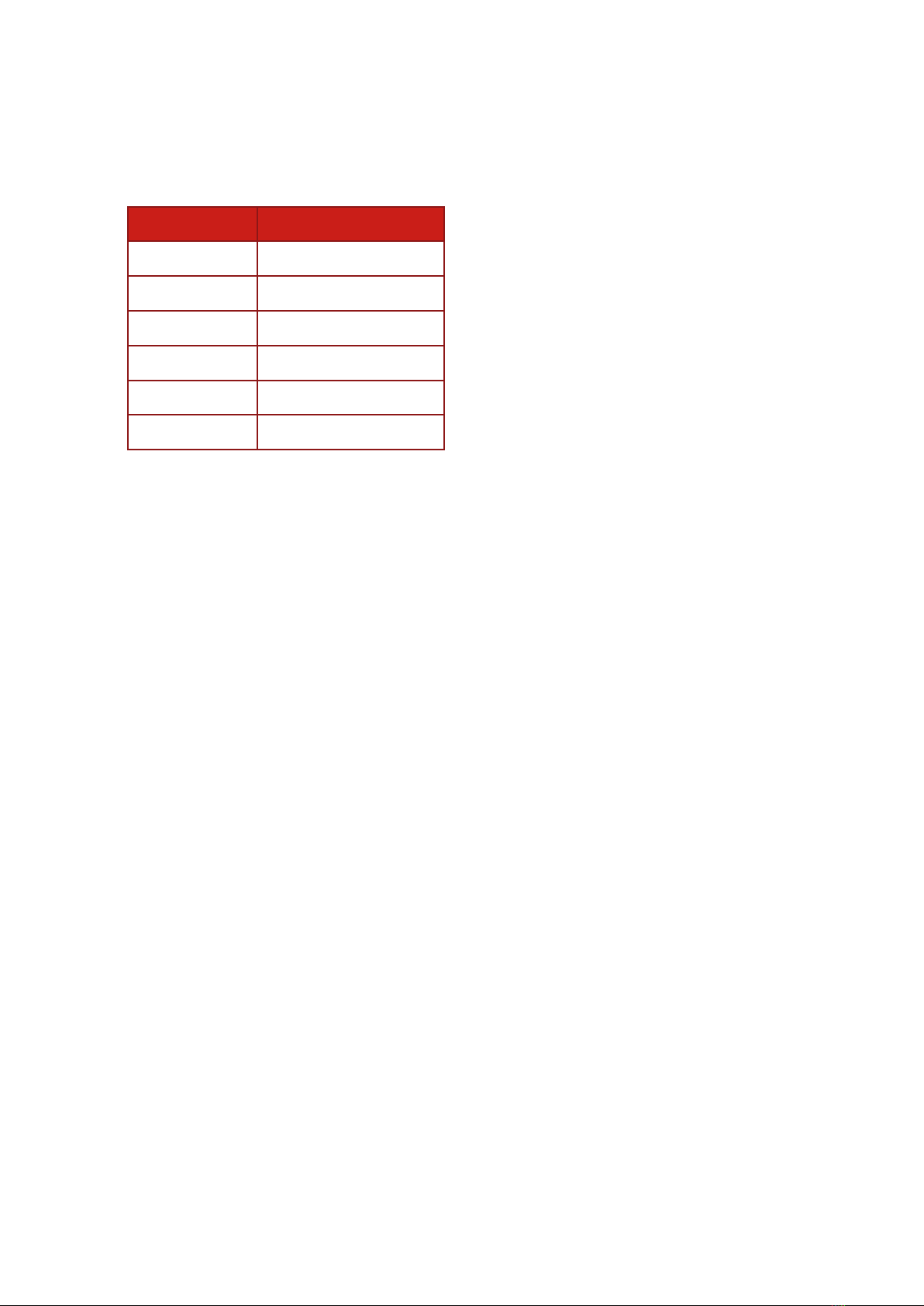

Table of Contents

MAN-G-SOLTWIB_160 (Ver. 1.005)4

Chapter 1: This Installation Guide.................................................................................7

Chapter 2: Safety Information ......................................................................................7

2.1. Warnings ....................................................................................................................8

2.2. Cautions......................................................................................................................8

2.3. Warranty Information ................................................................................................8

Chapter 3: Product Description.....................................................................................9

Chapter 4: Technical Information................................................................................10

4.1. Physical Specifications..............................................................................................10

4.2. D Type Technical Data ..............................................................................................10

4.3. Control Supply Input Voltage (VL) ............................................................................11

4.4. Product Features ......................................................................................................11

4.5. Environmental Conditions........................................................................................12

Chapter 5: Standards..................................................................................................13

5.1. CE Declaration ..........................................................................................................14

5.2. Environmental ..........................................................................................................14

5.3. EMC ..........................................................................................................................14

5.4. EtherCAT Conformance............................................................................................14

5.5. Other Compliant Standards......................................................................................15

Chapter 6: Installation................................................................................................16

6.1. Unpacking the Servo Drive Components..................................................................16

6.2. Mounting the Gold Solo Double Twitter to a Heat Sink...........................................17

6.3. The Gold Solo Double Twitter Connection Diagrams...............................................18

6.3.1. CAN Connection Diagram ..........................................................................18

6.3.2. EtherCAT Connection Diagram..................................................................19

Chapter 7: Wiring.......................................................................................................20

7.1. Wiring Legend...........................................................................................................20

7.2. Connectors Types .....................................................................................................22

7.2.1. Recommended Cable Lugs and Cabling.....................................................23

7.3. Mating Connectors, Wires, and Cables ....................................................................23

7.4. Logic and Control Cabling and Wiring ......................................................................24

7.4.1. J10 and J11 (Feedback ports, VL, RS232, USB, Analog Input)....................24

7.4.2. J11 (Digital Inputs/Outputs, STO)..............................................................24

7.4.3. J17, J18 EtherCAT or CAN Communication................................................24