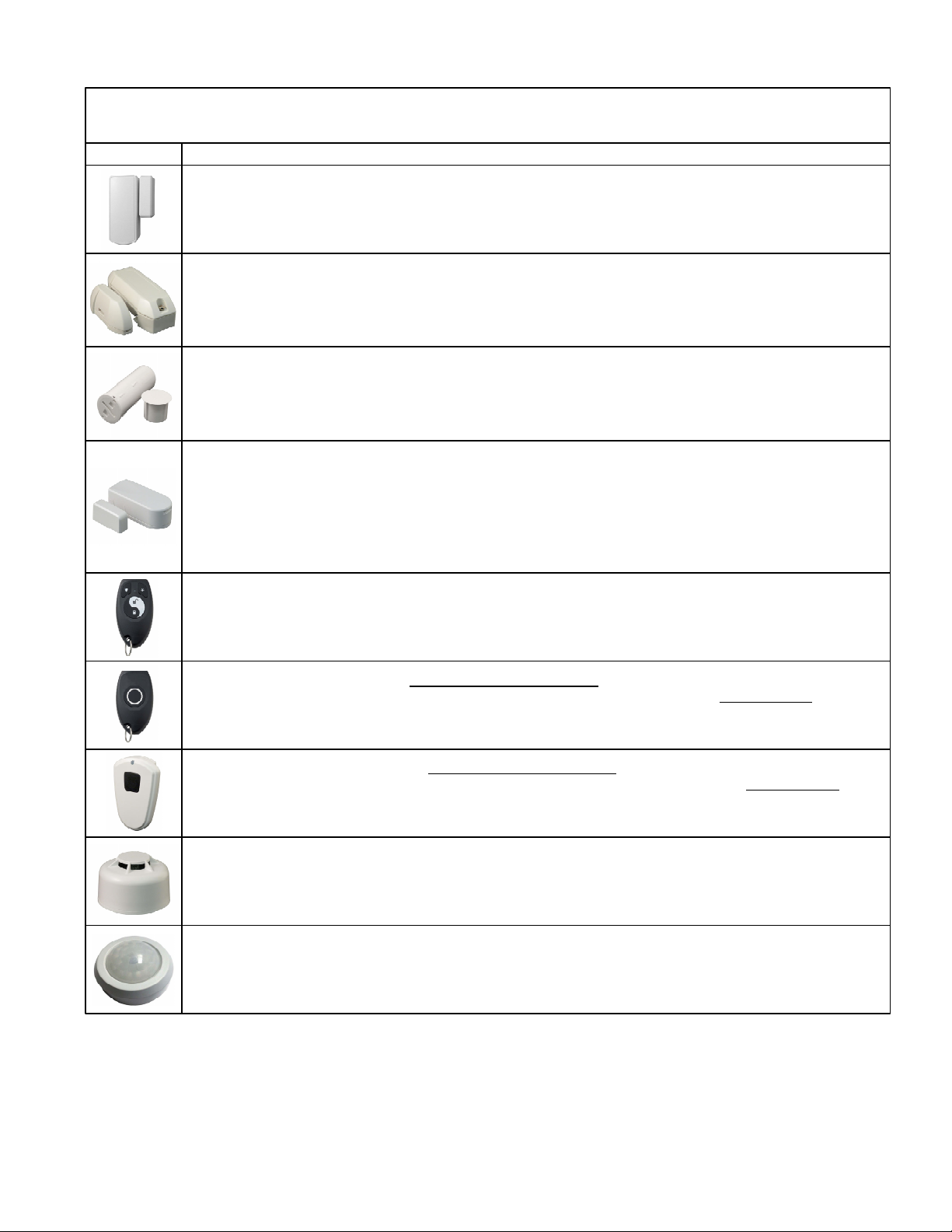

Elk makes no guarantee of compatibility for any transmitter model not listed. Elk shall not be responsible if a manufacturer changes or discontinues any listed model.

SmokeDetector‐Part#60‐848‐02‐95,orequivalent>Notes:None>EnrollProcess:Forunitswithtampersupervisionactivatethetamper,

otherwisepressthefrontTestbuttonwhichwilltransmitaviolation(alarm)>Options:SetOpt1to1(yes)forunitswithtampersupervision.

LeaveOpt2as0(no).>Loop:Setas2

SingleButtonWrist/PendantPanic‐Part#60‐906‐95,orequivalent>Notes:None>EnrollProcess:Pressandholdmainbutton>Options:

SetOpt1&Opt2to0(no)>Loop:Setas2

SingleButtonPendantPanic‐Part#60‐578‐10‐95,orequivalent>Notes:None>EnrollProcess:Pressandholdmainbutton>Options:Set

Opt1&Opt2to0(no)>Loop:Setas2

PIRMotionDetector‐Part#60‐880‐95,orequivalent>Notes:Transmitterdoesnotsendrestores.Controlautomaticallyassumesrestoral8

secondsafterviolation>EnrollProcess:Removebackcovertoactivatetamperswitch>Options:SetOpt1&Opt2to0(no)>Loop:Setas2

Door&WindowTransmitter‐Part#'s60‐362‐10‐319.5,60‐641‐95,orequiv.>Notes:ScrewterminalsallowexternalN/Oswitchtobeusedin

placeofthebuilt‐inreed.>EnrollProcess:Removebackcovertoactivatetamperswitch>Options:SetOpt1&Opt2to0(no)ifusingbuilt‐in

reedORSetOpt1&Opt2bothto1(yes)todisableinternalreedanduseexternalN/Oswitchconnectedtoscrewterminals>Loop:Setas2if

usingbuilt‐inreedORSetas1ifexternalN/Oswitchisconnectedtothescrewterminals.

