Elsner KNX PS640+IP Guide

Power Supply System

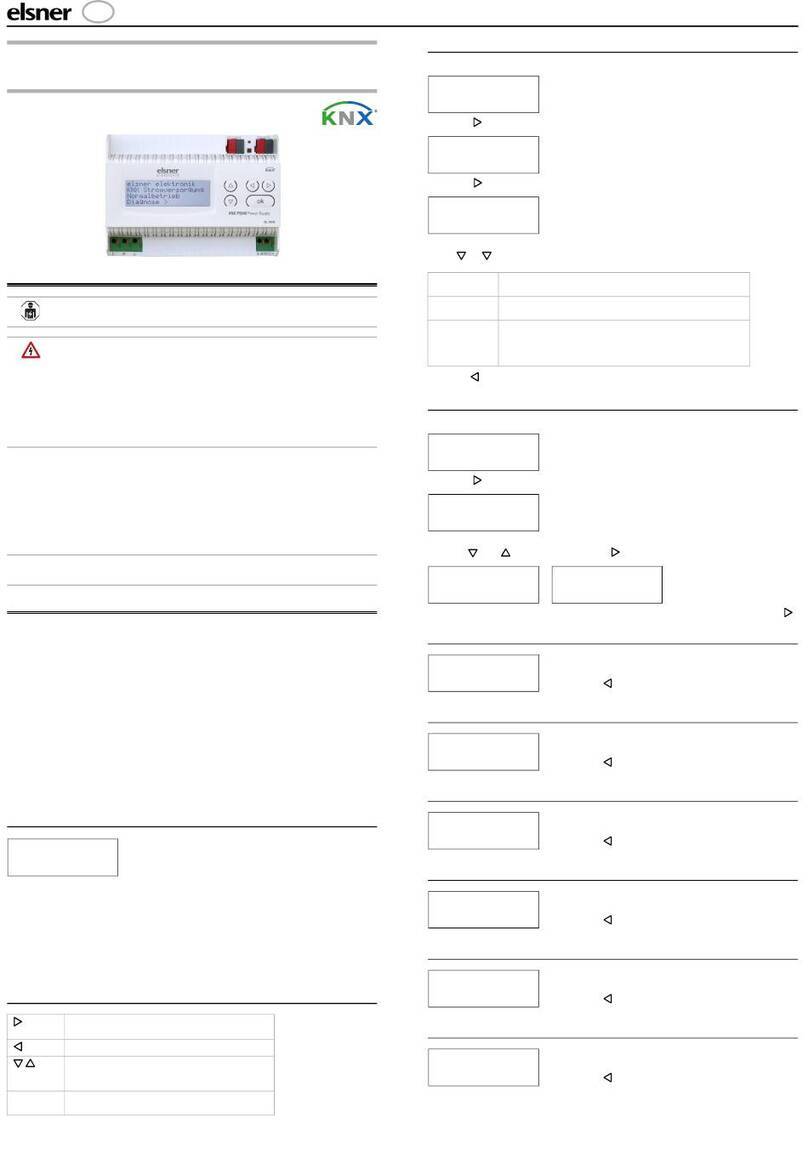

KNX PS640+IP

with Bus Functions and Ethernet Interface

Item Number 70145

Installation and Adjustment

Elsner Elektronik GmbH Control and Automation Technology

Sohlengrund 16 | 75395 Ostelsheim | Germany

Tel.: +49 (0) 70 33 / 30 945 - 0 | Fax: +49 (0) 70 33 / 30 945 - 20

2

Contents

Product description.......................................................................................................3

Technical data ...................................................................................................................................... 4

Application examples....................................................................................................4

IP Interface............................................................................................................................................ 4

Installation and commissioning ....................................................................................7

Connection ........................................................................................................................................... 7

KNX communication of IP interface and power supply unit .........................................8

Addressing ........................................................................................................................................... 9

Settings in der ETS .............................................................................................................................. 9

Settings at the device ...................................................................................................9

Starting position .................................................................................................................................. 9

Line reset ............................................................................................................................................ 10

Data memory ..................................................................................................................................... 10

Operating data ................................................................................................................................... 12

Language............................................................................................................................................ 12

Addressing the power supply unit (programming mode)............................................................. 12

Setting of parameters in the ETS ................................................................................14

Parameters of the IP interface .......................................................................................................... 14

Communication settings in the ETS............................................................................20

Setting the bus functions of the power supply unit in the ETS ..................................21

Transmission protocol ...................................................................................................................... 21

Parameters of the power supply unit .............................................................................................. 22

KNX PS640+IP from software version display 3.3, IP chip 2.0, ETS programme version 1.0

Version: 23.02.2016. Errors excepted. Subject to technical changes.

3

Product description

The Power Supply System KNX PS640-IP combines the central functions of a KNX bus

line:

Power supply with throttle and bus communication

IP router and IP interface

The device has got two KNX interfaces, one for the “PLUS” functions of the power

supply unit and one for the IP router. The functions are registered at the bus separately

and parametrised in different product files (ETS).

The power supply unit of the KNX PS640+IP delivers a 29 V bus voltage for the KNX

system and 24 V DC supply voltage for 24 V devices. Special operating conditions such

as short circuit, electrical surge, overcharge or excess temperature are recorded and

may be read off on the display. The present power discharge is displayed as well. It is

possible to reset the connected bus devices directly by means of the key pad.

In addition all functions can be realised via the bus, too, e. g. the transfer of malfunction

messages and operating data and a time/period reset. Malfunction messages are stored

by the KNX PS640+IP.

The IP router of the KNX PS640+IP allows for forwarding of telegrams between

different lines via a rapid LAN (IP) backbone. The KNX PS640+IP therefore also takes on

the function of a line coupler.

In parallel, the KNX PS640+IP can be used as interface for accessing the bus via IP.

Like this, the KNX system can be configured and supervised from any PC in the LAN

(Tunnelling). Access via smartphone (KNX app) is also possible.

This device works according to the KNXnet/IP specification using the core, the device

management, the tunnelling and the routing part. The router of KNX PS640+IP has a

filter table and is able to buffer up to 150 telegrams.

