P7 IMPORTANT SAFETY INSTRUCTIONS INSTALLATION P8

4. IMPORTANT SAFETY INSTRUCTIONS

The user guide you are holding includes essential information on the

safety measures to be implemented for installation and start-up.

Therefore, the installer as well as the user must read the instructions

before beginning installation and start-up. Keep this manual for future

reference.

1. A protective device is to be installed in the fixed wiring.

2. This appliance can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge

if they have been given supervision or instruction concerning use of the appliance in a

safe way and understand the hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall not be made by children without

supervision.

3. The appliance shall be installed in accordance with national wiring regulations means

for disconnection must be incorporated in the fixed wiring in accordance with the

wiring rules. A disconnected incorporated in the fixed wiring is to be provided.

4. The pump is to be supplied through a residual current device (RCD) or Ground Fault

Circuit Interrupt (GFCI) having a rated residual operation current not exceeding 30mA.

Correct disposal of this product

This symbol on the product, or in its packaging, indicates that this product may not be

treated as household waste. Instead, it should be taken to the appropriate waste

collection point for the recycling of electrical and electronic equipment. By ensuring

this product is disposed of correctly, you will help prevent potential negative

consequences for the environment and human health, which could otherwise be caused

by the inappropriate waste handling of this product. For more detailed information

about the recycling of this product, please contact your local council, your household

waste disposal service, or the shop where you purchased the product.

5. INSTALLATION

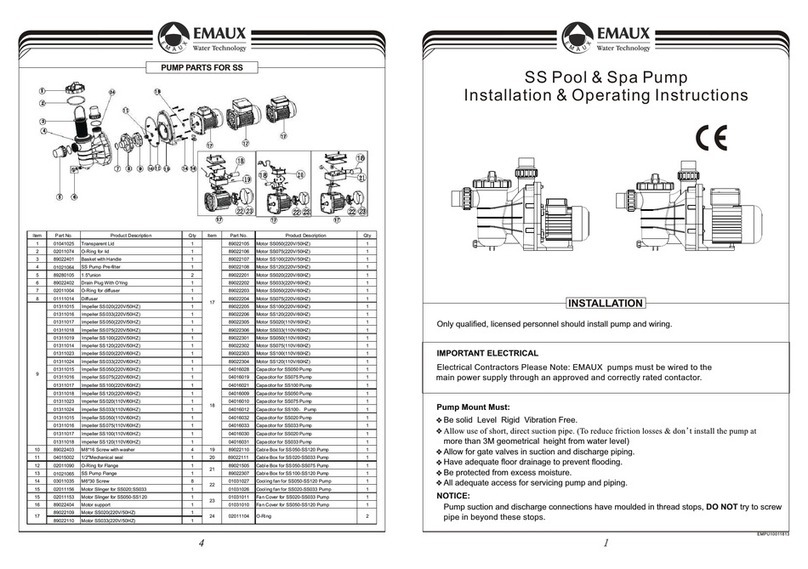

5.1 PIPING

4. Secure the pump to the base with screws or bolts to limit the vibration and the stress

on the pipe or the joints.

5. Leave enough space for gate valves in suction and discharge piping, if required.

6. Ensure there is enough clearance for pre-filter basket & Lid open and motor

ventilation.

7. Connect the suction and discharge pipe to the

outlet and inlet of the swimming pool.

8. Make sure that floor drainage is adequate to

prevent flooding.

9. Make sure that the pump and piping are

accessible for servicing.

Note: The pump suction and discharge connections are mounded in

thread stops, DO NOT try to screw the pipe beyond these stops.

The two sets 1.5” union adaptor are universal design for metric and

imperial PVC pipe connection.