DONOTUSEBOTHREEDANDEXT.SWITCHATSAMETIME.

PIRMotionDetector‐Part#60‐703‐95,orequivalent>Notes:Transmitterdoesnotsendrestores.Controlautomaticallyassumesrestoral8

secondsafterviolation>EnrollProcess:Removebackcovertoactivatetamperswitch>Options:SetOpt1&Opt2to0(no)>Loop:Setas2

PIRMotionDetector‐Part#60‐511‐01‐95,orequivalent>Notes:Transmitterdoesnotsendrestores.Controlautomaticallyassumesrestoral8

secondsafterviolation>EnrollProcess:Removebackcovertoactivatetamperswitch>Options:SetOpt1&Opt2to0(no)>Loop:Setas2

Door&WindowTransmitter‐Part#60‐499‐10‐319.5,orequivalent>Notes:ScrewterminalsallowexternalN/Oswitchtobeusedinplaceof

thebuilt‐inreed.>EnrollProcess:PressTestbuttonorTamperSwitch>Options:SetOpt1&Opt2to0(no)ifusingbuilt‐inreedORSetOpt1&

Opt2bothto1(yes)todisableinternalreedanduseexternalN/Oswitchconnectedtoscrewterminals>Loop:Setas2ifusingbuilt‐inreedOR

Setas1ifexternalN/Oswitchisconnectedtothescrewterminals.

DONOTUSEBOTHREEDANDEXT.SWITCHATSAMETIME

Door&WindowTransmitter‐Part#60‐688‐95,orequivalent>Notes:ScrewterminalsallowexternalN/Oswitchtobeusedinplaceofthe

built‐inreed.>EnrollProcess:PressTestbuttonorTamperSwitch>Options:SetOpt1&Opt2to0(no)ifusingbuilt‐inreedORSetOpt1&Opt2

bothto1(yes)todisableinternalreedanduseexternalN/Oswitchconnectedtoscrewterminals>Loop:Setas2ifusingbuilt‐inreedORSetas

1ifexternalN/Oswitchisconnectedtothescrewterminals.

DONOTUSEBOTHREEDANDEXT.SWITCHATSAMETIME

Door&WindowTransmitter‐Part#60‐741‐95,orequivalent>Notes:none>EnrollProcess:InsertBatterytopowerup>Options:SetOpt1&

Opt2to0(no)>Loop:Setas2

Heat'RateOfRise'Transmitter‐Part#60‐460‐319.5,orequivalent>Notes:none>EnrollProcess:PressTestButtonlocatedoncircuitboard

insideunitnexttobattery>Options:SetOpt1&Opt2to0(no)>Loop:Setas2

GlassBreakTransmitter‐Part#60‐873‐95,60‐834‐95,orequivalent>Notes:Opt2mustbesetto1(yes)>EnrollProcess:Activatetamper

switch>Options:SetOpt1to0(no)andOpt2to1(yes)>Loop:Setas2

ShockSensor‐Part#60‐886‐95,orequivalent>Notes:Opt2mustbesetto1(yes)>EnrollProcess:PressTestbutton>Options:SetOpt1

to0(no)andOpt2to1(yes)>Loop:Setas2

SingleButtonPanicTransmitter‐Part#60‐458‐10‐319.5,orequivalent>Notes:none>EnrollProcess:Pressmainbutton>Options:Set

Opt1to0(no)andOpt2to1(yes)>Loop:Setas2

GlassGuardTransmitter‐Part#6046210319.5>Notes:none>EnrollProcess:Presstamperswitch>Options:SetOpt1&Opt2to0(no)

>Loop:Setas2

FreezeSensorTransmitter‐Part#60‐504‐10‐95R,orequivalent>Notes:none>EnrollProcess:Presstamperswitch>Options:SetOpt1&

Opt2to0(no)>Loop:Setas2

FourButtonKeyfobTransmitter‐Part#60‐606‐319.5,orequivalent>Notes:none>EnrollProcess:PressandholdtheLockandUnlock

Buttons(buttons1&2)togetheratthesametime.>Options:SettingOpt1to1(yes)willswapthe4buttonassignmentsfrom1thru4to5thru8.

