User Manual

Lubrigun Pumps 50:1

7.3A-38010-C05

Page 5 of 22

Subject to change

LINCOLN GmbH & Co. KG

∗

Postfach 1263

∗

D-69183 Walldorf

∗

Fax + (49) 6227 33259 ∗Tel + (49) 6227 330

Safety Instructions

Warnings

• While operating or testing

Hands away from material outlet and lower part

(material inlet) of the pump.

Never point the material outlet (for example outlet of

flow guns, lubricating guns) at any part of the body

or at other persons. Do not deflect material flow at

outlet by hands.

• Shut pump off in the case of malfunction or changes

in the behaviour of the pump/ equipment during

operation.

• Do not attempt to repair or disassemble the

equipment while pump/system is pressurized.

• Do not use non-original equipment spare parts.

• Do not permit maintenance and service works to

persons not qualified to do.

• Always read and follow the safety instructions of the

manufacturer of materials used for dispensing or

cleaning/flushing the pump.

Use protective clothing when prescribed.

• Always follow recommendations of the material

manufacturer regarding use, compatibility and

disposal of the material.

Operating Precautions

• Always heed safety instructions and warnings listed

in this Operating Instructions Manual.

• When adding system components, use quality

products that comply with the technical requirements

regarding pressure and material compatibility; hoses

must have the proper length.

• For installation of compressed air and material

supply line, follow standard plumbing practice. They

must be laid and fitted properly. Ensure that no

connections are interchanged.

• Before operating the equipment, always make sure

that safety devices are in place and operating

properly.

• Do not exceed the working pressure of the

equipment.

• Follow operating instructions when putting or setting-

up equipment in operation.

• If the equipment is completely shut down for

maintenance and repair work, the pump must be

secured against inadvertent starting.

• Check all lines, hoses and screwed connections

regularly for leaks and obvious damage. Inspection

intervals depend on stress of the specific equipment.

▪Repair damage immediately. Repairs by authorized

personnel only.

• Check pump/pump unit regularly for proper operation

and working conditions.

• In case of malfunction or damages: Immediately shut

off pump (disconnect air coupler from pump).

Always disconnect air coupler from pump when pump

sits idle for long periods of time (pump not being used)

