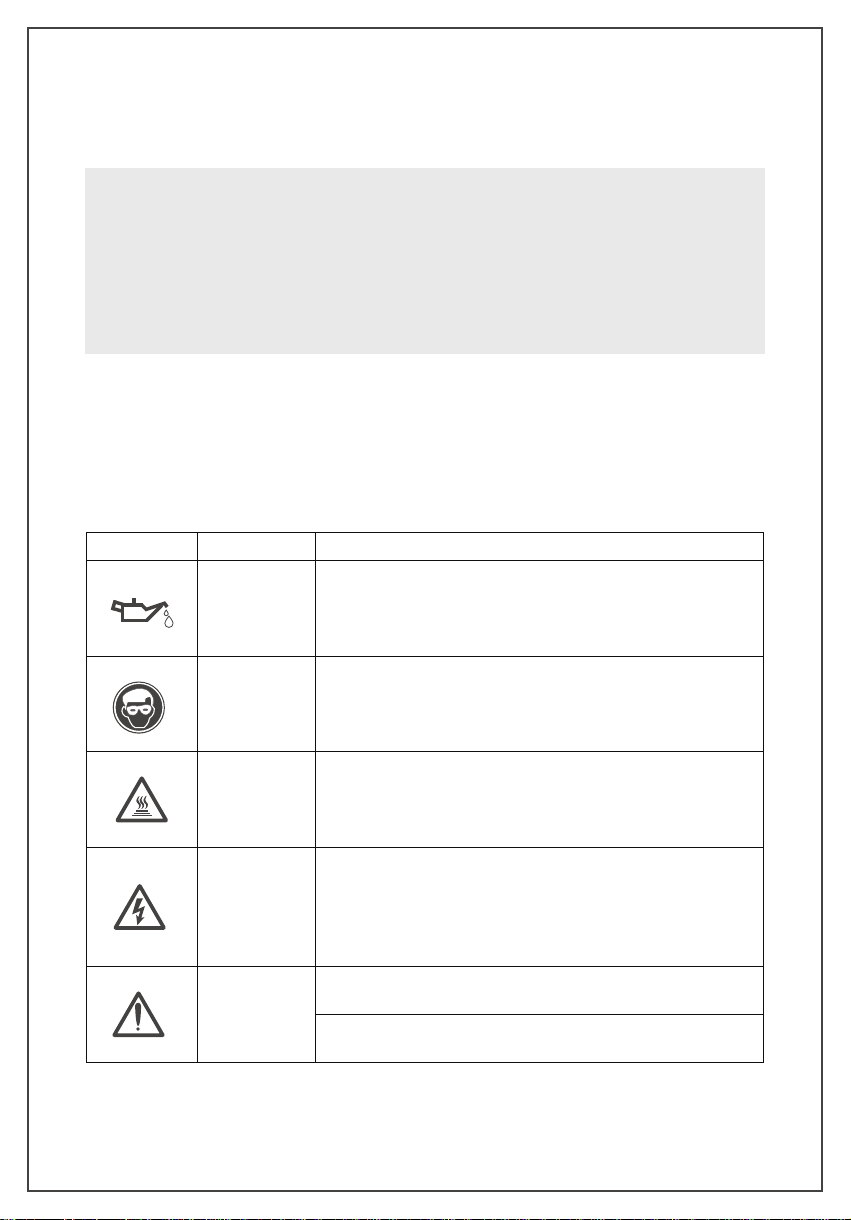

Disclaimer

WarningSigns

• Thevacuumpumpisheavy.Becareful while handling topreventpersonalinjury.

• Use only ISO 46 mechanical oil to avoid vacuum pump damage.

• Do not cover the exhaust port during vacuum pump operation.

• Donotexposethesuctionportcontinuouslytoatmosphereformorethan3 minutes.

• The air inlet pressure should not exceed 27. 5 bar to avoid sensor damage.

