Ellies FBIC3000VA/24V User manual

3000VA Inverter Charger

FBIC3000VA/24V & FBIC3000VA/48V User Manual

Please read this guide carefully before using this product

Important Safety Instructions

1. General Information

CONTENTS

Important Safety Instructions 1

1. General Information 1

2. Installation Instructions 4

3. Interface Instruction 7

4. Protection 14

5. Troubleshooting 14

6. Maintenance 15

7. Technical Specifications 16

Notes 17

• Please reserve this manual for future review. This manual contains all instructions about safety, installation and

operation for the inverter/charger.

• Read carefully all the instructions and warnings in the manual before installation.

• Non-safety voltage exists inside the inverter/charger, users must not dismantle it by itself in order to avoid personal

injury, contact professional maintenance personnel of our company in need of maintenance.

• Keep the inverter/charger out the reach of children.

• Do not place the inverter/charger in a damp, oily, inflammable and explosive or a severe environment with a large amount

of dust accumulation.

• The utility input and AC output with high voltage, don’t touch wire connections. Install the inverter/charger in well

ventilated places, it’s shell may produce heat during operation.

• It is suggested to install appropriate external fuses/breakers.

• Make sure switching o all connections with PV array and the fuse/breakers close to battery before inverter/charger

installation and adjustment.

• Make sure all connections remain tight to avoid excessive heat from a loose connection.

• It’s an o-grid inverter/charger, not for on-grid system.

• This inverter/charger can only be used singly, parallel or in series connections will damage the devices.

The UPower series is a new type of the inverter/charger combining with solar & utility charging and AC output, which adopts

a multi-core processor design and advanced MPPT control algorithm, and has the features of high response speed, high

reliability and high industrialization standard. It oers four charging modes including Solar priority, Utility priority, Solar and

Utility & Solar; two output modes for Battery and Utility, meeting the various application demands.

The up-to-date optimized MPPT tracking technology is adopted for the PV charging modules. It can quickly track the

maximum power point of the PV array in any environment and acquire the maximum energy of solar panel in real time;

The advanced control algorithm is adopted for AC-DC charging modules that realize fully digitalized double closed-loop

control for voltage and current, with high control precision, small volume. The input range of AC voltage is wide, the output

DC charging voltage/current is continuously adjustable in a certain range, and the complete input/output protection

functions can oer stable and reliable charging and protection for the battery.

The DC-AC inverter modules are based on full digital and intelligent design. It adopts the advanced SPWM technology,

outputs the pure sine wave and converts 24/48VDC to 220/230VAC suitable for AC loads of household appliances, electric

tools, commercial units, electronic audio and video devices etc.

The product adopts 4.2 inch LCD display design, which real-time displays the operational data and running state of the

system. The comprehensive electronic protection function guarantees more safe and more stable operation of the system.

Please reserve this manual for future review.

1.1 Overview

2

1.2 Characteristics

•Adoption of the advanced SPWM technology, with pure sine wave output.

•Fully digitalized voltage and current double closed-loop control.

•Advanced MPPT technology, with eciency no less than 99.5%.

•Four charging mode: Solar priority, utility priority, utility & solar and solar only.

•Two OUTPUT mode: Battery and utility.

•LCD design that enables dynamic display of system running data and operating state.

•Provided with common interface and advanced interface.

•Multiple LED indicators that instantly indicate the operating state of the system.

•2P circuit breaker provided at the utility input end.

•Independent control of AC output by AC OUT button.

•Battery temperature compensation function.

•Extensive electronic protection.

Features

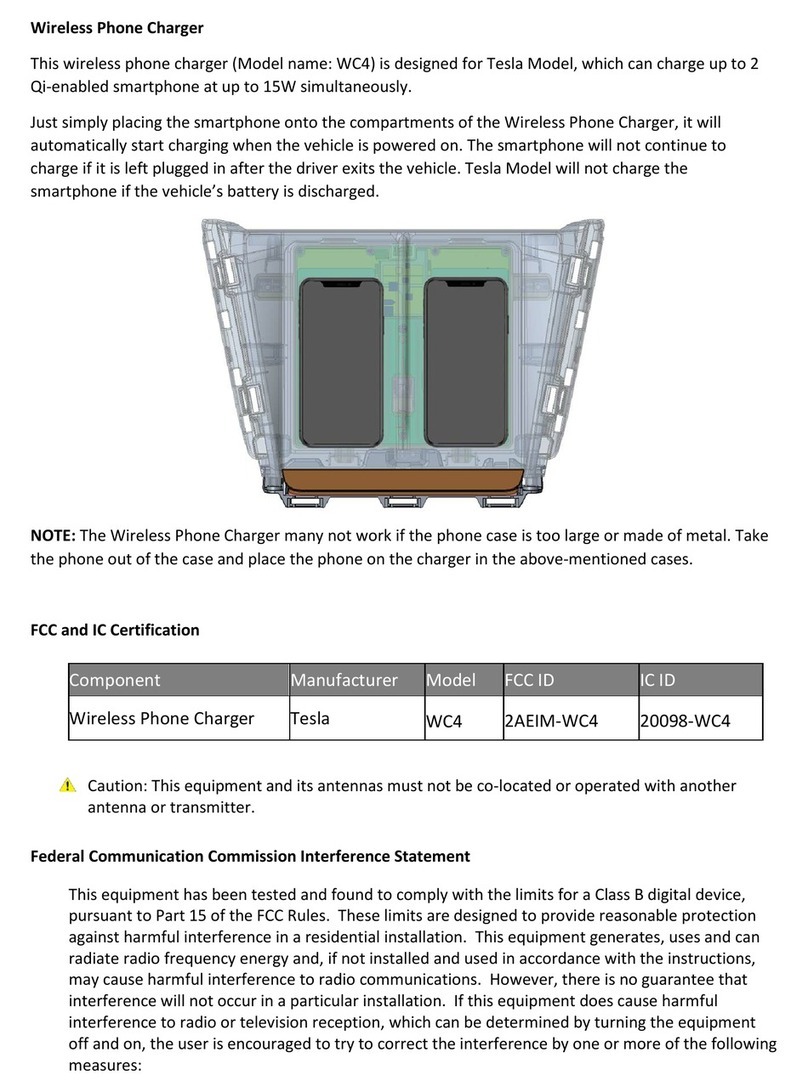

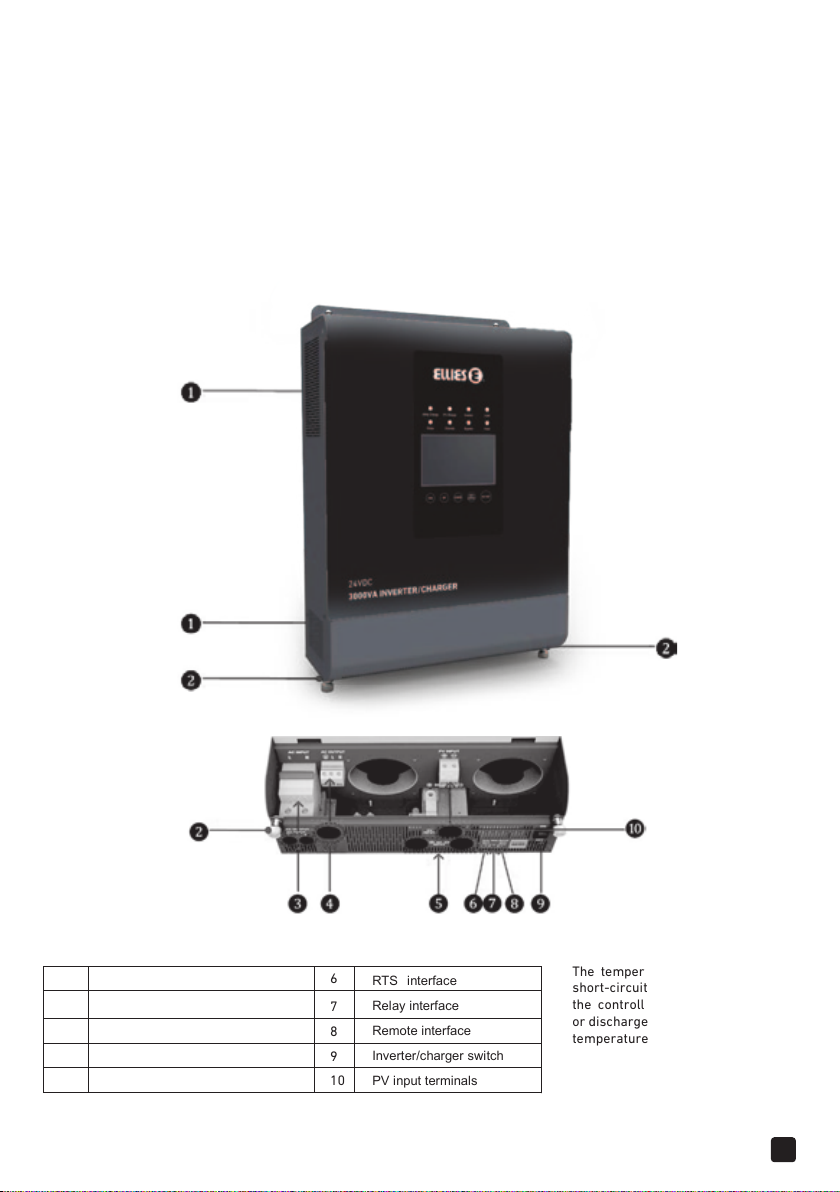

Figure 1 Product appearance

1

2

3

5

4

6

7

8

10

9

Ventilation RTSinterface

Captive screw (2 pcs) Relay interface

AC output terminals Remote interface

Utility input terminals Inverter/charger switch

Battery input terminals PV input terminals

The temperature sensor

short-circuited or damaged,

the controller will be charged

or discharged at the default

temperature 25 ºC.

