SRP 003-126, Issue 1

STANDARD RECOMMENDED PROCEDURE 003-126 | ISSUE 1 | OCTOBER 2012| PAGE 1 OF 9

| PRETERMINATED SYSTEMS | CABLES | CONNECTORS | CABLE ASSEMBLIES | HARDWARE | TOOL KITS AND ACCESSORIES | TEST EQUIPMENT | SPLICE EQUIPMENT | FAN-OUT KITS |

Pretium EDGE®Tap Module

Installation and Testing

1. General

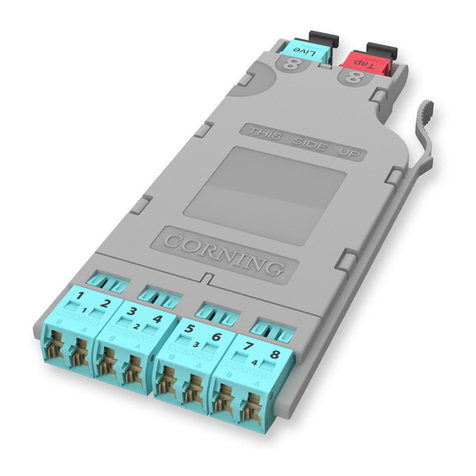

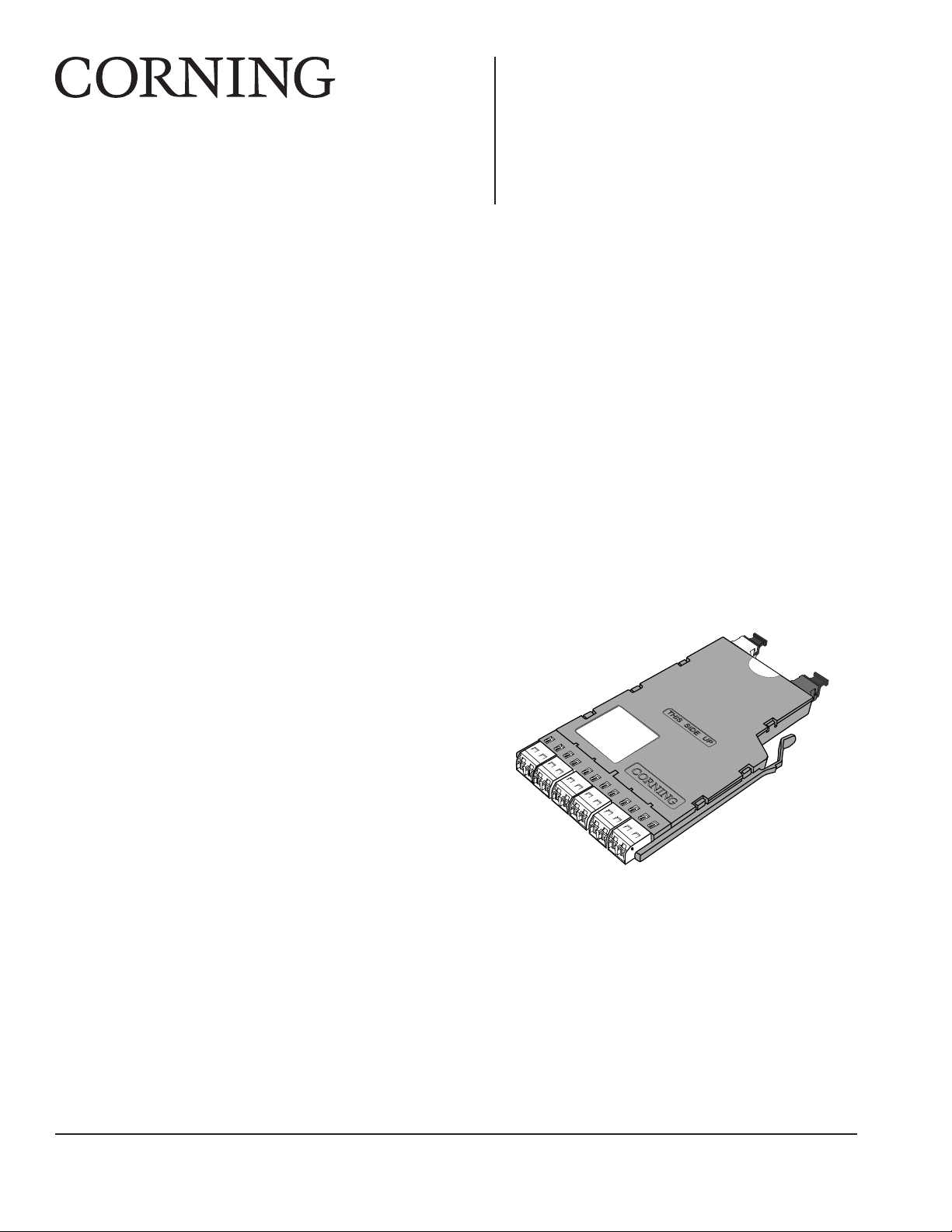

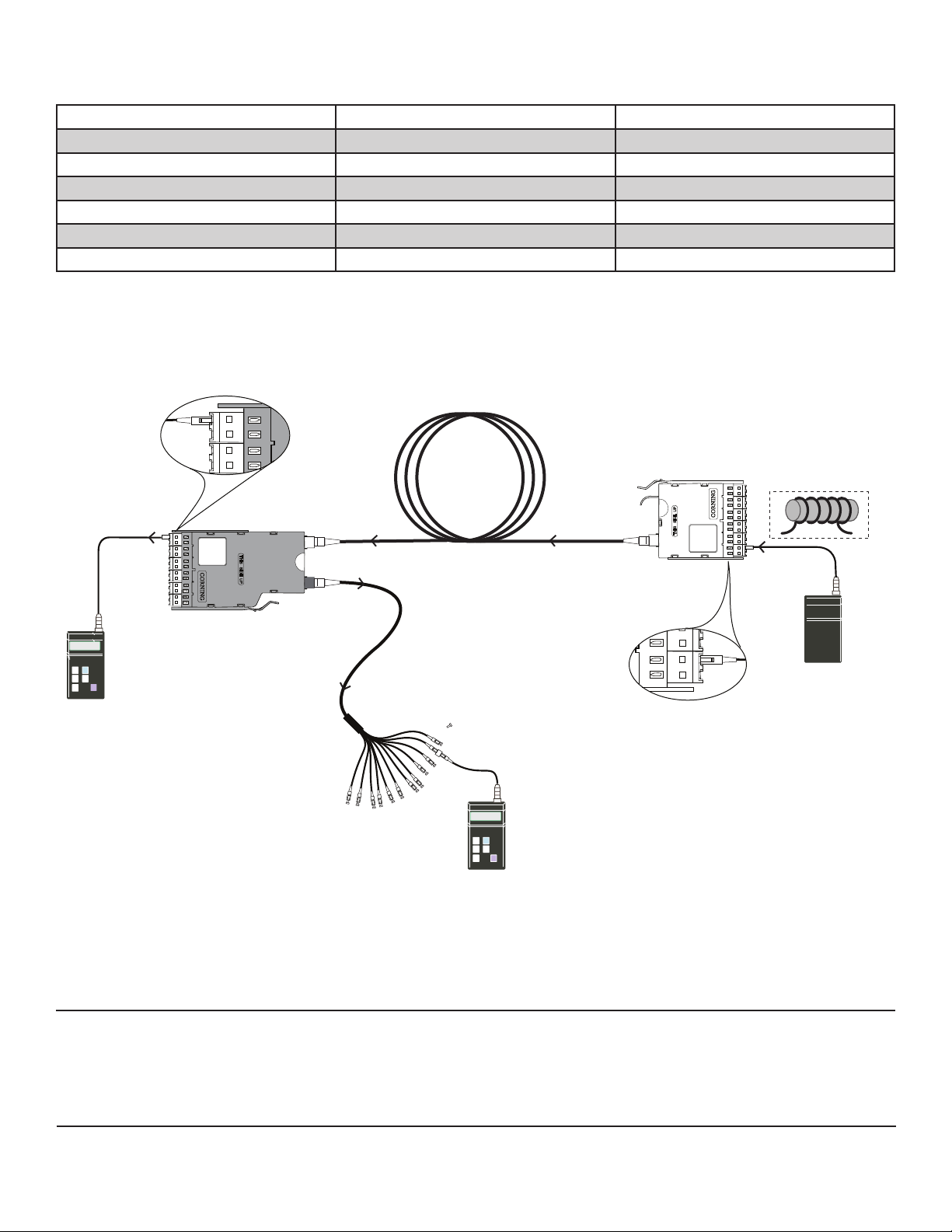

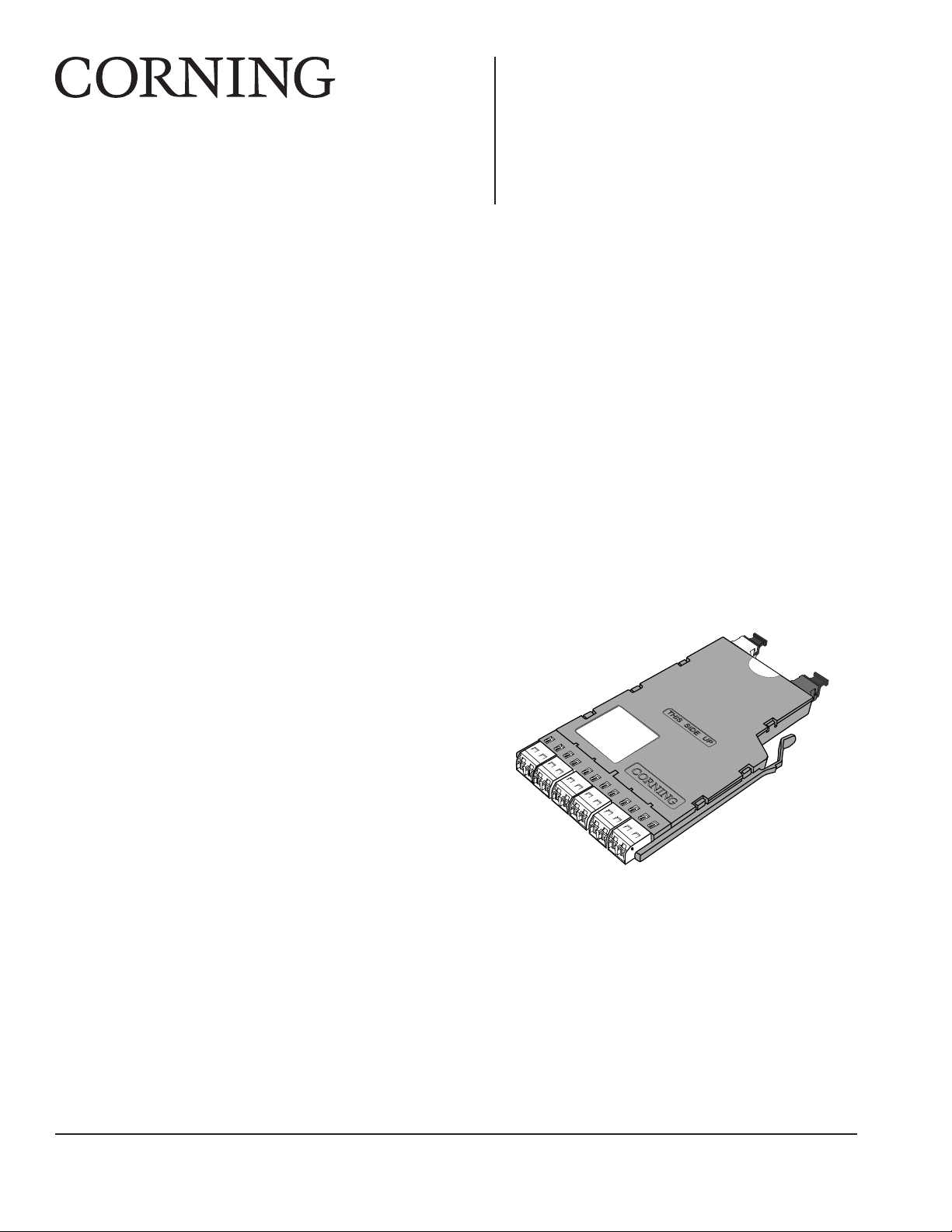

1.1 This procedure describes Pretium EDGE

Tap Modules, which are available for both multimode

and single mode applications. Compatible with all

Pretium EDGE rack-mountable connector housings,

TAP modules have twelve front-mounted shuttered

LC adapters and two MTP®connectors in back

(Figure 1).