-1-

Sign

Name

Content

Checkthe Oil

Level Add ISO46 mechanical oil

beforethefirstuseandkeeptheoillevel

betweenthemaximumandminimumlevel

WearGoggles

Weargoggleswhenworkingwithrefrigerants

.

Directcontactwith

refrigerantsmaycauseinjury

Bewareof High

Temperature

Burns

Thepumpsurfacebecomeshotduringnormaloperation. Donot

touchthepumpbodyormotorduringoperation

Avoid Electrical

Shock Hazards

Improperusemay causeelectricalshockhazards

Readandfollowtheinstructionscarefullyandtakeprecautionsto

avoidelectricalshockhazards . Confirmthatallassociateddevices

aregroundedcorrectlybeforepoweron

Danger

Pleaseremovetheexhaustcap beforestartingup

Checktheoillevelandprohibitrunningwithoutoil

ProductFeatures

TechnicalParameters

• Intelligent Control of Motor and Solenoid Valve

• Leakage Level Judgment

• Vacuum Change in Graph

• 4" Touch Screen Display

• Estimated Job Completion Time

•Data Logging and Storage via App

-2-

Models

SVP-7 SVP-9 SVP-12

Stage

2 stages

PowerSupply

110V / 60HZ; 220V/50HZ

Motor

AC induction motor

SpeedRegulation

Fixed speed

VacuumAccuracy

1-10000microns ±10% of Reading / ±10microns

10000-19000 microns ±20% of Reading

OperatingTemperature

5°C~40°C(41°F~104°F)

Transmission

Distance

30ft / 10m

LimitVacuum

15 microns

PumpingRate

7 CFM (3L/S) 9 CFM (4L/S) 12 CFM (5L/S)

MotorPower

3/4 HP ( 550 W ) 1 HP ( 750 W ) 1 HP ( 750 W )

FuelVolume

22oz /(650ml) 22 oz /(650ml) 25.3 oz(750ml)

OverallDimension

18.5in×10.5in×14.8in / (470mm*267mm*380mm)

Weight

34.2lbs / 14.8kg 35.3lbs / 15.3kg 36.8lbs / 16kg

AirInlet

1/4 SAE ;3/8 SAE

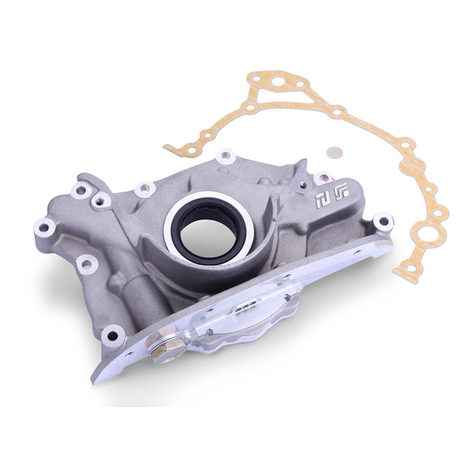

ServiceParts

① Display screen

② Handle

③ Air inlet

④ Solenoid valve

⑤ Catcher

⑥ Oil tank

⑦ Base

⑧ Motor

⑨ Motor housing

⑩ Power button

⑪ Vacuum sensor

⑫ Oil window

⑬ Oil drain plug

-3-

1

9

8

7

6

5

2

43

12

13

10 11

OperationGuide

InterfaceIntroduction

Conditions that must be met

1. Place on a flat surface.

2. Confirm the voltage and frequency at the outlet match with the vacuum pump

specifications.

3. Confirm the oil level is within the Min and Max level.

4.Remove the air inlet cap(1/4 SAE fitting as shown in the

right image), connect the pumped system(make sure the pipe

fitting is fit with the air inlet fitting). Tighten the air inlet and

make sure the system and hoses are sealed with no leakage.