3

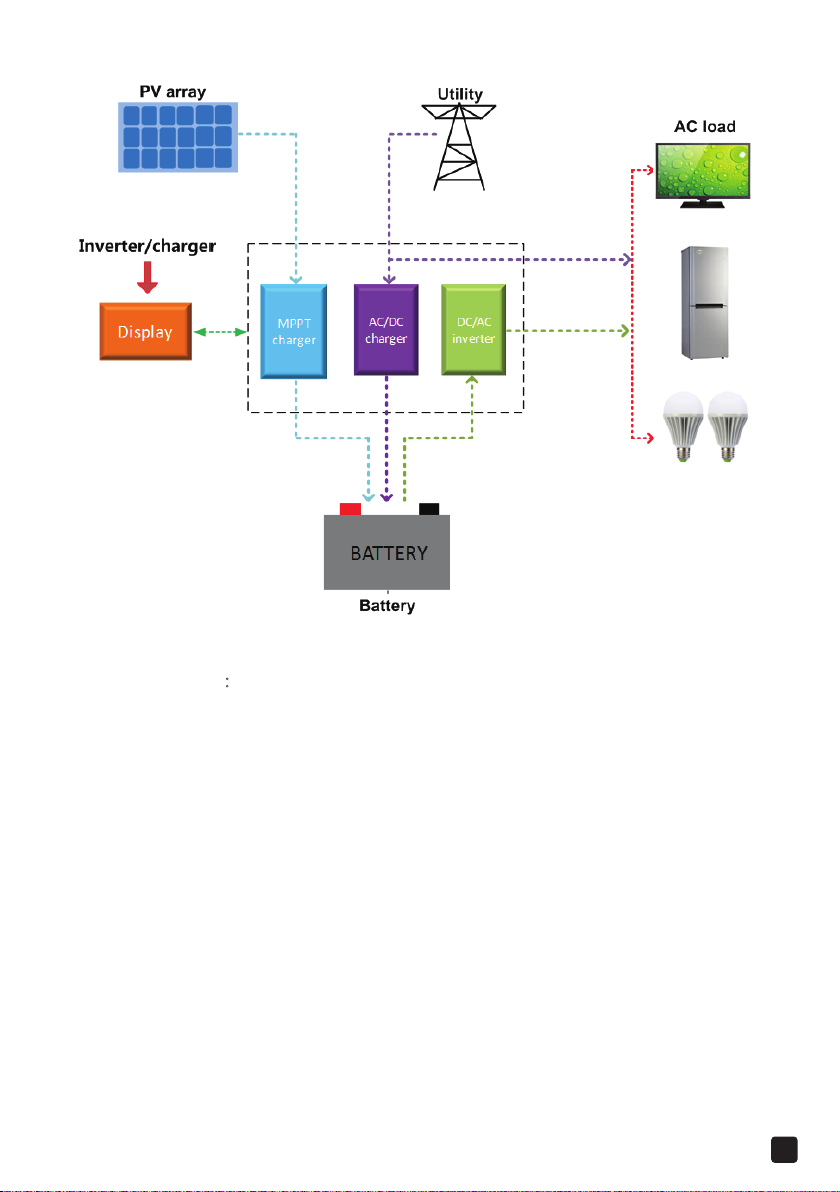

1.4 Schematic Diagram for Connections

Warning:Confirm the AC load power compatible with the power of the

inverter/charger, AC load selected exceeding the maximum output power

of inverter/charger is prohibited.

4

2.1 General Installation Notes

2.2 Wire Size & Breaker

•Please read the entire installation instructions to get familiar with the installation steps before installation.

•Be very careful when installing the batteries, especially flooded lead-acid battery. Please wear eye protection, and have

fresh water available to wash and clean if any contact with battery acid

•Keep the battery away from any metal objects, which may cause short circuit of the battery.

•Explosive acid battery gases may come out from the battery during charging, so make sure ventilation condition is good.

•Ventilation is highly recommended if mounted in an enclosure. Never install the controller in a sealed enclosure with

flooded batteries! Battery fumes from vented batteries will corrode and destroy the controller circuits.

•Lead-acid battery is only recommended, other kinds please refer to the battery manufacturer.

•Loose connections and corroded wires may result in high heat that can melt wire insulation, burn surrounding materials,

or even cause fire. Ensure tight connections and use cable clamps to secure cables and prevent them from swaying in

motion.

•Battery connection may be wired to one battery or a bank of batteries. The following instructions refer to a singular

battery, but it is implied that the battery connection can be made to either one battery or a group of batteries in a battery

bank.

•Select the system cables according to 5A/mm2 or less current density in accordance with Article 690 of the National

Electrical Code, NFPA 70.

•For outdoor installation, keep out of the direct sunshine and rain infiltration.

•High voltage still exists inside the inverter/charger after switching o the power switch, do not turn on or touch the

internal units, conduct the associated operation only after discharging the electric capacity.

•Do not place the inverter/charger in a damp, oily, inflammable and explosive or a severe environment with a large amount

of dust accumulation.

•Prohibit reverse connection at DC input end otherwise it may damage the equipment or unpredictable danger will occur.

The utility input and AC output are of high voltage, do not touch the wire connetion.

The wiring and installation methods must follow all national and local electrical code requirements.

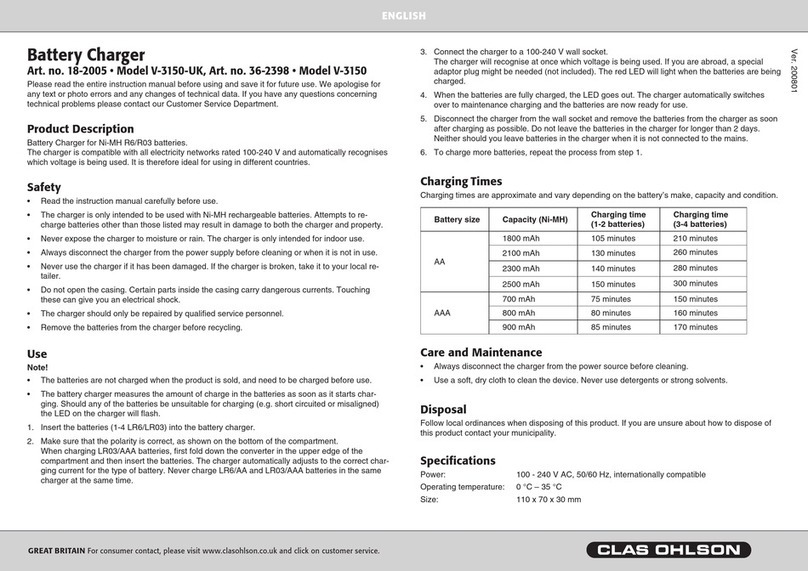

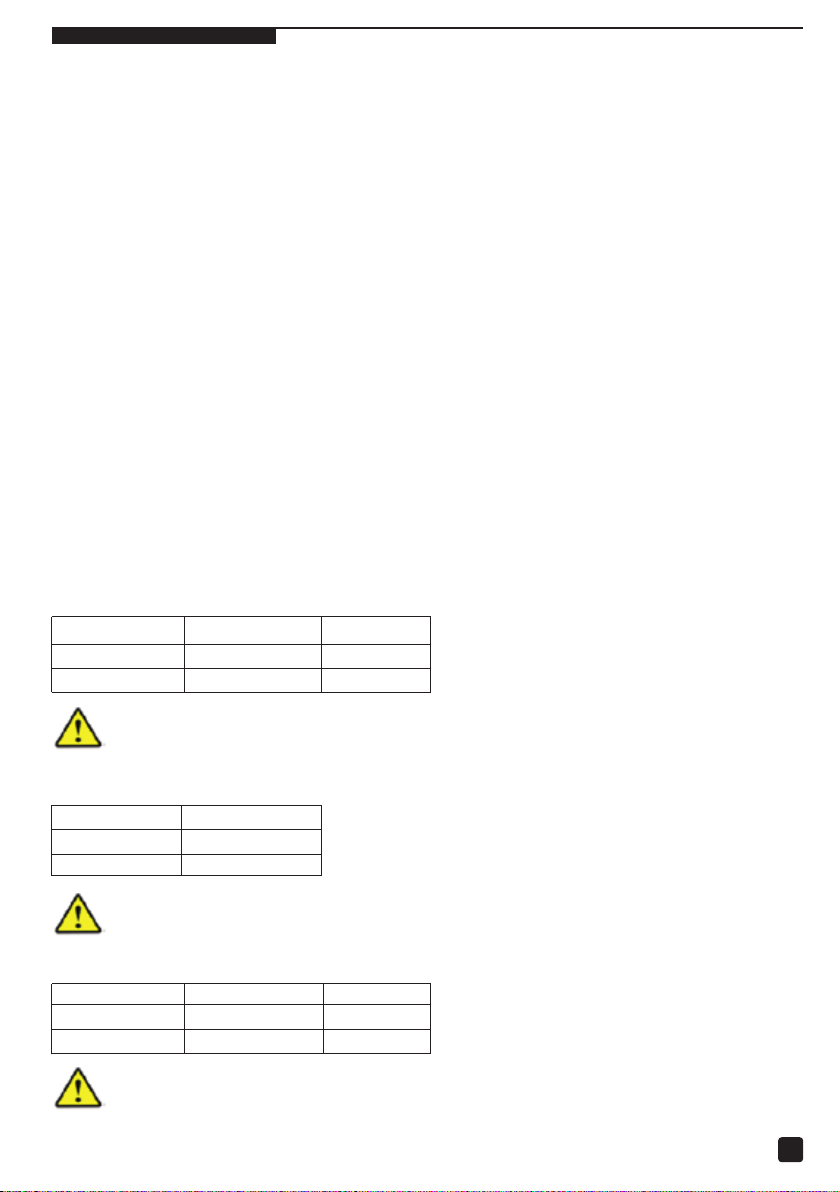

Recommended wire and circuit breaker of PV

2. Installation Instructions

Model PV wire size Breaker

FBIC3000VA/24V

FBIC3000VA/48V

FBIC3000VA/24V

FBIC3000VA/48V

FBIC3000VA/24V

FBIC3000VA/48V

10mm2/8AWG 2P—63A

6mm2/10AWG 2P —32A

NOTE: When the PV modules connect in series, the open circuit voltage of the PV array must not exceed max.

