Elseta IOMOD 8DI8DO User manual

ELSETA

IOmod 8DI8DO

User manual for IEC 60870-5-103 protocol

Elseta

4/17/2019

V1.1

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Introduction

2

TABLE OF CONTENTS

1 Introduction .................................................................................................................................................. 5

1.1 Features .................................................................................................................................................. 5

2 Operational information .............................................................................................................................. 5

2.1 IEC 60870-5-103 working information ................................................................................................. 5

2.1.1 Initialization .................................................................................................................................. 5

2.1.2 Data polling ................................................................................................................................... 5

2.1.3 Output control .............................................................................................................................. 6

2.1.4 Input messages .............................................................................................................................. 6

2.1.5 Time synchronization ................................................................................................................... 6

2.1.6 General interrogation .................................................................................................................... 6

2.2 Device configuration ............................................................................................................................. 6

2.2.1 Input inversion and polarity selection ......................................................................................... 6

2.2.2 Input / Output grouping .............................................................................................................. 6

2.2.3 Input filter ...................................................................................................................................... 8

2.2.4 Output pulse time ......................................................................................................................... 8

2.2.5 Output detection with inputs ...................................................................................................... 9

2.2.6 Addressing configuration ............................................................................................................ 10

3 Testing with “THE VINCI” software ........................................................................................................... 10

4 Technical information ................................................................................................................................. 12

5 Mounting and installation guide ................................................................................................................ 13

5.1 IOmod 8DI8DO RS485 interface ........................................................................................................ 13

5.2 IOmod 8DI8DO inputs ........................................................................................................................ 13

5.3 IOmod 8DI8DO outputs ..................................................................................................................... 14

6 Configuration over USB ............................................................................................................................... 15

6.1 Driver installation ................................................................................................................................ 15

6.2 IOmod configuration with PuTTY terminal ...................................................................................... 16

6.3 Main Menu .......................................................................................................................................... 19

6.4 Protocol simulator .............................................................................................................................. 20

6.5 Firmware upgrade over USB .............................................................................................................. 20

7 Information about the equipment manufacturer ..................................................................................... 22

8 Document history ....................................................................................................................................... 23

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Introduction

3

COPYRIGHTS AND TRADEMARKS

Elseta is a trademark of UAB Elseta and identifies products manufactured by UAB Elseta. All of the

product copyrights belong to UAB Elseta. These documents and product properties cannot be changed

without the knowledge and written consent of UAB Elseta. This document may be modified by UAB Elseta

without additional notice.

DECLARATION OF CONFORMITY

(in accordance with ISO / IEC Guide 22 and EN Section 45014)

Manufacturer: UAB Elseta

Address of the manufacturer L. Zamenhofo g. 3 LT Vilnius, Lithuania

We claim that:

The device IOmod 8DI8DO

Conforms to the following standards:

EMC:

Radiation EN 55022 (Class A)

1 emitted radiation (30-1000MHz)

Second radiation conductors (0.15-30MHz)

EN 50082-1 Immunity test

1 IEC 801-3: Radio-frequency electromagnetic field

2 IEC 801-2: Electrostatic discharge.

3 IEC 801-4: Quick periodic electrostatic discharges

Additional information:

The device complies with the Low Voltage Directive 73/23 / EEC and EMC Directive 89/336 / EEC.

Device assembly complies with the RoHS Directive.

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Introduction

4

SAFETY REQUIREMENTS

Equipment’s operating notes must be met for your personal safety, as well as to avoid damage to the

equipment. These notes are marked with a warning triangle symbol and the various degrees of risk of

falling within signs. All work related to electronic systems design, installation, commissioning, adjustment

and maintenance should be carried out in accordance with the safety requirements.

USED SYMBOLS

Danger - important notice, which may affect the safety of the user or device.

Attention - notice on possible problems that may arise in individual cases.

Information Notice - the information that is useful advice or special places.

Equipment installation, commissioning and maintenance may only be

performed by a qualified professional authorized to perform commissioning,

grounding and labelling for devices, systems and circuits. The person must

be aware of occupational safety in the workplace, understand the equipment

components and have the knowledge and skills to operate high voltage

equipment.

Always turn off the power supply before installation or maintenance. It must

be in mind that equipment can have a common ground connection even when

turned off. Always check power supply, cables and interconnected

components before reconnection.

This product cannot be implemented or resold to install in areas that are

regarded as high-security such as nuclear power plants, aircraft navigation,

military equipment, transport traffic management – areas where equipment

failure can result in a nature or human injury.

Do not operate the equipment in extreme weather conditions as they may

affect the operation of the equipment.

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Introduction

5

1 INTRODUCTION

IOmod 8DI8DO is a small size stand-alone Modbus RTU or IEC 60870-5-103 digital input and digital

output controller (protocol depends on firmware). IOmod can be used for industrial applications, where

digital signalling is used and robust communication is needed. IOmod is an ideal solution for applications

such as data acquisition, control, process monitoring at remote places. This user manual is written for

IEC 60870-5-103 protocol firmware version.

