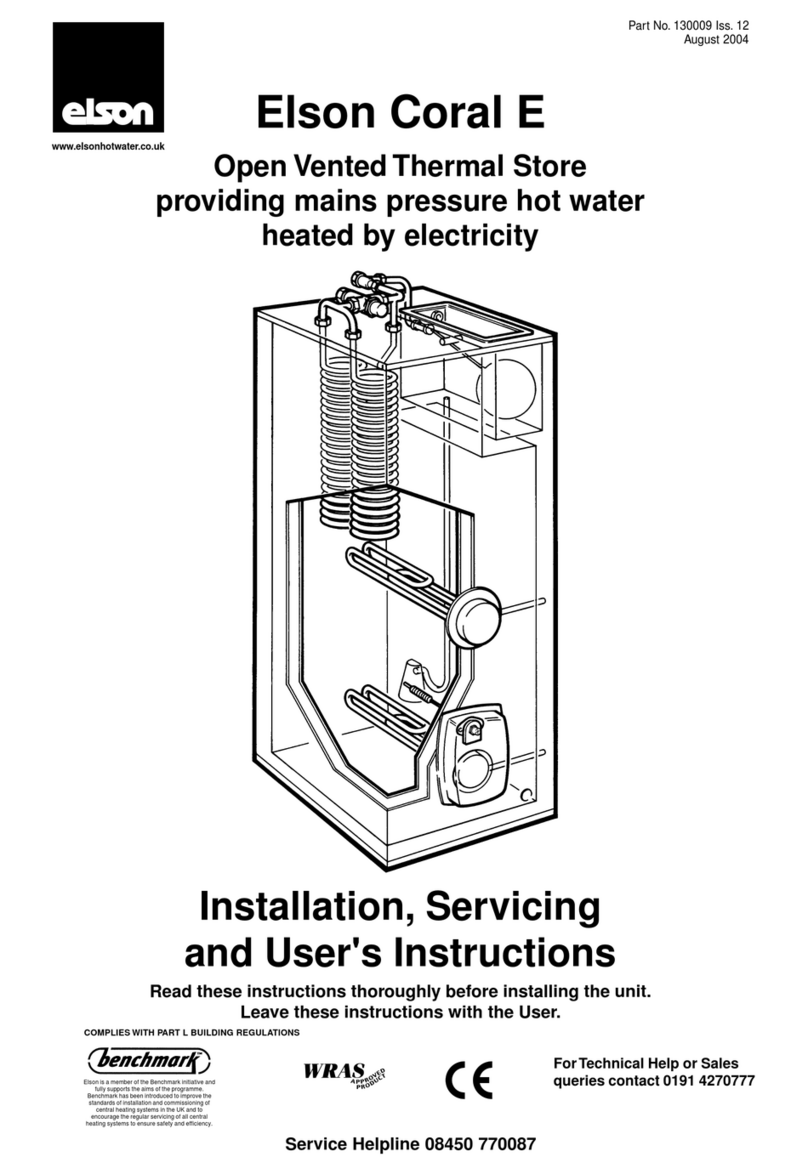

FILLING THE UNIT WITH WATER

Ensurethatallttingsandimmersionheatersarecorrectly

ttedandtightened.Animmersionheaterkeyisprovided

to aid tightening the immersion heater(s)

AUTO FILL UNIT

Check all connections for tightness including the•

immersion heater(s). An immersion heater key

spanner is supplied for this purpose.

Ensure that both drain cocks are CLOSED.•

Open a hot tap furthest from the Thermal Store.•

Openthe mains stop cockto ll theunit.When•

water ows from the tap, allow to run for a few

minutestothoroughlyushthroughanyresidue,

dirt or swarf, then close the tap.

Open successive hot taps to purge the system•

of air.

TheThermalStorewillcontinuetollviatheball•

valve located in the feed & expansion header tank.

This will stop when the cylinder store is full.

Set the level of water in the cistern by adjusting•

theheightoftheballoatusingtheinternalwater

height gauge as shown in Fig.11 page 13.

MANUAL FILL UNIT

Check all connections for tightness including the•

immersion heater(s). An immersion heater key

spanner is supplied for this purpose.

Ensure that both drain cocks are CLOSED.•

Open a hot tap furthest from the Thermal Store.•

Openthe mains stop cockto ll theunit.When•

water ows from the tap, allow to run for a few

minutestothoroughlyushthroughanyresidue,

dirt or swarf, then close the tap.

Open successive hot taps to purge the system•

of air.