PV input voltage at 25Cenvironment temperature.

NOTE: The utility input has the circuit breaker already and there is no need to add any more.

NOTE: Type of circuit breaker is selected based on non-independent connection of inverter at the battery end

where there is no antherinverter connected.

Recommended wire of Utility

Recommended wire and circuit breaker of battery

Model Utility wire size

6mm2/10AWG

6mm2/10AWG

Model Battery wire size Breaker

35mm2/2AWG 2P— 200A

16mm2/6AWG 2P— 100A

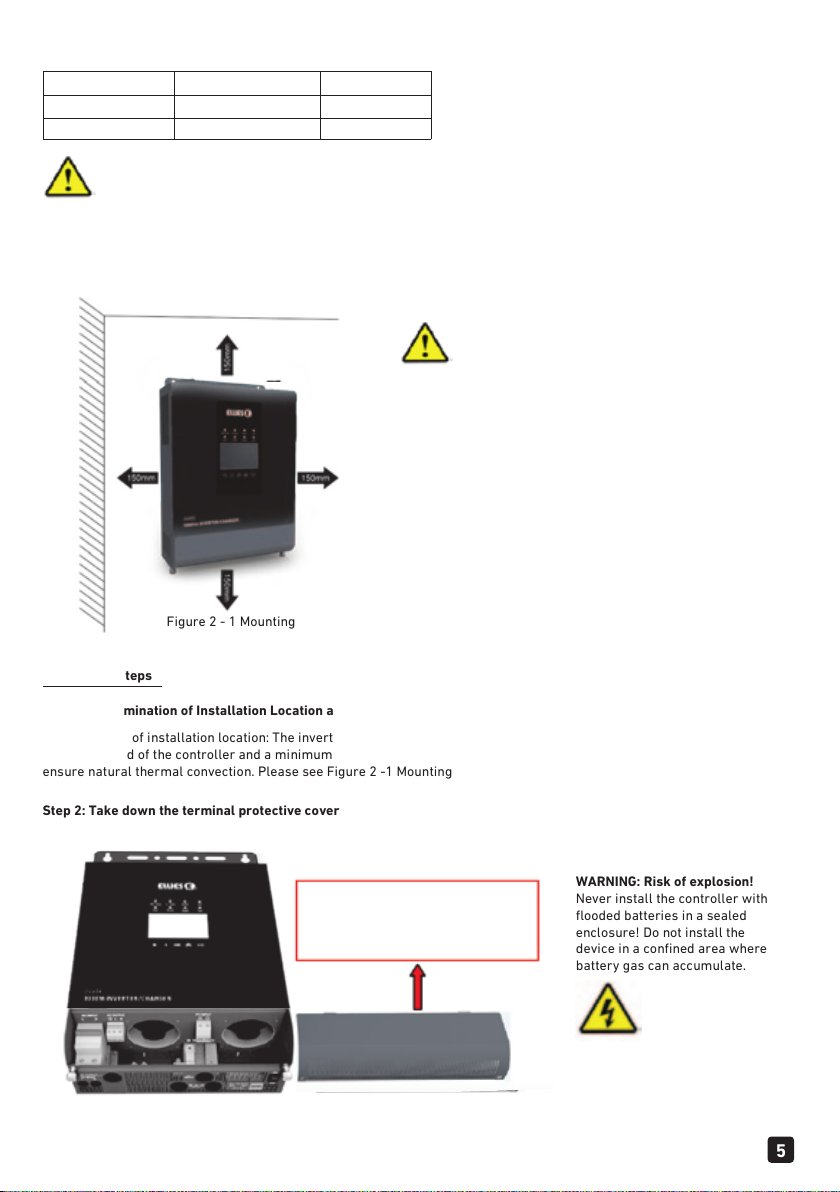

2.3 Mounting

Determination of installation location: The inverter/charger shall be installed in a place with sucient air flow through the

dissipation pad of the controller and a minimum clearance of 150 mm from the upper and lower edges of the controller to

ensure natural thermal convection. Please see Figure 2 -1 Mounting

5

NOTE: The wire size used for connection is for reference only, use thicker wires to lower the voltage drop

and improve the system performance when the distance between the whole solar system components is far.

NOTE: The above wire and the circuit breaker size

are for recommended use only, please choose the

suitable wire and circuit breaker according to the

practical situation.

WARNING: Risk of explosion!

Never install the controller with

flooded batteries in a sealed

enclosure! Do not install the

device in a confined area where

battery gas can accumulate.

Recommended wire and circuit breaker for AC output

Model AC wire size Breaker

4mm2/12AWG 2P— 16A

4mm2/12AWG 2P— 16A

6

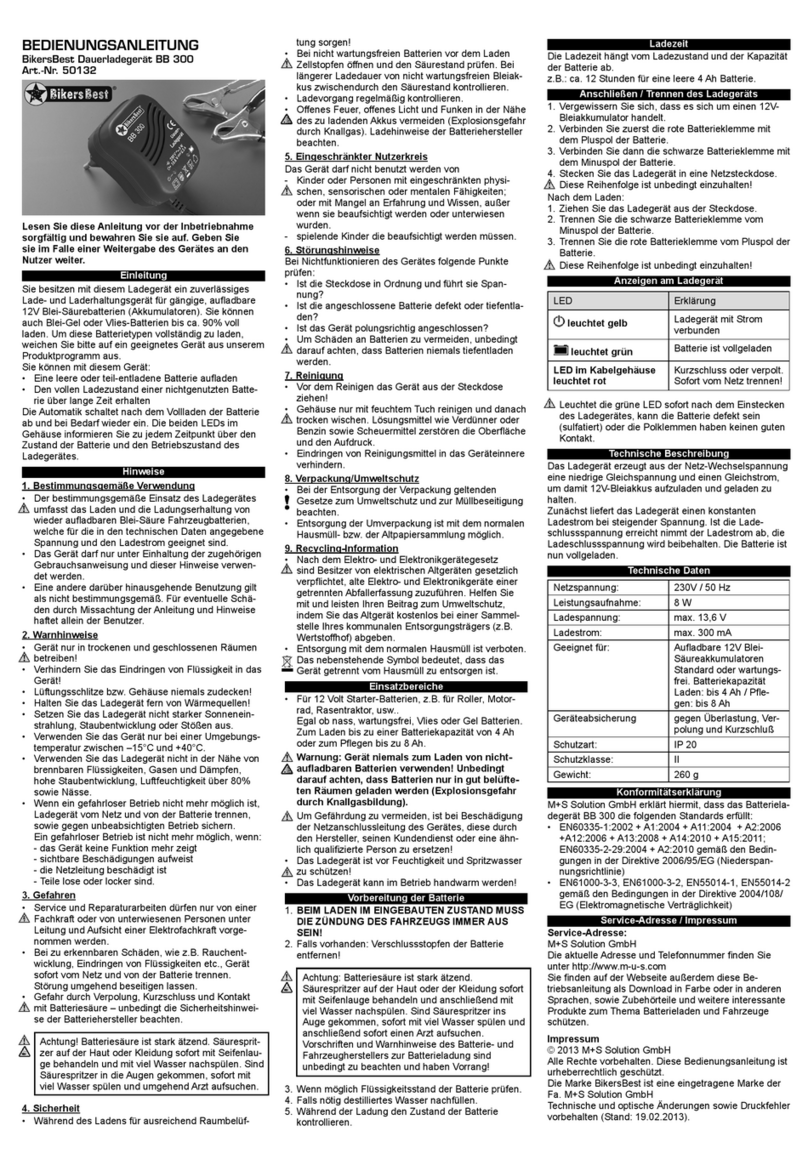

Installation Steps

Step 1: Determination of Installation Location and Heat-dissipation Space

Step 2: Take down the terminal protective cover

Figure 2 - 1 Mounting

FBIC3000VA/24V

FBIC3000VA/48V

Screw o the screws and take

down the terminal protective cover

of the inverter/charger before

wiring.

WARNING: Danger, High-voltage! Utility input, AC output and PV array will produce dangerous voltage,

make sure to disconnect the circuit breaker/ fuse before wiring.