1.1 FEATURES

• 8 digital inputs;

• Configurable active input signal polarity or input inversion;

• 8 digital open collector outputs;

• Galvanically isolated inputs and outputs;

• Pulsed or latched mode for individual outputs;

• Possible output feedback measurement with inputs;

• Configuration over USB console;

• Values with data and time information;

• Time synchronization over IEC-60870-5-103;

• Drag and Drop firmware upgrade over USB mass storage;

• Modbus RTU, IEC-60870-5-103 communication over RS485;

• Software-selectable line termination resistor on RS485;

• LED indication for input/output and data transmission;

• Easy integration with WCC Lite gateway and CloudIndustries.eu platform;

2 OPERATIONAL INFORMATION

IOmod 8DI8DO uses Modbus RTU or IEC 60870-5-103 protocol to communicate with master device over

RS485 interface. Protocol used by device can be changed by uploading corresponding firmware. Default

communication settings are: 9600 baud rate, 8N1, Link address – 1.

IOmod 8DI8DO configuration can be changed over USB interface with terminal console like PuTTY or

similar.

2.1 IEC 60870-5-103 WORKING INFORMATION

2.1.1 Initialization

IOmod uses a standard IEC-60870-5-103 communication scheme. Initiation, control messages

and queries are initiated by the master (controlling station), while IOmod device (controlled station) only

answers these requests. Therefore, the first message should be sent by master to start/restart

communication (RESET CU or LINK RESET FCB). This message is answered by IOmod with an

acknowledgement (ACK) to enable master to proceed with sending other messages defined by IEC-

60870-5-103 protocol. Other messages are ignored until a successful initialization has taken place.

2.1.2 Data polling

When initialization is complete, master may poll IOmod device with both Class 1 and Class 2 requests.

Class 2 is used when master polls for a cyclic data. Controlled device answers with a message containing

Access Demand flag when spontaneous data exists and master then sends request for Class 1. IOmod

would then respond with time-tagged message.

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Operational information

6

On first Class 1 request IOmod device always asks for the Access Demand to send an identification

string. However, if there are spontaneous messages to be sent, they will be sent before the identification

string.

2.1.3 Output control

To control device outputs master (controlling station) sends command conforming to the IEC-60870-5-

103 protocols. It should contain output address which is 128 by default. Info number represents number

of output pin, while info elements shows DPI information of output state (1 – off, 2 – on, 0 - intermediate

and 3 – not used (defines error)). Successful command is accepted with a positive acknowledge.

Negative acknowledge is returned if the output is already set or if another command for the same output

is already in progress and hasn’t finished yet.

2.1.4 Input messages

When input status changes, IOmod device filters input glitches through filters with a user configurable

filter time. When the filter is passed device sends “Spontaneous” message with “Function type” as input

address (default function type of inputs – 160), and “Info number” as input pin number. Please note that

spontaneous messages are answered with a four-byte time structure not containing date info. Controlling

station should therefore be able to handle the signals sent before the start of a new day.

2.1.5 Time synchronization

To initiate the time synchronization between devices master must send variable frame, with function code

“User data with ACK”, ASDU type “6” and Cause of Transmission “8”. Info elements must contain the 7-

byte time structure.

As per IEC-60870-5-103 protocol specification time synchronization can be completed for multiple

devices using broadcasting messages. It is included in IEC-60870-5-103 firmware since version 1.7.3.

To broadcast time synchronization message, link address should be equal to 255.

2.1.6 General interrogation

General Interrogation (GI) is initiated by the master with variable frame, including function code “3” (User

data with ACK), ASDU type “7” and Cause of Transmission “9”. Slave device then responds with an

acknowledgement (ACK). Master gets GI data by polling with Class 2 request till slave transmits “End of

GI” (Cause of Transmission – “10”). IOmod device responds with a time-tagged message, including DPI

states of inputs and outputs (Outputs are sent first). Output and input numbers are represented by “Info

number” in protocol.

2.2 DEVICE CONFIGURATION

2.2.1 Input inversion and polarity selection

When active low signalling is needed, user can configure input polarity. When internal pull-up resistors

are turned on, all input statuses are turned on. When low signal is connected to input, status of that input

is turned off. If user desires to turn input status on, when that input signal is low, user then inverts inputs

logically. All input indication LED’s stay the same (are not inverted).

2.2.2 Input / Output grouping

Sometimes two inputs or two outputs must be captured as one DPI input or output. Inputs and outputs

can be grouped into the pairs of two. This allows outputs to be controlled by one DPI command (of

address of first output in the group). Only two neighbour pins can be grouped into pair, while first pin in

pair must be an odd number pin. When grouped, second pin in the pair is not used anymore – all requests

for this pin generate an error. For example – OUT1 and OUT2 can be grouped, after that OUT2 is not

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Operational information

7

used; OUT2 and OUT3 cannot be grouped; OUT3 and OUT4 can be grouped, but OUT4 is not used,

etc.

Fig. 3.1 shows outputs and inputs ungrouped and controlled independently. In this mode, General

Interrogation will be composed of 8 output states and 8 input states.