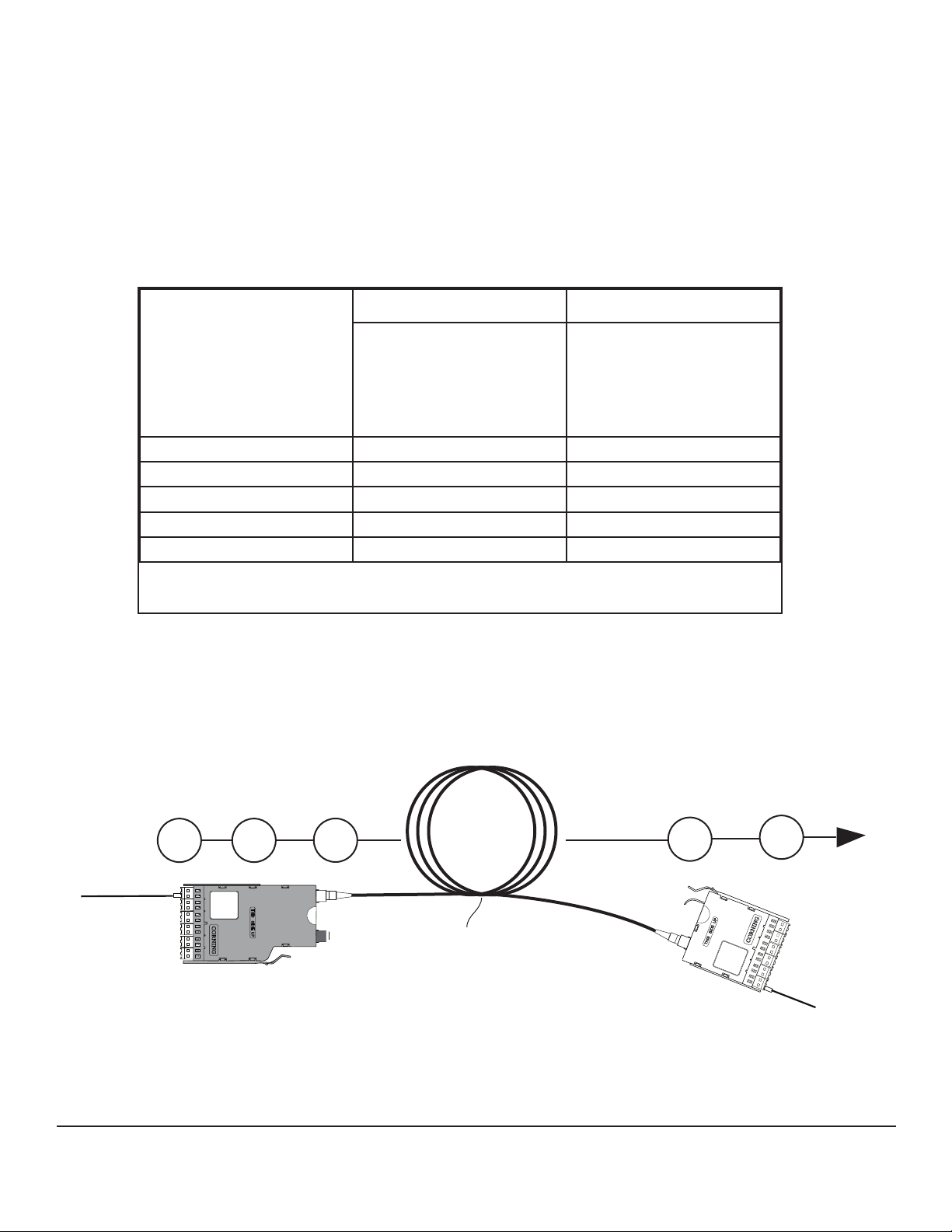

1.2 Themodulecontains12beropticsplitterswhichdividetheincomingopticalsignalsintotwo

outputs,oneforlivelinktrafcandoneformonitoring.Themonitortrafcisroutedviathe“TAP”-labeled

MTPconnectortoamonitoringdevicewhichltersthedataandsendsittovarioussoftwaretoolsfor

analysis, where it is then viewed in application-layer software for security threats, performance issues, or

system optimization.

