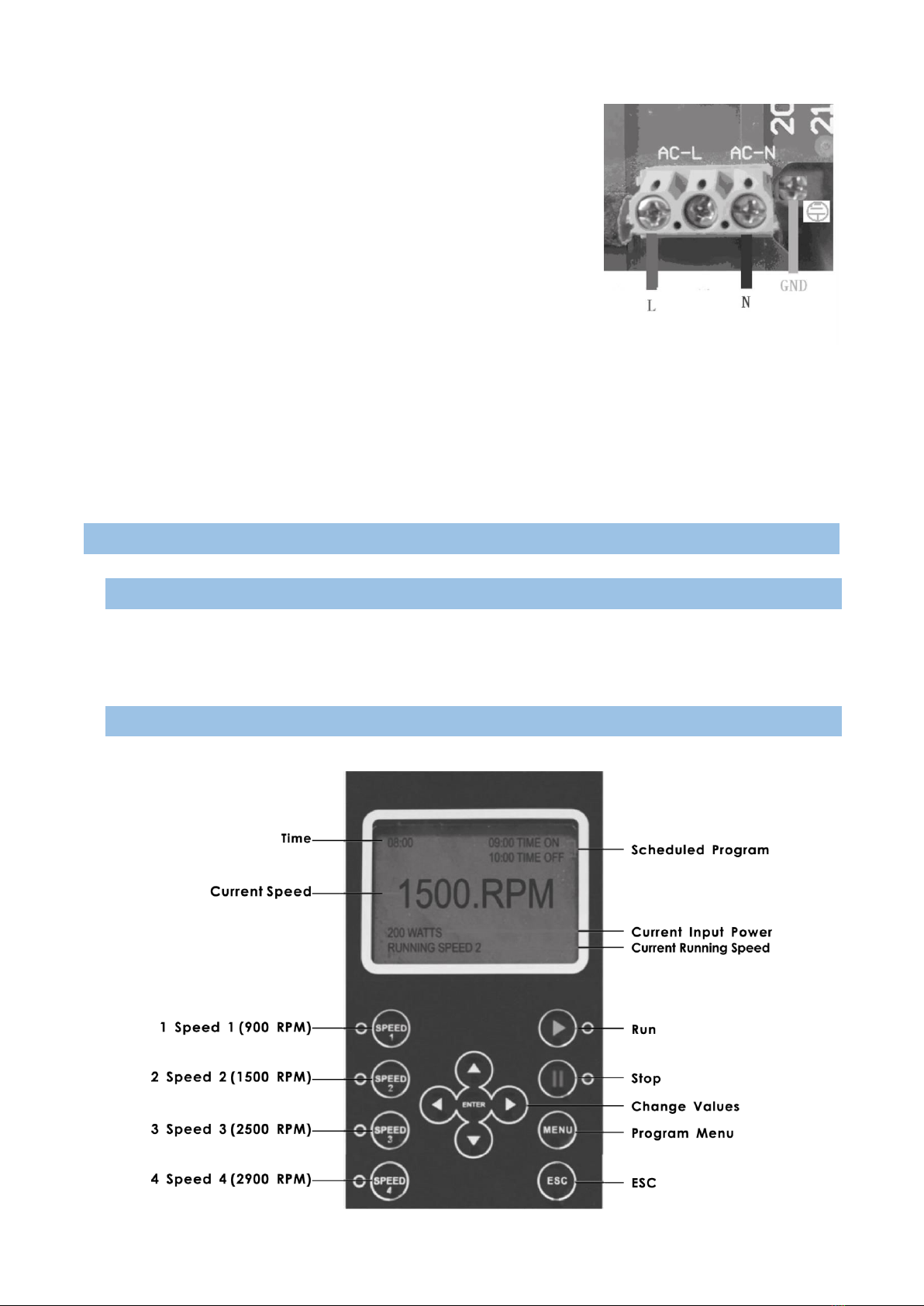

To revise / update "Time On" settings within “Schedules 1” menu:

Use “Up” / “Down” buttons to go to “Time on” option and press “Enter”.

Choose hours / minutes using “Left” / “Right” buttons.

Change hours / minutes using “Up” / “Down” buttons.

Press “Enter” to save settings or “ESC” to cancel.

Press “ESC” to exit.

To revise / update "Time Off" settings within “Schedules 1” menu:

Use “Up” / “Down” buttons to go to “Time off” option and press “Enter”.

Choose hours / minutes using “Left” / “Right” buttons.

Change hours / minutes using “Up” / “Down” buttons.

Press “Enter” to save settings or “ESC” to cancel.

Press “ESC” to exit.

To set up the Schedules 2, 3 & 4 use the same method as for Schedule 1.