Fig. 3.1. Independent control of input and output pins

In addition to this, Fig. 3.2 shows first two outputs grouped into pair, while 3rd and 4th inputs are grouped

into pair. Now, General interrogation will be composed of 7 output states (with OUT2 missing), and 7

input states (with IN4 missing). Output and input numbers is represented by “Info number” in protocol.

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Operational information

8

Fig. 3.2. Control of grouped output and input pins

2.2.3 Input filter

Input filter is a simple glitch filter with time input. This filter time corresponds to stable time that input must

achieve before sending a status change.

2.2.4 Output pulse time

User can configure outputs to be pulse controlled – it means that output will be turned on for configured

amount of time. When this time runs out, output is turned off. This is useful when pulse toggle relays are

used. Output pulse is independent from output grouping option and can be used on both grouped and

ungrouped outputs. When output is grouped, device will allow only one command completion at a time –

when output is already turned ON, other “turn ON” requests will be responded with NACK. If user desires

latching outputs to be used, output pulse time is set to 0.

Fig. 3.3 shows example of pulse output usage. In this example inputs and outputs are grouped, and

output pulse time is set to 1s. When user sends ON command, OUT2 is pulsed for 1s, and relay is set.

This will connect NO contact and IN2 will turn on (assuming it is not inverted). When user sends OFF

command, OUT1 is pulsed, and relay is reset, turning IN1 on.

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Operational information

9

Fig. 3.3. Controlling a relay with a pulsed output

2.2.5 Output detection with inputs

User can detect an output change with inputs (example shown in Fig. 3.4).

Fig. 3.4. Detecting outputs with an input feedback

To find out if relays are turned on, user can connect relay outputs to IOmod inputs (maximum allowed

voltage must be taken into account). When relays are turned on, device responds with IEC-60870-5-103

protocol message “Remote Operation”. If inputs are never turned on or off, device will send “Remote

Operation” message after time-out period, with current input statuses. Time-out period is configured by

user as a Feedback Time.

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Testing with “THE VINCI” software

10

2.2.6 Addressing configuration

Devices Output, Input and Output feedback addresses are configurable. This addresses in IEC 60870-

5-103 protocol are considered as “Function Type”. Output address and Output feedback address are 128

by default. Input address is 160 by default.

Device is addressed by “Link address”, which is 1 by default.

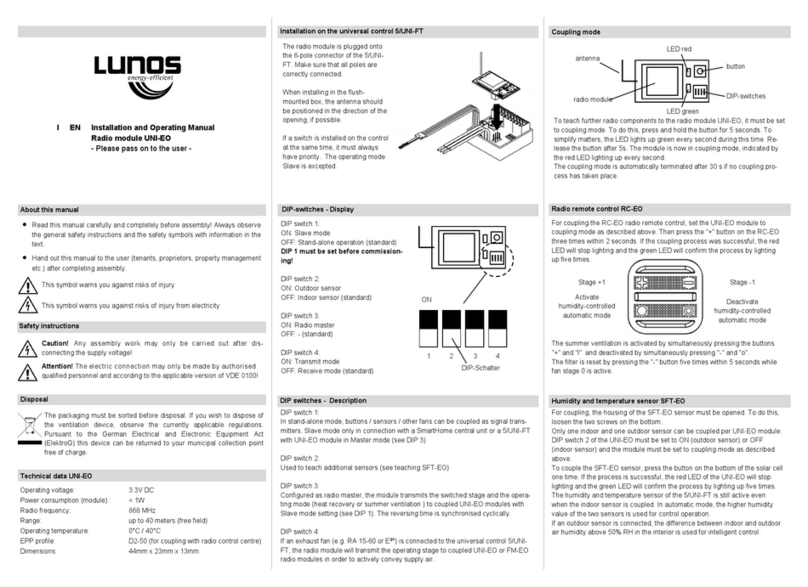

3 TESTING WITH “THE VINCI” SOFTWARE

To test IOmod with default settings, user connects device through RS485 to IEC 60870-5-103 master.

Example using “The Vinci Expert” as serial interface converter and adapter to PC with “The Vinci”

software. When opening “The Vinci” software, choose IEC 60870-5-103 – Master mode. Initial settings –

9600 baud rate; 8 data, no parity, 1 stop bit. Press Start, send Time synchronization, General

interrogation and go to the “Statistic” tab:

Fig. 3.5. Testing IOMOD device with “THE VINCI” software

As seen in Fig. 3.5, Outputs and inputs are shown with info numbers 1-8, and function types are 128 and

160 respectively.

General Interrogation, Time Synchronization and General Command options can be found at right side

of the program, in “System” tab.

Output commands are controlled by “General command” window at right side of the program, in “System”

tab, with Output address (Function type) 128, and output number (Info number). Fig. 3.6 shows 1st and

6th output command sent and “CMD ACK” response received.

Fig. 3.7 shows first 4 Outputs and last 4 Inputs grouped (notice the order of info numbers).

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Testing with “THE VINCI” software

11

Fig. 3.6. Replies from IOmod device after a command has been sent though “THE VINCI” software

Fig. 3.7. Representation of grouped output and inputs in “THE VINCI” software

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Technical information

12

4 TECHNICAL INFORMATION

System

1.

Dimensions

101 x 119 x 17.5, mm

2.