or before servicing (inspection, maintenance, repair) the

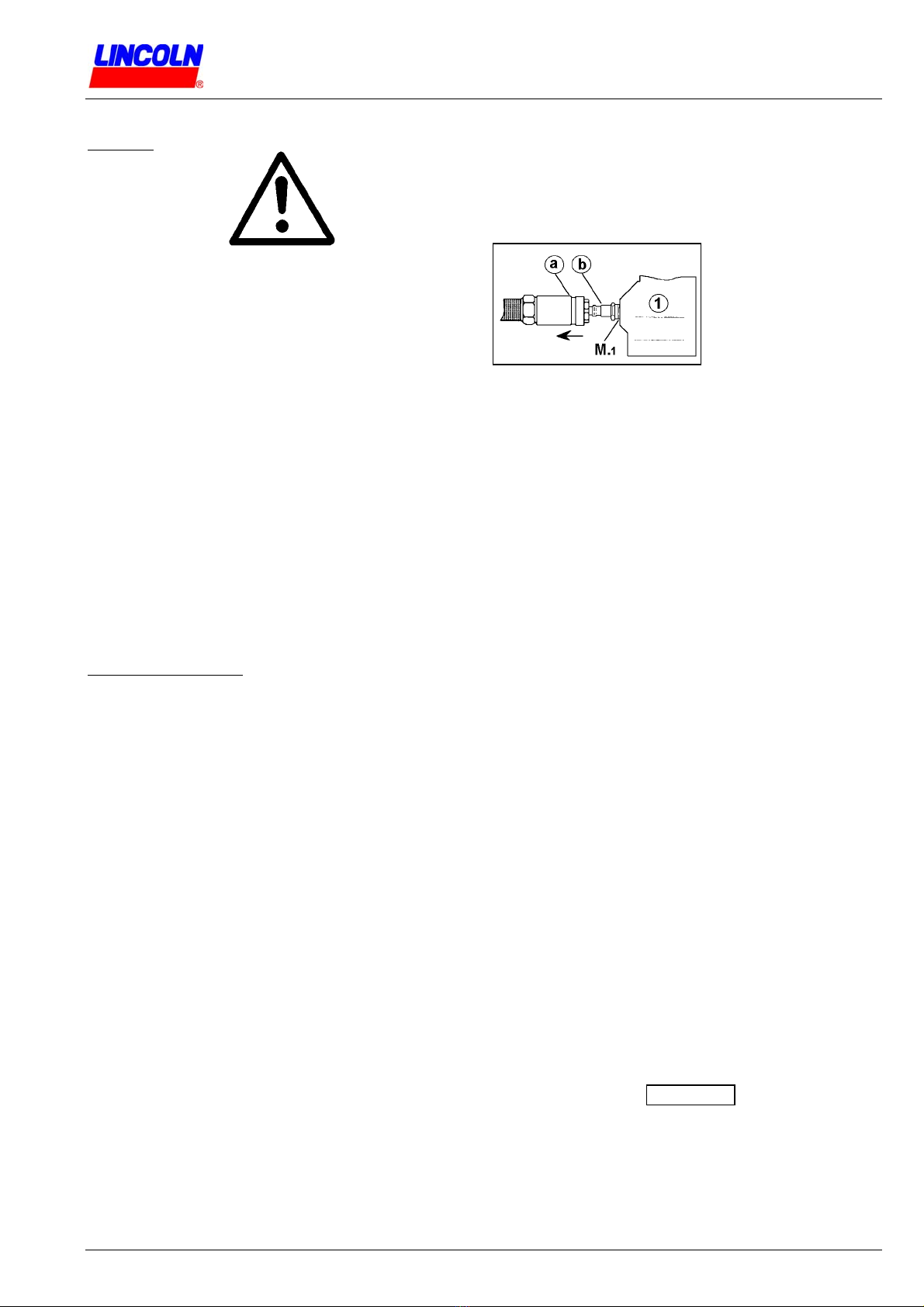

pump/equipment. (See illustration).