6

Determination of installation location: The inverter/charger shall be installed in a place with sucient air flow through the

dissipation pad of the controller and a minimum clearance of 150 mm from the upper and lower edges of the controller to

ensure natural thermal convection. Please see Figure 2 -1 Mounting

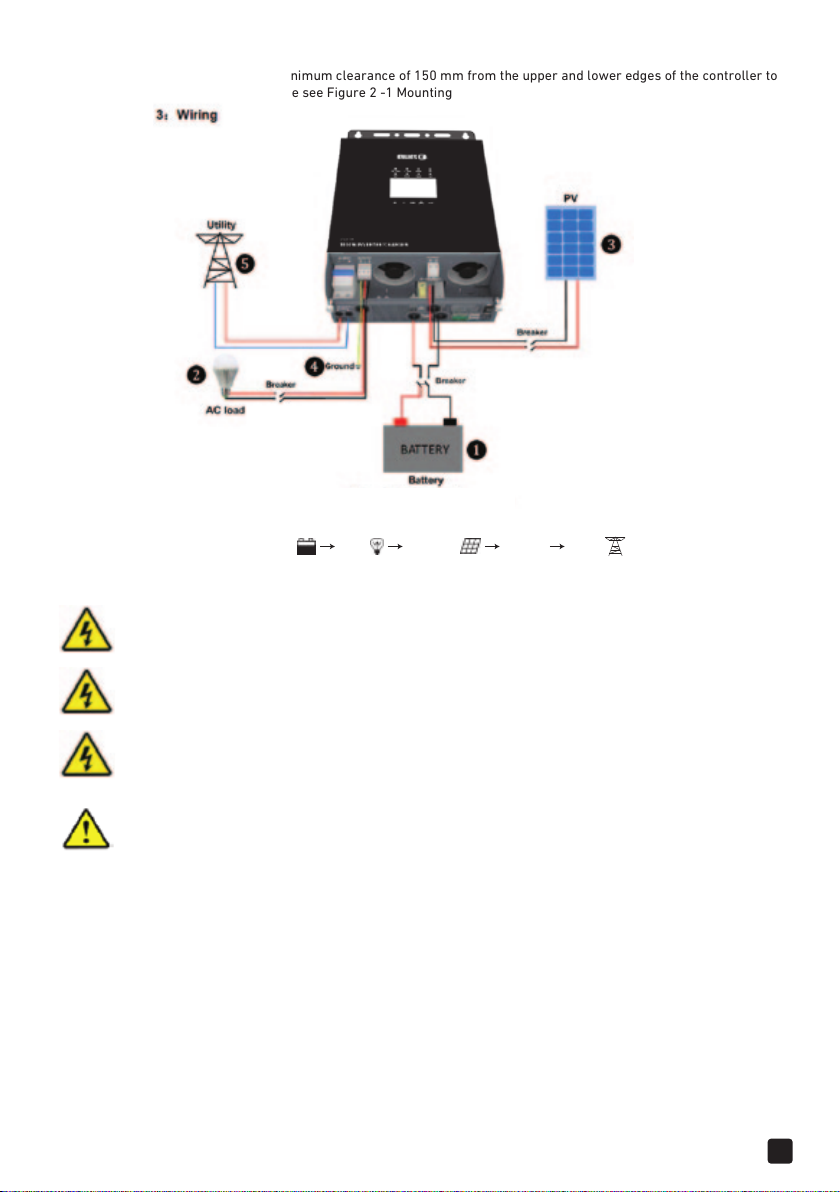

Connect the system in an order of battery load PV array Ground Utility in accordance with Figure

2-2: Wiring Diagram. Disconnect the system in the reverse order.

Grounding

Grounding connection must be made when utility is connected to the inverter/charger. The inverter/charger has

dedicated grounding terminal as shown in Fig. 2-2, the grounding must be reliable, the grounding wire shall be the

thicker wire (wire is not less than 4mm2, the grounding point shall be as close as possible to the inverter/charger, the

grounding wire shall be as short as possible.

AC output, Ground and PV wiring terminal use way:

1. When wiring, do not close the circuit breaker, and it is necessary to use a slotted screwdriver to unscrew the screws

for connecting their corresponding wires.

2. When removing the wirings, first the integrated machine must stop working, and then the screws shall be unscrewed by

using a slotted screwdriver, so as to dismantle their corresponding wires.

Step 3: Wiring

Step 5: Install the terminal protective cover

Figure: 2-2 Wiring Diagram

WARNING: Do not turn on the circuit breaker/ fuse when wiring, and at the same time, ensure that

the wiring of “+”, “-” are correctly connected.

WARNING: A circuit breaker must be installed at the battery end, for selection, refer to Section 2.3

"Wire and Circuit Breaker".

Note: If the inverter/charger is to be used in an area with frequent lightning strikes, it is

recommended to install an external surge arrester at the PV input.

3. Interface Instruction

7

Connect the remote temperature sensor cable (model: RTS300R47K3.81A) Connect one end of the

remote temperature sensor cable to the interface⑦and place the other end close to the battery.

Step 6: Connect Accessory

3.1 Indicator

Step 7: Recheck if the wire connection is correct

Step 8: Rower on the inverter/ charger

①Turn on the circuit breaker at the battery end.

②Switch on the switch then the inverter indicator is on.

③Turn on the breaker of PV array and Utility.

④Turn on the AC load when the AC output is normal.

NOTE: The temperature sensor short-circuited or damaged, the inverter/charger will

be charging or discharging at the default temperature 25C.

NOTE: In case the power is supplied to the dierent AC loads, it is suggested to turn on the loads with larger

surge current, till the load working well, then turn on the loads with smaller surge current.

NOTE: In case the inverter/charger is not in normal operation, or LCD or indicator displays abnormal,

refer to Section 5 to clear the fault or contact the after-sale service personnel of our company.

NOTE: The installation steps and accessory list also refer to the cardboard

3.2 Buttons

8

Indicator

Color

Status

Instruction

Green

OFF No utility input

On Solid Utility connection normal but no

charging

Slowly Flashing Utility charging

Fast Flashing Utility charge module fault

Green

OFF No PV input

On Solid PV connection normal but no charging

Slowly Flashing PV charging

Fast Flashing PV charge module fault

Green

OFF Inverter turn o

On Solid Inverter turn on

Slowly Flashing Inverter output

Fast Flashing Inverter fault

Green

OFF No load output

On Solid Load output

Green

OFF Relay turn o

On Solid Relay turn on

Green

OFF Input voltage (3.3 〜12VDC)

On Solid No Input voltage

Green

OFF Inverter output

On Solid Utility output

Red OFF Device normal

Operation Instruction

Press the button Exit the current interface

Press the button and hold on 5s Clear the faults

Press the / button

Browse interface

:

Up / Down

Setting interface

:

Up / Down

Press the button

Switch to Browse Parameter Column “Confirm

the setting parameters”

Press the button and hold on 5s

Switch the "Real Time Interface"over to" Set

Browse Interface"

Switch the"Set Browse Interface" over to

"Parameter Setting Interface"