Case

IP20, blend PC/ABS self-extinguishing, black

3.

Working environment

Indoors

4.

Operating temperature

-40 ÷ +85°C

5.

Humidity

5-95% RH (non-condensing)

6.

Configuration

USB – serial console

7.

Firmware upgrade

USB – mass storage device

Electrical specifications

8.

Inputs

8 x 2kV RMS (1 minute) isolated 12-24VDC;

Selectable inversion.

9.

Outputs

8 x 3kV isolated open collector outputs (300mA

each, Max 50V);

Power

10.

Power Supply

9V to 33V

11.

Current consumption

70 mA

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Mounting and installation guide

13

5 MOUNTING AND INSTALLATION GUIDE

5.1 IOmod 8DI8DO RS485 INTERFACE

IOmod 8DI8DO has an integrated 120Ω termination resistor which can be enabled or disabled over USB

configuration. It is recommended to use termination at each end of the RS485 cable. See typical

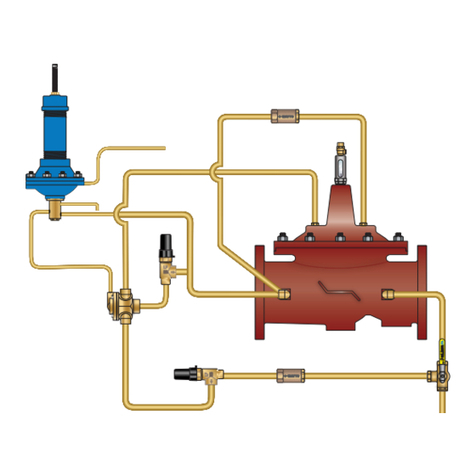

connection diagram on Fig. 5.1.

Fig. 5.1. Typical device connection diagram

IOmod 8DI8DO has 1/8 Unit load receiver which allows to have up to 256 units on line (compared to

standard 32 units). To reduce reflections, keep the stubs (cable distance from main RS485 bus line) as

short as possible when connecting device.

5.2 IOmod 8DI8DO INPUTS

Typical application of IOmod 8DI8DO inputs is shown on Fig. 5.2. When default configuration for inputs

is applied, user will see inputs connected to +12-24V as “high” or state “1” and input status LED will glow.

Fig. 5.2. Example input configuration

User also can configure to enable pull-up resistors (function is applied for all inputs) and software input

inversion. With this configuration, user will see inputs connected to 0V (see Fig. 5.3) as “high” or state

“1”, input status LED will NOT glow.

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Mounting and installation guide

14

Fig. 5.3. Configuration with pull-ups and software input inversion on input pins

5.3 IOmod 8DI8DO OUTPUTS

IOmod 8DI8DO has 8 open collector digital outputs. Internal clamp diodes are connected to each output

which makes IOmod 8DI8DO ideal for driving inductive loads like relays. Maximum 300mA per output is

allowed. For higher loads outputs can be connected in parallel. Make sure your power supply can provide

enough power. Typical application of outputs is shown on Fig. 5.4

Fig. 5.4. Typical output configuration

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Configuration over USB

15

6 CONFIGURATION OVER USB

6.1 DRIVER INSTALLATION

Device requires USB drivers to work as a Virtual COM port. First-time connection between device and

computer could result in “Device driver software was not successfully installed” error (Fig. 6.1).

Fig. 6.1. Driver software error

User then manually installs drivers by selecting downloaded driver folder:

Go to Control Panel -> Device Manager;

Select failed device;

Press “Update driver software”; screen in Fig. 6.2. should appear:

Fig. 6.2. Software update screen

Select “x86” driver for 32-bit machine, or x64 for 64-bit machine. If not sure, select root folder (folder in

which x64 and x86 lays inside).