Functions:

Delivers a 29 V KNX bus voltage (reduced), output current max. 640 mA, short-

circuit proof

Delivers 24 V DC (not reduced), output current max. 150 mA

Reset of a line directly on the device

Record of operating hours, overload, external overvoltage, internal overvoltage,

short circuit and excess temperature

Display of operating data bus voltage, bus current and temperature of the device

The display may be shown in German, English, French, Italian, Spanish or Dutch

Bus connection for data transfer (e. g. malfunction messages, operating data)

Possibility for reset and diagnostic via the bus

Routing: Transfer of KNX data via LAN (rapid backbone)

Line coupler function via LAN

Tunnelling: Configuration and supervising of the KNX system from any PC in the

LAN, access via smartphone (KNX app)

4

Configuration is made using the KNX software ETS. The product file, the data sheet and

the manual can be downloaded from the Elsner Elektronik homepage on www.elsner-

elektronik.de in the “Service” menu.

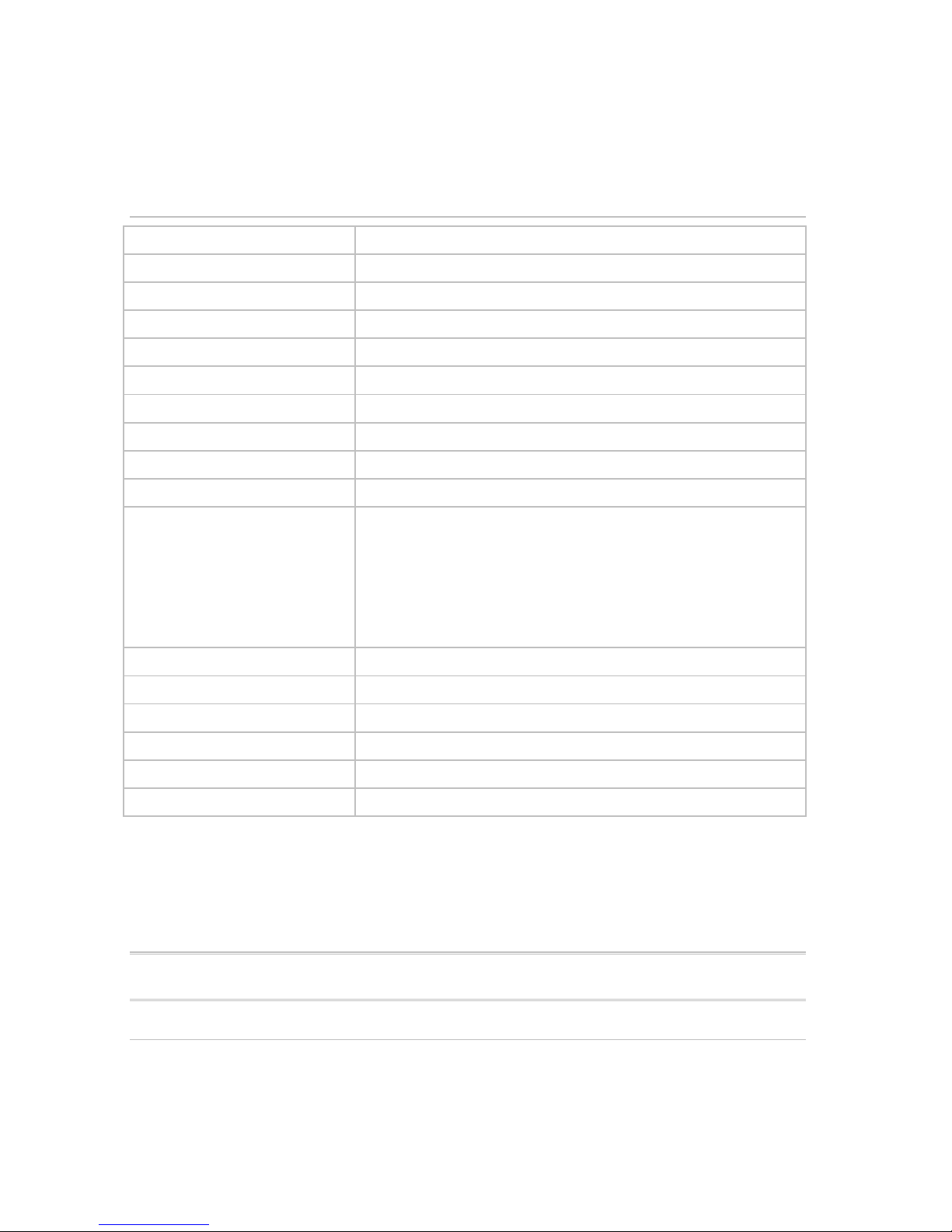

Technical data

Housing: Plastic material

Colour: White

Mounting: Snap-on fitting on mounting rails

Protection category: IP 20

Dimensions: approx. 123 x 89 x 61 (W x H x D, mm), 7 width units

Weight: approx. 370 g

Ambient temperature: Operation -5…+45 °C, Storage -25…+70°C

Ambient air humidity: max. 95% R. H., avoid bedewing

Operating voltage: 230 V AC , 50 Hz

Power consumption: Full load: approx. 28 W, Standby: approx. 2.7 W

Outputs: • KNX bus voltage 29 V (reduced),

Output current max. 640 mA, short-circuit proof

• 24 V DC (not reduced), Output current max. 150 mA

• KNX data

• LAN connector RJ45; 10BaseT (10Mbit/s), Supported

internet protocols: ARP, ICMP, IGMP, UDP/IP and DHCP

Data output KNX +/- bus terminal plug

BCU type Own microcontroller

PEI type 0

Group addresses max. 200

Allocations max. 200

Communication objects Power supply unit: 27

The product conforms with the provisions of EU guidelines.

