PIPEFITTINGS

Allpipettingsaremadevia22mmcompression

ttingsdirectlytotheunit.Thettingsarethreaded

3/4”BSPmaleparallel,shouldthreadedpipe

connectionsberequired.

COLDFEED

A22mmcoldwatersupplyisrecommended,however,

ifa15mm(1/2”)supplyexists,whichprovidessufcient

ow,thismaybeused(althoughmoreownoise

maybeexperienced).

Astopcockorservicingvalveshouldbeincorporated

intothecoldwatersupplytoenablethecylinderand

itsassociatedcontrolstobeisolatedandserviced.

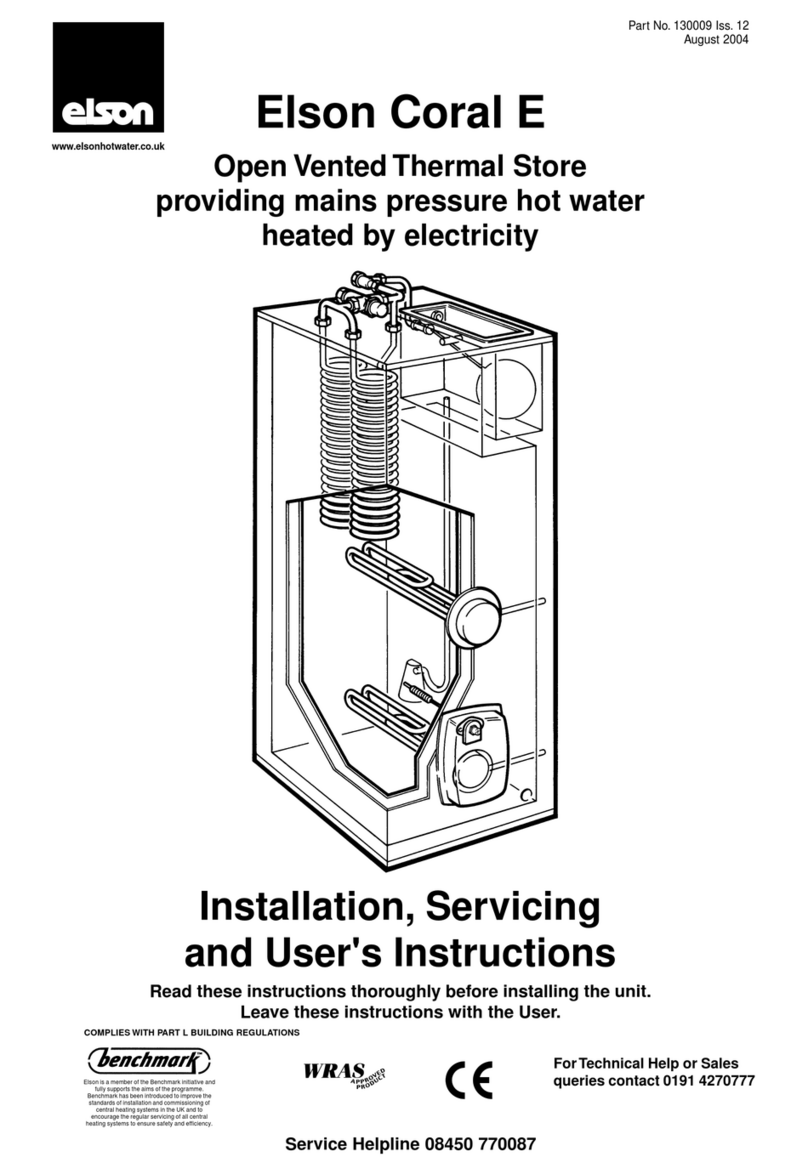

COLDWATERCOMBINATIONVALVEASSEMBLY

The2-piececoldwatercombinationvalveassembly

(seeFig.2)canbelocatedanywhereonthecold

water mains supply prior to the expansion vessel

(seeFig.6Page10)butthetwopiecesdonothave

tobeinstalledtogether.

The pressure reducing valve incorporates the

pressure reducer and strainer and the expansion valve

incorporatestheexpansionandcheckvalves.Ensure

that the valves are installed in the correct order

andorientation.Noothervalvesshouldbeplaced

betweentheexpansionvalveandthecylinder.A

connectioncanbemadebetweentheexpansionand

pressurereducingvalvestoprovideabalancedcold

waterconnection.Theexpansionvalveconnection

mustnotbeusedforanyotherpurpose.

DRAIN TAP

Asuitabledrainingtapshouldbeinstalledinthecold

watersupplytothecylinderbetweentheexpansion

valve(seeFig.6Page10)andtheheaterataslowa

levelaspossible.Itisrecommendedthattheoutlet

pointofthedrainpipeworkbeatleast1metrebelow

theleveloftheheater(thiscanbeachievedby

attachingahosetothedraintapoutletspigot).

EXPANSIONVESSEL

The expansion vessel accommodates expansion

thatresultsfromheatingthewaterinsidetheunit.

Theexpansionvesselispre-chargedat0.35MPa

(3.5bar).Theexpansionvesselmustbeconnected

betweentheexpansionvalveandthecylinder(see

Fig.6Page10).Thelocationoftheexpansion

vessel should allow access to recharge the pressure

asandwhennecessary,thiscanbedoneusing

anormalcarfootpump.Itisrecommendedthat

theexpansionvesselisadequatelysupported.An

expansionvesselwallmountingbracketissupplied

forthispurposeandshouldbetted.

SECONDARYCIRCULATION

Ifsecondarycirculationisrequireditisrecommended

thatitbeconnectedtothecylinderasshown (see

Fig.3page5)via a swept tee joint into the cold

feedtotheunit.Asweptteejointisavailableasan

accessory(ordercodeno.5133565).

Thesecondaryreturnpipeshouldbein15mmpipe

andincorporateacheckvalvetopreventbackow.

AsuitableWRASapprovedbronzecirculation

pumpwillberequired.Onlargesystems,dueto

theincreaseinsystemwatercontent,itmaybe

necessarytotanadditionalexpansionvesseltothe

secondarycircuit.Thisshouldbedoneifthecapacity

ofthesecondarycircuitexceeds10litres.

Pipe capacity (copper):

15mmO.D.=0.13l/m(10litres=77m)

22mmO.D.=0.38l/m(10litres=26m)

28mmO.D.=0.55l/m(10litres=18m)

NOTE:SecondarycirculationisNOTrecommendedfor

directelectricunits.

OUTLET

Thehotwateroutletisa22mmcompressiontting

locatedatthetopofthecylinder.Hotwaterdistribution

pipeworkshouldbe22mmpipewithshortrunsof

15mmpipetoterminalttingssuchassinksand

basins.Pipesizesmayvaryduetosystemdesign.

INSTALLATION GENERAL

Fig.2:Coldwatercombinationvalveassembly

Fig.3:Secondarycirculationconnection