Fig. 6.3. Folder with Elseta device drivers

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Configuration over USB

16

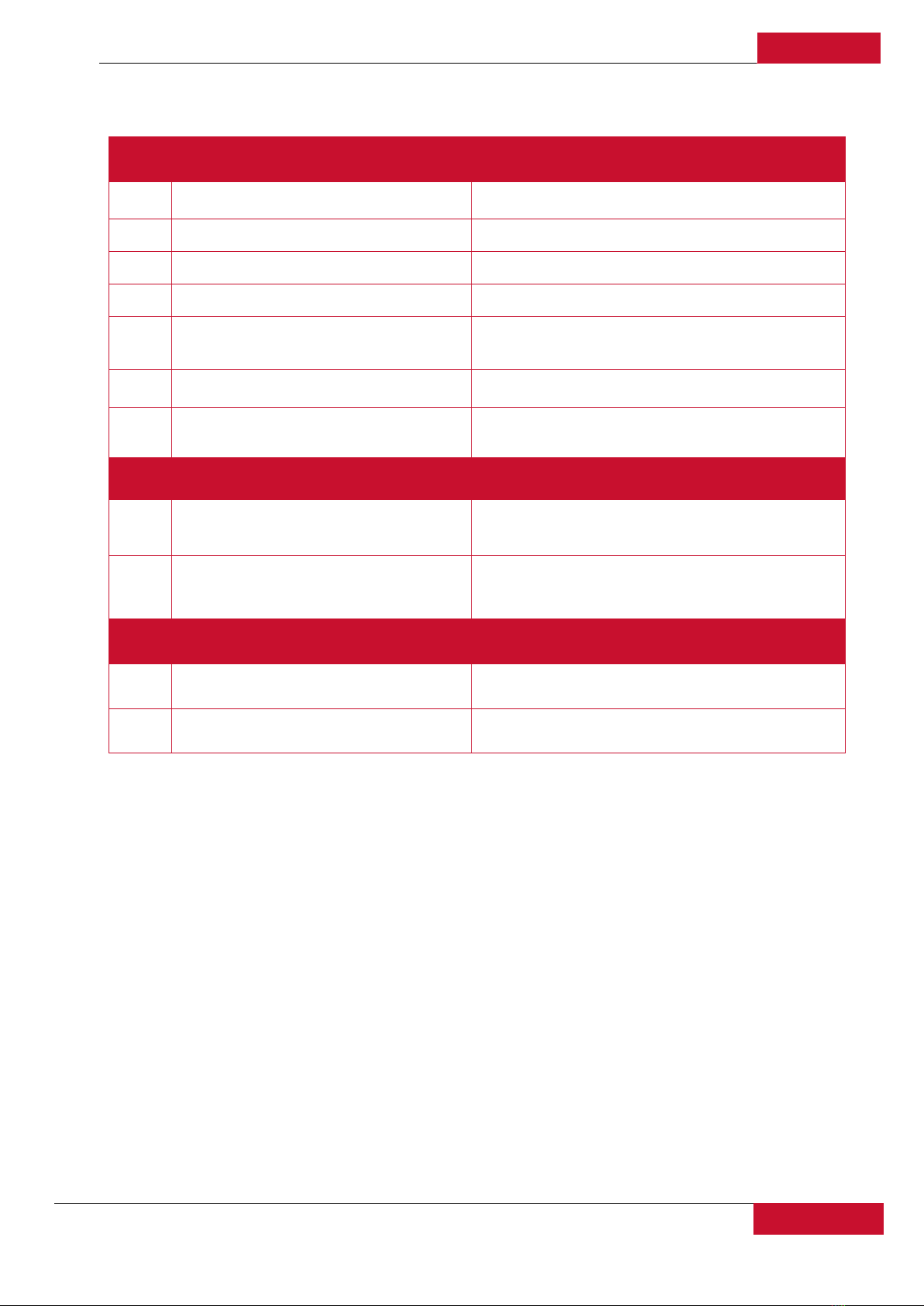

6.2 IOmod CONFIGURATION WITH PUTTY TERMINAL

Configuration of IOmod device is done through CLI (Command Line Interface) on a virtual COM port.

Drivers needed for MS Windows to install VCOM will be provided. To open up CLI simply connect to

specific V-COM port with terminal software (it is advised to use PuTTY terminal software. If other software

is being used, user might need to send <return> symbol after each command). When connected user

should immediately see main screen. Accidental close of the terminal window doesn’t stop USB

connection, user can connect terminal program again, and press any key on keyboard to show up main

menu again.

User can select the link address of the device as shown on Fig. 6.4.

Fig. 6.4. Link address selection

Navigation is performed by sending number to terminal. User then proceeds by following further on-

screen instructions. For example, to set Baud rate, press [2] to enter baud rate screen; press [1] to edit;

enter new configuration; press [RETURN] to save, or [ESC] to cancel changes. When done, press [0]

(exit) before disconnecting device. Default values is set by pressing [6] on main screen and confirming

changes [1]. Baud rate window is shown in Fig 6.5.