Application examples

IP Interface

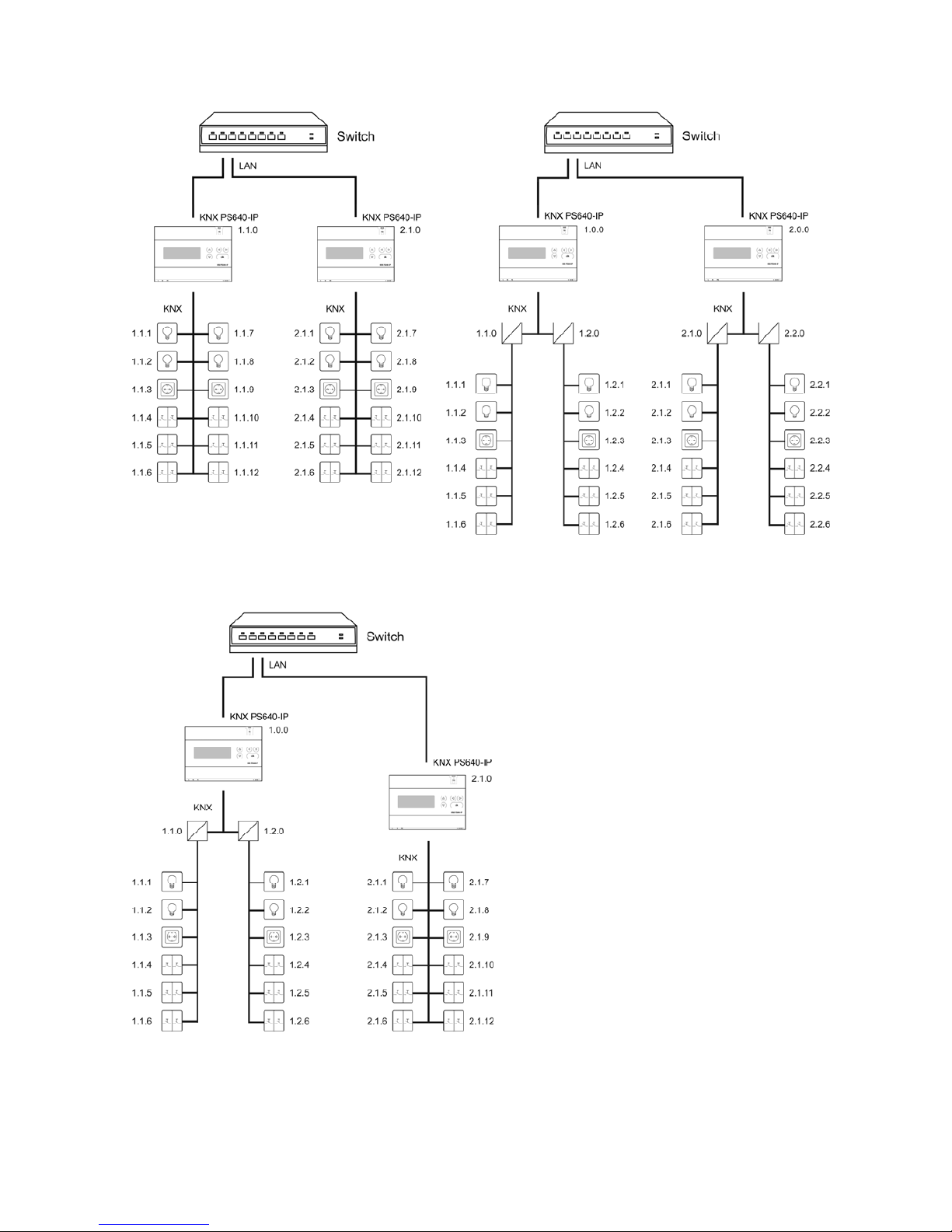

Coupler function (KNXnet/IP Routing)

The Power Supply System KNX PS640+IP can operate as a line and/or backbone

coupler. In both cases, the LAN (IP) acts as a backbone.

5

KNX PS640+IP as a line coupler KNX PS640+IP as a backbone coupler

KNX PS640+IP as a backbone and line coupler

The physical address assigned to the

KNX PS640+IP determines whether the

device operates as a line or backbone coupler. If the physical address is in the form of

x.y.0 (x, y: 1..15), the router operates as a line coupler. If it is in the form of x.0.0 (x:

1..15), the router acts as a backbone coupler.

6

Attention: If the KNX PS640+IP is used as a backbone coupler (x.0.0), there must be no

KNX IP Router in the topology beneath it. For example, if a KNX PS640+IP has the

physical address of 1.0.0, there must be no KNX IP Router with the address 1.1.0.

If the KNX PS640+IP is used as a line coupler (x.y.0), there must be no KNX IP Router in

the topology above it. For example, if a KNX PS640+IP has the physical address of 1.1.0,

there must be no KNX IP Router with the address 1.0.0.

The KNX PS640+IP has a filter table and thus contributes to reducing bus load. The filter

table is automatically generated by the ETS.

Because of the speed difference between the Ethernet (10 Mbit/s) and KNX (9.6 kbit/s), a

far greater number of telegrams can be transmitted on IP. If several consecutive

telegrams are transmitted on the same line, they must be buffered in the router to avoid

telegram loss. The KNX PS640+IP 750 has a memory for 150 telegrams (from IP to

KNX/EIB).

Bus access (KNXnet/IP Tunnelling)

The Power Supply System KNX PS640+IP can be used as an interface to KNX. KNX can

be accessed from any point in the LAN. For this purpose, a second physical address

must be assigned in the ETS. Please refer to chapter “ETS Connection Manager”.

Power Supply

Housing example with central operating unit

7

Installation and commissioning

Installation, testing, operational start-up and troubleshooting should only be

performed by an electrician.

DANGER! Risk to life from live voltage (mains voltage)!

There are unprotected live components inside the device.

• VDE and national regulations are to be followed.

• Ensure that all lines to be assembled are free of voltage and take

precautions against accidental switching on.

• Do not use the device if it is damaged.

• Take the device or system out of service and secure it against unintentional

use, if it can be assumed, that risk-free operation is no longer guaranteed.

The device is only to be used for its intended purpose. Any improper modification or

failure to follow the operating instructions voids any and all warranty and guarantee

claims.

After unpacking the device, check it immediately for possible mechanical damage. If it

has been damaged in transport, inform the supplier immediately.

The device may only be used as a fixed-site installation; that means only when

assembled and after conclusion of all installation and operational start-up tasks and

only in the surroundings designated for it.

Elsner Elektronik is not liable for any changes in norms and standards which may occur

after publication of these operating instructions.

Connection

Observe the correct installation. Incorrect installation may destroy the power supply

system or connected electronic devices.

After the auxiliary voltage is applied the device will enter an initialization phase lasting

about 5 seconds. During this phase no information can be received via the bus.

8

Housing

1 LAN connection (RJ45, for

Ethernet patch cable)

2 Programming LED and

programming button

3 Bus connection (KNX terminal

+ / -)

4 Input operating voltage 230 V

AC, L / N / PE

5 Output direct current voltage 24

V DC, + / -

Connections 4 and 5 are suitable for

solid conductors up to 1.5 mm² or

conductors with fine wires.

Scheme

KNX communication of IP interface and

power supply unit

The device has got two KNX interfaces, one for the “PLUS” functions of the power

supply unit and one for the IP router. The functions are registered at the bus separately

and parametrised in different product files (ETS).

Auxiliary Voltage 24 V DC

(max. 150 mA)

9

Addressing

IP interface and KNX power supply unit are addressed separately at the bus.

