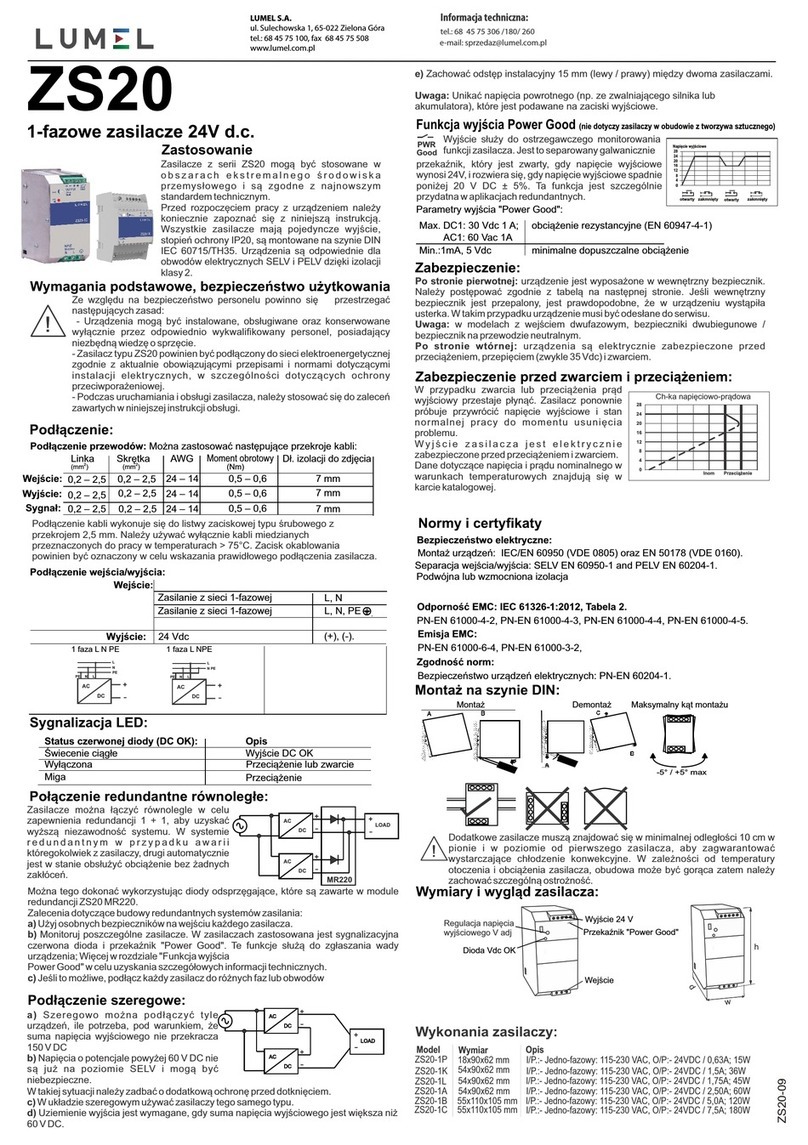

Programmable DC Power Supply User’s Guide

1

Introduction of Programmable DC Power Supply

Programmable power supply is a new generation of programmable DC power supplies of

our factory. The power supply has RS232 programmable interface and optional USB

interface, digital nixie tube, LED and indicator light to show working status, key light

shows setting status. Double digital knobs and keypad are supplied to set parameters,

while using of the adjusting knob, user can directly set the voltage and current and don’t

need to switch the key and knob. The built-in function module, controlled by 32 bits MPU,

use CAN bus-mastering to supply the reliable output and over-load hardware protection,

the step of over-load protection is adjustable and could be selected to be on or off. Except

of this, power supply also protect itself by warning and cutting off output once fun

controlling module gets fault, transistor over-heating, internal bus gets fault. It is of

programmable CV/ CC adjustable step. The two working states, CV and CC, can be

switched varying with the load. Meantime, the external voltage sampling terminal is

supplied to output stable voltage for user load within the range of wire voltage drop.

Programmable power supplies are widely applied in national defense, institution,

university and factory, especially in the areas of computer measuring and automatic

control system as DC power supply.