Fig. 6.5. Baud rate and communication settings selection

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Configuration over USB

17

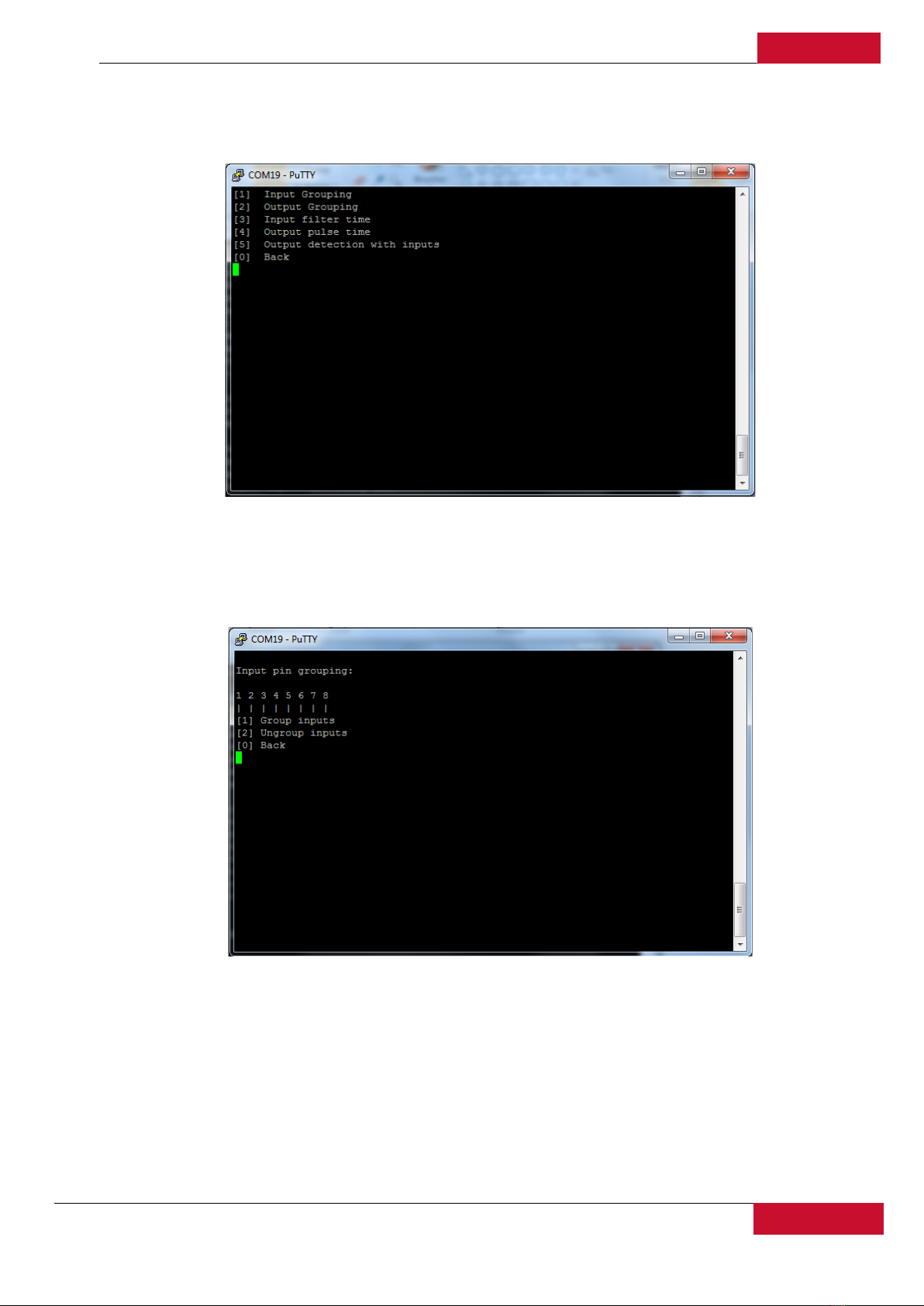

A lot of options can be changed after entering Input / Output configure screen (Fig.6.6). These include

filter time, output pulse time, input and output configuration, output detection with inputs screens.

Fig. 6.6. Input / Output Configure screen

Input (Fig.6.7) and output grouping screen show the connection between neighbour pins. Straight pins

show that input or outputs are not grouped. Grouped inputs or outputs contain fold slashes in direction

of another pin in the pair.

