2

TABLE OF CONTENTS

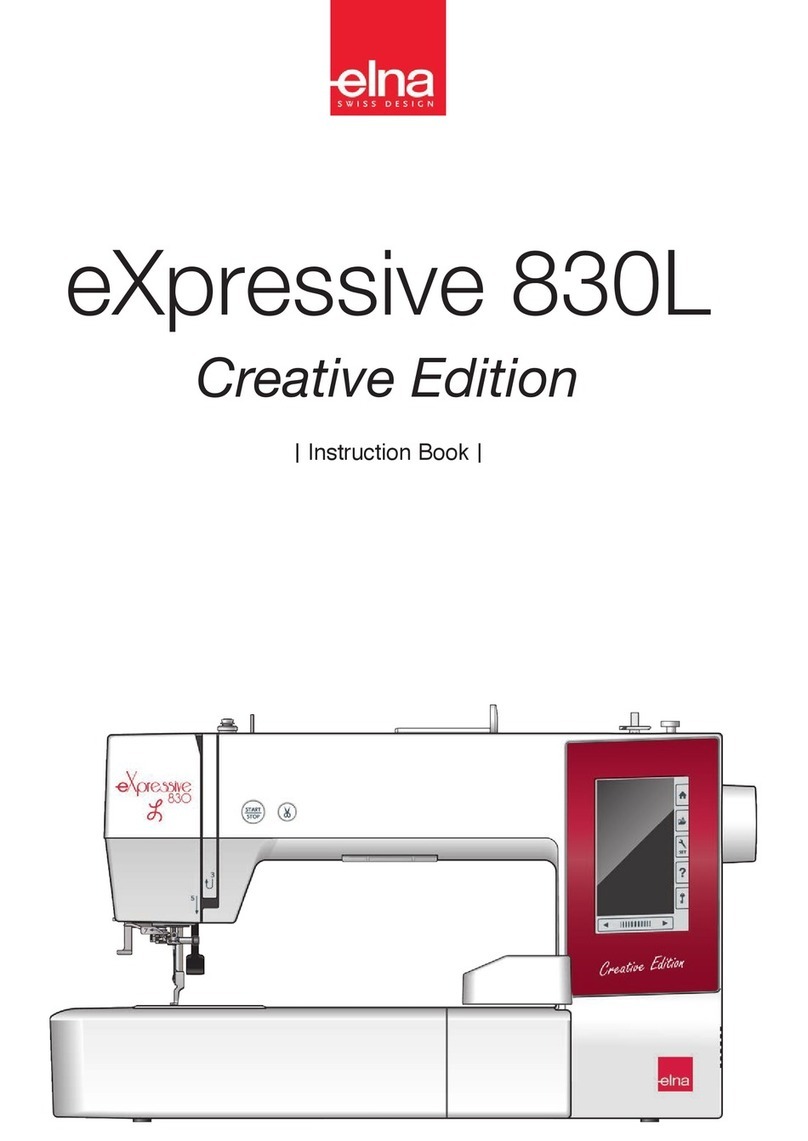

ESSENTIAL PARTS

Names of Parts............................................................... 3

Accessories Storage ...................................................... 4

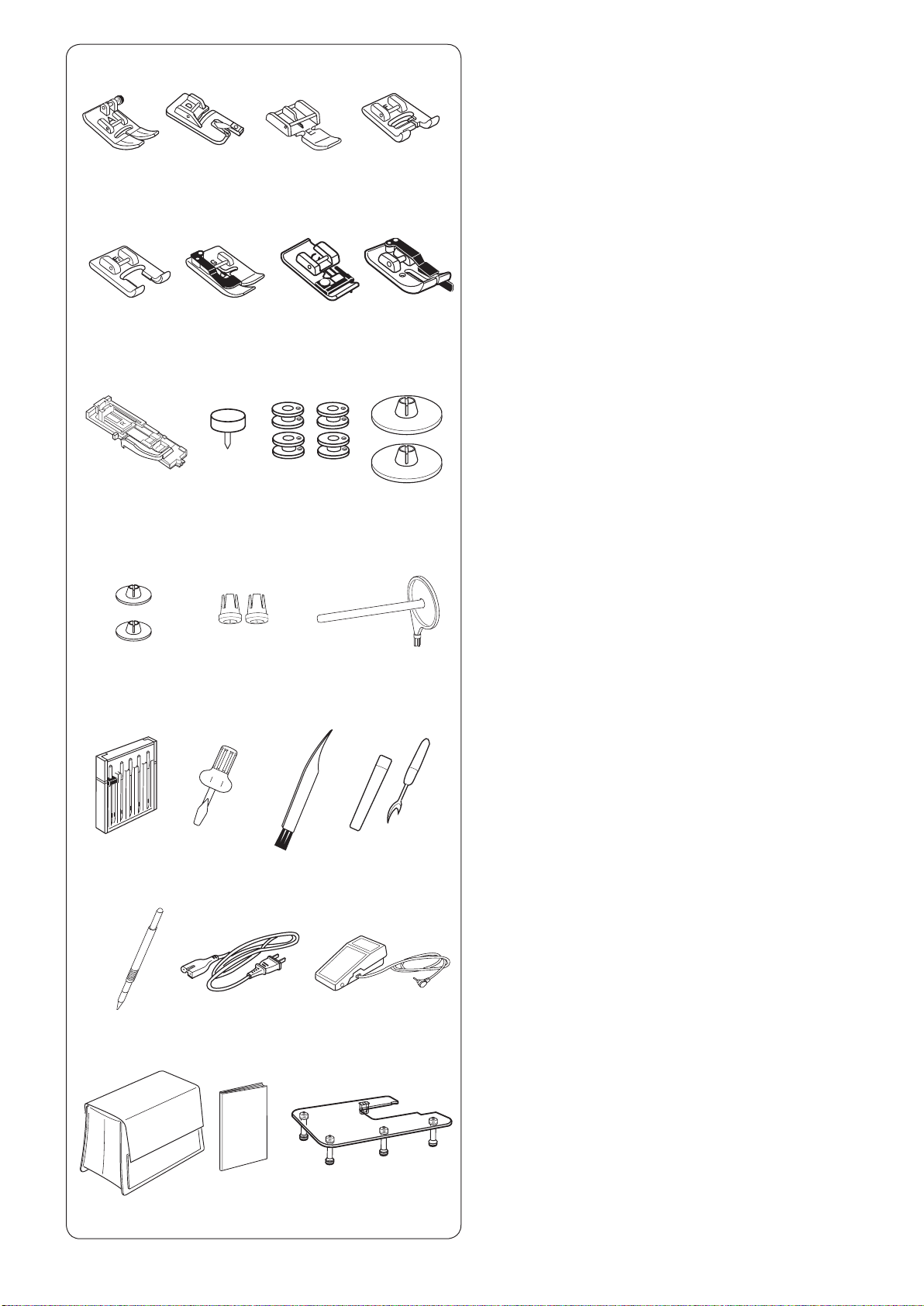