5. Plug in the power cordand open the exhaust port.

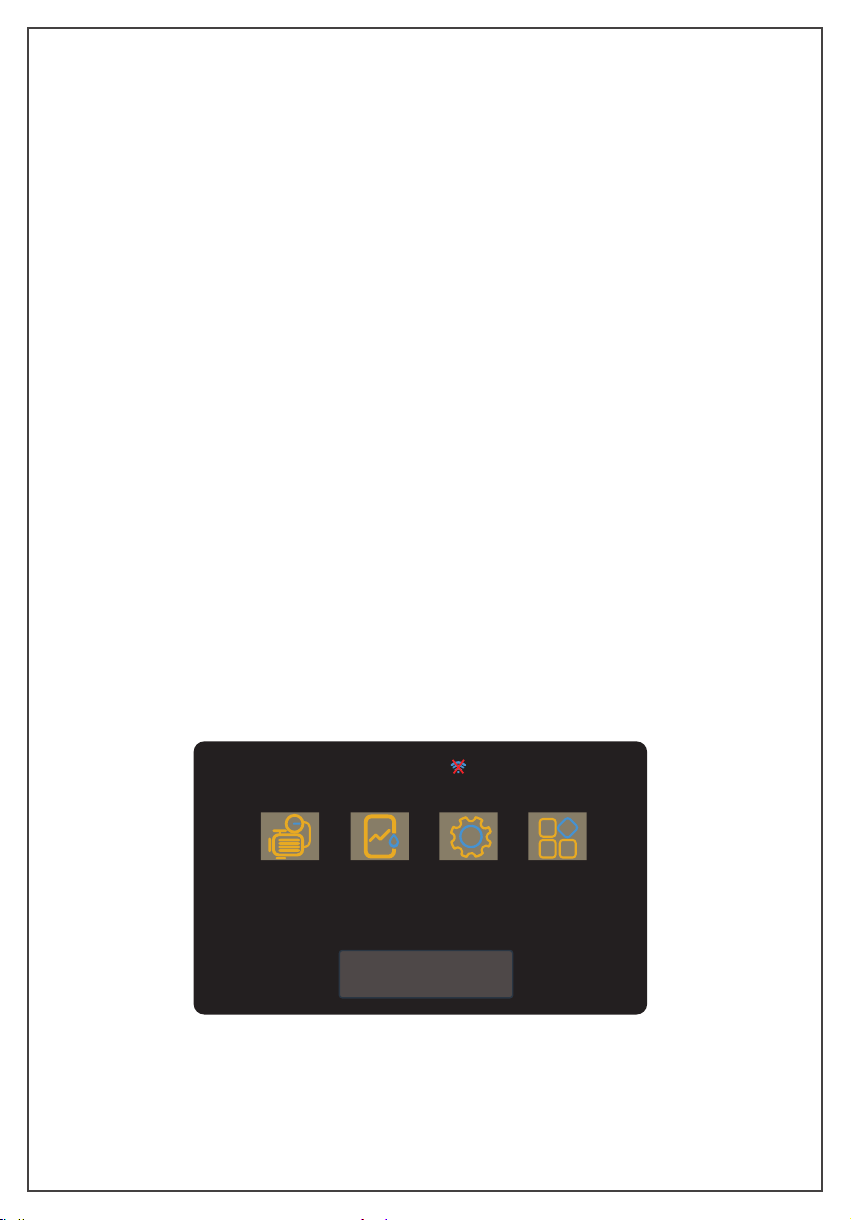

Maininterface

-4-

SVP-7 (110V)

Measure Graph Sengs System

16:22:34 Record: OFF

Start

1/4 SAE

(1) Thestatusbarontop ofthepageshowsthe product model,time,Bluetoothstatus

andrecordstatus.

①Model numbers varies depending on the product models.

② Bluetooth not connect; Bluetooth connected.

③During operation, appear when temperature exceeds the upper alarm limit,

and appear when temperature below the lower alarm limit.

④Record: close means no data is recorded.Record: Open means that data is

being recorded.

(2) The middle part of the page is the sub-interface button.

① : Real-time measurement interface

② : Graph

③ : Vacuum parameter setting

④ : System parameter display and setting

(3) Thebottompartisthe “Start” and“Stop”button. Themotoriso bydefaultafter

power-on. Click “Start” to start the motor. Button will be locked (within 3 sec);

Click “Stop” to stop the motor. Button will be locked (within 10 sec).