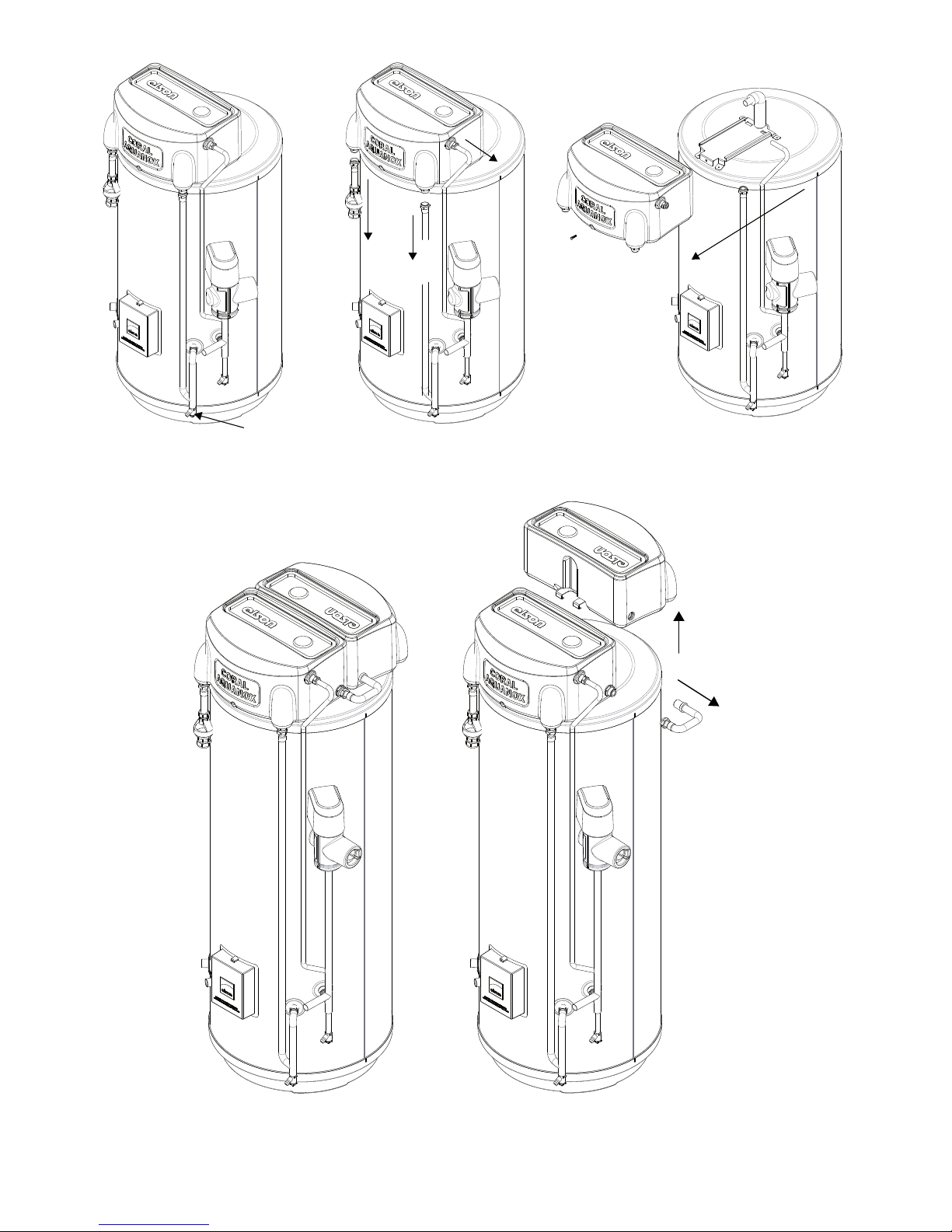

The ‘lling loop’ is used for introducing mains•

water into the cylinder for lling and topping up

purposes.The‘lingloop’hasanisolatingvalve

at each end. To introduce water into the system,

undo one of these valves completely and gently

opentheothervalvetocontroltherateofowof

water into the cylinder. Introduce water until the

sight gauge on the feed & expansion tank is level

withthebottomlllineasshowninFig.12page

13.Turnbothvalvesofffully.Thetemporarylling

loop should be disconnected after installation to

comply with the requirements of the Water Supply

(Water Fittings) Regulations 1999

The feed & expansion header tank water level•

should be checked regularly. If required ll with

cleancoldwaterviathellingloopto‘topup’.

SYSTEM CHECKS

Upon commissioning a competent engineer should:

Check all water connections for leaks and rectify•

as necessary.

Check water pressure – maximum 5.0bar•

Check operation of all service valves•

COMMISSIONING Check operation of the blending valve and test that•

the water temperature (hot ow mix) is at 55°C

when the store temperature is operating at 75°C.

Check operation of the immersion heater•

thermostats and settings.

Complete the service record at the back of the

commissioning booklet provided to comply with

the manufacturers guarantee and Benchmark

requirements.

DIRECT UNIT

Switch on electrical supply to the immersion heater(s)

and allow the cylinder to heat up to normal working

temperature (75°C recommended, approximately

graduation 4 on the thermostat). If necessary the

temperature can be adjusted by inserting a flat

bladed screwdriver in the adjustment knob on top of

the immersion heater thermostat and rotating. The

adjustment range 1 to 5 represents a temperature

range of 37°C to 85°C. Check the operation of

thermostat(s).