Standard Accessories .................................................... 5

Extension Table.............................................................. 6

Free-arm sewing ............................................................ 6

Extra wide table........................................................... 6-7

GETTING READY TO SEW

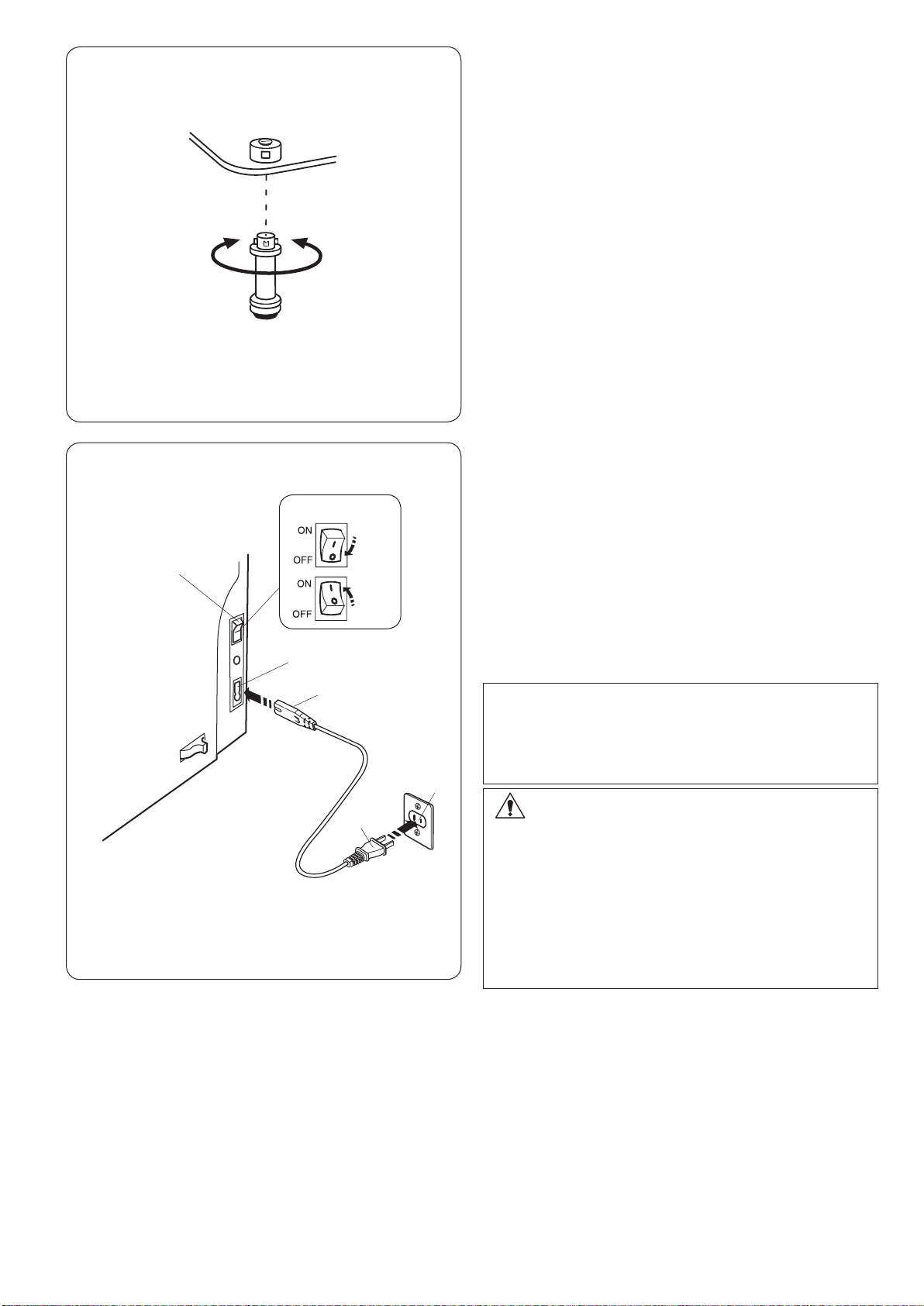

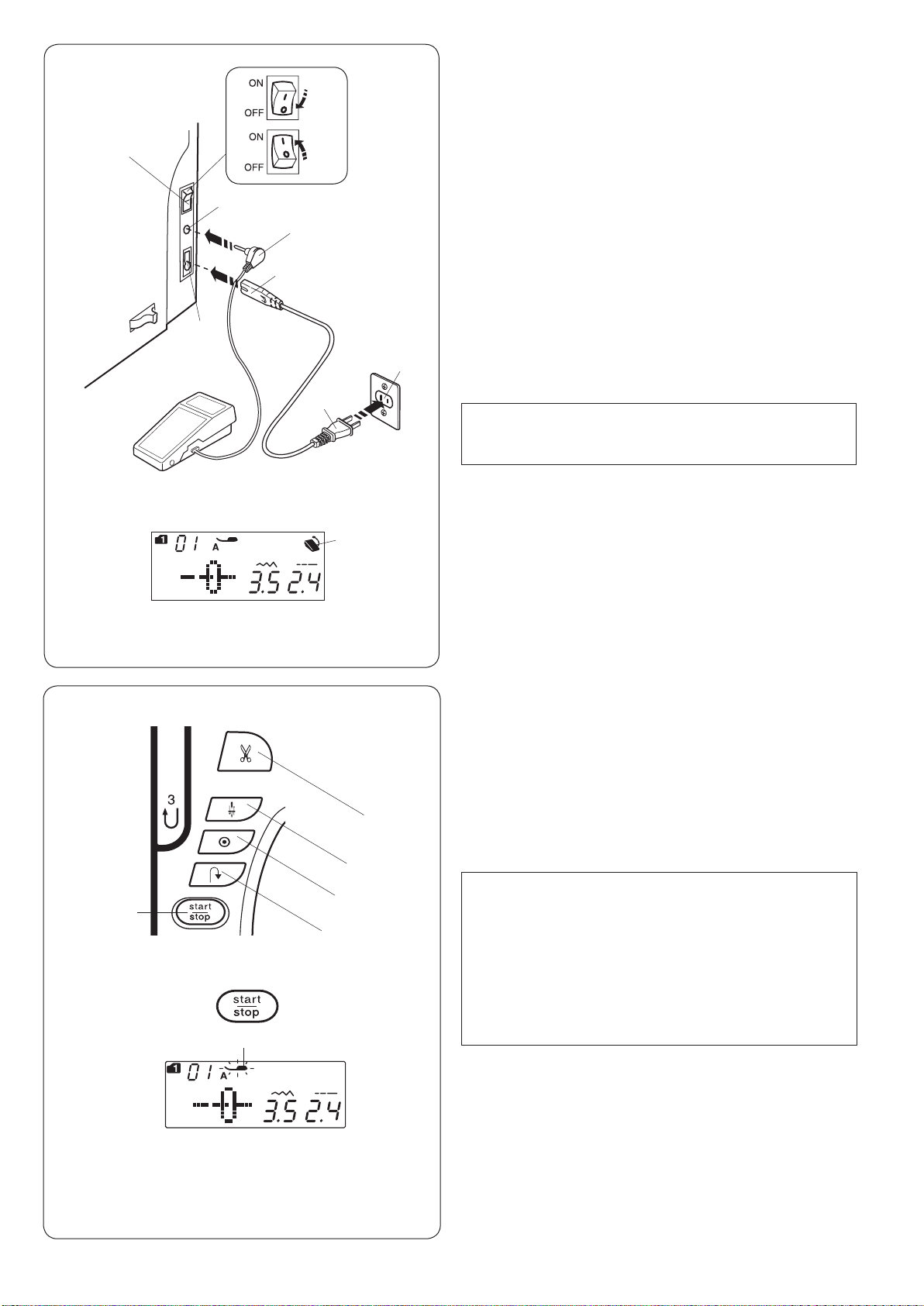

Connecting the Power Supply..................................... 7-8

Operating Instructions: ................................................... 8

Machine Operating Buttons.........................................8-9

Controlling Sewing Speed.............................................. 9

Foot Control.................................................................... 9