After the motor stops, in order to prevent frequent start and stop, the button is

invalid within 10 seconds.

When the motor starts, the solenoid valve automatically opens instantly. The

solenoidvalveclosesautomaticallyafter the motor stopstoavoidtheoilbesuck to

vacuum sensor.

1. Real time measurement interface

Clickthe“Measure”buttononthemaininterfacetoenterthereal-timemeasurement

interface.

-5-

(1) Motor Status: show the current status of the motor.

(2) Motor Temp/Limit: show the surface temperature of the pump chassis and set

the alarm temperature.

(3) OilTemp/Limit:show vacuumpumpoiltemperatureandsetthealarmtemperature.

(4) Vacuum Status: display the current vacuum value status, "Decrease", "Stable",

"Rise", "--".

(5) Estimated End Time: when the vacuum is stable, it shows the estimated job

completiontimeincludingholdingtime.

(6) Vacuum Reading Display: Vacuum readings shows when the vacuum of the

system in real-time is below 60000microns. The waiting time for the vacuum

reading is longer for a larger system.

Note: The vacuum reading varies due to the sensor placement dierent. The reading

variances is caused by the uneven air flow during the vacuuming process. The farther

the air from the pump, the higher the air density is thus the vacuum reading is higher.

(7)Leakagelevel: when the vacuum is stable, checktheleakage possibility from 0 to

100 levels. 0 represent uncertain leakage. The larger the number, the greater the

possibility of the leakage.

(8) Key: return to the main interface.