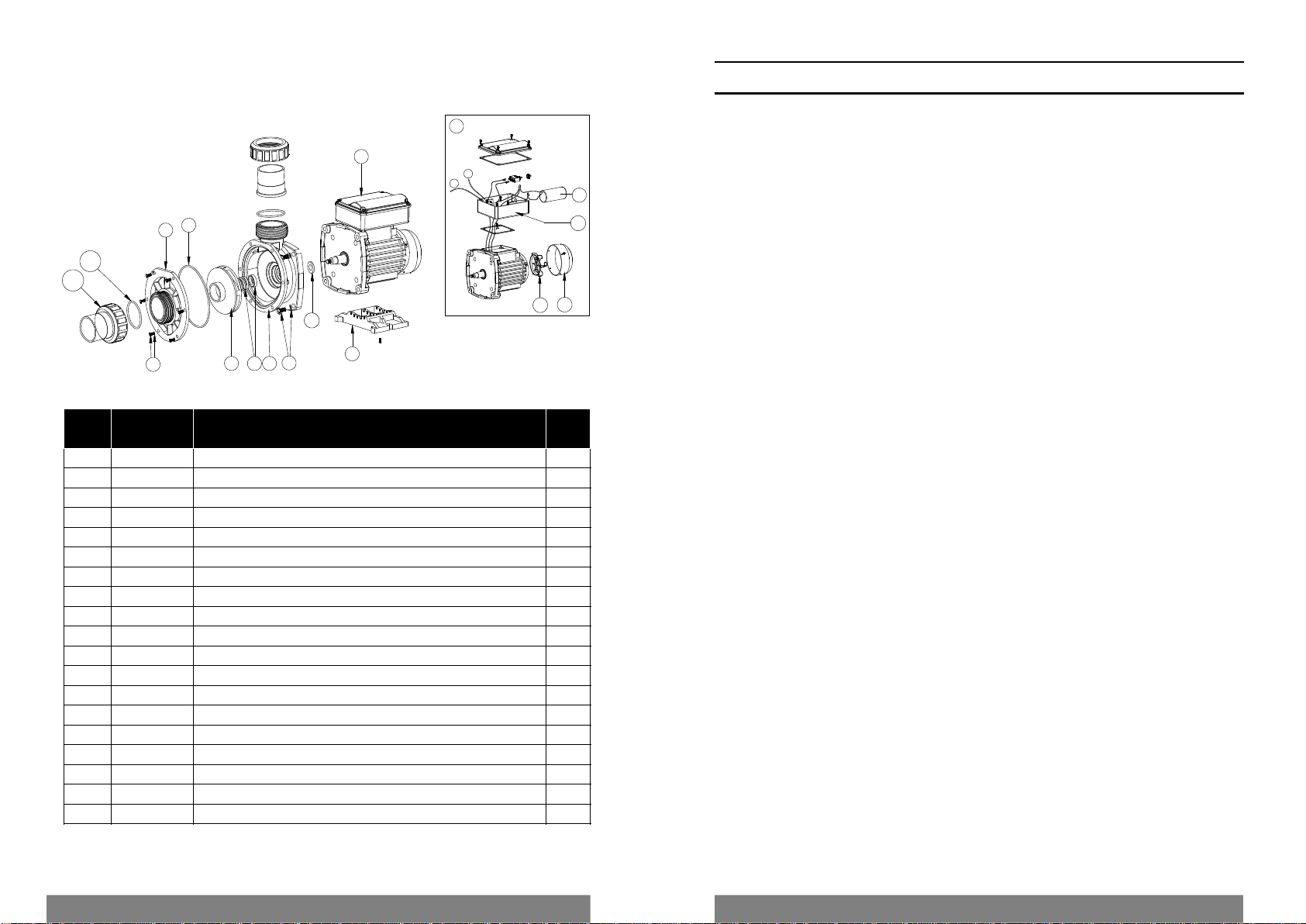

5.2 ELECTRICAL WIRING

This power pump demand licensed or certified electrician or

qualified pool installer to ensure there is adequate protection

between the pump motor and mains power supply according to

individual countries safety code.

The pump has power cord with plug attached on the plug, plug

it to a power socket with circuit breaker to isolate the motor from the mains power for

over load protection. The circuit breaker rating should refer to the electrical specification

of individual pump working voltage and power.

The power has to be with a Residual Current Device (RCD) or Ground Fault Circuit

Interrupt (GFCI) having a rated residual operating current not exceeding 30mA.

1. Install the pump as close to the pool as possible, preferably in a dry, well ventilated

area away from direct sunlight. Protect the pump from excessive moisture.

2. Place the pump as close to the water source as possible, so that the suction pipe is

short, straight and direct to reduce the friction loss. Don't install the pump at more

than 10 ft (3 meters) of geometrical height from water level.

3. Before installing the pump, make sure that the surface is solid, elevated, rigid and

vibration free.

If the RCD / GFCI device trips, it means there is fault on the power line

or motor. Do not use this pump. Disconnect the pump and have the

problem corrected by a qualified service representative before using.

Press the reset button to reset the RDC / GFCI devices after fixed. It will

keeps the circuit shut off and will not reset if the power line problem is

not fixed.

It is recommend to test the RCD / GFCI at least once a month.

Pumps should be shipped with Power cord with plug for corresponding countries. If there

is not power cord attached to the pump, it is necessary to follow the local electricity

power line color code to connect the power according to the wiring for individual pump

diagram.

Bonding Instructions – Permanently wired units will need to include instructions for

connecting the solid copper, equipotential bonding conductor. For SDUS050, SDUS075,

SDUS100, SDUS150, STUS050 and STUS075 with ETL Mark for the United States, the size

of the bonding conductor should be No. 8 AWG. For Canada the size of the bonding

conductor should be No. 6 AWG. Bonding Nut location is as photo.