Press the button and hold on 5s Inverter ON/OFF

3.3 Real-time Interface

9

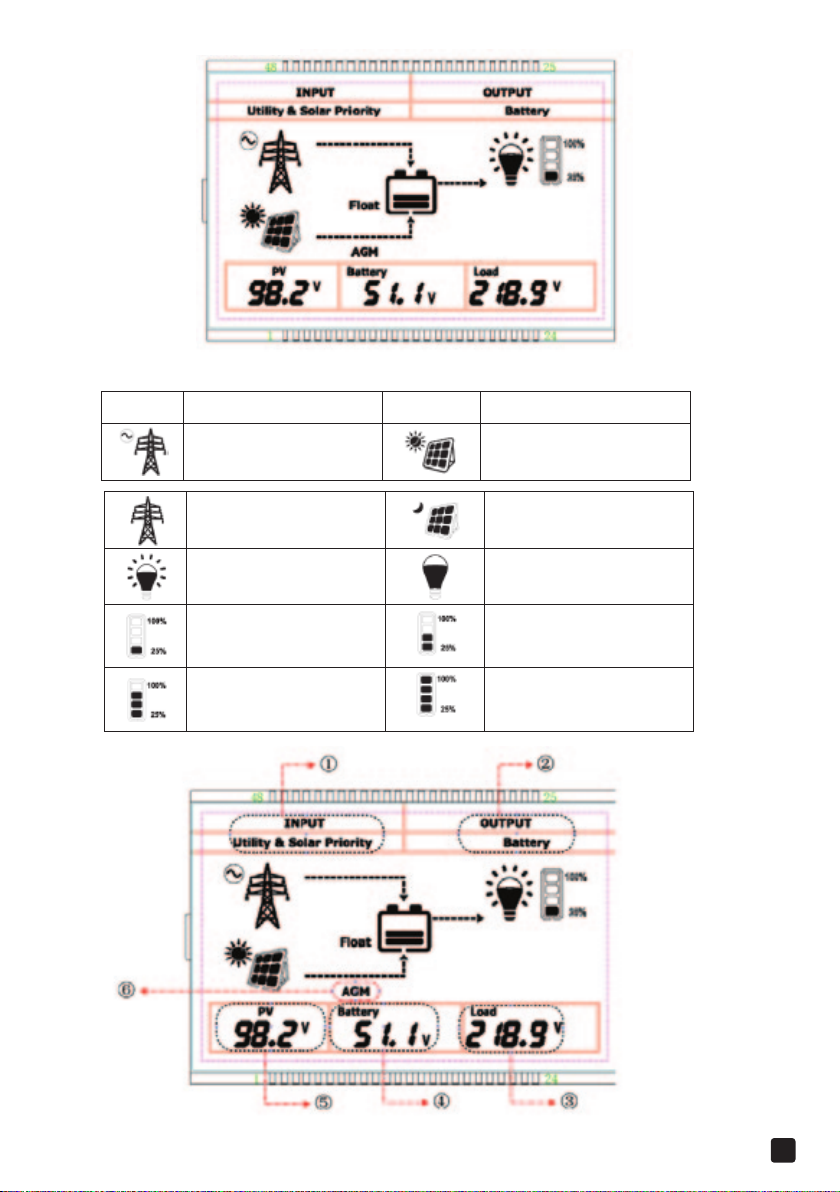

Icon instruction Icon instruction

Utility connected

PV connected

No Utility

No PV

Load ON

Load OFF

Battery capacity level 8

〜

25%

Battery capacity level25

〜

50%

Battery capacity level 50

〜

75% Battery capacity level 75

〜

100%

10

Item

Setting

Content

①INPUT

Solar priority

Utility priority

Utility & solar

Solar

②OUTPUT Battery

Utility

③Load

AC output voltage

AC output current

AC output power

AC output frequency

④Battery

Battery voltage

Max. charging current

(PV charging current+Utility charging current)

Battery temperature

Battery SOC

⑤PV

PV input voltage

PV charging current

PV charging power

PV charge energy

Utility

Utility input voltage

Utility charging current

Utility charging power

Utility charge energy

⑥Battery Type

AGW

GEL

FLD

USER

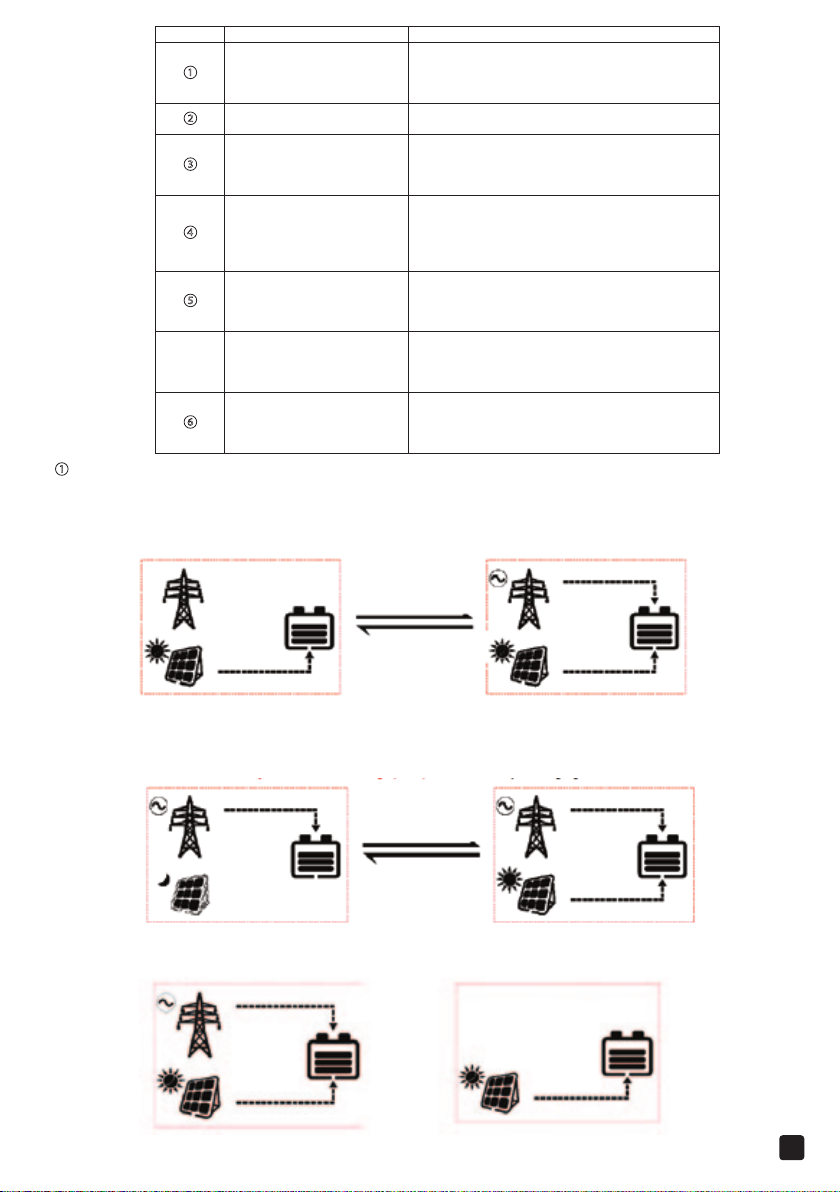

①INPUT

Solar priority

The battery is charged in solar priority mode and when the battery voltage is lower than “Auxiliary Module ON Voltage

(VAON)”, the utility starts charging. When the battery voltage reaches to “Auxiliary Module OFF Voltage (VAOF)”, the

utility stops charging.

The battery is charged in utility priority mode and when the battery voltage is lower than “Auxiliary Module ON Voltage

(VAON)”, the solar starts charging. When the battery voltage reaches to “Auxiliary Module OFF Voltage (VAOF)”, the

solar stops charging.

Utility priority

Utility & solar Solar

Utility & solar charging the battery Solar charging the battery

VBAT < VAON

VBAT < VAOF

VBAT < VAON

VBAT < VAOF

3.2 Setting Interface

12

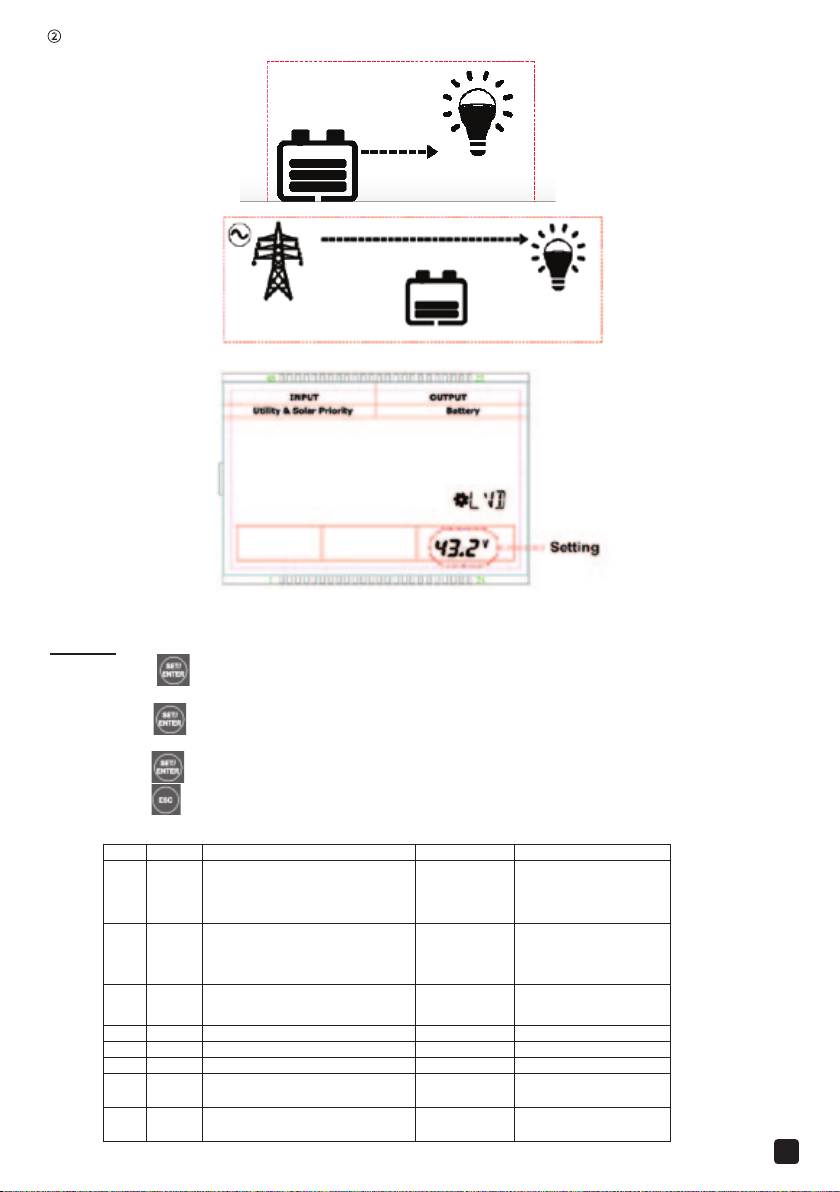

②OUT PUT

Battery

11

Utility

1) Common interface for common user

Operation:

Step 1: Press the button and hold on 5s at the real-time interface to go to the common interface

Step 2: Press the button and hold on 5s at the setting parameter interface and choose the parameters.

Step 3:Press the button to set the parameter, and press this button again for confirmaton.

Step 4:Press the button to exit the setting interface.