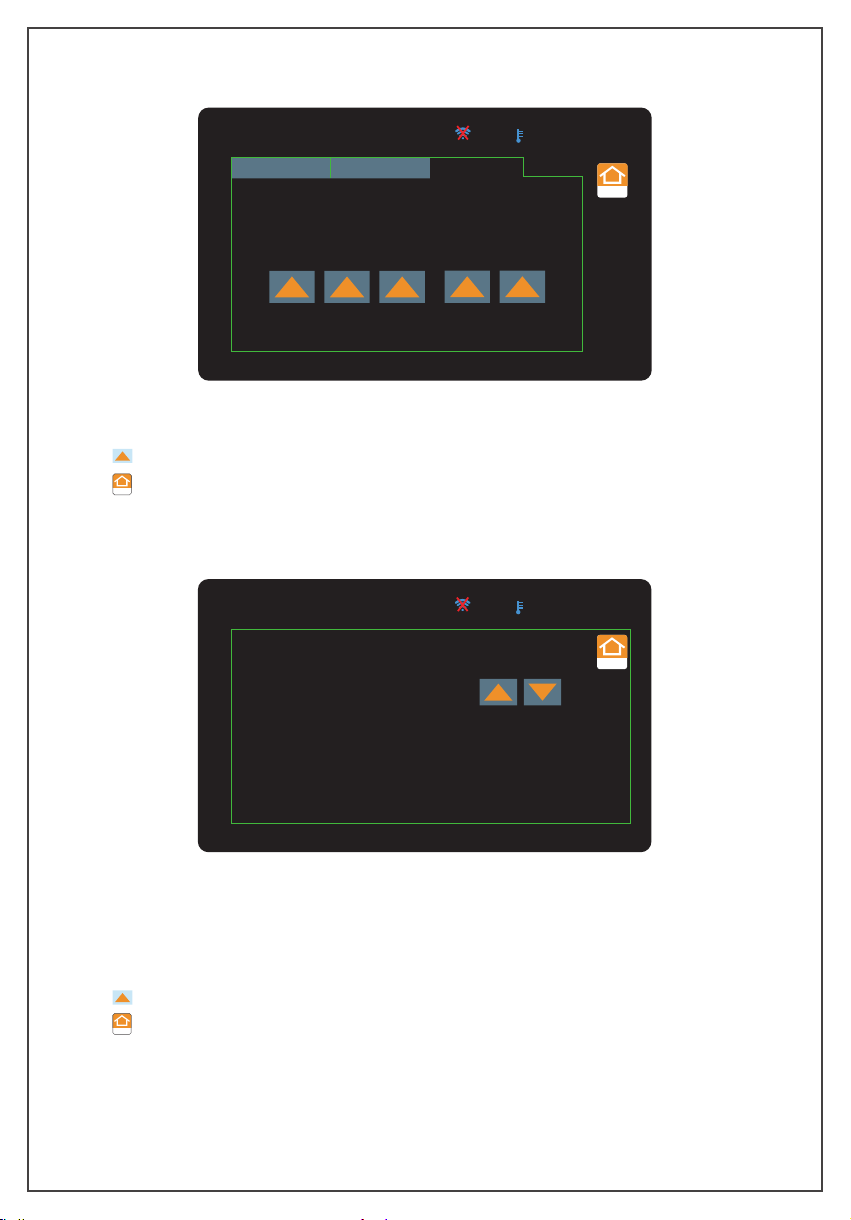

2. Graph

Clickthe“Graph”buttononthe maininterfaceto viewthevacuumchangeinrealtime.

(1) When the vacuum value drops below 60000microns, the vacuum change graph

is displayed.

(2) The X axis represent time. Y axis represent vacuum. The vacuum value is from

0-60000microns.

(3) Key:return tothemaininterface.

-6-

Return

Return

3. Settings

Click the “Settings”button on the main menu to enter the setting interface.

Unit(P/T)

SelectUnitto settheunitforvacuumand temperature.Theselectedunits areingreen.

Vacuum

Set the minimum vacuum value, logging interval, and recording status.

(1) MinimumVacuum:setthetargetvacuumvalue.Therangeof theminimumvacuum

valueis8-750microns.Clickthechangebuttontoswitchtheminimum vacuumvalue;

the display unit changes according to the selected unit.

(2) Logging Interval (S):1, 5, 10, 30, 60, 120, 300.

(3) Recording Status: The logging can be turned on and o. The upper right corner

shows the logging/recording status.

-7-

Time

(1) Set and save the time then it shows at the top of the screen.

(2) : Change key.

(3) : return to the main interface.

SVP-7 (110V) 16:22:34 Record: OFF

Return

Unit(P/t) Vacuum Time

M D Y

9 / 12 / 20 HMin

16 : 22

-8-

Return

SVP-7 (110V)

Running Time:

Holding Time:

Flow Rate:

3 Min

0 Min

7 CFM

16:22:34 Record: OFF

Return

4. System

In the main menu, click the “ System” button to enter the system interface.

(1) Running Time: refer to theaccumulatedrunning time of themotor.

(2) Holding Time: refer to the time for the vacuum pump to continue vacuuming

after the target vacuum value is stable.

(3) Flow Rate: refer to the pumping speed of the vacuum pump.

(4) : Change key.

(5) : return to the main interface.

Return

Other functions

1. Temperaturealarm:Whentheoiltemperatureormotorchassistemperature exceeds

theupperlimitalarm temperature setbytheAPP,themotorand solenoid valveare

closed,thetemperaturealarm icon" "isdisplayed atthetopofthe screen;When

thetemperaturedecreasewithinthealarmtemperature,thealarmwillbecleared,and

thevacuumworkcontinues.Iftemperatureexceedstheoinealarmtemperature,the

temperaturealarmicon" "willbedisplayedonthetopofthevacuumpumpscreen,

themotoroperationwillnotbeaected.

5. After using the vacuum pump

1. Closethe valvebetweenthepump andthepumpedcontainer.

2. Turn o the power switch on the pump, unplug the power plug, and remove the

connectingpipe.

3.Finally,closethe airinletcapto preventdirtorfloatingparticlesfrom enteringthe

pumpcavity.