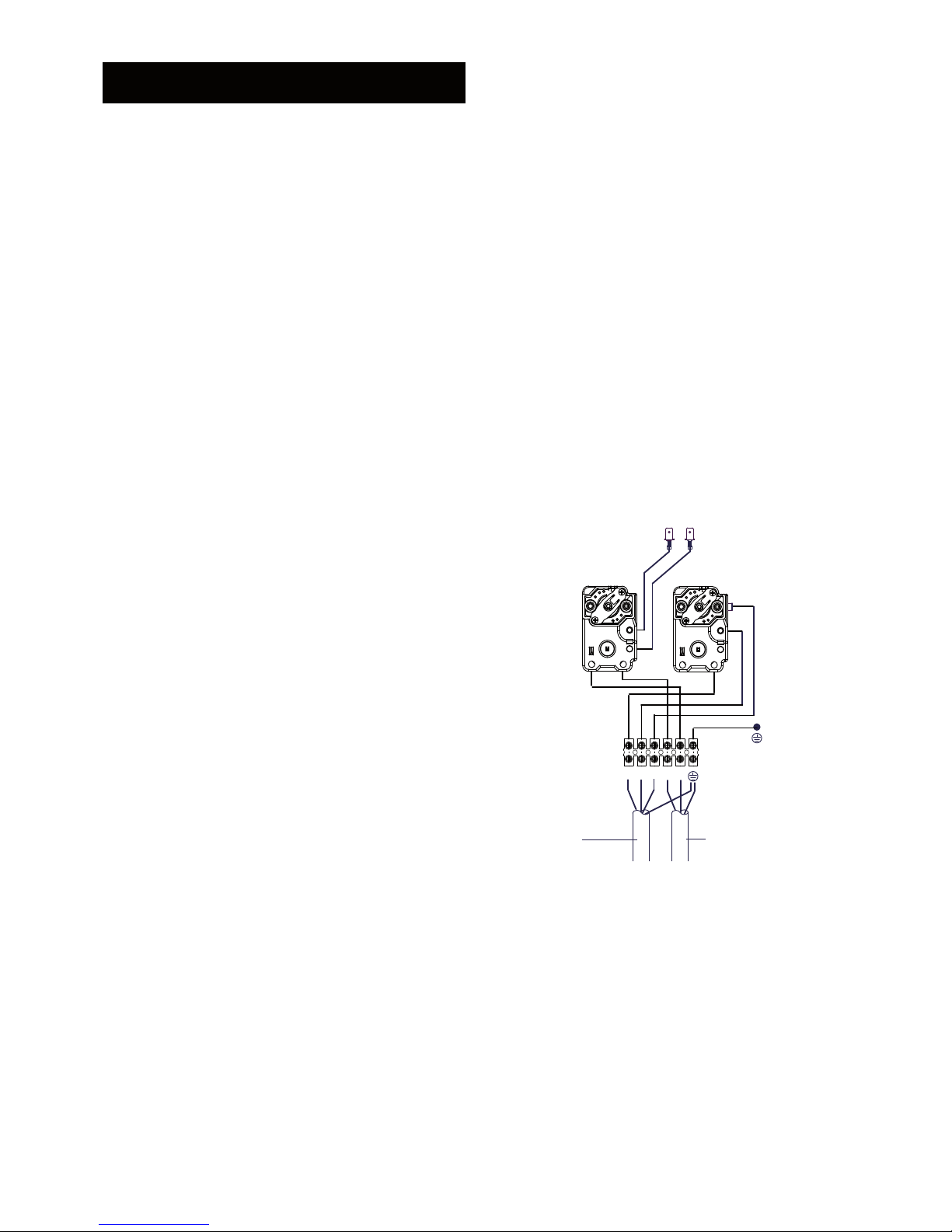

INDIRECT UNIT

Fill the indirect (primary) circuit following the boiler

manufacturer’s commissioning instructions. To ensure

thecylinderprimaryheatexchangerislled,the2port

motorised valve should be manually opened by moving

the lever on the motor housing to the MANUAL setting.

When the primary circuit is full return the lever to the

AUTOMATIC position.

Switch on the boiler, ensure the programmer is set to

Domestic Hot Water and allow the cylinder to heat up

to a normal working temperature (75°C recommended,

approximately graduation 5 on the thermostat).

If necessary the temperature can be adjusted by

insertingaatbladedscrewdriverintheadjustment

knob and rotating. The minimum thermostat setting

is 12°C.

The adjustment range 1 to 5 represents a temperature

range of 37°C to 85°C.

Check the operation of the indirect thermostat and

motorised valve during the heating cycle.

BENCHMARK LOG BOOK

On completion of the installation and commissioning

procedures detailed in this manual the Benchmark

“Installation, Commissioning and Service Record Log,

pages 26 and 27 should be completed and signed off

by the competent installer or commissioning engineer

in the relevant sections. The various system features,

location of system controls, user instructions and

what to do in the event of a system failure should be

explained to the customer. The customer should then

countersign the BenchmarkTM commissioning checklist

(page 26) to accept completion. The Service Record

should be lled in when any subsequent service or

maintenance operation is carried out on the product.