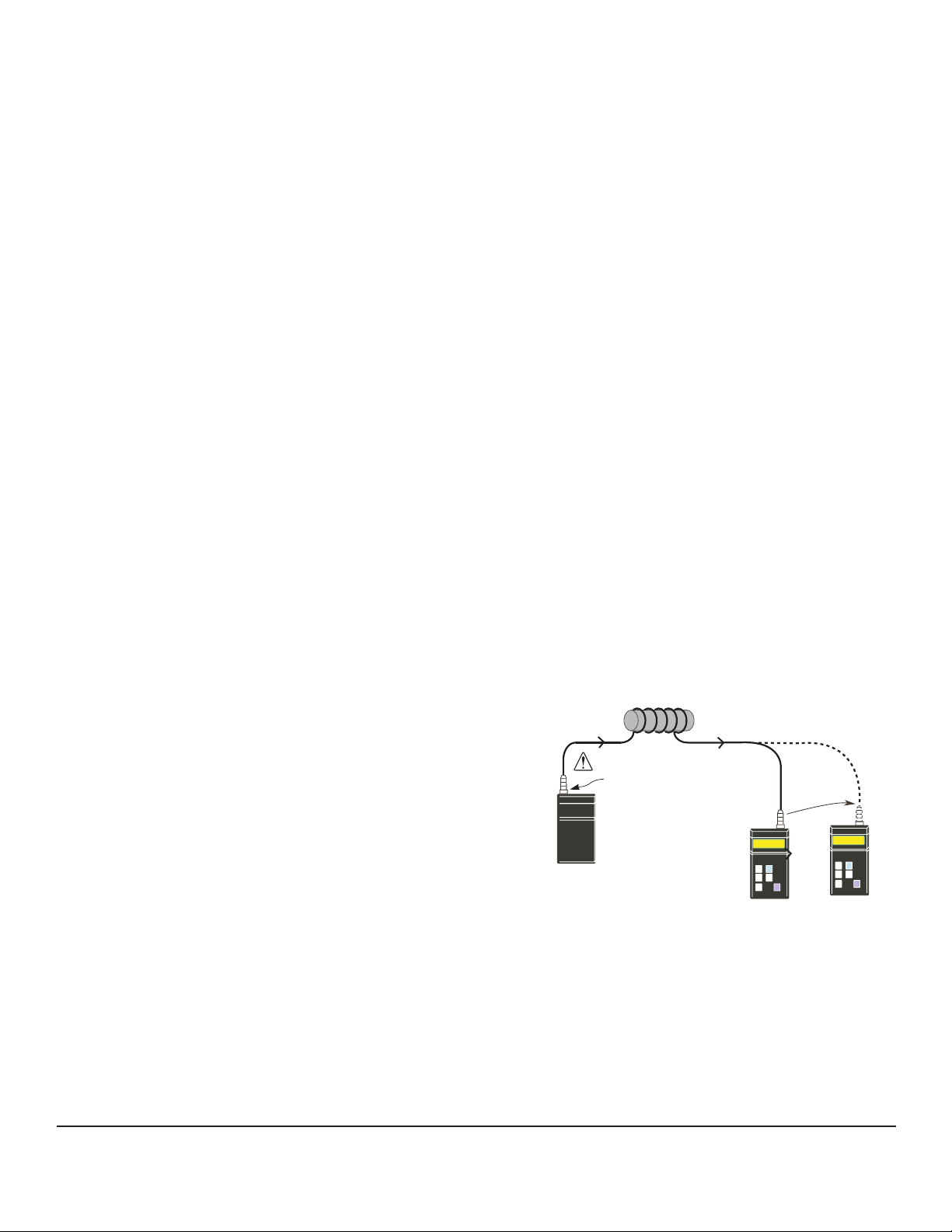

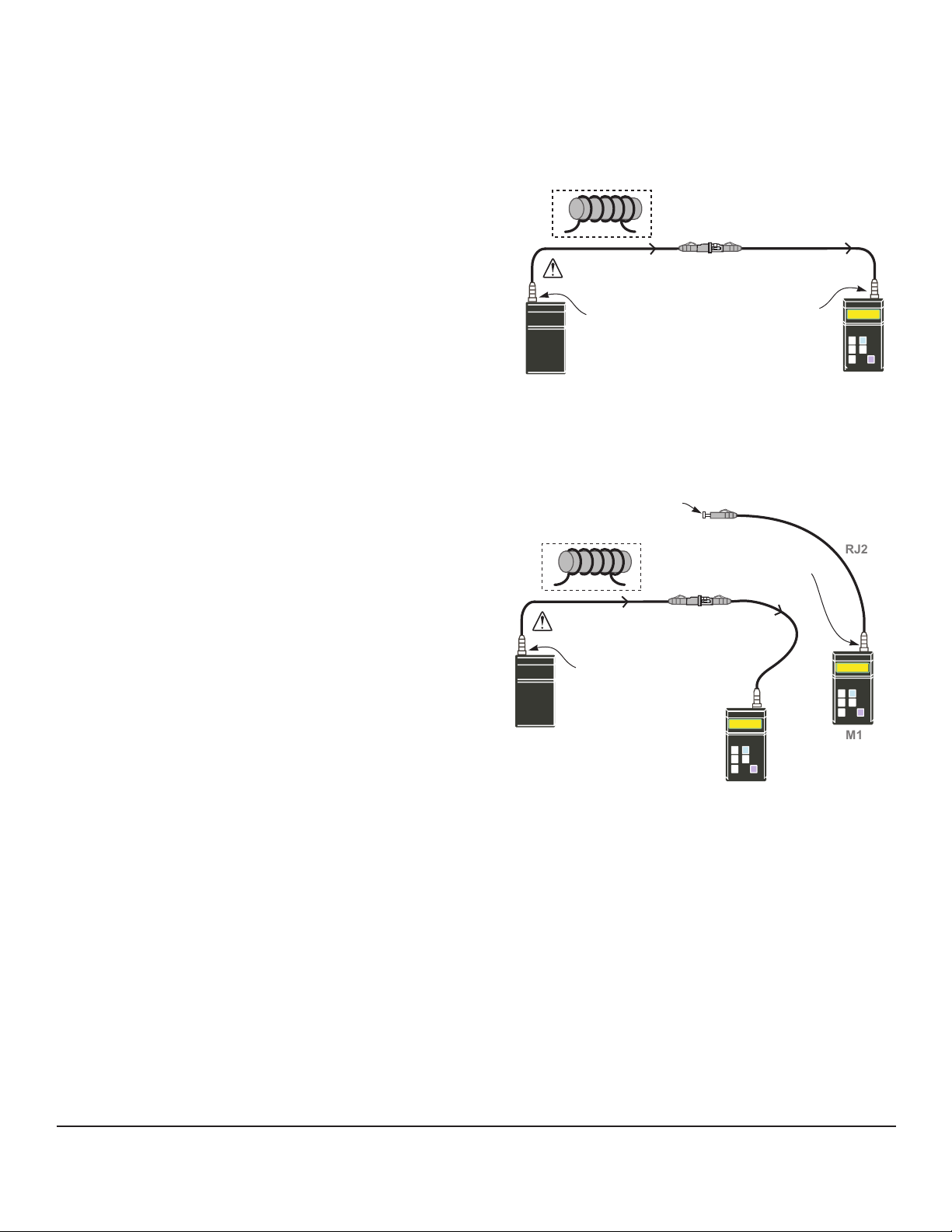

IMPORTANT: Please note that Tap module systems have two outputs for each input, which may

requiretwopowermeters,anddependingonthesystemconguration,possiblyrequireanadditional

craftsperson in another location.

