EmberGlo AR30 Troubleshooting guide

Installation Service

Manual & Parts

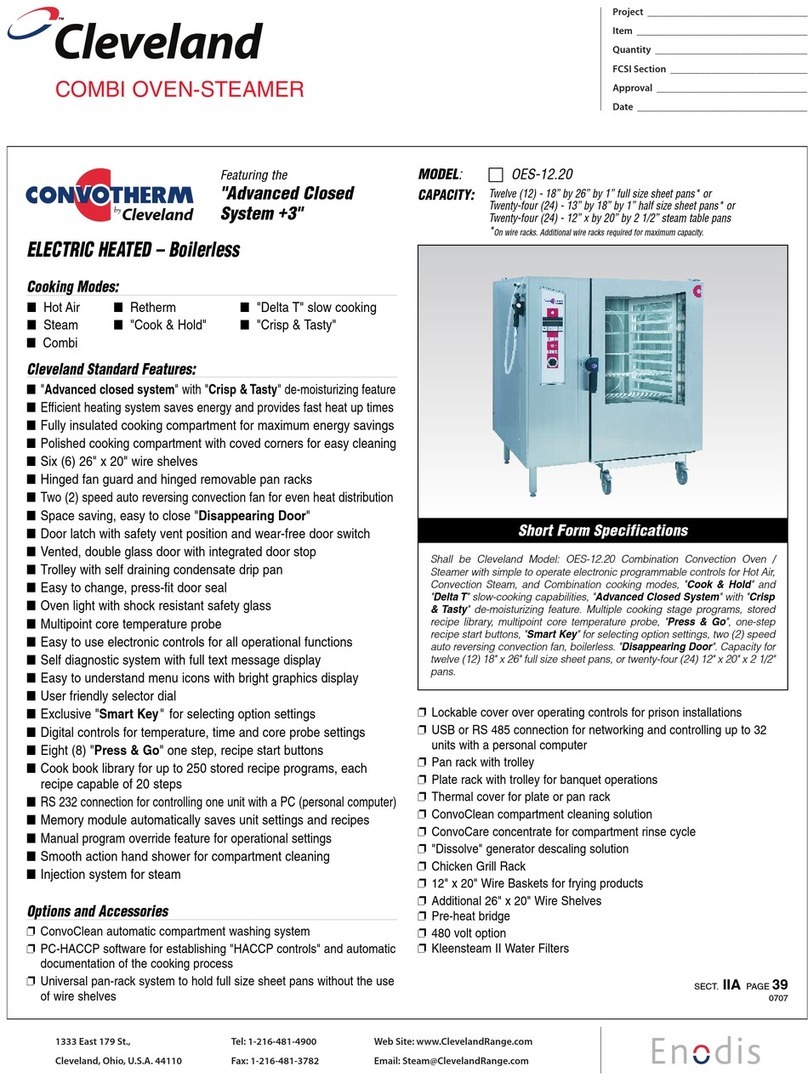

EmberGlo Model AR30

EmberGlo

A Division of Midco International Inc.

4140 West Victoria Street

Chicago, Illinois 60646

tel 773.604.8700

fax 773.604.4070

web www.emberglo.com

Quality Designed for Proven Performance

PRINTED IN U.S.A.

699

8449-80

CAUTION:

This steamer to be used with distilled water only

(demineralized). Without treated water, deposits can build

up in steam generators causing reduced steam volume and

eventual stoppage of steam production. Clogged or limed

steam generators caused by use of non-distilled water will not

be covered under the terms of the warranty.

Warranty

All electrical equipment sold under the Ember-Glo trademark

is warranted against defects in material and workmanship for

a period of one year from date of original installation. Midco's

obligation under this warranty shall be limited to repairing or

replacing, at our option, any part of said equipment which

Midco's examination shall disclose to its satisfaction to be

thus defective.

Under the terms of this warranty, models considered portable

(devices with cords and plug caps such as Midco Steamers)

must be returned to the nearest service station, transportation

prepaid. Non-portable units with permanent wiring will be

serviced on the customer's premises. Under these terms,

Midco agrees within the terms of this Warranty, to make all

repairs at no charge. Portable units will be returned,

transportation collect.

This warranty does not apply to damages resulting from

accident, misuse, abuse or alteration.

No equipment may be returned without written authorization

from Midco. Returned goods must be shipped prepaid to the

factory.

WARNING: Improper installation and use of this

product could result in personal or property injury.

Warranty card must be filled in and returned to Midco to

validate warranty.