Fig. 6.7. Input grouping screen

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Configuration over USB

18

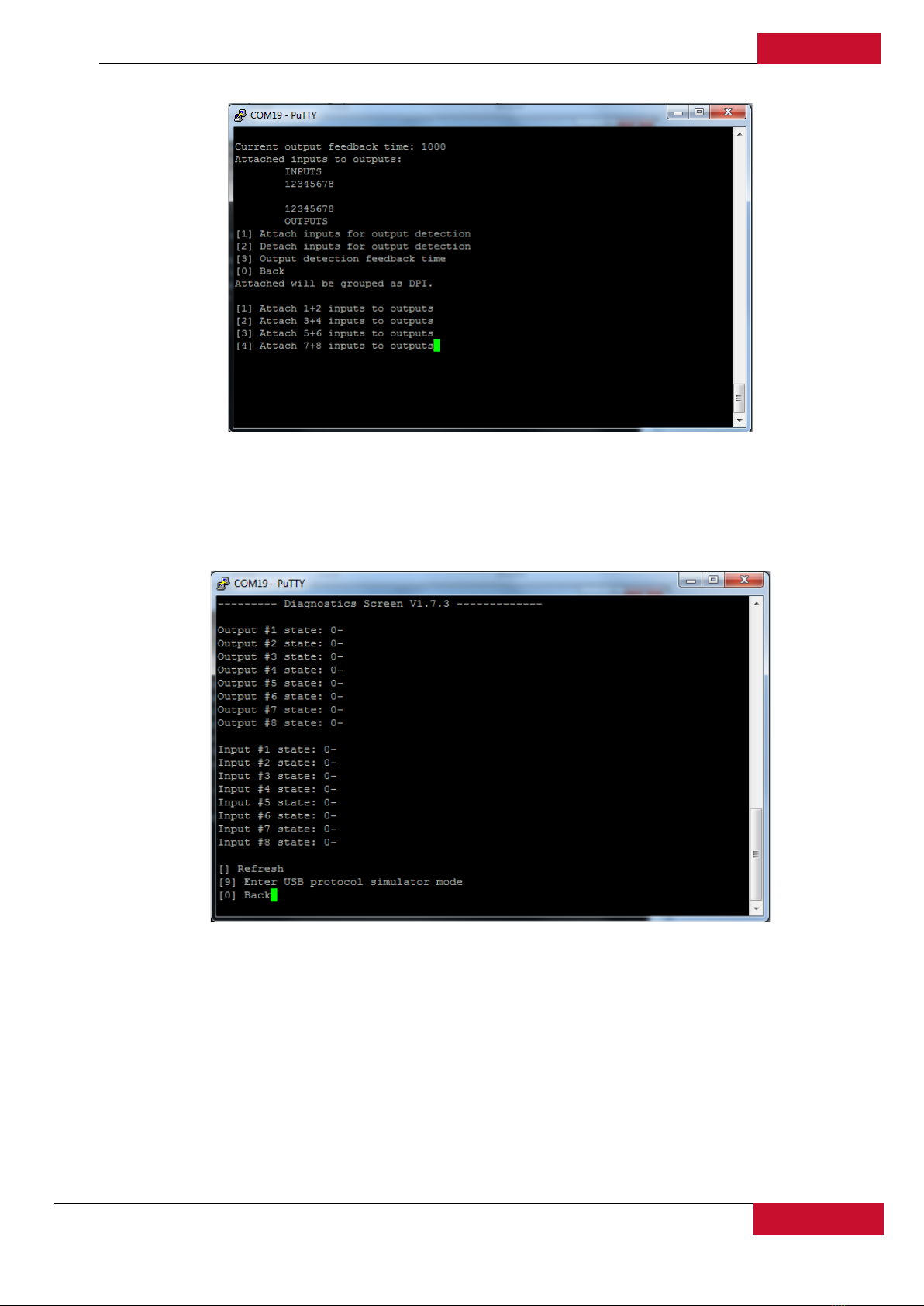

Fig. 6.8. Output detection with inputs screen

Input / Output Configure screen lets user to configure Output detection with input (Fig. 6.8). This screen

contains feedback time and connection between inputs and outputs. Connection between inputs and

outputs is noted with straight pins. Attached pins are automatically grouped to conform to IEC-

60870-5-103 protocol.

Fig. 6.10. Diagnostics screen

Changes in the device and firmware version are shown in a Diagnostics Screen. Such diagnostics screen

for IOmod 8DIDO is shown in Fig. 6.10.