1.4 If this procedure is reissued, a summary of the changes will appear in this paragraph.

2

1

BA

1

4

3

BA

2

6

5

BA

3

8

7

BA

4

10

9

BA

5

12

11

BA

6

VOID

W

A

R

R

A

N

T

Y

Port Tap Module

M

Part Number:

Serial

MADE IN MEXICO

US PATENT NO.

TAP LIVE

Figure 1

HPA-0753

related literature |

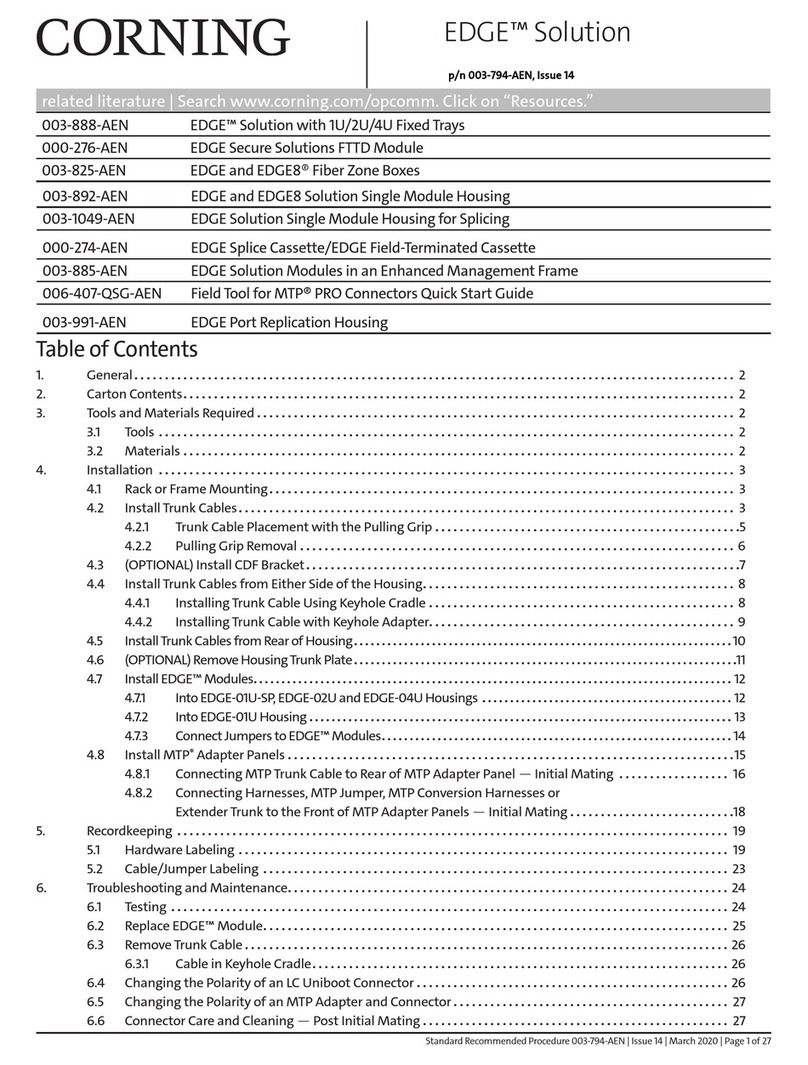

SRP-003-794, Pretium EDGE®Solution

SRP-006-136,MultiberConnectorandPortCleaningwiththeTKT-CLEAN-MFC-Mkit

table of contents |

1. General .................................................................................................................................................1

2. Precautions ...........................................................................................................................................2

3. Tools and Materials ...............................................................................................................................2

4. Connector and Adapter Cleaning ..........................................................................................................2

5. Calculating System Loss .Budgets .......................................................................................................3

6. The Functionality of the Tap Module Splitters .......................................................................................5

7. Installing Pretium EDGE Tap Modules ...................................................................................................6

8. Referencing the Test Equipment for a Tap Module ...............................................................................6

9. Testing Pretium EDGETap Modules .....................................................................................................8