Elliwell LKD 500 User manual

1

Refrigerant Leak Detection

P/N: 0024-9551 | November 2019 Revision F

Refrigerant Gas Detectors

for Machinery Rooms, Cold Rooms & Freezer

LKD 500 / 600

User

Manual

2

NOTICES

Product improvements and enhancements are on-going, therefore the specications and information contained in

this document may change without notice.

Manufacturer shall not be liable for errors contained herein or for incidental or consequential damages in connection

with the furnishing, performance, or use of this material.

3

Table of Contents

Introduction ..................................................... 5

1.1 About this Manual ........................................................................................................... 5

1.2 Conventions...................................................................................................................... 5

1.3 General Safety Statements............................................................................................. 5

1.4 Product Overview ............................................................................................................ 6

Product Description......................................... 7

2.1 Intended Uses / Applications.......................................................................................... 7

2.2 LKD 500............................................................................................................................. 8

2.2.1 LKD 500 Product Overview..........................................................................................................................8

2.2.2 LKD 500 Components ..................................................................................................................................9

2.3 LKD 600 ........................................................................................................................... 10

2.3.1 LKD 600 Product Overview........................................................................................................................10

2.3.2 LKD 600 Design Features...........................................................................................................................11

Installation ..................................................... 13

3.1 General Information...................................................................................................... 13

3.2 Restrictions..................................................................................................................... 14

3.3 Mechanical Installation................................................................................................. 14

3.4 Electrical Installation..................................................................................................... 15

3.4.1 Preparations...............................................................................................................................................15

3.4.2 Power & Signal Wiring ...............................................................................................................................15

3.4.3 Relay Wiring................................................................................................................................................16

3.4.4 Installation of Remote Sensing Head (LKD 600) .....................................................................................17

3.4.5 Modbus RTU RS-485 Interface ..................................................................................................................18

3.4.6 Conclusion ..................................................................................................................................................19

Operation........................................................ 20

4.1 Overview of Normal Operation.................................................................................... 20

4.1.1 Applying Power & the Start-up Sequence................................................................................................21

4.1.2 Verifying Analog Signals ............................................................................................................................21

4.1.3 Verifying the Modbus Signal .....................................................................................................................22

4.1.4 Status Indication ........................................................................................................................................22

4.1.5 Switch Functions.........................................................................................................................................23

4.1.6 Reset System to Factory Default Settings.................................................................................................24

4

Care & Maintenance ...................................... 25

5.1 Overview of Normal Operation.................................................................................... 25

5.2 Adjustments ................................................................................................................... 26

5.2.1 Introduction................................................................................................................................................26

5.2.2 General Calibration Procedure ................................................................................................................26

5.2.3 Zero Adjustment.........................................................................................................................................27

5.2.4 Span Adjustment........................................................................................................................................28

5.2.5 System Bump Test......................................................................................................................................29

5.3 Troubleshooting............................................................................................................. 30

5.3.1 Hexadecimal Format .................................................................................................................................30

5.3.2 Fault Codes .................................................................................................................................................30

5.4 Sensor Maintenance...................................................................................................... 33

5.4.1 Replacing the Sensor Module ...................................................................................................................33

5.5 Cleaning the Instrument............................................................................................... 33

Additional Information ................................. 34

6.1 Sensor Principle ............................................................................................................. 34

6.1.1 Electrochemical Sensors............................................................................................................................34

6.1.2 Catalytic Bead Sensors ..............................................................................................................................34

6.1.3 Semiconductor Sensors.............................................................................................................................35

6.1.4 Infrared Sensors.........................................................................................................................................36

6.2 Disposing of the Instrument......................................................................................... 36

6.2.1 Disposing of the Electrical & Electronic Equipment................................................................................36

6.2.2 Disposing of Sensors..................................................................................................................................36

6.3 TechnicalSpecications................................................................................................ 37

6.3.1 GeneralSpecications...............................................................................................................................37

6.3.2 SensorSpecications.................................................................................................................................39

6.4 Modbus Registers .......................................................................................................... 40

6.4.1 Integration - Dynamic Sensor Data..........................................................................................................40

6.4.2 Integration - Static Sensor Data ...............................................................................................................42

6.4.3 Integration - General System Setup .........................................................................................................45