CareAndMaintenance

Precautions

-9-

1. When the vacuum is started, the air pressure is relatively high and the pump

exhaustvolume islarge,thusoilmist will beoverflowingwithalarge amount of

gas.Thisisacommonphenomenonforarotaryvanevacuumpump.

Whenthevacuumdrops to avery low level, thepumpexhaustvolumeissmall,

andtherewill benooilmist.Therefore,usershould regularlymonitorthe oillevel

viatheoilwindowtoavoidrunningoutofoil.

2.During operation,storage and transportation, keep the vacuum pumpcleanto

prevent pollutants such as water, mechanical impurities,etc.fromenteringthe

pump so as not to aect the service life of the vacuum pump and the normal

operationofthesystem.

3.Theoilinthepump should be drained if it is not usedforalongtime.Storethe

pumpinadry and clean environment.

4.The diameter ofthe pipe islarger than theinner diameter ofthe air inletto avoid

aectingthepumpingspeed.

5.Checkthe tightnessof thepipe connectionto preventleakage. Recommendusing

thevacuumgreaseontheconnectionandclampitwithaclamptoensuretheseal.

6.Donotusethepumptopump outgaseswhich containhighlevelofoxygen,metal

corrosiveandexplosivegases.Inaddition,donotpumpinanygasesthat react

withpumpoilandcontaininglargeamountof watervapor.

7.Itis recommendedtocleanthecatcheronceeveryhalfyear.

TroubleshootingGuide

-10-

Failure

Phenomenon Cause of Issue Troubleshooting Method

Low Vacuum

1. InsucientOil Add oil between the maximum and minimum

level

2. Pump oil Emulsified, Polluted

Replace with new oil

3. The Oil Inlet Is Blockedor the Oil

Supply is Insucient

Clean the oil inletand filter

4. Leakage of the Pump System and

Connection

Check the system and the connection to

prevent the leakage

5. Improper Selectionof Pump Check the size of the pumped container,

recalculate and select the appropriate type of

pump

6. Parts Wear and Tear due to Long

Time Used.

Repair or replace with a new pump

OilLeakage

1. The Oil Seal Is Damaged Replace oil seal

2. Looseor D

amaged

Tank

Connections

Tighten the screws and replace the O -ring

How to replace the vacuum pump oil

1. Runthepumpforabout3-5minutesuntilitiswarmeduptorunsout the pumpoil.

2. Whenthepumpisrunning,opentheairinletportatthesametimetolet theoilflow

backtothe oil tank.Thepumpmuststop whenreplacingtheoil.

Stopthe pump and open the oil drain plug. Then open the catcher to speed up the

processofoil exhausting.

3. Tiltthepumpbody tocompletelydraintheresidual oil,andtightenthedrain plug.

4.Open the catchdeviceandadd the newpumpoil.

5.Cover the air inlet cap and start the pump to run-check the oil level after one

minute.Iftheoillevelis below the lowerlimit,slowlyaddtheoiluntil it reaches the

normal oil level. Finally, screw on the catcher.

1.Poweronthe vacuumpump.

2.TurnontheBluetooth functionofthemobilephone.

3.Openthe“ElitechGauge”APP.

