8

ELECTRICAL

Plug pump into a grounded, GFCI-protected 115 Volt circuit only.

Incorrect voltage can cause fire or seriously damage motor and voids

warranty.

Risk of electrical shock. Connect only to a grounded type re-

ceptacle protected by a ground-fault circuit-interrupter (GFCI).

GFCI tripping indicates an electrical problem. If GFCI trips and will not

reset, have a qualified electrician inspect and repair electrical system.

Risk of electrical shock. Unplug motor before servicing or re-

pairing pump or motor.

Voltage:

Voltage at motor must be not more than 10% above or below motor name-

plate rated voltage or motor may overheat, causing overload tripping and re-

duced component life. If voltage is less than 90% or more than 110% of rated

voltage when motor is running at full load, consult power company.

Grounding:

Pump is supplied with grounded 3-wire cord and plug. Do not modify cord or

plug. Plug into GFCI protected, grounded outlet only.

Wiring:

Table I, Page 4, and Table II, Page 5, give correct circuit breaker sizes for the

pump alone. If other lights or appliances are also on the same circuit, be sure

to add their amp loads to pump amp load before figuring wire and circuit

breaker sizes. (If unsure how to do this or if this is confusing, consult a li-

censed electrician.) Use the load circuit breaker as the master on-off switch.

Plug into a GFCI receptacle on a 115 Volt, 60 Hertz grounded circuit only;

the GFCI will sense a short-circuit to ground and disconnect power before it

becomes dangerous to pool users. For size of GFCI required and test proce-

dures for GFCI, see manufacturer’s instruction.

In case of power outage, check GFCI for tripping (which will prevent normal

pump operation). Reset if necessary.

Do not modify cord, plug or receptacle! If an existing circuit must be used

and the receptacle and factory installed plug do not match exactly, consult a

licensed electrician.

Do not use an extension or drop cord.

Match circuit breaker size to Table I, Page 4, or Table II, Page 5 (depending

on pump model).

OPERATION

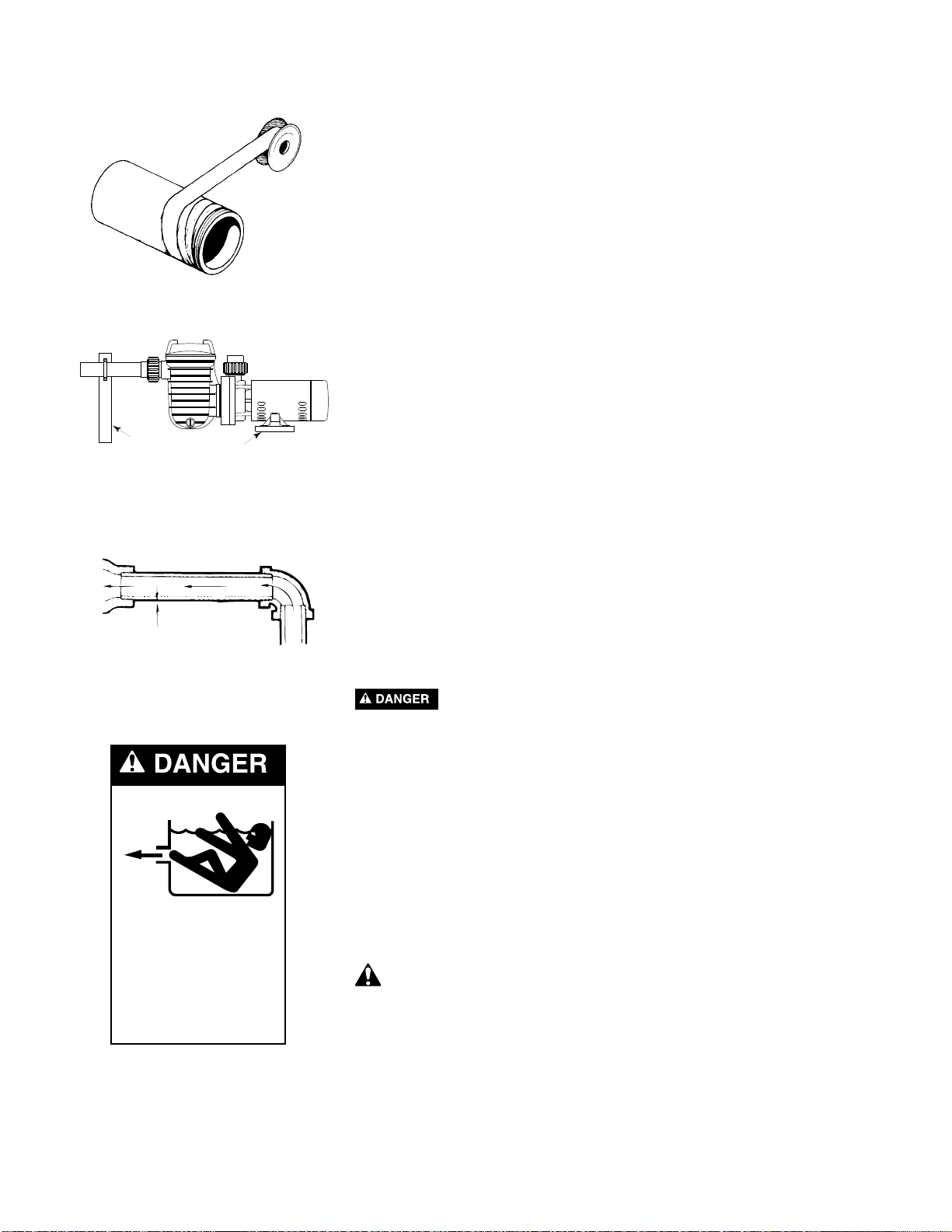

Hazardous suction. Can trap and tear hair or body parts. Can

cause drowning. Small children using pool/spa must ALWAYS have close

adult supervision.