6.4.4 Integration - Calibration............................................................................................................................47

6.4.5 Integration - User Debug Tools.................................................................................................................47

6.4.6 LKD Compatibility - Status Flags...............................................................................................................48

6.4.7 Integration - Status Flags ..........................................................................................................................48

6.4.8 LKD Compatibility - Clear Special States .................................................................................................49

6.4.9 Integration - User Task ..............................................................................................................................49

5

1. Introduction

1.1 About this Manual

Thank you for investing in a LKD Gas Detector. To ensure operator safety and the proper

use of the gas detector, please read the contents of this manual for important information

on the operation and maintenance of the instrument.

IMPORTANT: Before installing this product, carefully read and strictly follow the

instructions in the manual.

Alert Icon Description

DANGER Imminently hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING Potentially hazardous situation which, if not avoided, could

result in death or serious injury.

WARNING Potential electrical shock hazard which, if not avoided, could

result in death or serious injury.

CAUTION

Potentially hazardous situation which, if not avoided, could result

in physical injury or damage to the product or environment. It

may also be used to alert against unsafe practices.

IMPORTANT Additional information on how to use the product.

1.2 Iconography

1.3 General Safety Statements

IMPORTANT: Before using this product, carefully read and strictly follow the instructions

in the manual. Ensure that all product documentation is retained and available to

anyone operating the instrument.

6

1.4 Product Overview

WARNING: Before connecting this instrument to electrical devices not mentioned in

this manual, consult the manufacturer or a qualied professional. Failure to comply

may result in injury and / or damage to the product.

DANGER: This instrument is neither certied nor approved for operation in oxygen-

enriched atmospheres. Failure to comply may result in personal injury or death.

WARNING: Use this product only for the purposes specied in this document and

under the conditions listed.

WARNING: This instrument has not been designed to be intrinsically safe for use

in areas classied as being hazardous locations. For your safety, DO NOT use it in

hazardous (classied) locations.

WARNING: In the event of an alarm or over-range condition, the sensor must be

recalibrated to ensure continued accuracy.

WARNING: This product must be recalibrated if installed in a non-room condition

environment (i.e. temperature or humidity extremes).

WARNING: The gas diusion path can become occluded (moisture, dust, debris, frozen

condensation) over time resulting in reduced or complete lack of gas detection and

alarming function. Routine visual inspection of the gas detector and bump testing are

suggested to ensure proper gas detection and alarm function.

CAUTION: Except for maintenance detailed in this manual, these products should only

be opened and / or serviced by authorized Bacharach personnel. Failure to comply may

void the warrant.

CAUTION: Operator assumes responsibility for complying with all laws, rules and

regulations governing the use of this product.

CAUTION: Use only genuine Bacharach parts and accessories. Failure to comply may

impair the operation of the product and / or void the warranty.

CAUTION: Only operate the product within the framework of a risk-based alarm

signaling concept.

7

2. Product Description

2.1 Intended Uses / Applications

LKD Gas Detection Series instruments continuously monitor ambient air (indoor or outdoor)

for the following gas types:

• Refrigerants

• Toxic and combustible gases

The instruments may be purchased in the following congurations:

• LKD 500 - IP66

• LKD 500 - IP41

• LKD 600 - IP66 with Remote IP66 Sensor

LKD gas detectors may be connected to a third-party device capable of accepting digital and/

or analog outputs from the gas detectors, such as a Building Management System (BMS),

Programmable Logic Controller (PLC) and/or Modbus RTU. With the integrated audio-visual

alarm indication, an instrument can be operated as a stand-alone unit (with additional local

alarm signaling as required).

WARNING: This instrument is neither certied nor approved for operation in oxygen-

enriched atmospheres. Failure to comply may result in EXPLOSION.

WARNING: This instrument has not been designed to be intrinsically safe for use in

areas classied as being hazardous locations. For your safety, DO NOT use it in hazardous

(classied) locations.

