Content

s

and

Us

eful

Hi

nts

Pre

pari

ng y

our

EL

NA

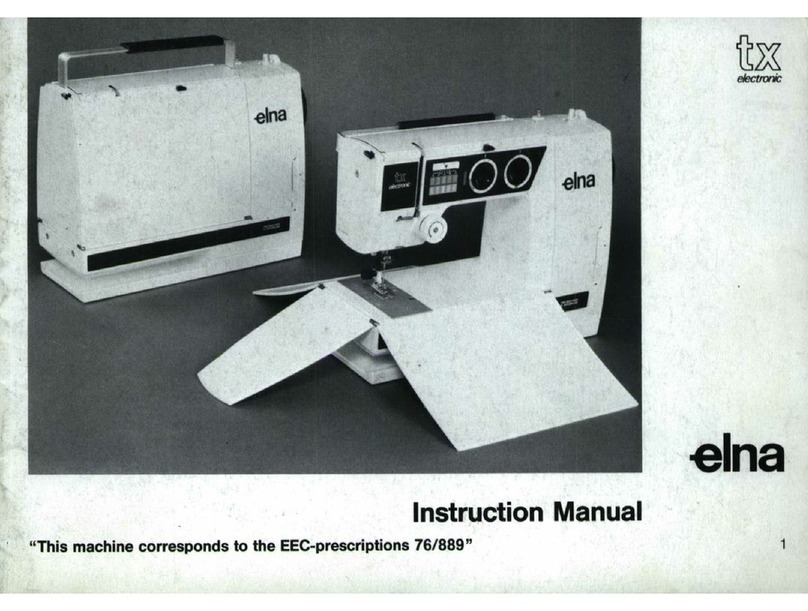

Giving your m hln Iii

s rves Is y

our

gu r

p rform In

II d -

p rf cl

Evon th b t wing m Ichlno will not

se

w prope

rl

y with a n

ee

dle

0'1

poor

quality. Choose needles of first-class

quality, system

70

5

or

the

Americ

an

st

yl

e 15

x1.

•

Ne

edle and thread

must

be adapted to

the kind

of

work

to

be do

ne

.

Pages

3-10

E

LNAgraph

11

Straight

Sewing

12-1

3

• Universal tension 13

Se

wing

with

aut

om

atic s

titches

14-16

an

d

23

• Selection dial

fo

r use with the built-in

ELNAdiscs 14

• Interchangeable EL

NAdiscs

15 and 23

• Variations of Stitch

Width

16

• Centering the Needle 16

Some

Pr

actical Sew

ing

17-22

Addit

i

onal

ELN

A

Su

per Fe

atures

23

• "

Com

bi "

St

i

tch

Pa

ttern

s 23

• Bu

ttonhole,

No

-turn

24

•

Practica

l Stitch

es

w

ith

EL

NA

Super

25-26

• First f

am

iliarize yourselfwiththe simpler

kinds

of

work. You will then take b

ett

er

advantage of

th

e ma

ny

o

ther

possibili-

ties provid

ed

by

your

ELNA

.

Other

Us

es of ELN

Adiscs

27

As

s

ortme

nt of

ELNAdiscs

28

Examp

les

of

..

Com

bi

" St

it

ch

Pa

ttern

s

28

Ex

tra

Accesso

r

ies

29-

30

Servici

ng

and

D

isorders

31

• Do

not

tr

y to re

me

dy a disorder

withou

t

fir

st having consulted

our

re

commenda-

tions.

• Make as much use

of

your EL

NA

ser-

vice as you wish. In each

ELNA

shop

,

there is a qualified personnel ready to

help you. Under the

conditions

of

the

guarantee, they are the only ones

competent

to

deal with .technical

ma

tt

ers concerning your machine.

Ta

ble of

Adjust

m

ents

32

Alph

ab

etic

Index

33

EL

NA

Star

de

Luxe CI.

41

EL

NA

P

la

na

Star

de

Luxe

CI.

43

ELNA

Su

per

CI.

62

ELNA

Plana

Super

CI.

64

2