Addressing the IP interface

The IP interface is supplied with the bus address 15.15.0. You can program another

address in the ETS (product file of IP interface) by overwriting the 15.15.0 address or by

teaching via the programming key at the unit.

Addressing the KNX power supply unit

The power supply unit is supplied with the bus address 15.15.250. You can program

another address in the ETS (product file of power supply unit) by overwriting the

15.15.250 address or by using the “Prog. Mode” of the unit (see chapter Addressing the

power supply unit (programming mode)).

Settings in der ETS

Different product files are used for setting of the IP interface and the KNX functions of

the power supply unit.

Parametrise the IP interface

Use the product file of PS640-IP power supply unit, item number 70142.

For description of parameters please see manual, chapter Setting the IP interface in the

ETS.

Parametrise the KNX power supply unit

Use the product file of PS640+(USB) power supply unit, item numbers 70141, 70144.

For description of parameters please see manual, chapter Setting the bus functions of

the power supply unit in the ETS.

Settings at the device

Starting position

The following may be read off and set on the display of the Power Supply System KNX

PS640+IP:

Reset of a line

Recall of the data memory with operating hours, overcharge, external electrical

surge, internal electrical surge, short circuit and excess temperature

Recall of the operating data bus voltage, bus current and temperature

el

sner e

l

e

kt

ron

ik

KNX PS640+IP

Normal Operation

Diagnostics >

10

Language of display

Activate the programming mode for addressing of the power supply unit at the

KNX bus

The display will be dimmed after 60 seconds if no key has been pressed during this

time. In addition, the backlight of the display will be switched off automatically if the

temperature inside the housing exceeds 50°C. Thus a high thermal load is avoided.

Line reset

In starting position, press key once to get into the

sector “Diagnostics”.

Press key once more in order to get into the sector

“Line reset”.

Move the cursor (flashing rectangle at right edge) to

the desired setting with the keys or and confirm

with key .

Yes: Reset is activated. The line is switched to neutral and shorted. The

basic setting displays: “Reset is active!”

No: Reset not activated. The power supply system works in normal

operation.

30 seconds: A reset of 30 seconds is started. Afterwards, the line is supplied

with voltage as usual. During the reset state, which lasts 30

seconds, the basic setting displays: “Reset active: XX sec”

(countdown).

With key , you return to the previous menu level.

Data memory

In starting position, press key once.

Move the cursor (flashing rectangle at right edge) to

the “Data memory” menu with the keys and and

confirm with key .

el

sn

e

r e

l

e

kt

ron

ik

KNX PS640+IP

Normal Operation

Diagnostics >

Li

ne

R

e

se

t

>

™

Data Memory >

Operating Data >

Language

R

ese

t

:

Y

es

™

No

30 seconds

Reset not active!

el

sner e

l

e

kt

ron

ik

KNX PS640-IP

Normal Operation

Diagnostics >

Li

ne

R

e

se

t

>

Data Memory > ™

Operating Data >

Language > v

11

Move the cursor to the desired menu with the up and down keys and press key .

Operating hours

The operating hours of the power supply system are

displayed in years, days and hours.

With key you return to the previous menu level.

Overload

The number of overload incidents and the total time in

days, hours and minutes are displayed.

With key you return to the previous menu level.

External overvoltage

The number of external overvoltage incidents is

displayed.

With key you return to the previous menu level.

Internal overvoltage

The number of internal overvoltage incidents is

displayed.

With key you return to the previous menu level.

Short circuit

The number of short circuit incidents at the bus is

displayed.

With key you return to the previous menu level.

Excess temperature

The number of excess temperature incidents on the

circuit board of the device is displayed.

With key you return to the previous menu level.

Sh

or

t

c

i

rcu

it

>

Excess Temperat. >

Hours of Operation> ™

Overload >

Ext. Overvoltage >

Int. Overvoltage > v

R

un

ti

me:

0

year

s

0 day 0 hrs.

< = Back

O

ver

l

oa

d

d

e

t

ec

t

e

d

0 times. Duration:

0 day. 0 hrs. 0 min

< = Back

E

x

t

erna

l

O

vervo

lt

age

was detected

0 times.

< = Back

I

n

t

erna

l

O

vervo

lt

age

was detected

0 times.

< = Back

A

s

h

or

t

at

th

e

b

us

was detected

0 times.

< = Back

E

xcess

T

empera

t

ure

on the board

was detected

0 times!

12

Operating data

In starting position, press key once.

Move the cursor (flashing rectangle at right edge) to

the “Operating Data” menu with the keys and and

confirm with key .

The current values of

Bus voltage

Bus current

Temperature on the circuit board of the device

are displayed.

With key you return to the previous menu level.

Language

In starting position, press key once.

Move the cursor (flashing rectangle at right edge) to

the “Language” menu with the keys and and

confirm with the key .

Move the cursor to the desired language with the up

and down keys and press the key . The display

automatically jumps to the previous menu in the

desired language.

With key you get back by one menu level to the basic setting.

Addressing the power supply unit (programming

mode)

To set the physical address of the power supply unit at the KNX bus, the programming

mode is activated here.

Instarting position, press key once.

el

sner e

l

e

kt

ron

ik

KNX PS640+IP

Normal Operation

Diagnostics >

Li

ne

R

e

se

t

>

Data Memory >

Operating Data > ™

Language > v

el

sner e

l

e

kt

ron

i

k

KNX PS640-IP

Normal Operation

Diagnostics >

L

i

ne

R

e

se

t

>

Data Memory >

Operating Data >

Language > ™

S

prac

h

e :

D

eu

t

sc

h

™

Language :English

Idioma :Espanol

Taal :Hollands

el

sner e

l

e

kt

ron

ik

KNX PS640+IP

Normal Operation

Diagnostics >

B

us

V

olt

age

29

.

4

V

Bus Current 320 mA

Temperature 42.1°C

13

Move the cursor (flashing rectangle at right edge) to

the “Prog. Mode” menu with the keys and and

confirm with the key .

Move the cursor with the keys and to “On” and

press the key . The programming mode is active just

as long the text “Prog. Mode active” is shown.

To switch off programming mode, move the cursor

with the keys and to “Off” and press the key .

With key you get back by one menu level to the basic setting.

L

i

n

e

R

e

se

t

>

Data Memory >

Operating Data >

Language > v

P

rog.

M

o

d

e

>

™

P

rog.