8

2.2 LKD 500

2.2.1 LKD 500 Product Overview

The LKD continuously monitors indoor or outdoor ambient air for the following gases:

• Refrigerants

• Toxic and combustible gases

The instruments may be purchased in one of two congurations with or without relays

output:

• LKD 500 - IP66

• LKD 500 - IP41

With the integrated Modbus communication, analog output and relays, the instrument can

be operated as a stand-alone unit or a third-party device capable of accepting digital and/

or analog outputs from the gas detectors, such as a Building Management System (BMS) ,

a Programmable Logic Controller (PLC) and/or Modbus RTU. The instrument is designed to

be installed in non-classied, non-hazardous, permanent locations.

9

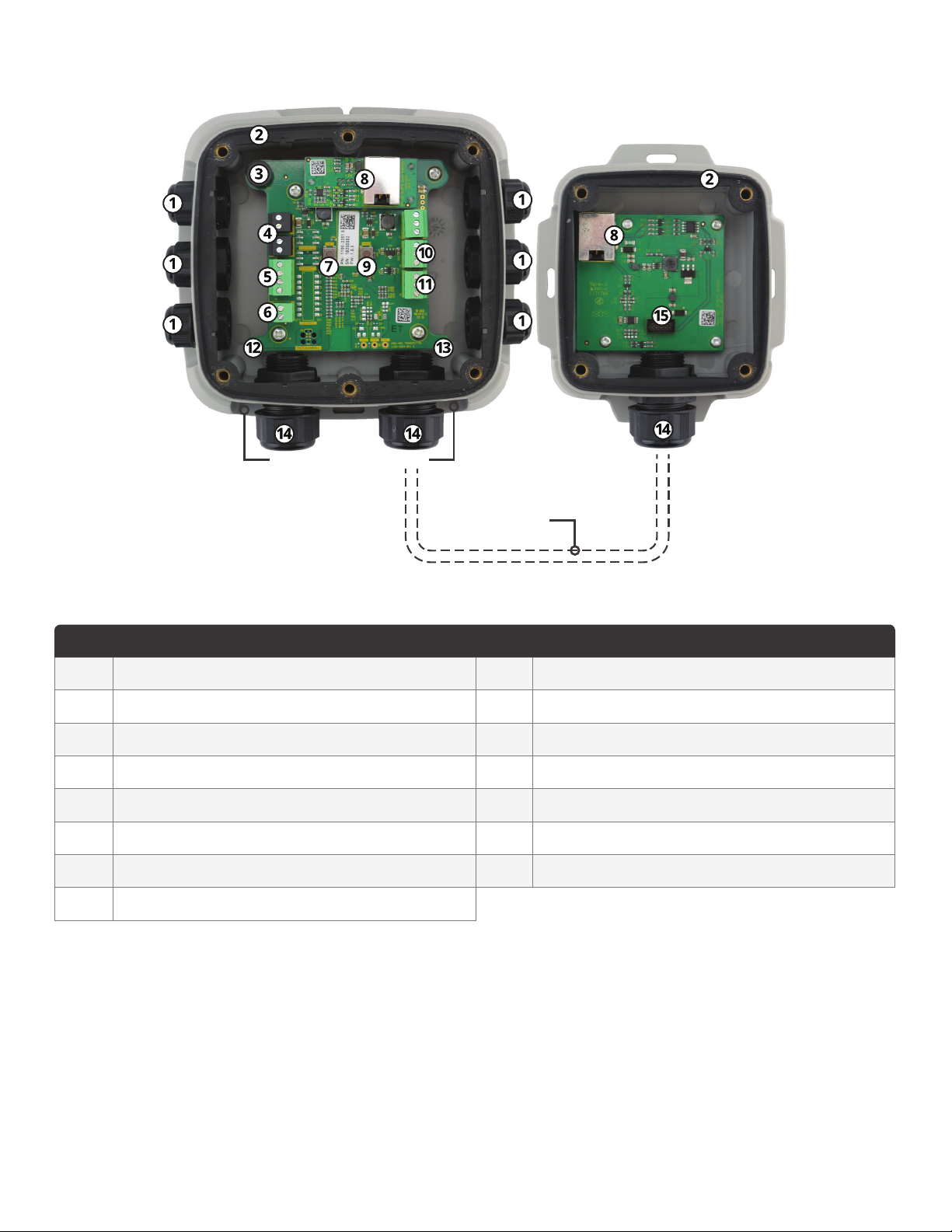

2.2.2 LKD 500 Components

This product uses semiconductors which can be damaged by electrostatic discharge (ESD).