Function Keys............................................................... 10

Raising and Lowering the Presser Foot ........................11

Adjusting the Foot Pressure ..........................................11

Dropping the Feed Dog.................................................11

Balancing Thread Tension............................................ 12

Changing the Presser Foot .......................................... 13

Removing and Attaching the Foot Holder .................... 13

Changing Needles........................................................ 14

Fabric and Needle Chart .............................................. 14

Needle Denitions ........................................................ 15

Winding the Bobbin ................................................. 16-18

Threading the Machine................................................. 19

Built-in Needle Threader .............................................. 20

Drawing up the Bobbin Thread .................................... 21

Selecting the Patterns .................................................. 22

Customizing Machine Settings................................23-25

BASIC SEWING

Straight Stitch ............................................................... 26

Securing Seams ........................................................... 26

Sewing from the Edge of Thick Fabric ......................... 26

Changing Sewing Direction.......................................... 26

Cutting Threads............................................................ 27

Needle Plate Guides .................................................... 27

Cornering Guide ........................................................... 27

Adjusting the Needle Drop Position ............................. 28

Adjusting the Stitch Length .......................................... 28

Lock-a-Matic Stitch....................................................... 29

Locking Stitch............................................................... 29

Straight Stitch with Left Needle Position ...................... 29

Saddle Stitch ................................................................ 30

Triple Stretch Stitch ...................................................... 30

Knit Stitch ..................................................................... 30

Zipper Sewing ......................................................... 31-33

Rolled Hem................................................................... 34

Gathering...................................................................... 35

Pintucking..................................................................... 35

Zigzag Stitch................................................................. 36

Multiple Zigzag Stitch (Tricot stitch) ............................. 37

Overcasting Stitch ........................................................ 37

Knit Stitch ..................................................................... 38

Double Overedge Stitch ............................................... 38

Visible hemming........................................................... 39

Blind Hemming........................................................39-40

Shell Tuck ..................................................................... 40

Attaching Elastic........................................................... 41

Super Overlock Stitch................................................... 41

Button Sewing .............................................................. 42

Buttonholes .................................................................. 43

Square Buttonhole...................................................44-47

Round End and Fine Fabric Buttonholes ..................... 48

Keyhole Buttonhole ...................................................... 48

Stretch Buttonholes...................................................... 48

Corded Buttonhole ....................................................... 49

Welted Buttonhole ................................................... 50-51

Darning....................................................................52-53

Tacking ......................................................................... 54

Eyelet............................................................................ 55

DECORATIVE STITCHING

Applique ....................................................................... 56

Fringing......................................................................... 57

Drawn Work............................................................. 57-58

Smocking...................................................................... 58

Fagoting........................................................................ 59

Scallop.......................................................................... 59

French Knots ................................................................ 59

Patchwork Piecing ........................................................ 60

Patchwork..................................................................... 60

Circular Sewing ............................................................ 61

Stippling........................................................................ 61

Clasp Stitches .............................................................. 61

Satin Stitches ............................................................... 62

Twin Needle Sewing ................................................63-64

PROGRAMMING A PATTERN COMBINATION

Pattern Combination..................................................... 65

Programming Auto-lock Stitch...................................... 66

Programming Automatic Thread Cutting...................... 67

Pattern Combination with a Mirror Image..................... 68

Resuming a Pattern from the Beginning

........................ 69

Resuming a Pattern Combination from the Beginning

... 69

Bridge Stitches ........................................................ 70-71

Monogramming ....................................................... 72-73

Editing a Pattern Combination...................................... 73

Deleting and Inserting a Pattern....................................74

Duplicating a Pattern .....................................................74

Uniform Stitch Adjustment............................................ 75

Unied Needle Drop Position ....................................... 75

Individual Stitch Adjustment ......................................... 76

Correcting Distorted Stitch Patterns............................. 77

CARE AND MAINTENANCE

Cleaning the Hook Area ............................................... 78

Cleaning the Inside of the Thread Guide ..................... 79

Problems and Warning Signals .................................... 80

Troubleshooting............................................................ 81

EC DECLARATION OF CONFORMITY ....................... 82