SSAAFFEETTYYIINNFFOORRMMAATTIIOONNTTEERRMMSS::The following terms are

used to identify hazards, safety precautions or special

notations and have standard meanings throughout this

manual. When you see the safety alert symbol and one of the

safety information terms, as shown below, be aware of the

hazard potential.

DANGER: Identifies the most serious hazards which

will result in sever personal injury or death.

WARNING: Signifies hazards that could result in

personal injury or death.

CAUTION: Identifies unsafe practices which would

result in minor personal injury or product and

property damage.

Installation

Operation

Maintenance

Daily as Required

Service

1. Position steamer on level surface and plug power cord into 3-hole 120 volt AC grounded

receptacle. If an adapter is used, it must be grounded properly.

2. Pull out water pan and fill with distilled (NOT HOT OR BOILING) water to 1/4" from the

top of the water pan baffles; then close drawer. Unit is now ready for operation.

1. Move toggle switch to ON position. The pilot light remains on at all times. Allow 15-20

minutes to reach operating temperature.

2. Open food drawer, place food in pan; close drawer and operate lever as required per

cooking guide.

3. At end of time cycle, open drawer and remove food.

4. Keep drawer closed when not in use.

5. To shut off unit move toggle switch to OFF position.

Caution: Operate lever to the left and return to vertical position. Rapid repeated

operation will over steam the unit. The amount of steaming necessary is determined

by the type and amount of food to be heated. For more than one shot, wait 15

seconds between shots. A "shot" is one operation of the lever.

The food pan is removed by lifting up. Clean the inside thoroughly and wipe the outside to

remove any material which might have accumulated.

■■

■■

To remove the food drawer, pull the drawer out until it stops, release stop located at rear

underside of drawer to unlock, and pull out the frame. Wipe the drawer and frame clean and

return by inserting the drawer slide into the slide of the frame, then push the food pan to the

rear until the lock engages automatically.

Note: Before attempting service, unplug power cord.

For service or examination, all "working parts" of the steamer are exposed by removing first

the cabinet top, then the back. The wiring diagram and spare cleanout gasket is located on

inside of back.

Electric Switch/Thermostat

The on-off switch should audibly "click" when operated manually. To determine if electrically

operative, a continuity check should be made.

■■

■■The thermostat is factory calibrated and non-adjustable and should no be repaired. Replace

if defective.

Pump System

Operate pump lever and observe length of pump shaft travel. It should travel approximately

5/8". If travel is less, check for broken or disengaged pins, links, crank or half moon key.

■■

■■Disconnect brass fitting at water riser tube and bend tube up slightly so discharging water

will clear front of unit. Operate pump lever; water should shoot out about 15 feet. If water

does not shoot out, remove and inspect inlet tube assembly for leaks. Any air entering tube

will break the suction on the water. Check installation and alignment of dip tube spring as

detailed under next section. If water still doesn't not shoot out, pump should be replaced.

■■

■■A strainer is located in the inlet tube at pump fitting. Loosen fitting and remove pump inlet

tube. Dump strainer out of tube and wash under running water, then replace.

Dip Tube and Spring

If the dip tube does not enter the water pan properly it must be replaced. When replacing, the

open end or point of hook must be at the bottom and the eye must be in a vertical plane, like

a coin standing on edge.