When handling the PCB, care must be taken so that the electronics are not damaged.

(MAG #2)(MAG #1)

# COMPONENT DESCRIPTION # COMPONENT DESCRIPTION

1M16 Cable Glands (×6) 8Ribbon Cable Connection (To Sensor)

2Rubber Gasket (IP66 Version Only) 9Tactile Switch #2

3Internal Alarm Buzzer 10 Relay 2 Connection (HIGH)

4Power Connections (×2) 11 Relay 1 Connection (LOW)

5Digital Connection (Modbus) 12 Magnetic Switch #1

6Analog Connection 13 Magnetic Switch #2

7Tactile Switch #1 14 M20 Cable Glands (×2)

10

2.3 LKD 600

2.3.1 LKD 600 Product Overview

The LKD 600 continuously monitors indoor or outdoor ambient air for the following gases:

• Refrigerants

• Toxic and combustible gases

The instruments may be purchased in one of two congurations with or without relays

output:

• IP66 with Remote IP66 Sensor, connected via RJ45 cable (up to 20 meters ?? in length)

With the integrated Modbus communication, analog output and relays, the instrument can

be operated as a stand-alone unit or a third-party device capable of accepting digital and/

or analog outputs from the gas detectors, such as a Building Management System (BMS),

a Programmable Logic Controller (PLC) and/or Modbus RTU. The instrument is designed to

be installed in non-classied, non-hazardous, permanent locations.

11

2.3.2 LKD 600 Design Features

Transmitter options:

2× IP66 rated ABS enclosure connected via RJ45 cable (up to 5 meters in length)

Power options:

24 VAC

19.5 to 28.5 VDC

Diagnostic/status LED (3 color: green, orange and red)

Congurable output signal options:

2 x relays as option (high alarm / low alarm / fault)

1× Analog Output (4 to 20 mA, 0 to 5 V, 0 to 10 V, 1 to 5 V, 2 to 10 V)

Digital output Modbus RTU signal

Pre-calibrated sensor exchange modules can be used for maintenance of the instrument

instead of performing gas calibration on site.

Non-intrusive magnetic wand can be used to initiate calibration of the device.

12

# COMPONENT DESCRIPTION # COMPONENT DESCRIPTION

1M16 Cable Glands (×6) 9Tactile Switch #2

2Rubber Gaskets (×2) 10 Relay 2 Connection (HIGH)

3Internal Alarm Buzzer 11 Relay 1 Connection (LOW)

4Power Connections (×2) 12 Magnetic Switch #1

5Digital Connection (Modbus) 13 Magnetic Switch #2

6Analog Connection 14 M20 Cable Glands (×2)

7Tactile Switch #1 15 Ribbon Cable Connection (To Sensor)

8Remote Sensor Connections (×2)

(MAG #2)

Connection Cable

(MAG #1)

Remote Sensor

Transmitter

13

3. Installation

3.1 General Information

Every detail of installation site selection is critical to ensure overall system performance and

eectiveness. Strict compliance and considerable thought must be given to every detail of

the installation process, including, but not limited to the following:

• Regulations as well as local, state, and national codes that govern the installation of

gas monitoring equipment

• Electrical codes that govern the routing and connection of electrical power and signal

cables to gas monitoring equipment

• The full range of environmental conditions to which the instruments will be exposed

• The physical characteristics of the gas or vapor to be detected

• Thespecicsoftheapplication(e.g.,possibleleaks,airmovement/draft,etc.)

• The degree of accessibility required for maintenance purposes

• The types of optional equipment and accessories that will be used with the system

• Anylimitingfactorsorregulationsthatwouldaectsystemperformanceorinstallations

• Wiring details, including:

– The LKD 500 enclosure provides the following cable gland openings:

2×, M20, supports 10-14mm cable outer diameter

6×, M16, supports 4-8mm cable outer diameter

– The LKD 600 enclosure provides the following cable gland openings:

1×, M20, supports 10-14mm cable outer diameter

6×, M16, supports 4-8mm cable outer diameter

IMPORTANT: The manufacturer of this product requires that a bump test or calibration

be performed following installation to verify instrument functionality.