Setting

Item

LCD

Instruction

Default

Range

1 BTP Battery type AGM

AGM

GEL

FLD

USER

2 CSP Charge source priority Solar priority

Solar priority

Utility priority

Utility & solar

Solar

3 OSP Output source priority Battery Battery

Utility

4 TMU Temperature unit /

5 BLT Backlight time 30S 30S/60S/100S

6 BAS Buzzer alarm switch ON ON/ OFF

7 LVD Low voltage disconnect voltage 21.6VUser 21.0

〜

22.6V

step size 0.2V

8 LVR Low voltage reconnect voltage 25.0VUser 24.0

〜

26.0V

step size 0.2V

12

The voltage parameter are at 25C, 24VDC system, and twice in 48VDC system.

NOTE: When Output source priority is Battery and the battery voltage lower than the Low Voltage Disconnect

Voltage(LVD adjustable), the system will switch utility to supply power for load.

2) Advanced interface for engineers

Operation:

Step1: Press the + button and hold on 5s under the real-time interface.

Step2: Press the button and hold on 5s under the setting parameter interface.

Step3: Press the button to enter the parameter.

Step4: Press the button to exit the setting interface.

Setting:

Item LCD Instruction Default Range

9 BCT Boost ChargingTime 30M 30M/60M/120M/180M

10 BCV Boost ChargingVoltage

AGM

:

28.8 VDC

GEL:28.4 VDC

FLD:29.2 VDC

USER:28.8 VDC

VDC

VDC

VDC

VDC

User 25.0〜29.6

Step size 0.2

11 BVR Boost Voltage Reconnect 26.4VDC

User: 25.0〜28.0

Step size 0.2

12 FCV Float ChargingVoltage 27.6 VDC

User: 26.0

〜

28.0VDC

Step size 0.2VDC

13 OVR Over Voltage ReconnectVoltage 30.0 VDC

User: 29.0

〜

31.0VDC

Step size 0.2VDC

14 OVD Over Voltage DisconnectVoltage 32.0 VDC

User: 31.0〜32.2VDC

Step size 0.2VDC

15 AOF Auxiliary module OFF voltage

Auxiliary module ON voltage

28.0VDC

User: 24.0

〜

29.6VDC

Step size 0.2VDC

16 AON 24.0 VDC

17 DON 22.2 VDC

User: 21.6〜24.0VDC

Step size 0.2VDC

18 DOF Dry connect OFF voltage

Dry connect ON voltage

24.0 VDC

User: 24.0

〜

26.5VDC

Step size 0.2VDC

19 MCC Max. charging current 60.0A

15.0〜60.0A

20 PSM Power saving mode OFF ON/OFF

21 CFA Clear fault OFF ON/OFF

22 QCL Clear the accumulated energy OFF ON/OFF

23 VER Software version U-1.0 —

The voltage parameter are at 25C24VDC system (twice in 48VDC system ).

For the inverter/charger of dierent power, the current setting range is not the same, see Technical Parameters

for details.

NOTE

15/16:Stop/restore auxiliary module charging voltage

Only when the charging mode is Solar priority or Utility priority will the auxiliary module charging voltage be

eective.

20: Power saving mode

When the switch is on “Saving” side, the inverter will enter into the Saving Mode. It will shut o the output ifthe loads

value isless the 70W. Then restart and detect the power of the load again after 10s. If the load is more than 70W, the

inverter will turn on the output. Otherwise it will shut o output. It cycles like this. So please don’t use the saving mode

if the load is smaller then 70W.

21: Clear the faults

In occurrence of short circuit or overload caused to AC output, the fault can be cleared out.

3.5 Other Function

13

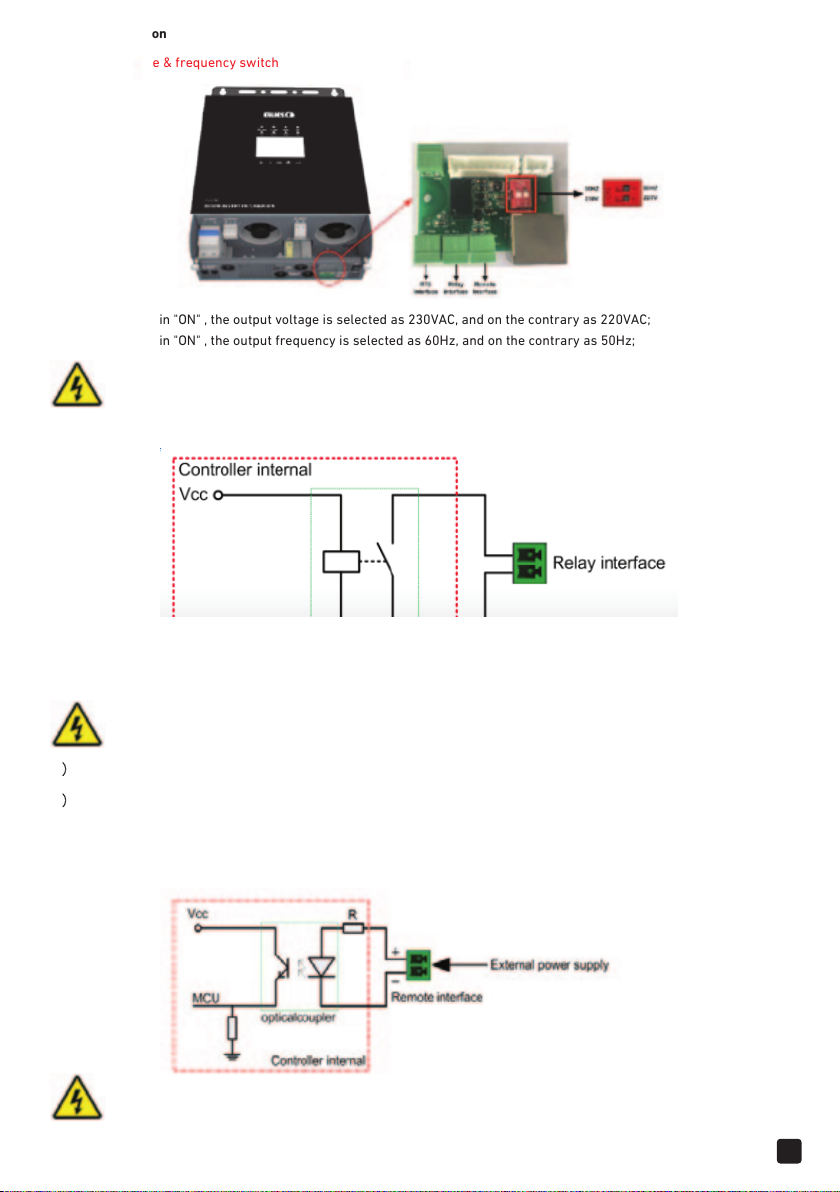

1))Output voltage & frequency switch

When Switch 1 is in "ON" , the output voltage is selected as 230VAC, and on the contrary as 220VAC;

When Switch 2 is in "ON" , the output frequency is selected as 60Hz, and on the contrary as 50Hz;

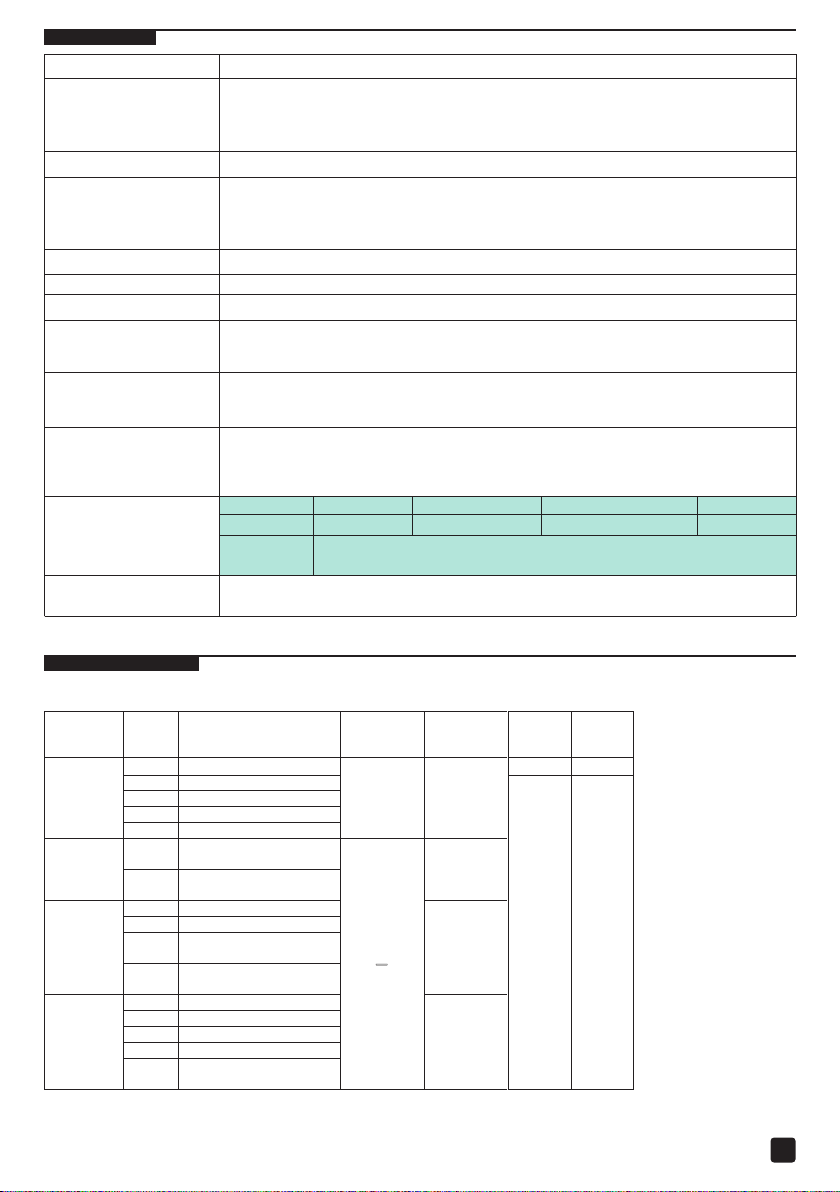

2) Relay interface

NOTE: If the output frequency or voltage of the inverter/charger is to be reset, it is required to turn o the

inverter/charger and power on the unit after setting.