Opt2shouldbeleftas0(no).>Loop:N/AAdditionalinfo:CombopressingtheLockandUnlockbuttonsatsametimewilltriggertheevent

assignedtoKey7.PressingtheLightandAsterisktogetherwilltriggertheeventassignedtoKey8.

CarbonMonoxideSensor‐Part#600‐6520‐95>Notes:none>EnrollProcess:TXIDIDnumberprintedonsensorlabelmustbeentered

manuallyintotheM1WirelessZone(Wzone)TXIDprogrammingfield.Thissensorcannotbelearnedinbythetransmissiontriportamper

methods.>Options:SetOpt1&Opt2to0(no)>Loop:Setas0ElkRPprogrammingofM1–SetZoneDefas17=CarbonMonoxideandset

ZoneTypeas0=EOL/Wireless.IntheWirelessSetupsettheEnabledboxandsetSupervisionto3=FireSupervision.

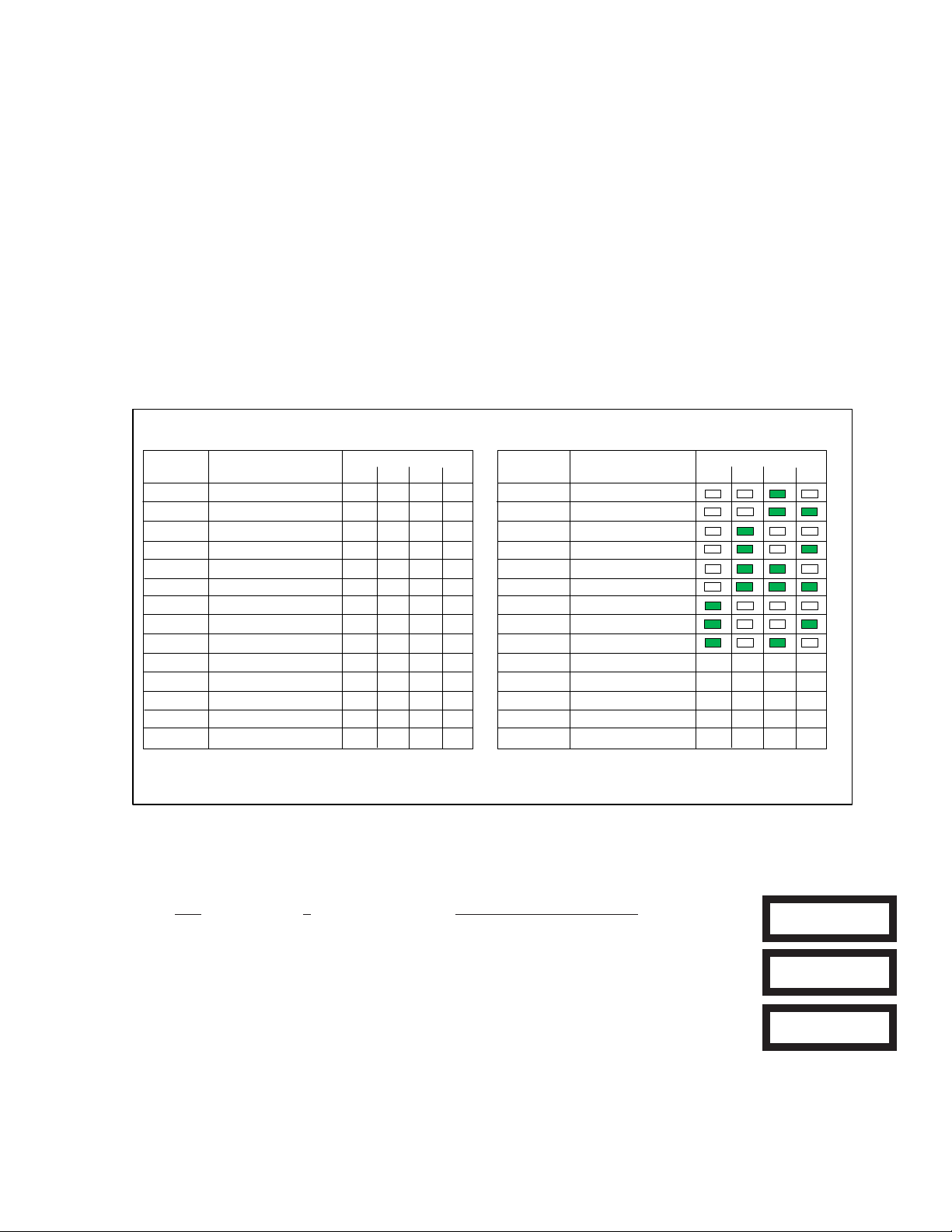

Part Number, Description, Notes, Enroll Process, Options and Loop ID

Image

Thesealternatebrandtransmitters,whenusedwithanElkM1Control,canbeenrolledfromeitherKeypadInstallerProgramming(Menu14.Sub‐Menu3)viathe

“Lrn”method,ORbyenteringtheTXIDthroughElk’sRPProgrammingSoftware.Carefullyfollowthespecifictransmitternotesoutlinedbelow.