elsner elektronik WS1000 Style User manual

WS1000 Connect assembly 1

WS1000 Connect assembly • Version: 07.09.2021 • Technical changes and errors excepted. • Elsner Elektronik GmbH • Sohlengrund 16 • 75395 Ostelsheim • Germany • www.elsner-elektronik.de • Technical Service: +49 (0) 7033 / 30945-250

Assembly - Brief instructions

WS1000 Connect controls

Article numbers 60241-60246

Attention, mains voltage!

VDE (German Association of Electricians) regulations are to

be observed. Installation, checking, commissioning and

troubleshooting the device may only be performed by

skilled electricians (pursuant to VDE 0100).

Notes on wireless equipment

When planning facilities with devices that communicate via radio, adequate radio

reception must be guaranteed. The range will be limited by legal regulation and

structural circumstances. Avoid sources of interference and obstacles between re-

ceiver and transmitter, that could disturb the wireless communication. Those

would be for example:

• Walls and ceilings (especially concrete and solar protection glazing).

• Metal surfaces next to the wireless participants (e. g. aluminium

construction of a conservatory).

• Other wireless devices and powerful local transmitters (e.g. wireless

headphones), which transmit on the same frequency. Please maintain a

minimum distance of 30 cm between wireless transmitters for that reason.

Preparing the installation location

The device must only be installed and operated in dry, indoor spaces.

Avoid condensation.

Concealed box cut-out dimensions:

W = 248 mm +1 -0

H = 165 mm +1 -0

D = 84 mm

Preparing the control unit

The WS1000 Connect assembly is delivered assembled. Therefore, the device

first has to be dismantled. After installing the concealed box the electrics, the de-

vice is reassembled in the reverse order.

When handling the display unit, take care with the loudspeaker (1). It is connected

magnetically and with thin, sensitive wires.

For maintenance, the covers can be carefully pried out in order to access the

screws.

BEWARE!

Mains voltage!

Beneath the safety cover there are unprotected live components.

Store the circuit board in a location protected against dirt. It must never be ex-

posed to dust or moisture!

Mounting on the wall

Cavity wall installation

The bag with the installation screws is in the concealed box for the controls when

delivered.

Connection and installation of the control unit

For the electrical installation, guide all the connection cables through the lower or

upper side wall into the concealed box. Keep the connection wires short here to

prevent loops.

After installation of the concealed box, screw the circuit board back in. Connect the

power supply, weather station, display, network and all devices, motors, buttons,

etc. (step 6 and chapter Structure of the connection board).

WARNING!

Danger from electrical voltage (mains voltage)!

The concealed box contains uncovered live components.

Attach safety cover before the controls are commissioned.

Pass the display cable through the square cut-out of the black support plate and

screw the plate to the concealed box (step 4). The screws must grip securely into

the threads of the concealed box in order to support the display unit.

Cover the support plate screw connection with the caps provided.

Connect the display unit (step 3).

Hang the display unit at the top of the support plate and fold it down (step 2). The

display snaps in but also has to be secured with 2 screws (step 1).

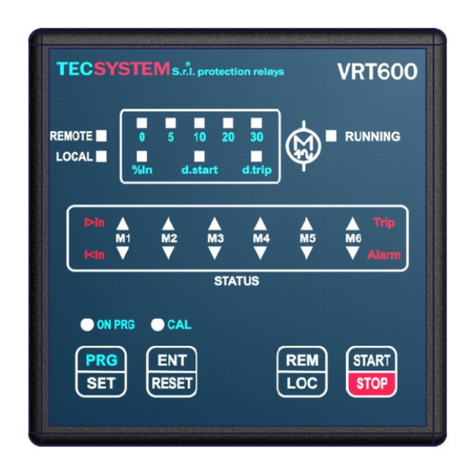

Structure of the WS1000 Connect connection board

*Power supply to the indoor sensor

The indoor sensor can be powered with +12 V DC via the multifunction inputs:

No. 21, terminal 1(+), 2(-) | 4(+), 5(-)

No. 23, terminal 3(+), 4(-) | 6(+), 7(-)

total maximum 400 mA

Structure of the WS1000 Connect PF (potential-free) connection

board

*Power supply to the indoor sensor

The indoor sensor can be powered with +12 V DC via the multifunction inputs:

No. 19, terminal 1(+), 2(-) | 4(+), 5(-)

No. 21, terminal 3(+), 4(-) | 6(+), 7(-)

total maximum 400 mA

Separate installation of display and power electronics

The display with support panel and power electronics can be installed at separate

locations, for example if the power electronics are to be houses in a distribution

cabinet. Install the power electronics correctly, e.g. in the concealed box and with

the cover provided.