M

o

d

e

:

O

n

™

Off

PLUS Funktions are

active in Prog.Mode

14

Setting of parameters in the ETS

Parameters of the IP interface

General

Device name [free entry]

The KNX PS640+IP can be assigned a name of your choice. The device name should be

descriptive (e. g. Line TF). It is used to search for and recognize a device.

Monitoring bus voltage failure disable • enable

If a KNX failure is detected, it is reported on the IP. Return of the bus voltage is also

reported.

IP address assignment automatic (DHCP) • manual

Automatic (DHCP): The IP address is automatically assigned on the DHCP, i.e.

additional settings are not required. To be able to use this function, there must be a

DHCP server in the LAN (many DSL routers have an integrated DHCP server).

Manual: In this case, the IP address, the subnet and the gateway IP address must be

entered manually.

15

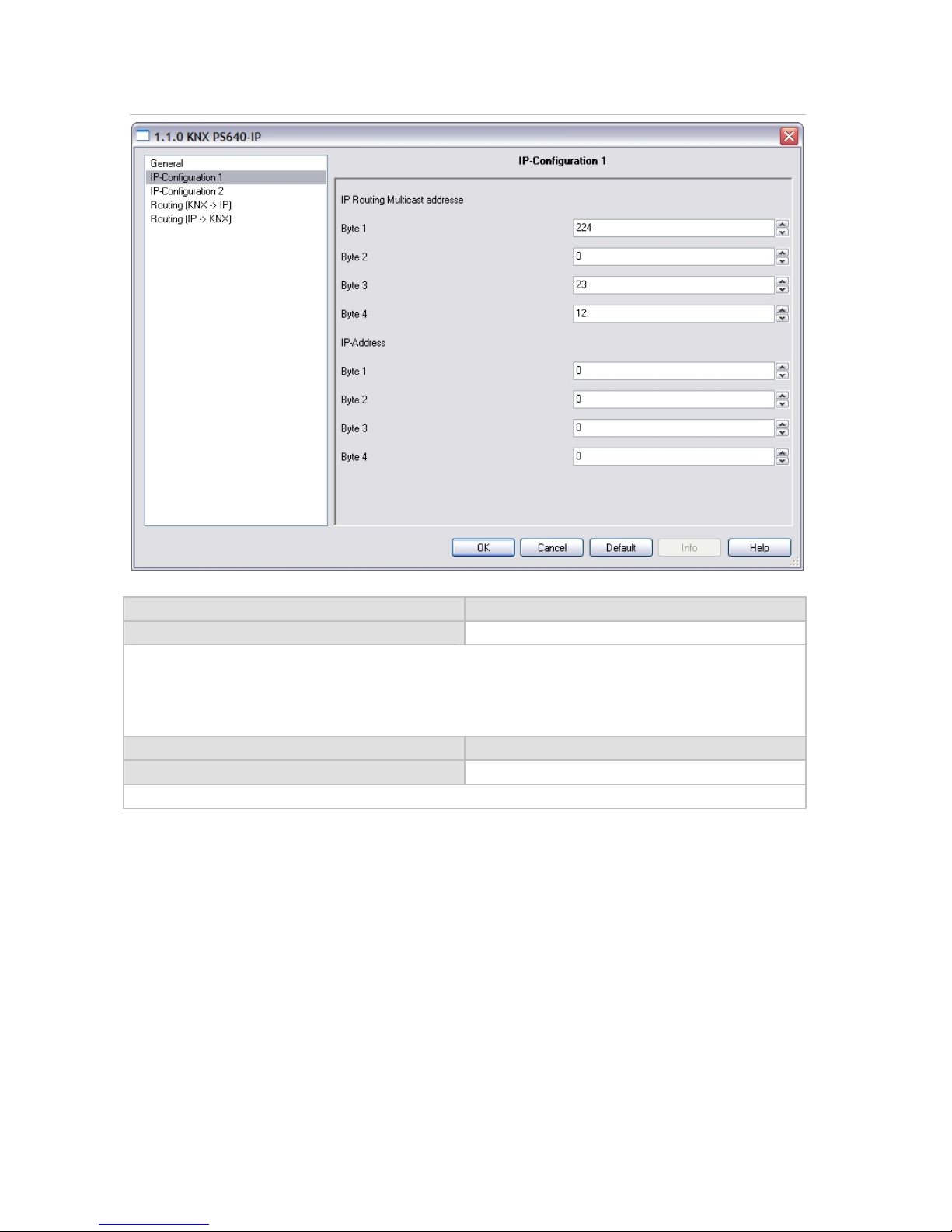

IP configuration

IP Routing Multicast address

Byte 1 / 2 / 3 / 4 0 … 255

This address is used for routing telegrams on IP. The multicast IP address 224.0.23.12

was reserved (KNXnet/IP) at the IANA (Internet Assigned Numbers Authority) for this

purpose. If a different multicast IP address is required, it must lie within the range of

239.0.0.0 to 239.255.255.255.

IP address

Byte 1 / 2 / 3 / 4 0 … 255

This is the IP address of the KNX PS640+IP.

16

IP subnet

Byte 1 / 2 / 3 / 4 0 … 255

Enter the subnet mask here. The device uses the values entered in this mask to

determine whether there is a communications partner in the local network. If there is

no partner in the local network, the device will not send the telegrams directly to the

partner but to the gateway that routes the telegram.

IP gateway address

Byte 1 / 2 / 3 / 4 0 … 255

Enter the IP address of the gateway here.

Note: If the KNX PS640+IP will only be used in the local LAN, the entry of 0.0.0.0 can

remain unchanged.

Example of assigning IP addresses

A PC is to be used to access the KNX PS640-IP.

IP address of the PC: 192.168.1.30

Subnet of the PC: 255.255.255.0

The KNX PS640-IP is located in the same local LAN, i. e. it uses the same subnet. The

subnet constrains the IP addresses that can be assigned. In this example, the IP address

of the KNX PS640-IP must be 192.168.1.xx, where xx can be a number from 1 to 254

(with the exception of 30, which is already in use). It must be ensured that no numbers

are assigned twice.