14

– Secondary circuit must be supplied from an isolating source

– The wiring for the relays must be selected and fused according to the rated voltages,

currents, and environmental conditions

– If stranded conductors are used, a ferrule should be used

– To comply with RFI immunity regulations, it is necessary to ground the shield of

the communications cable at the PLC, GDA controller, front-end controller, or Building

Management System (e.g., the chassis, the ground bus-bar, etc.).

3.2 Restrictions

The installation location must have appropriate supply power available for the instrument

(i.e., 19.5 to 28.5 VDC or 24 VAC). This ultimately determines the distance the instrument

can be mounted from the controller or power supply.

3.3 Mechanical Installation

The installation location must have appropriate supply power available for the instrument

(i.e., 19.5 to 28.5 VDC or 24 VAC). This ultimately determines the distance the instrument

can be mounted from the controller or power supply.

WARNING: DO NOT allow the lid / sensor to hang from the ribbon cable. Failure to

comply may result in damage to the product.

Using the provided hardware, securely mount the LKD Gas Detector according to the

product dimensions, maximum wiring lengths and following considerations:

• Environment: the full range of environmental conditions when selecting a location.

• Application: the specics of the application (possible leaks,air movement / draft,

etc.) when selecting a location.

• Accessibility: the degree of accessibility required for maintenance purposes when

selecting a location.

• Target Gas: the specific gravity of the target gas when selecting the height of

the instrument.

1. Usinga5/32″(4 mm)hexkey/allenwrench(not included) remove the lid and disconnect

the ribbon cable from the base.

2. Setthelidandrubbergasket (IP66 version only) aside to be reinstalled later.

15

3.4 Electrical Installation

3.4.1 Preparations

WARNING: Ensure wiring for relays and connections for sensor(s) are made before

applying power.

CAUTION: This product uses semiconductors which can be damaged by electrostatic

discharge (ESD). When handling the printed circuit boards (PCBs), observe proper ESD

precautions so that the electronics are not damaged.

3.4.2 Power & Signal Wiring

The product comes with cable glands and plugs pre-installed. The power entry cable gland is

without a gland plug. Use the appropriate cable glands to insert and connect the wires for power

and signal to the appropriate terminals as indicated in the gure and wiring table that follow. The

PCB terminal blocks are pluggable type and may be removed to aid termination.

Polarity must not be reversed.

For 24 VAC installations in a daisy-chain conguration, the neutral polarity must be maintained for

all instruments.

Fasten terminal screws.

16

Connection Description Label Wiring Termination

Power

24 VDC/VAC IN 24V IN: - 24 VDC/VAC neutral /

ground

24V IN: + 24 VAC neutral

24 VDC/VAC OUT

(power daisy chain

terminal)

24V OUT: - 24 VDC/VAC neutral /

ground

24V OUT: + 24 VAC neutral

Digital Output Modbus Network

Communications

MODBUS: B RS-485 “B” (inverted)

MODBUS: A RS-485 “A” (non-

inverted)

MODBUS: GND RS-485 GND

MODBUS: SH RS-485 Shield

Analog Output Voltage or Current ANALOG: - Analog output ground

Output ANALOG: + Analog output signal (+)

3.4.3 Relay Wiring

WARNING: Relays are rated for 0 to 24 VAC/DC. DO NOT apply mains power onto

these relays.

Using appropriate cable glands, connect the wires for relay 1 and relay 2 to the terminals as

indicated in the following wiring table.

Relay Function

1Low Alarm

2High Alarm

When congured according to the factory default settings, the relays are de-energized during

normal operation (not fail-safe). Fail-safe mode can be congured. When congured for fail-safe

operation, relays are energized during normal operation. Fail-safe operation ensures relays are

triggered in cases of power failure at the instrument. In failsafe operation normally open and

normally closed terminals are reversed as indicated by the following table

17

Terminal Normal Operation Failsafe Operation

NC Normally Closed Normally Closed

COM Common Common

NO Normally Open Normally Closed

3.4.4InstallationofRemoteSensingHead(LKD600)

Standard RJ45 “Cat 5E STP” Ethernet cables up to 5 meters long may be used with the remote

sensor. The cable provided from the factory is 5 meters long.