Installation and Service

2

Service

Continued

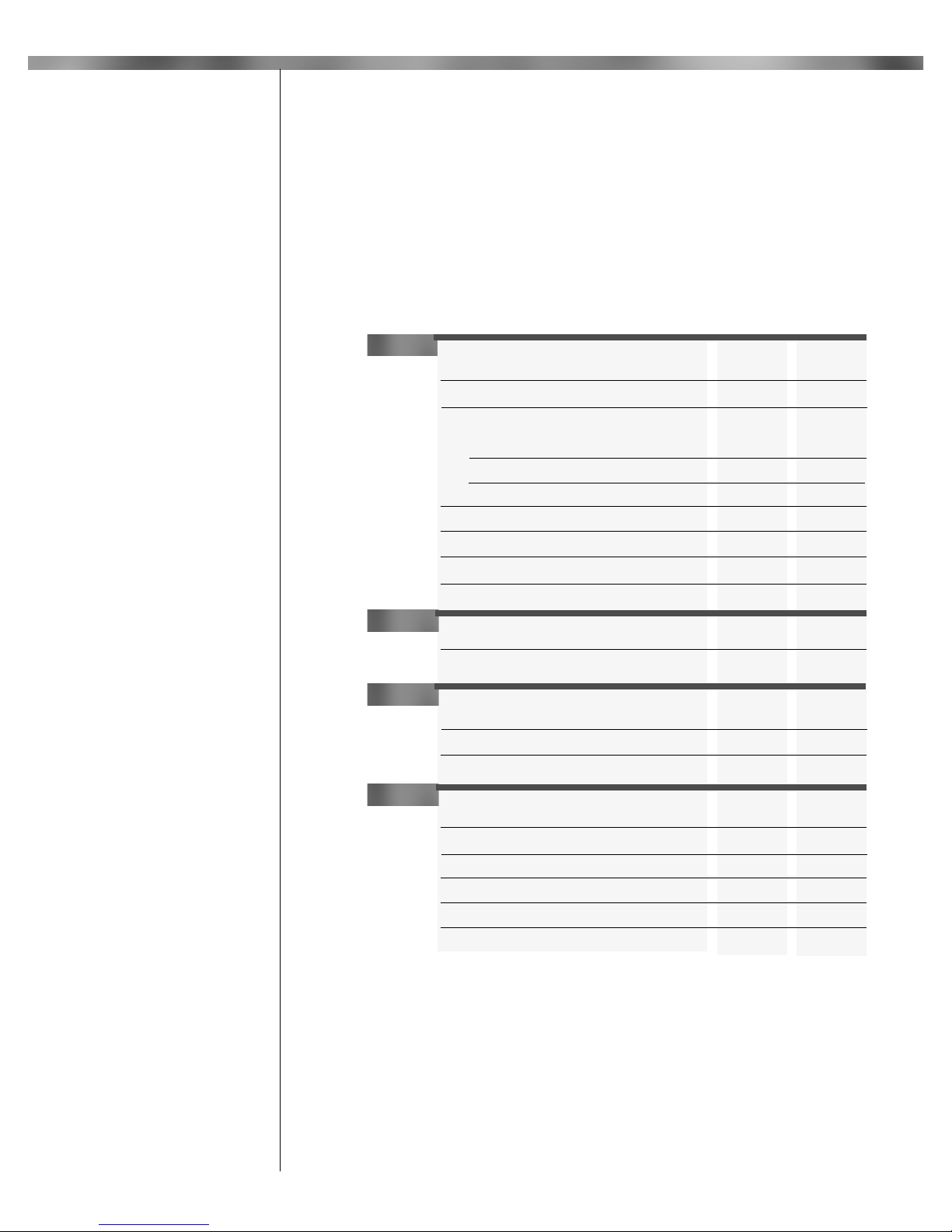

Trouble

Chart

Steam Generator

1. To Clean. Remove cabinet top and generator insulation. This will expose a square plate

on the generator, which is removable for cleaning water passages.

■■

■■

Check the three exposed holes when the clean-out cover is removed. If any of these

holes are clogged, clean them out by hand-twisting a 7/64" drill for the center hole and a

3/16" drill for the two side holes.

■■

■■

After thoroughly cleaning the three holes, plug in power supply and operate lever to

steam unit. THE UNIT MUST BE HOT. Operate several times to blow out any

accumulation.

■■

■■

Replace the clean out cover, using new gasket. With the unit hot, operate lever. The

unit should steam properly. If it does not, and the pump is operative as detailed under

PUMP SYSTEM, the entire generator assembly is probably limed and must be

disassembled and cleaned or replaced.

■■

■■To clean generator assembly, separate casting from plate and clean lime from cavity in

casting.

Caution: Do not damage plate by scratching or polishing the finish.

2. To Remove.

■■

■■Disconnect the water riser tube.

■■

■■Disconnect electric wiring at the two terminals.

■■

■■Remove 16 hex nuts. Note: Remove food drawer and hold screws up to prevent

turning.

■■

■■Lift off generator.

3. To Replace. Place flat plate on steamer housing so the 12 steam holes line up. Lay a

bead of Dow-Corning 732 or General Electric 159 RTV Silicone adhesive (available at

hardware stores) around large cavity in casting. The bead should be about 1/16" to 1/8"

(diameter) and approximately 1/8" from edge of cavity. Use finger to smooth out the

silicone, be careful not to block steam holes.

■■

■■Place casting on plate, replace screws and tighten securely. Allow the RTV to set about

24 hours before operating unit.

Note: Also refer to TroubleShooting Guide (8471-03) for addition service information.

1. Unit will not heat up; light out.

a. No power.

b. Plug out.

c. Loose internal connection.

d. Defective switch.

2. Unit will not heat up; light on.

a. Defective thermostat.

b. Loose heating element connection.

c. Defective generator electrical unit.