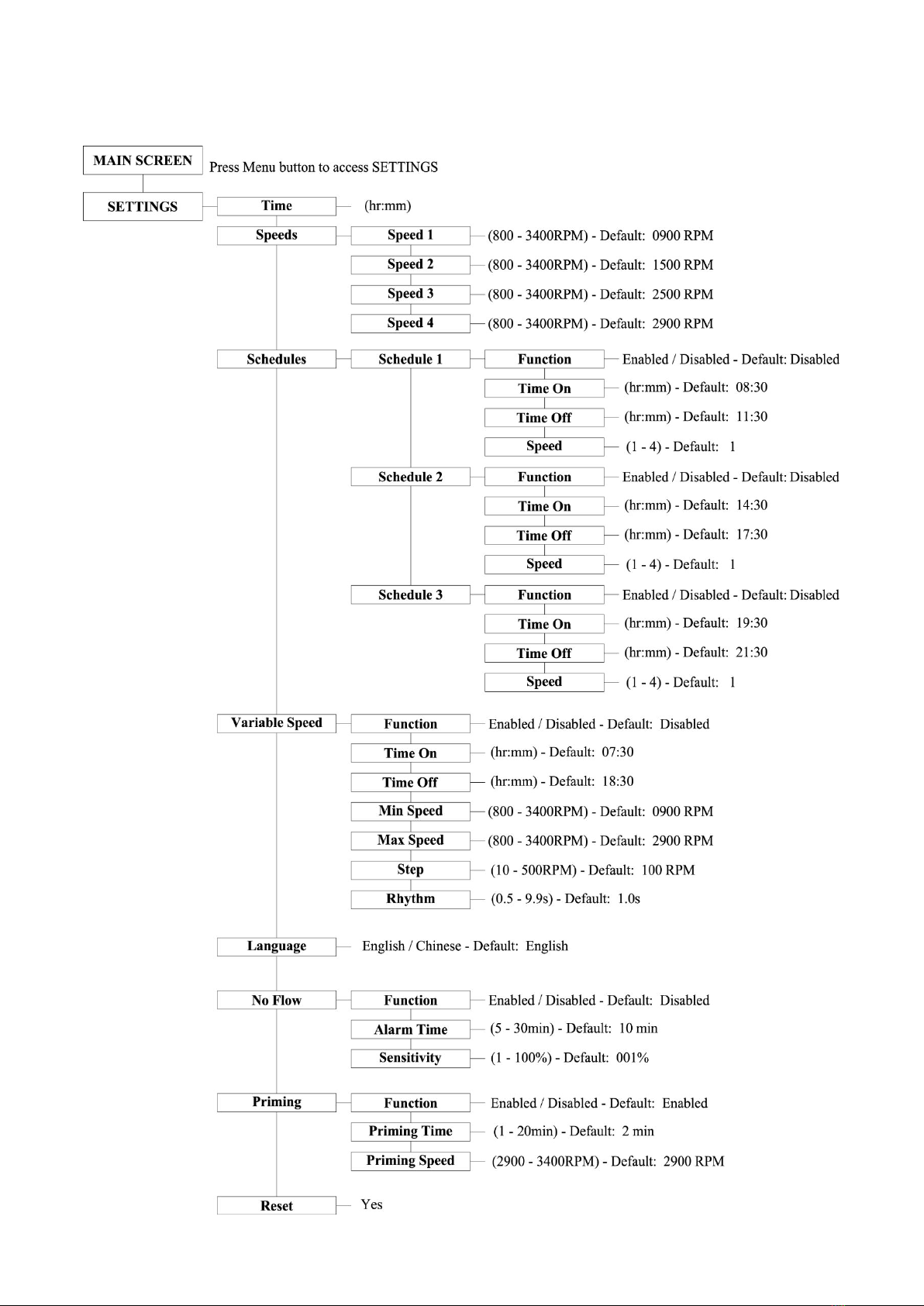

2.5.5. VARIABLE SPEED SET UP

This function is set up through the following parameters:

“Function”: Enable / Disable the speed.

“Time On”: Set the start time.

“Time off”: Set the off time.

“Min Speed”: Set the minimum speed (RPM).

“Max Speed”: Set the maximum speed (RPM).

“Step”: Set the speed for different time frames.

“Rhythm”: Set the time frame for water flow to change.

The “Step” & “Rhythm” options are particularly useful for water features like a water descent,

making water flow change and creating a visual effect.

Make sure the pump is in off position before changing the settings.

Press “Menu” to highlight the settings.

Use “Up” / “Down” buttons to go to “Variable Speed” and press “Enter”.

To set up the parameters above use the same method as for Schedule 1.

2.5.6. LANGUAGE SET UP

Make sure the pump is in off position before changing the program.

Use “Up” / “Down” buttons to go to "Language" option and press “Enter”.

The symbol “>” indicates the language in use.

Press “Enter” again to enter in editing mode, use “Up” / “Down” buttons to select the