APPOperatingInstructions

-11-

Fuel

Injection

1. Too Much ofOil

Drain theoil to the oil level line

2. The Air Inlet Is OverPressured for

aLong Time

Choose a pump with larger pumping speed

Diculty

Starting

1. Oil Temperature is Too Low Open the air inlet, start the motor repeatedly

or heat up the pump oil

2. Motor Failure Check and repair

3. Foreign Objects Fallen into the

Pump

Check and clean

4. Power Failure Check and repair

5. The Power Supply Voltage Is Too

Low Check the powersupply voltage

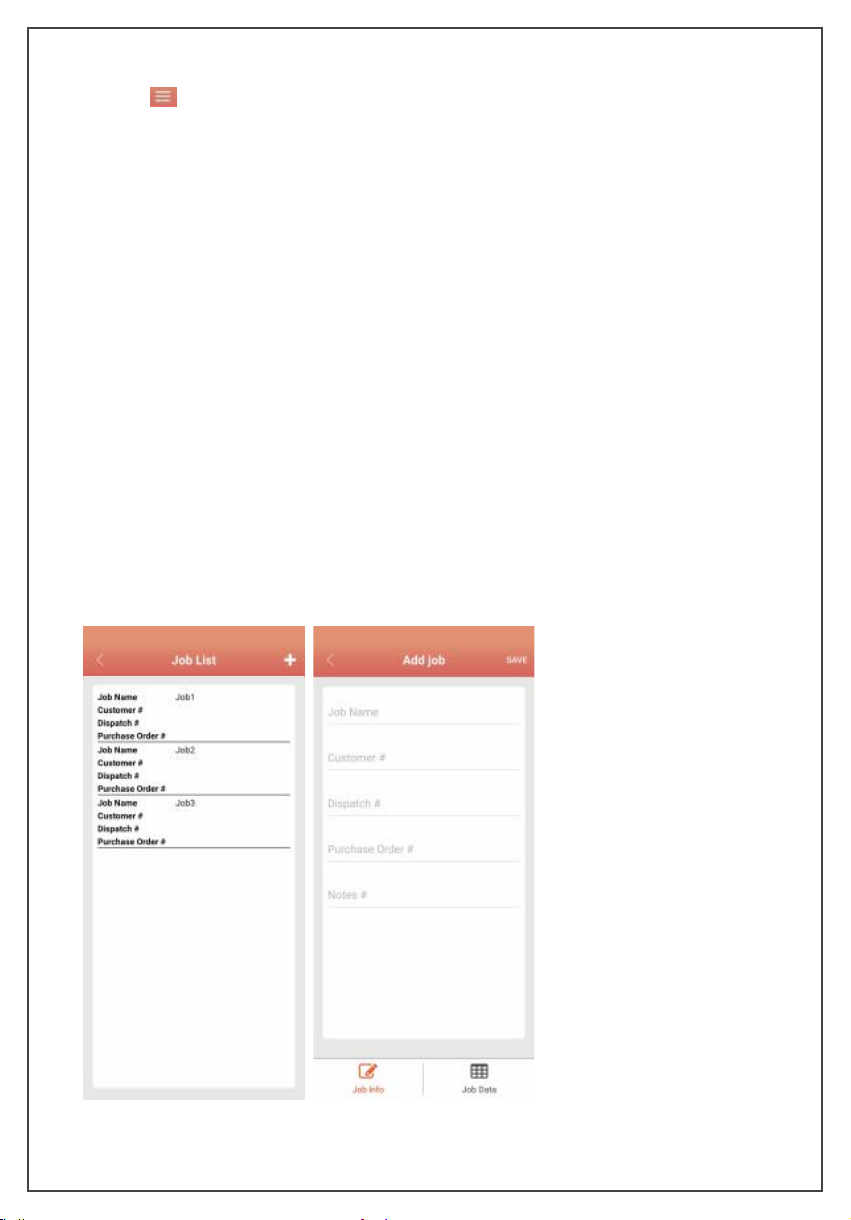

4. Click"AddDevice"to enter the devicemanagementinterface.Andthe devices that

can be connected are displayed in red. Click on the top right of the device to

establish aconnection.Aftersuccessful connection, the device barturnsgreenand

the Bluetooth icondisplays .

5. For the connected device, click “+”at the bottom right of the device to add the

device to the work interface. The bottom of the screen shows that the device has

been added successfully.

6. Clickthereturnbuttoninthe upper left cornerofthedevicemanagementinterface

to enter the workinterface.

-12-

-13-

The interface includes historical devices and the new devices.

(1) The history device displays the previously connected devices, click the device bar

toautomaticallyconnectthedevice.Whenthe connection is successful, and" "

is displayed in the upper left corner.

(2) : after clicking it will search for new devices.

(3) : Bluetooth is not connected, click and try to connect this device.

(4) : Bluetooth has been connected successfully, click to disconnect.