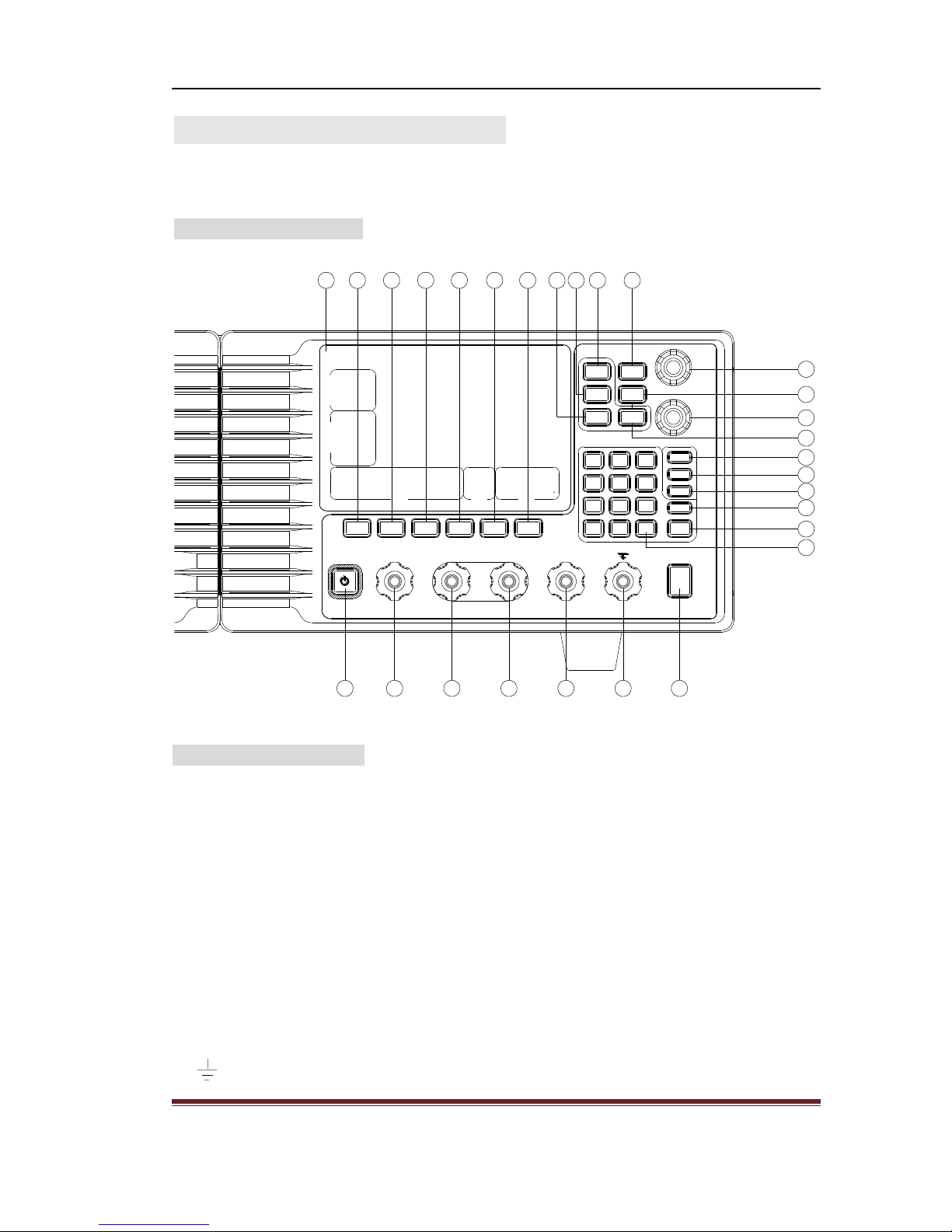

Main function characteristics

All digital control, inside CAN bus controlling, low drift and high resolution

Nixie tube + LED + Key Indicator to show working state, clarity and simple

User-defined storage/recall function

Adjust by digital knob roughly or finely. Convenient setting and direct output

Keypad lock function, to avoid the misoperation

Hardware of OVP (Over Voltage Protection), setting is adjustable and ON/OFF also

could be selected.

Distanced wire voltage drop compensate, ON/OFF available

Temperature fan controlling, with warning of fan/over heat/fault of internal module

Standard configuration: RS232 interface

Optional configuration: USB device