IP address of the KNX PS640-IP: 192.168.1.31

Subnet of the KNX PS640-IP: 255.255.255.0

17

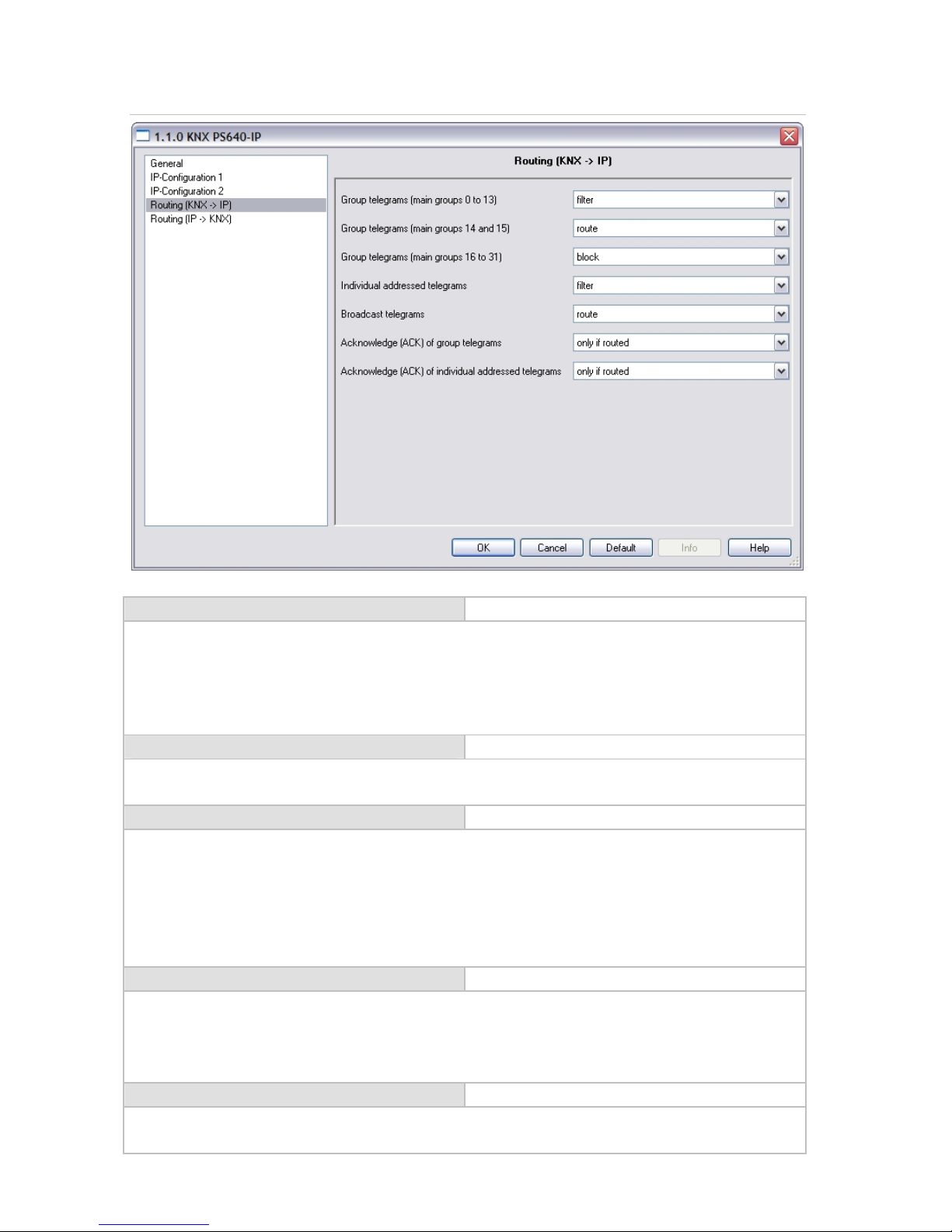

Routing (KNX -> IP)

Group telegrams (main group 0 to 13) block • route • filter

Block: No group telegrams of this main group are routed to IP.

Route: All group telegrams of this main group are routed to IP independent of the filter

table. This setting is for testing purposes only.

Filter: The filter table is used to check whether or not the received group telegram

should be routed to IP.

Group telegrams (main groups 14 and 15) block • route

Block: No group telegrams of main groups 14 and 15 are routed to IP.

Route: All group telegrams of main groups 14 and 15 are routed to IP.

Group telegrams (main groups 16 to 31) block • route

Block: No group telegrams of these main groups are routed to IP.

Route: An additional page appears on which the routing of main groups 16 to 31 can be

disabled or enabled in pairs.

Note: The group addresses of main groups 16 to 31 are reserved addresses that can be

used for special applications (e.g. in Easy Mode). These group addresses are not

available in the ETS.

Physically addressed telegrams block • route • filter

Block: No physically addressed telegrams are routed to IP.

Route: All physically addressed telegrams are routed to IP.

Filter: The physical address is used to check whether the received physically addressed

telegram should be routed to IP.

Broadcast telegrams block • route

Block: No received broadcast telegrams are routed to IP.

Route: All received broadcast telegrams are routed to IP.

18

Acknowledge (ACK) of group telegrams always • only if routed

Always: An acknowledge is generated for every received group telegram (from KNX).

Only if routed: An acknowledge is only generated for received group telegrams (from

KNX) if they are routed to IP.

Acknowledge (ACK) of physically

addressed telegrams

always • only if routed • answer with

NACK

Always: An acknowledge is generated for every received physically addressed telegram

(from KNX).

Only if routed: An acknowledge is only generated for received physically addressed

group telegrams (from KNX) if they are routed to IP.

Answer with

NACK: Every received physically addressed telegram (from KNX) is responded to with

NACK (not acknowledge). This means that communication with physically addressed

telegrams on the corresponding KNX line is not possible. Group communication (group

telegrams) is not affected. This setting can be used to block attempts at manipulation.

Routing (IP -> KNX)

Group telegrams (main groups 0 to 13) block • route • filter

Block: No group telegrams of these main groups are routed to KNX.

Route: All group telegrams of this main group are routed to KNX independent of the

filter table. This setting is used for testing purposes only.

Filter: The filter table is used to check whether the received group telegram should be

routed to KNX.

19

Group telegrams (main groups 14 and 15) block • route

Block: No group telegrams of main groups 14 and 15 are routed to KNX.

Route: All group telegrams of the main groups 14 and 15 are routed to KNX.

Group telegrams (main groups 16 to 31) block • route

Block: No group telegrams of these main groups are routed to KNX.

Route: An additional page appears on which the routing of main groups 16 to 31 can be

disabled or enabled in pairs.

Physically addressed telegrams block • route • filter

Block: No physically addressed telegrams are routed to KNX.

Route: All physically addressed telegrams are routed to KNX.

Filter: The physical address is used to check whether the received physically addressed

telegram should be routed to KNX.

Broadcast telegrams block • route

Block: No received broadcast telegrams are routed to KNX.