In order to install the display without the concealed box, place two standard

switch boxes at a normal distance above each other (71 mm). The support panel

is mounted on top so that the round cut-outs in the panel sit over the sockets. The

loudspeaker then sinks into the lower socket.

DANGER!

Danger to life from electrical voltage (mains voltage)!

If the display unit is installed separately, unshielded

components are in the installation sockets. Voltage

can jump to the device if these components come

into contact with defectively insulated cables.

• Mains voltage cables in the sockets must have stronger

insulation (coat undamaged).

Use the support panel as a drill template. Place it over the position of the two stan-

dard switch boxes and mark the 4 drill holes for the 4 fixing screws. Use suitable

fastening material (anchors) for the base.

To connect the display and power electronics, a Cat.6A network cable is used, the

shield of which is branched and whose cross section is at least AWG28. The con-

nection cable must not be more than 10 m long.

The manual with additional information about commissioning,

functions and use of the controls WS1000 Connect can be

downloaded from www.elsner-elektronik.de in the menu area

"Service/Downloads".

Step 1 Display from below

The display unit is screwed to the sup-

port plate from below. Loosen the

screws.

Step 2 Display from the side

Hold the lower section of the display

unit and pull forwards, and hang it on

the upper edge.

The display can now be removed.

Caution! The display is connected

to the connection board in the

concealed box by a cable.

1

2

Display from above

Detailed view: Notices

and mounts of the dis-

play unit.

Step 3 Display reverse

Loosen the cable connection between

the display unit and circuit boards.

1 Loudspeaker

2 Socket without function (only for

KNX-capable model)

1

2

Step 4 Support plate on concealed

boxes

Remove the support plate from the

concealed box. To do this, loosen the

4 screws.

Support plate on concealed box

After commissioning the screws

should be covered with the supplied

covers.

Step 5 Concealed box with safety co-

ver

The safety cover in the concealed box

is fastened with four screws. Loosen

the screws and remove the cover.

Step 6 Concealed box with circuit

board

Remove the circuit board to install the

concealed box.

Step 7 Concealed box

Place the concealed box in the wall so

that the arrow points up.

Step 8a Concealed box with plaster-

board

For plastering, screw the plaster cover

(board) to the concealed box using the

enclosed screws. As a result, the box

moves less when plastered over.

Step 8b Cavity wall installation faste-

ning screws

Clamp the concealed box to the wall

using the four enclosed screws.

or

20

1 2

3 4

5

6

7 8 9 10 11

12 13 14 15 16

17

18

19

21 22 23

24

25

26

27

28

1 Multifunction output 1

(potential-free)

2 Multifunction output 2 (pot.free)

3 Multifunction output 3 (pot.free)

4 Multifunction output 4 (pot.free)

5+6Outer conductor L1

7-11Motor group 1-5

12-16Motor group 6-10

17 Mains connection L/N/PE 230 V/

50 Hz

18 Wall sensor 1 (terminal 1-3),

2 (terminal 4-6), 3 (terminal 7-9),

4 (terminal 10-12)

19 Wall sensor 5 (terminal 1-3),

6 (terminal 4-6), 7 (terminal 7-9),

8 (terminal 10-12)

20 Wall sensor 9 (terminal 1-3),

Wall sensor 10 (terminal 4-6)

21*Multifunction input 1 (terminal 1-3),

MF input 2 (terminal 4-6)

22 Weather station (terminal 1-2)

Wire assignment: red = 1, black = 2,

yellow and white = not connected

23*Multifunction input 3 (terminal 3-5),

MF input 4 (terminal 6-8)

24 Socket connection display unit

(with power cable)

25 Socket for network connection

(LAN)

26 Micro-fuse T6,3 A (motor 1-5)

27 Micro-fuse T6,3 A (motor 6-10)

28 Micro-fuse T630 mA

18

1 2

3 4

5 6 7

10 11 12 13 14

15

16

17

19 20 21

22

23

24

8 9

1 Multifunction output 1

(potential-free)

2 Multifunction output 2 (pot.free)

3 Multifunction output 3 (pot.free)

4 Multifunction output 4 (pot.free)

5-9Motor group 1-5

10-14 Motor group 6-10

15 Mains connection L/N/PE 230 V/

50 Hz

16 Wall sensor 1 (terminal 1-3),

2 (terminal 4-6), 3 (terminal 7-9),

4 (terminal 10-12)

17 Wall sensor 5 (terminal 1-3),

6 (terminal 4-6), 7 (terminal 7-9),

8 (terminal 10-12)