(5) : Motor stop status, click to start running.

(6) : Motor running status, click to stop the motor.

(7)Real-time vacuum value: display the real-time vacuum value.

Screenshot

Historical device

Device name

Mac address

Search to add

a new device

Real-time

vacuum value

7. Click“ ” in the top left corner of the working interface to enter the menu.

(Only some functions related to vacuum pump are described here).

(1) REPORTS

①JobSettings:Clicktheworkbuttontoentertheworklist.Addaworklistatthetopright.

Add work information and save the work.

-14-

②Reporting: Click the report button to enter the report interface.

Click the New report button, select data information by work or time, click the

chart analysis button to view historical graph, click the “Export" button at the

bottom to export data in Excel or PDF.

Click the saved report to view historical Excel and PDF reports,and long press the

report to delete.

③Screenshot Archive: save the screen capture file of the work interface. Thefile

type is PDF.

-15-

(2) CONFIGURATION

①Settings:Click the “Settings”button to enter the system settings.

Keep Screen On: control the backlight of the screen.

Switch language: select language English or Chinese.

General Alarm Preferences: single sound, single vibration or sound vibration alarm

at the same time.

②Help: Click the "Help" button to enter thehelpinterface; click the "About"button

toobtainversion information; click"Usermanual"toenterthedownload interface,

and click the "Start" button to download the vacuum pump user manual.

③Exit:Click the“Exit”button to exit the APP.

-16-

8.Device Detail

Clicktheconnecteddeviceicontoenterthedetailedinterfaceofthedevice,displaythe

vacuumpumpstatus, andcontrolthe vacuumpump.

-17-

Graph

Motorcontrolbutton

Expectedcompletion

time

Real-timevacuum

Vacuumstatus

Vacuumunitswitch

Readhistoricaldata

Leakagelevel

Temperaturestatusof

oilandshell

Editdevicename

Setlogginginterval

Recordingstatus

(1) Graph: when the vacuum valuedropsbelow60000micron,thereal-timevacuum

graph will be displayed.

(2)Expectedcompletiontime:whenthevacuumstatusisclosetostable,theremaining

vacuuming time will be displayed including the holding time.

(3)Motorcontrol: motorstop statusdisplays" ",clicktorun themotor;themotor

running status displays" ", click to stop the motor.

(4)Vacuum Value: display the real-time vacuum value.

(5)Temperature status of oil and shell: According to the setting alarm temperature,

display the temperature status "high", "normal", and "low" .

(6)Extraction Status: vacuum status display, (Rise), (Decrease), (Stable), ––

(exceed the range of vacuum sensor).

(7) Leakage Rate: under the stable state of thevacuumvalue,makeajudgmenton

the possibility of leakage of the current system, which is represented by 0-100;

0 means the uncertain of the leakage status. The larger the number, the

possibility of leakage is larger.

(8) DeviceName:modifythedevicename, supportupto 10 characters andnumbers,

click OK to confirm.

(9) Vacuum Unit: select vacuum unit,inHg, Torr, mbar, mTorr, Pa, micron, kPa.

(10) Record Switch: vacuum pump data recording switch, closed by default.

(11) Interval Time: select logging interval, 1S, 5S, 10S, 30S, 1Min, 2 Min, 5 Min.

(12) Read historical data: read the value saved by the vacuum pump while recording.

Before reading the data, it will remind whether to delete the data after reading.

9. Setting

(1) Click Settings to set parameters and alarm values of vacuum pump.

-18-

This manual suits for next models

2

Table of contents

Other Elitech Water Pump manuals

Popular Water Pump manuals by other brands

Barmesa Pumps

Barmesa Pumps 6BSE-LDS Series Installation, operation & maintenance manual

Grundfos

Grundfos MAGNA1 C Series Installation and operating instructions

Cirs

Cirs 769 user guide

JEC Pumps

JEC Pumps JRZL Series operating & maintenance manual

Simer

Simer 4850C owner's manual

KSB

KSB Sewabloc Series Installation & operating manual