Working principle:

When the battery voltage reaches the Low Voltage Disconnect Voltage (LVD)the coil of relay is energized, and the switch is

turned on. The dry contact can drive resistive loads 125VAC /1A, 30VDC/1A.

NOTE: When the utility input is abnormal, this dry contact can control the generator switch to charge the battery.

NOTE: If it is to change the range of input voltage, it can be realized by changing the resistance value of R.

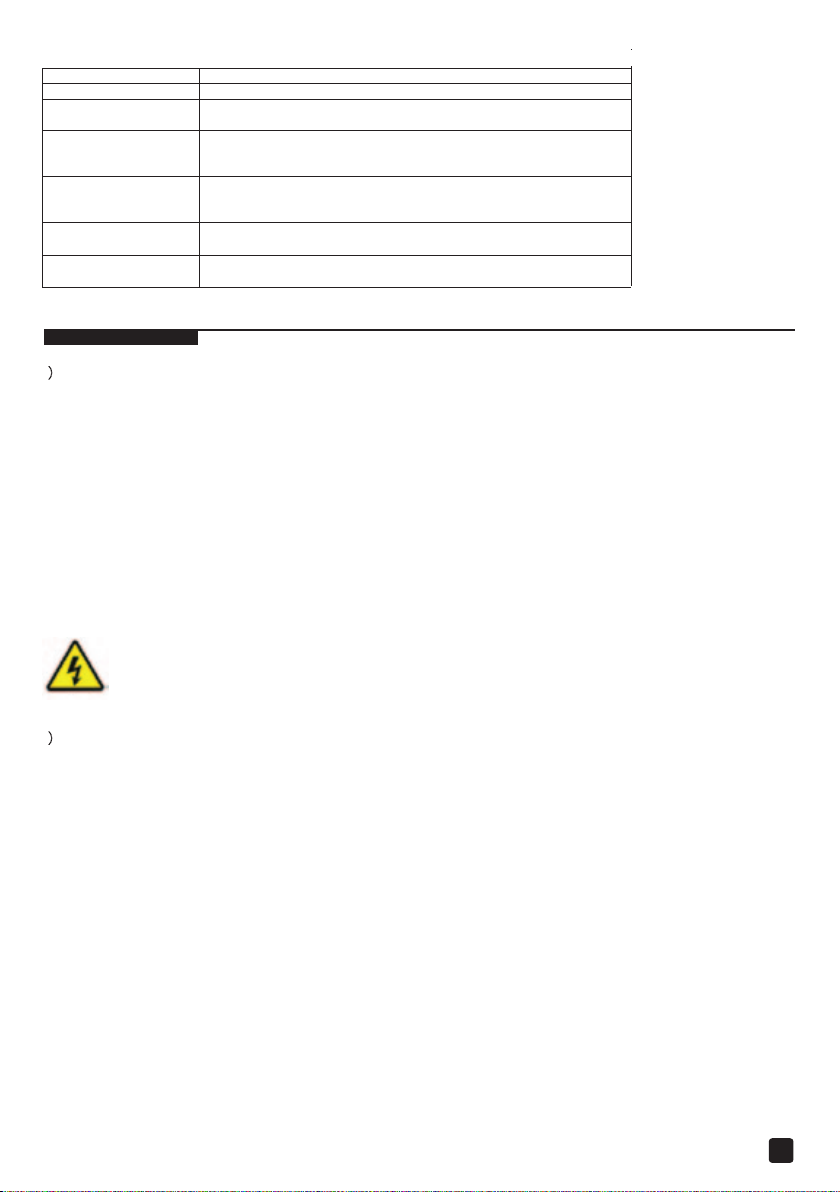

1)Remote interface

2)Remote interface input voltage (3.3 ~ 12V )DC

(1) The input voltage Vi is with in 2.5~ 10s, the AC output state is reversed (when the AC is formerly in output state, now itis

in 2.5~ 10s, thein no-output state; when the AC is formerly in no-output state, now itisin output state;)

(2) The input voltage Vi is greater than 10s, the AC is in output state all the time till the input voltage Vi disappears.

5.1 Fault

14

4. Protection

5. Troubleshooting

Protection Instruction

PV Limit Current

PV Short Current

PV Reverse Polarity

Night Reverse Charging

When the charging current of the PV array exceeds its rated current, it will be charged at

the rated current. NOTE: When the PV modules are in series, ensure that the open circuit

voltage of the PV array does not exceed the "maximum PV open circuit voltage".

Otherwise the inverter/charger may be damaged.

When PV is not charging and short circuit, the inverter/charger is not damaged.

Fully protection against PV reverse polarity, correct the wire connection to resume normal

operation. NOTE: The inverter/charger will be damaged when the PV array straight polarity

and the actual operation power of the PV array is 1.5 times greater than the rated charge

power!

Prevent the battery discharging through the PV module in the night.

Utility Input Overvoltage When the utility voltage exceeds 280VDC, it will stop utility charging/discharging.

Utility Input Under Voltage When the utility voltage less than 160VDC, it will stop utility charging/discharging.

Battery Overvoltage When the battery voltage reaches to the set point of Over Voltage Disconnect Voltage,

the inverter/charger will stop charging the battery to protect the battery from being over

charged to break down.

Battery Over Discharge When the battery voltage reaches to the set point of Low Voltage Disconnect Voltage, the

controller will stop discharging the battery to protect the battery from being over

discharged to break down.

Load Output Short Circuit

Load Output Overload

Device Overheating

It will immediately close the output in occurrence of short-circuit and hereafter the output

is automatically recovered in time delay (the first time delay for 5s, the second time delay

for 10s, the third time delay for 15s); if the short-circuit remains after 3 times of delay,

restart the inverter/charger only after clearing the fault.

Overload 105% 130% 160% 180%

15min. 30s 10s 5s

The first time delay for 5s, the second time delay for 10s, the third time

delay for 15s

Recover 3

times

The inverter/charger will stop charging/discharging when the internal temperature is too

high, and will restore charging/discharging when the temperature is recovered to normal.

Continuance

Module Code Fault

Battery

frame

blink

Indicator Buzzer Fault

indicator

Battery

BLV Battery Low Voltage

Flashing —

— —

BOV Battery Over Voltage

Alarm On

Solid

BOD

Battery Over discharge

NVE Nominal Voltage Error

LTP Low Temperature

PV

charging

module

OTP Over Temperature

(PV Charge Module)

—

PV charge

Fast

Flashing

CFA Communication Fault

Alarm

Utility

charging

module

IOV

Input Over Voltage

Utility

Fast

Flashing

ILV

Input Low Voltage

OTP

Over Temperature

(Utility Charge Module)

CFA Communication Fault

Alarm

Inverter

output

module

OVA

Output Over Voltage

Inverter

Fast

Flashing

IOS

Input Low Voltage

OOL

Output Over Load

OTP

Inverter Temperture

CFA

Communication Fault

Alarm

WARNING: Risk of electric shock! Make sure that all the power is turned o before above operations, and then

follow the corresponding inspections and operations.

5.3 Troubleshooting

15

6. Maintenance

Fault Troubleshooting

Battery Over Voltage Check if battery voltage too high, and disconnect solar modules.

Battery Over Discharge When the battery voltage resume to or above LVR point (low voltage

reconnect voltage), or change the battery by other ways

Battery Overheating

The inverter/charger will automatically turn the system o.

But while the device temperature declines

to be belowoverheating

recover temperature value, the inverter/charger will work normally.

The inverter/charger will automatically turn the system o.

But while the battery temperature declines

to be below overheating

recover temperature value, the inverter/charger will work normally.

Device Overheating

Output Overload

Please reduce the number of A

C loads

.

②Restart the device or CFA of setting interface change to ON.

Output Short Circuit Check carefully loads connection, clear the fault.

②Restart the device CFA of setting interface change to ON..

1)The following inspections and maintenance tasks are recommended at least two times per year for best performance.

•Make sure inverter/charger firmly installed in a clean and dry environment.

•Make sure no block on air-flow around the inverter/charger. Clear up any dirt and fragments on radiator.

•Check all the naked wires to make sure insulation is not damaged for serious solarization, frictional wear, dryness,

insects or rats etc. Repair or replace some wires if necessary.

•Tighten all the terminals. Inspect for loose, broken, or burnt wire connections.

•Check and confirm that LED is consistent with required. Pay attention to any troubleshooting or error indication.

Take corrective action if necessary.

•Confirm that all the system components are ground connected tightly and correctly.

•Confirm that all the terminals have no corrosion, insulation damaged, high temperature or burnt/discolored sign, tighten

terminal screws to the suggested torque.

•Check for dirt, nesting insects and corrosion. If so, clear up in time.