Route: All received broadcast telegrams are routed to KNX.

Resending of group telegrams block • route

Disable: The received group telegram is not resent to KNX in case of a fault.

Enable: The received group telegram is resent up to three times in case of a fault.

Resending of physically addressed

telegrams

block • route

Disable: The received physically addressed telegram is not resent to KNX in case of a

fault.

Enable: The received physically addressed telegram is resent up to three times in case

of a fault.

Resending of broadcast telegrams block • route

Disable: The received broadcast telegram is not resent to KNX in case of a fault.

Enable: The received broadcast telegram is resent up to three times in case of a fault.

20

Communication settings in the ETS

If the IP-configuration of the KNX PS640+IP is valid the device can act as an interface to

KNX. The following configuration is necessary:

Select the button “Settings” and the tab “Communication” in the main window of

ETS4. All available connections are listed by “Configured connections”. Select the

desired connection.

The button “Local settings” enables the configuration of the individual address, which

is used for bus access.

A dummy device may be created in the ETS-project to reserve this address.

The KNX PS640+IP supports up to 5 connections simultaneously. An additional physical

address has to be reserved for every connection. The first additional physical address is

allocated (as shown above) to the connection in the ETS. The remaining additional

addresses can be assigned directly by the device, in which cast the learn button should

be pressed for at least one second. The automatic address allocation is performed as:

Connection 2 contains the next higher address from Connection 1,

Connection 3 the next higher from Connection 2

etc.

For example:

Connection 1 uses the additional individual address 15.15.250.

Connection 2 is automatically set to 15.15.251, connection 3 is 15.15.252,

connection 4 is 15.15.253 and connection 5 is 15.15.254.

The assignment of the additional individual addresses is shown by a fast blinking learn

led.

Note: It is necessary to check whether the additional individual addresses are unused

before they are assigned.

For new devices (i.e. in the factory settings state), only the additional individual address

of the first connection is active with the address 15.15.250. To support multiple

concurrent connections the additional address assignment is required.