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Configuration over USB

19

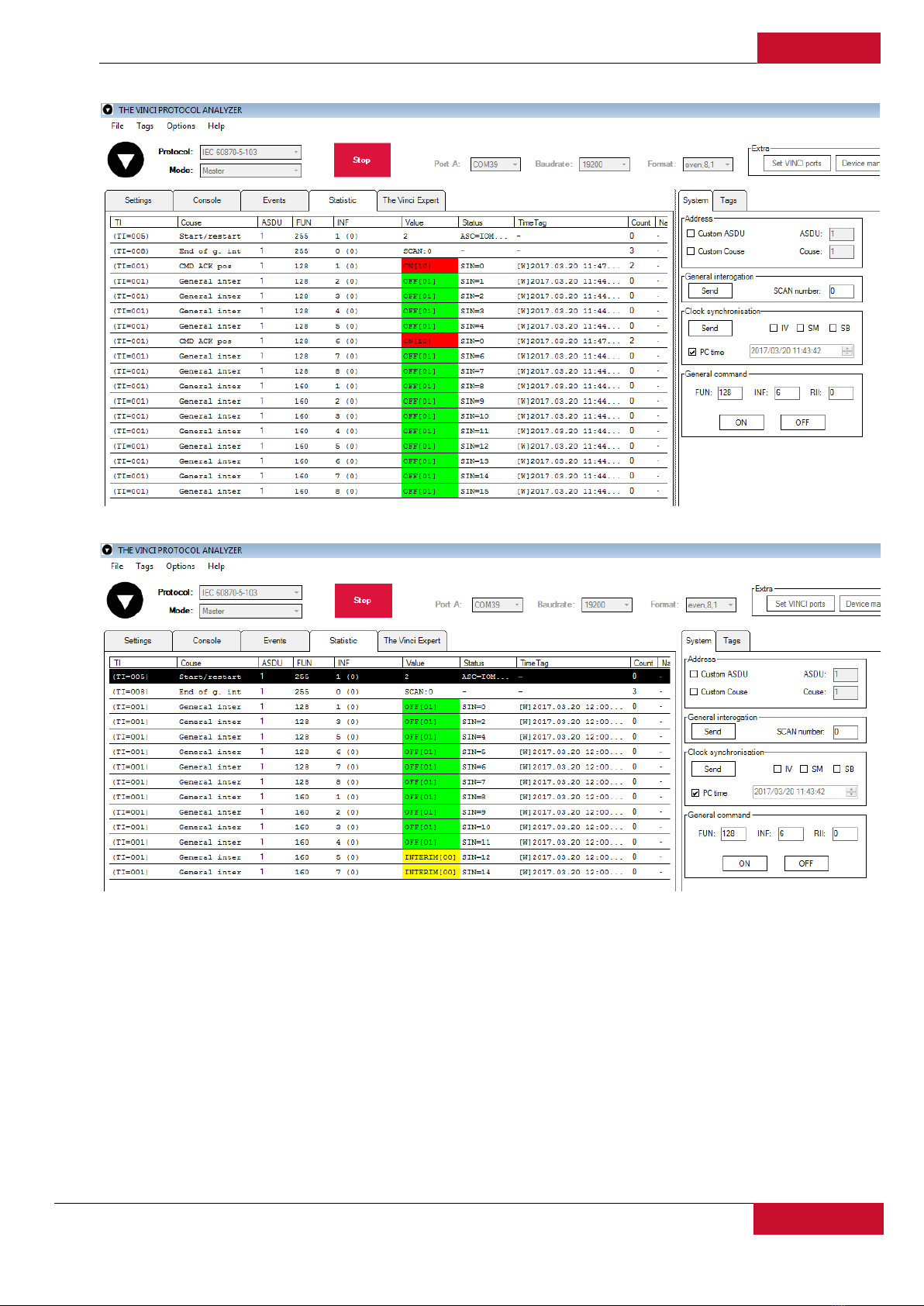

6.3 MAIN MENU

Menu Name

Function

Values

Default

Values

1.

Link Address

Setts Link address

1-255

1

2.

Baudrate, Parity

and stop bits

Enters configuring

screen for

communication

settings

8+1 or 8+2

(Data+Stop),

None, Odd,

Even, Mark,

Space (Parity)

9600,

8+1, Parity -

None

3.

Data addressing

config

Enters configuring

screen for Input/

Output address

(function type)

1 – 255 each

160 – Inputs;

128 – Outputs;

128 – Output

feedback

4.

RS485

Terminating

Resistor

RS485 120 Ohms

Terminating Resistor

0 – 1 (off/on)

1

5.

Input pull-up

enable and state

inversion

Enables input pull-up

resistor. Inputs then

activated by low

signal;

Input inversion

(Inverts input states

in protocol logic)

0 – 1 (off/on)

0 (both off)

6.

Input / Output

configure

Enters screen for

configuring (see 6.1

– 6.5 rows below)

-

-

6.1

Input grouping;

Groups or ungroups

inputs

8 inputs

ungrouped / 4

pairs grouped

All inputs

ungrouped by

default

6.2

Output grouping;

Groups or ungroups

outputs

8 outputs

ungrouped / 4

pairs grouped

All outputs

ungrouped by

default

6.3

Input filter time;

Input glitch filter –

minimum stable time

to detect input

1 – 60000

milliseconds

100

6.4

Output pulse time;

Sets output pulse

time

0 – 60000

milliseconds (0 if

not used)

0

6.5

Output detection

with inputs

(feedback)

Attach and detach

inputs to outputs for

detection;

Set detection timeout

(timeout to send

“Remote Operation”

0 – 60000

milliseconds (0 if

not used)

0

IOmod 8DI8DO

4/17/2019

V1.1 | ELSETA | Configuration over USB

20

Menu Name

Function

Values

Default

Values

if inputs not

triggered)

7.

Set Default

Settings

Sets Default Settings

(1 to confirm, 0

to cancel)

-

8.

Firmware Upgrade

Mass Storage Device

Firmware Upgrade

(1 to confirm, 0

to cancel)

-

9.

Diagnostics

Input / Output states

-

-

0.

Exit

Exit and disconnect

-

-

6.4 PROTOCOL SIMULATOR

When entered diagnostics screen, user can turn on protocol simulator by pressing [9]. When protocol

simulator is turned on, device will communicate through USB port rather than RS-485 line.

Communication on RS-485 line is closed and all IEC-103 commands will be accepted only from USB. To

exit this mode user must restart device.

6.5 FIRMWARE UPGRADE OVER USB

To update device firmware user must enter main configuration menu and enter Firmware upgrade screen

by pressing [4] is shown in Fig 6.11.

Fig. 6.11. Firmware upgrade confirm window

Confirm upgrade by pressing [1];

Device should enter a Firmware Upgrade mode. It means that device switches from USB Console mode

into Mass storage device and computer recognize it as USB Storage.

It is recommended to close terminal window when entered firmware upgrade mode.

Device should the reconnect as a Mass Storage Device:

Other manuals for IOMOD 8DI8DO

1

Table of contents

Popular Control Unit manuals by other brands

Lexicon

Lexicon NUVERB TDM - REV manual

Symmons

Symmons 3DIVBODYSRT Operation & maintenance manual

CORNING

CORNING Pretium EDGE ETM-7B-G Installation and Testing

Solar Frontier

Solar Frontier SolarSet 2.0 Safety Guidelines

Reznor

Reznor RHCLN Installation, commissioning, servicing

schmersal

schmersal SRB 206ST operating instructions

National Instruments

National Instruments NI 9770 Getting started guide

Honeywell

Honeywell RV281 installation instructions

Watts

Watts LFM127-2 Series Installation, operation and maintenance

Crestron

Crestron BiAmp AudiaFlex quick start guide

Nigos

Nigos MC-3000 user manual

Emerson

Emerson KEYSTONE F320 Operating and safety instructions