•Check and confirm that lighting arrester is in good condition. Replace a new one in time to avoid damaging of the

inverter/charger and even other equipments.

•Damage from improper use or use in an unsuitable environment.

•PV or load current, voltage or power exceeding the rated value of controller.

•The inverter/charger is working temperature exceed the limit working environment temperature.

•User disassembly or attempted repair the inverter/charger without permission.

•The inverter/charger is damaged due to natural elements such as lighting.

•The inverter/charger is damaged during transportation and shipment.

2)This warranty does not apply under the following conditions:

16

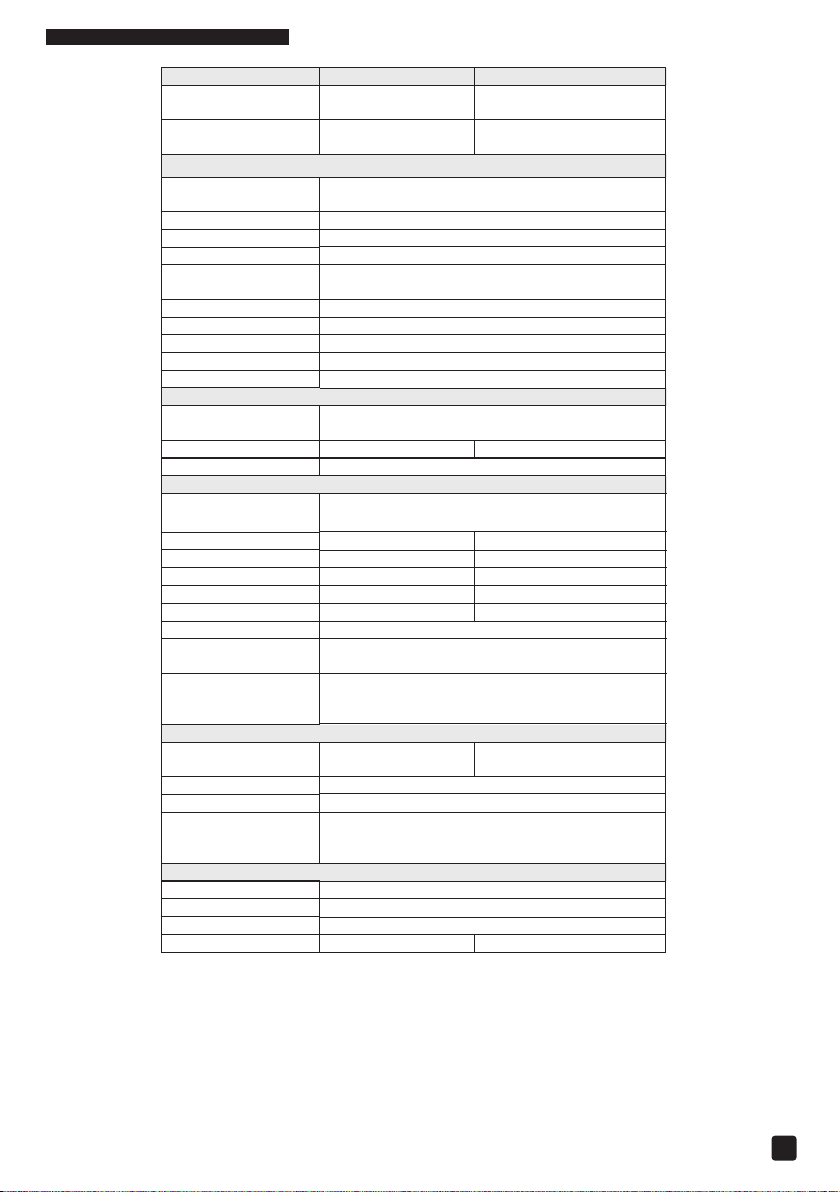

7. Technical Specifications

Inverter Output

Item

System Battery

Voltage 24VDC 48VDC

Battery Input

Voltage Range

21.6〜32VDC 43.2〜64VDC

Continuous Output

Power 2400VA

Output Power (15min.)

3000VA

O

verload Power

(5

s

)

4800VA

Max. Surge Power

6000VA

Output Voltage

Range 220VAC ±3%

Output Frequency 50HZ/60HZ

Output Wave Pure Sine Wave

Power Factor

0.8

Distortion THD

≤3%(24V,,4V or 48V Resistive Load)

Inverter Eciency

≤95%

Utility Input Voltage

Range 170VAC 〜275VAC

Utility Charge Current

30A

15A

Transfer Time 20mS

Max. PV Open Circuit

Voltage

150V*

138V*

Max. PV Input Power

780W

1040W

PV Charging Current 30A 20A

Equalization Voltage

29.2V 58.4V

Boost Voltage

28.8V

57.6V

Utility Input

Solar Charging

Others

Mechanical Parameters

Float Voltage 27.6V 55.2V

Tracking Eciency ≤99.5%

Charging Conversion

Eciency ≤98%

Temperature

Compensate

Coecient

-3mV/C/2V (Default)

No Load

Consumption ≤0.8A ≤0.6A

Enclosure

IP30

Relative Humidity

< 95%(N.C.)

Working

Environment

Temperature

-20〜50 (100% Input and Output)

Dimension 444×300×126mm

Mounting Dimension

230mm

Mounting Hole Size

Φ8mm

Product Weight

9.8kg

10.6

kg

At minimum operating environment temperature

At 25Cenvironment temperature

FBIC3000VA/24V FBIC3000VA/48V

17

NOTES

18

NOTES

Help Line

South Africa: 0861-ELLIES (355437)

For branch or agent contact details,

please refer to website: www.ellies.co.za

This manual suits for next models

1

Table of contents

Other Ellies Batteries Charger manuals

Popular Batteries Charger manuals by other brands

VOLTCRAFT

VOLTCRAFT 20 20 09 operating instructions

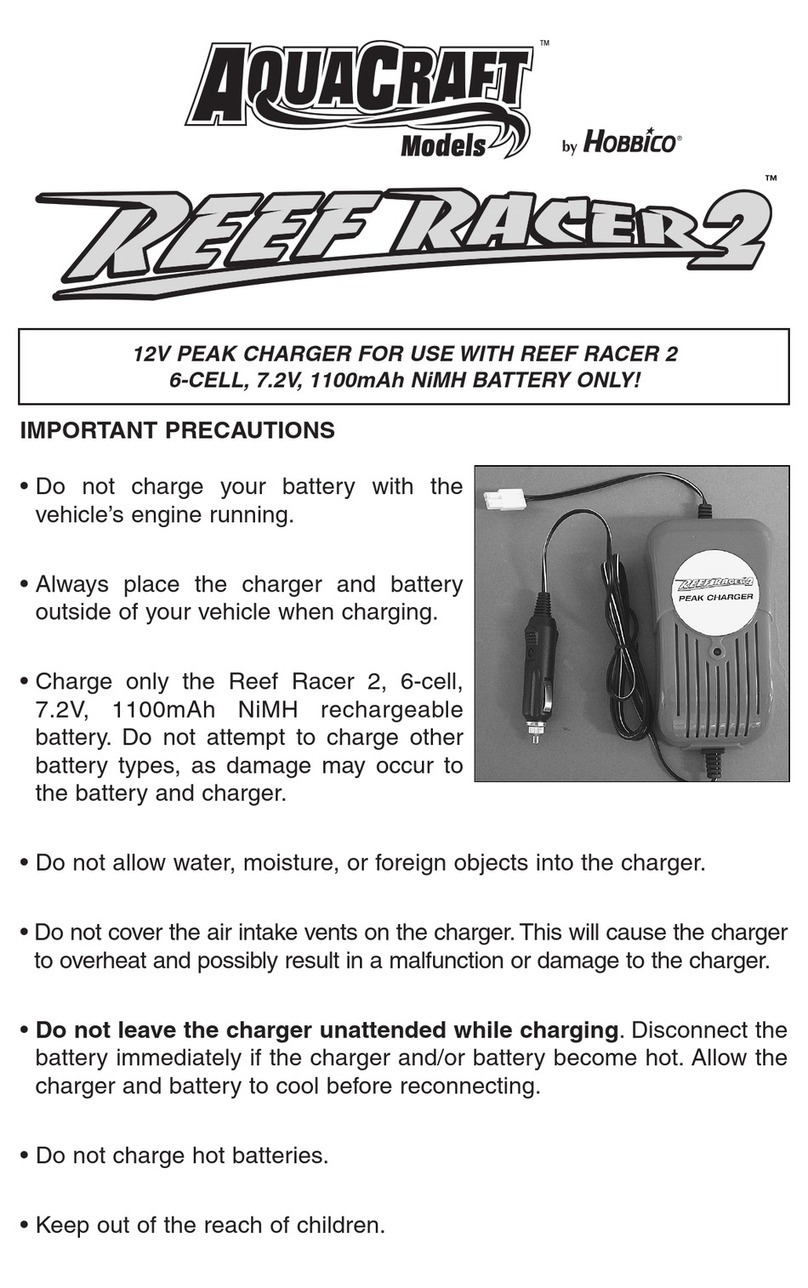

Hobbico

Hobbico AquaCraft Reef Racer 2 AQUP9929 quick start guide

GYS

GYS STARTPACK PRO 12.24 XL Translation of the original instructions

Perun

Perun AL C20C instructions

Altronix

Altronix AL1024X220 Series installation guide

Smappee

Smappee EV Base installation manual