18 Wall sensor 9 (terminal 1-3),

Wall sensor 10 (terminal 4-6)

19*Multifunction input 1 (terminal 1-3),

MF input 2 (terminal 4-6)

20 Weather station (terminal 1-2)

Wire assignment: red = 1, black = 2,

yellow and white = not connected

21*Multifunction input 3 (terminal 3-5),

MF input 4 (terminal 6-8)

22 Socket connection display unit

(with power cable)

23 Socket for network connection

(LAN)

24 Micro-fuse T3,1 A

All dimensions in mm

EN

WS1000 Connect assembly 2

WS1000 Connect assembly • Version: 07.09.2021 • Technical changes and errors excepted. • Elsner Elektronik GmbH • Sohlengrund 16 • 75395 Ostelsheim • Germany • www.elsner-elektronik.de • Technical Service: +49 (0) 7033 / 30945-250

Wiring diagrams

Motor and MF outputs WS1000 Connect (60241-60244):

max. 400 W per motor output,

total max. 1.5 kW for all motor outputs

Motor and MF outputs WS1000 Connect-PF (60246):

per motor output max. 5 A / 230 V

Motors with different voltages may be operated at the drive outputs (230 V AC and

low voltages SELV). The low voltage drives still correspond to the SELV specifica-

tions.

230 V and SELV must not be mixed at adjacent multifunction outputs (1 and 2 or

3 and 4). A mixed connection does not correspond to the SELV specifications. Ei-

ther 230 V or extra-safety voltages are permitted here.

E.g. it is possible to connection SELV to MF outputs 1 and 2 and 230 V to MF out-

puts 3 and 4 (or vice versa).

Inputs:

Connection examples for multifunction outputs

230 V consumers at MF outputs:

Low-voltage consumers and potential-free contacts at MF outputs:

Technical Data, central unit WS1000 Connect

The product is compliant with the provisions of EU Directives.

MF Output 1 MF Output 2 MF Output 3

Neutre

Heating valve 230V

Lamp 230V

Protection / relay (on-site)

MF Output 4

Borne L1 / L1

Fan 230V

F1 6,3A retardé

Radiant heater

Housing Glass, plastic

Colour black

Assembly Flush / cavity wall

Degree of protection IP 20

Dimensions Display front approx. 279 x 185 (W x H, mm),

Installation depth approx. 29 mm,

Concealed box approx. 254 × 171 × 85 (W × H

× D, mm)

Display resolution 1280 × 800 px

Weight approx. 2.2 kg for model WS1000 Connect-10

Ambient temperature Operation 0...+45°C, Storage -30…+70°C

Ambient humidity 5…95% RH, avoid condensation

Operating voltage 230V AC, 50 Hz

Power consumption Readiness max. 17 W

Load capacity

Motor outputs

230 V outputs:

per motor output, max. 400 W,

total max. 1.5 kW

Potential-free outputs (PF model):

per motor output max. 5 A / 230 V

Radio frequency radio

channels

868.2 MHz (Elsner RF).

WLAN frequency band 2.4 GHz and 5 GHz

MF Output 1 MF Output 2 MF Output 3 MF Output 4

e.g. 24V (ext. power supply)

Heating valve 24V

other consumers 24V

Thermostat

Signal contact for e.g.

rain / wind / frost /

smoke detector / alarm

replacement

(on-site)

Other manuals for WS1000 Style

7

This manual suits for next models

11

Other elsner elektronik Control System manuals

Popular Control System manuals by other brands

Intellitec

Intellitec SMART EMS Service manual

CAME

CAME DIR10 instructions

Vertiv

Vertiv Liebert iCOM CMS Installer/user guide

Leb Electronics

Leb Electronics CTR500 instructions

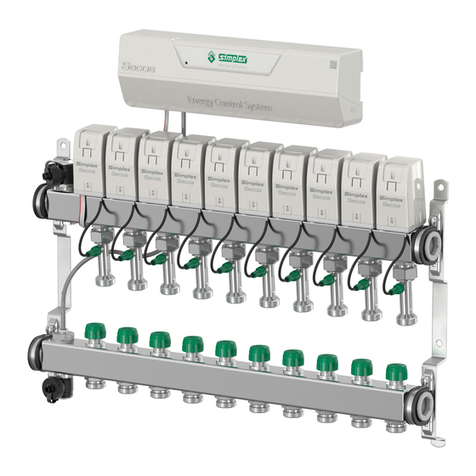

Simplex

Simplex Secos Installation instructions operating instructions

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries SC-SL2NA-E Technical manual