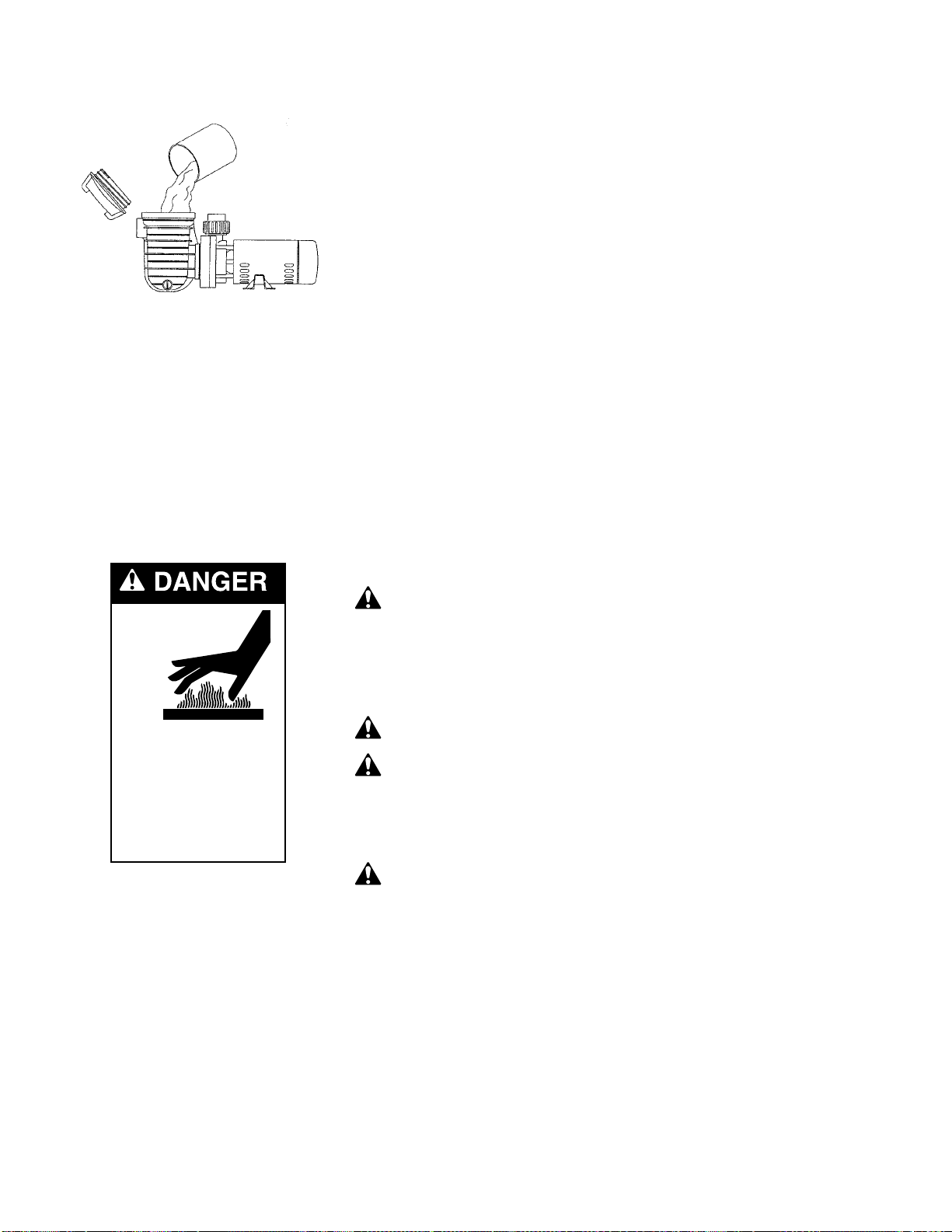

NEVER run pump dry. Running pump dry may damage seals, causing

leakage and flooding. Fill pump with water before starting motor.

Before removing trap cover:

1. STOP PUMP before proceeding.

2. CLOSE GATE VALVES in suction and discharge pipes.

3. RELEASE ALL PRESSURE from pump and piping system.

If pump is being pressure tested, be sure pressure has been released be-

fore removing trap cover.

Priming Pump

Open gate valves before starting system.

Release all air from filter and piping system: see filter owner’s manual.

Hazardous voltage.

Can shock, burn,

or cause death.

Disconnect power

before working

on pump or motor.