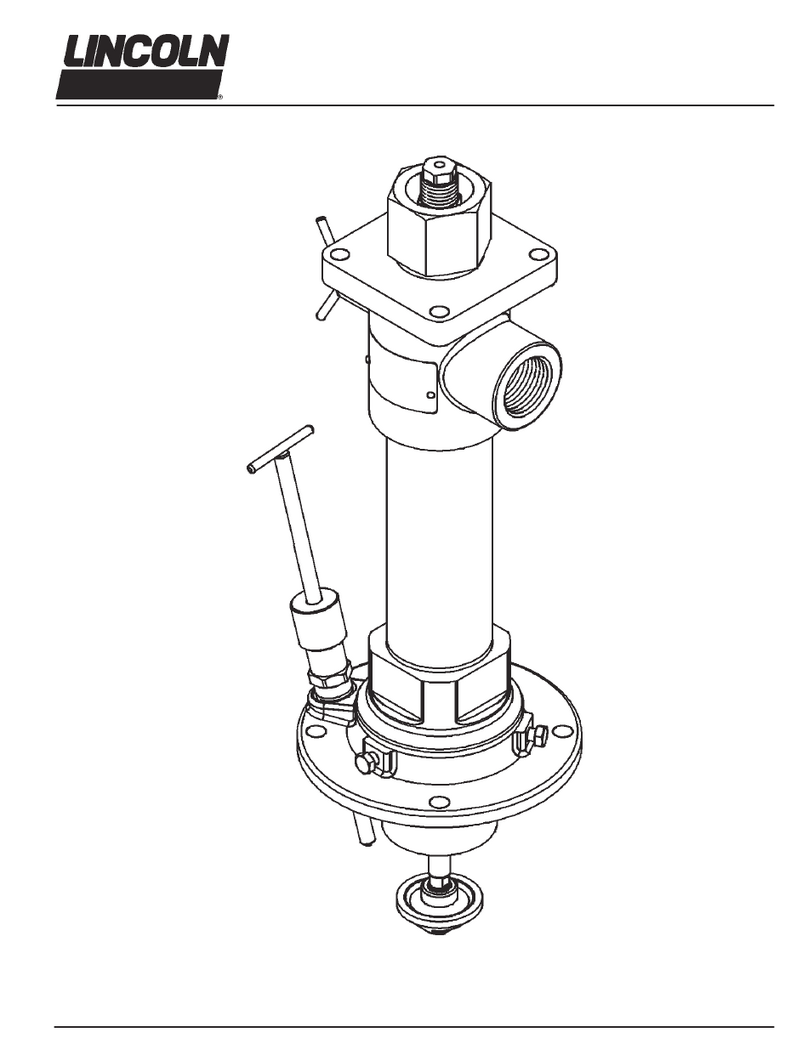

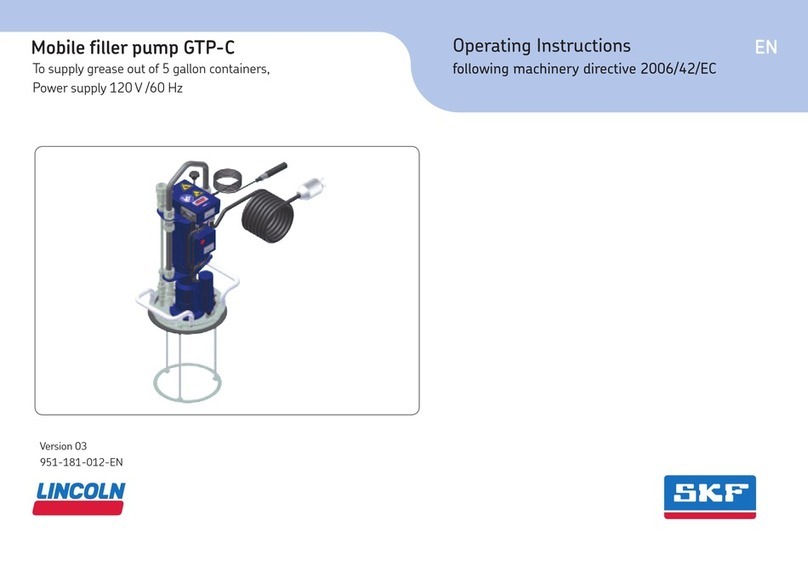

1 Pump drive

(airmotor)

M.1Air inlet

a Air quick coupler

b Coupler nipple

Note: a & b to supple-

ment by user.

• Report damages or malfunction of the equipment

immediately to the competent authority/ person.

Have any defects rectified immediately by qualified,

authorized personnel.

• Observe the adjusting, maintenance and inspection

activities and intervals set out in the operating

instructions, including information on the

replacement of parts/components. These activities

must be executed by skilled personnel only.

• Pay attention to instructions concerning the

execution of maintenance and repair!

• Before carrying out maintenance and repair works or

any disassembly of the pump or system components

(for example hose, swivel, control valve, etc.),

ensure that air supply line to pump is disconnected.

Perform pressure relief procedure to depressurize

pump and components of fluid system (material

dispensing system). If depressurizing is restricted by

clogged material supply line/system components,

very slowly loosen connectors cautiously to relieve

the pressure. Wear safety glasses!

• Perform maintenance and repair safely; methods

and tools to be adequate for carrying out the work.

• If replacing parts/components take care that

replacement parts comply with requirements

• Use original spare parts only.

• On re-assembly of high pressure sections, do not

interchange mistakenly connectors, hoses, etc. with

those for compressed air lines.

• Always tighten any screwed connections that have

been loosened during maintenance and repair.

▪Adhere to stated torque specifications.

• Any safety devices removed for set-up, maintenance

or repair purposes must be refitted and checked

immediately upon completion of the maintenance

and repair work.

• Ensure that all consumables and replaced parts are

disposed of safely and with minimum environmental

impact.

CAUTION

Use clean and moisture-free compressed air only to

operate pump. Do not operate with air contaminated

with materials not compatible with NBR seals.

Do not operate pump when out of material.