IMPORTANT: Before using this product, carefully read and strictly follow the instructions

in the manual. Ensure that all product documentation is retained and available to

anyone operating the instrument.

Remove the bottom right M20 cable gland plug and gland cap, and carefully remove the gland

rubber insert. The rubber insert is split to allow it to be installed around the provided RJ45 cable.

Slip the cable gland nut over one end of the terminated RJ45 cable. Apply the split rubber insert

onto the cable so that it is between the gland nut and the end of the cable.

Feed the RJ45 connector through a cable gland and into the enclosure, taking care to not damage

the PCB.

Reassemble the cable gland by sliding the rubber insert into the gland body and then tightening

the gland nut. Conrm that the RJ45 cable is not binding or stressing the PCB terminal blocks

(leave no excess cable inside the enclosure).

Plug the RJ45 connector into the provided RJ45 socket.

IMPORTANT: Before using this product, carefully read and strictly follow the instructions

in the manual. Ensure that all product documentation is retained and available to

anyone operating the instrument.

18

3.4.5 Modbus RTU RS-485 Interface

For the Modbus RS-485 network use a 16 to 24 AWG (0.5 to 1 mm2) 3-core, 2 twisted pair + ground,

shielded cable with 120 Ω characteristic impedance.

Recommended: Belden 3106A (or equivalent)

The Modbus address, baud rate, stop bit, parity and slave termination is congured through the

setup menu. No jumpers or hardware switch settings are required.

Ensure that the communication parameters within the network, including the Building Management

System, are congured identically.

To ensure optimal performance of the Modbus network ensure the following guidelines

are implemented:

• Ensureinstrumentsareconguredinasinglebustopology,connectingmultiplebuses

in parallel or branching multiple units from the main bus, may introduce impedance

mismatches,reectionsand/orsignaldistortions

• Avoid long stubs when connecting instruments to the bus, stubs should be less than

1 meter in length

• Ensureinstrumentsatendofbushave120Ωterminatingresistorenabled.Terminating

resistorsmaybeenabled(refertoSection4.2.3.6formoreinformation).

• EnsureA/BsignalpolarityismaintainedthroughoutRS-485network

• Connect cable shield drain to physical earth or ground at the controller only.

• Connectcableshielddrainto(SH)terminalatinstrument

• EnsurecableshieldintegrityismaintainedthroughoutRS-485network.

• Do not use shield connection for signal ground. Use cable that provides dedicated ground

conductorforsignalground.Connectsignalgroundto(GND)terminalofinstrument.

19

3.4.6 Conclusion

After all wiring is completed, power the transmitter and conrm operation, and then prepare to

seal the enclosure. Note that the IP 41 congurations do not include a sealing gasket.

Ensure gasket is aligned correctly (IP66 versions only) and tighten the lid using the supplied

hardware in an “X” pattern. To achieve proper seal, the lid screws should be torqued to 15 to 20

lbf in (1.5 to 2.0 Nm).

20

4. Operation

4.1 Overview of Normal Operation

WARNING: Before leaving the instrument for normal operation, check the conguration

for proper settings and check calibration.

4.1.1 Applying Power & the Start-up Sequence

After applying power, the instrument will go through a start-up sequence (initialization, audible/

visual test and self-test sequence). After start-up sequence completes, the instrument will enter a

warm-up period to allow the sensor element to stabilize before reporting a valid output.

Step Description

1. Switch power on.

2.

Observe start-up sequence and warm-up phase.

· Green LED will blink at 0.5 Hz for about 5 minutes

· Modbus ag for warm-up is set

· Buzzer is o

· Relay state is “no alarm”

· Gas reading invalid

3.

Observe normal operation.

· Green LED is steady on

· Modbus ag for warm-up is cleared

· Buzzer is o

· Relay state is “no alarm”

· Gas reading valid

This manual suits for next models

1

Table of contents

Popular Gas Detector manuals by other brands

Seitron

Seitron BEAGLE manual

S&P

S&P 6002-A Installation, operation and maintenance manual

Hansen Technologies

Hansen Technologies HSC4H-N10K Specifications, Applications, Service Instructions & Parts

Sensitron

Sensitron P user manual

S&S Northern

S&S Northern Merlin Detector i-S Installation operation & maintenance

Inficon

Inficon IRWIN quick start guide