This manual suits for next models

1

Table of contents

Other Elsner Power Supply manuals

Popular Power Supply manuals by other brands

Vertiv

Vertiv NetSure V200D50 Installation and user manual

Altronix

Altronix VertiLine24C Series installation guide

Rigol

Rigol DP700 Series Calibration guide

Altronix

Altronix ALTV2432UL3 Series installation guide

CARLO GAVAZZI

CARLO GAVAZZI SPDE 75 Series Installation and operation manual

APM

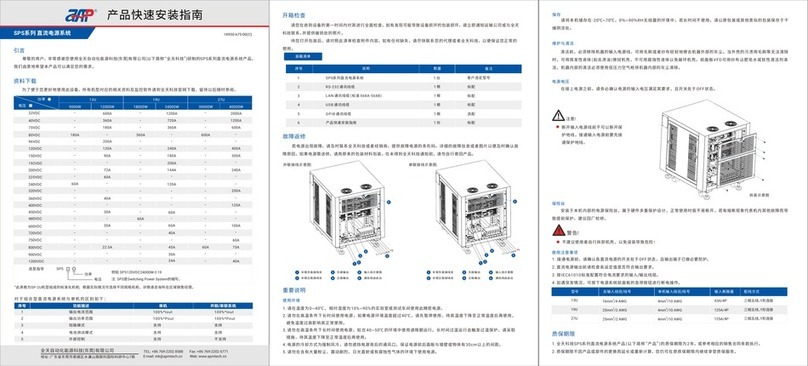

APM SPS Series quick guide

Red Ion

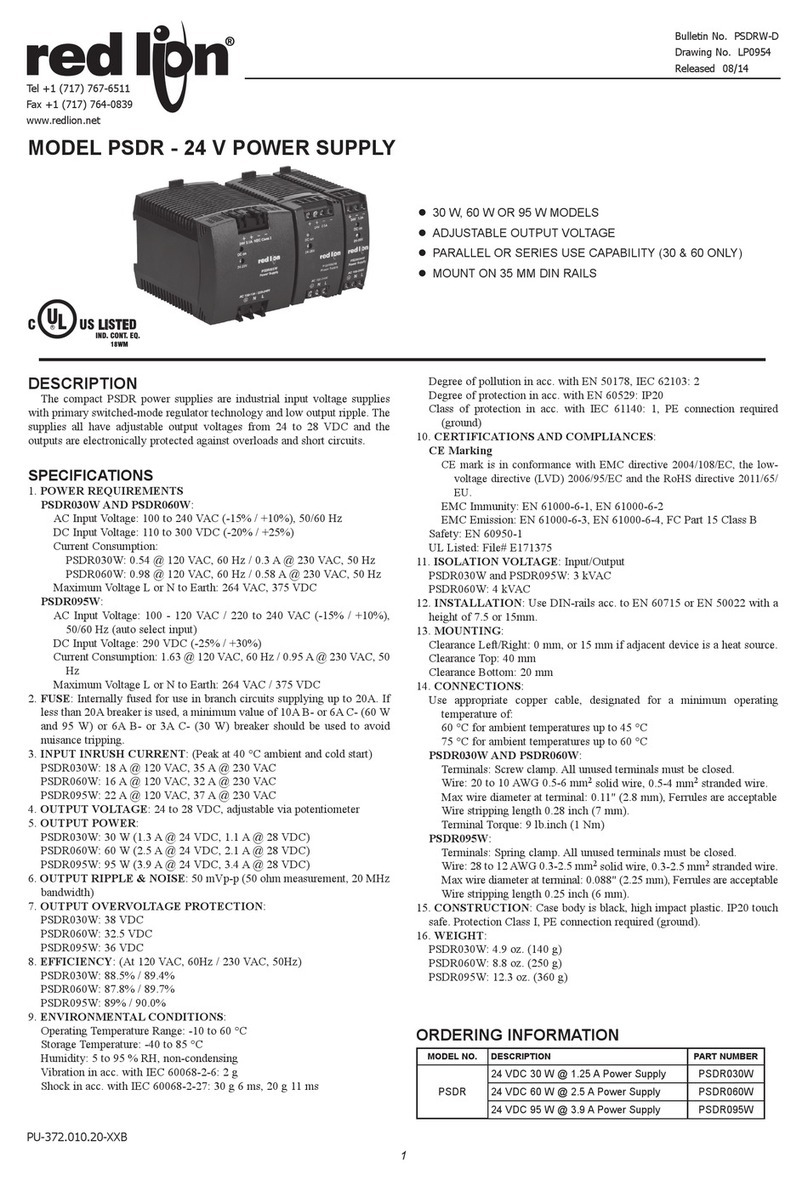

Red Ion PSDR030W manual

ZALMAN

ZALMAN ZM450-GS user manual

VOSS.farming

VOSS.farming Impuls duo DV 40 operating instructions

Cabletron Systems

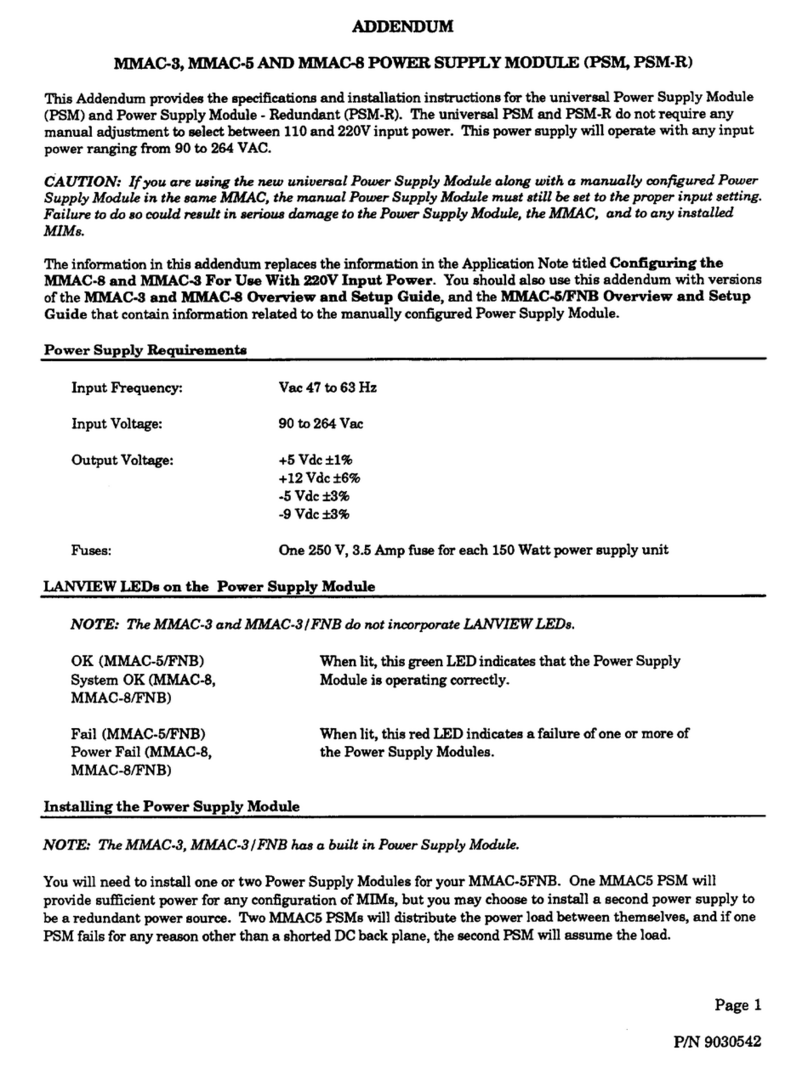

Cabletron Systems MMAC-3 Addendum

Balluff

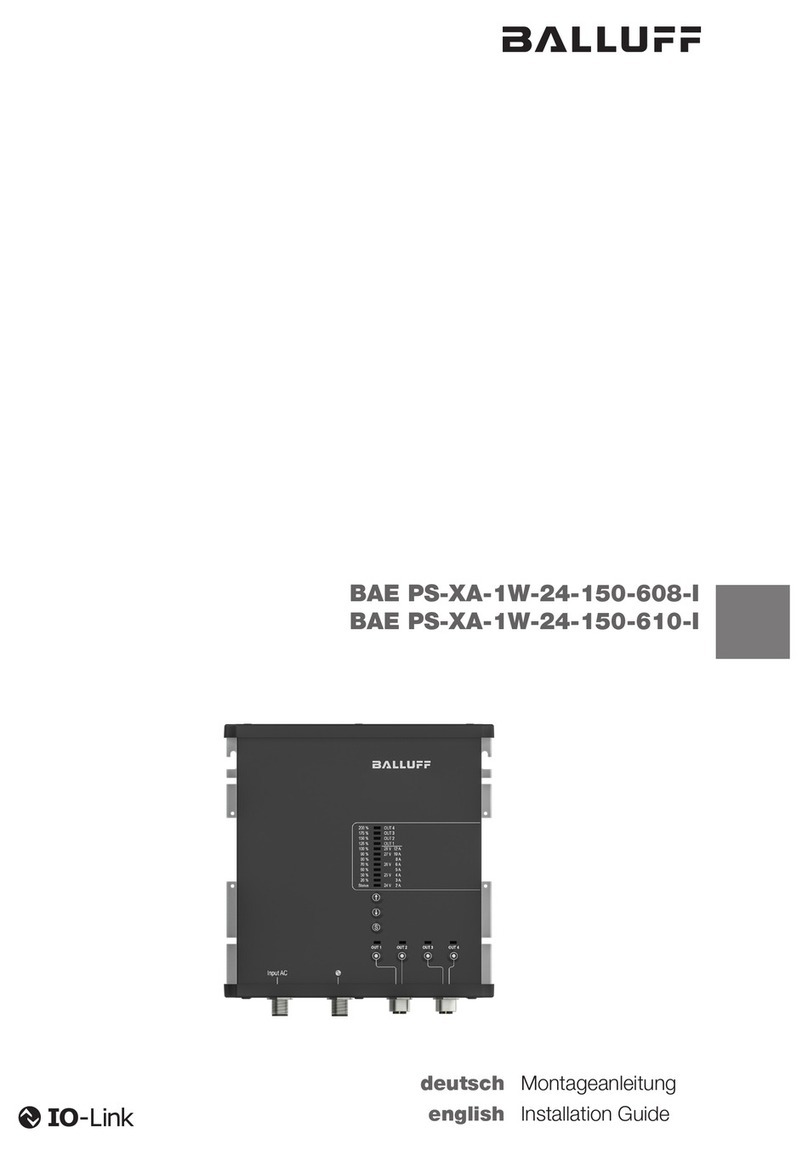

Balluff BAE PS-XA-1W-24-150-608-I installation guide

EPS Stromversorgung

EPS Stromversorgung PS 5040-10 A operating guide