3. Unit heats up light will not light.

a. Defective light in switch.

b. Loose connection.

4. Unit heats up; does not steam.

a. No water in pan.

b. Defective pump.

c. Cam, pins or linkage broken or disengaged.

d. Leak in inlet tube.

e. Dip tube spring assembly misaligned.

f. Clogged steam generator.

Note: If electrical trouble is other than loose connections, it is recommended that parts be

replaced rather than repaired.

3

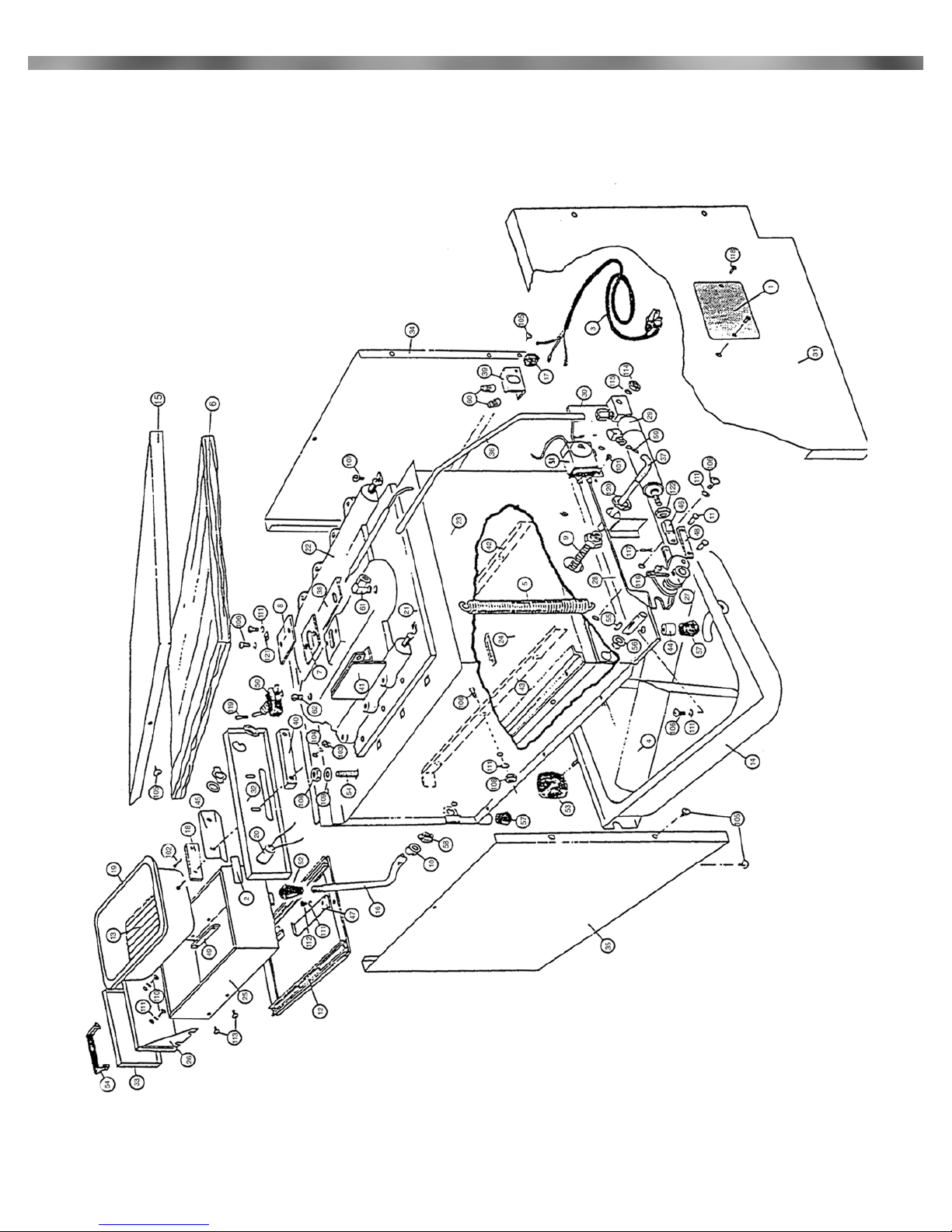

PART NUMBER DESCRIPTION

1 1402-00 Spec Label

2 1694-00 Caution Label

3 2618-00 Cord Set

4 2619-30 Water Pan Baffle (2-Required)

5 2625-30 Pump Spring

6 5601-40 Generator Insulation

7 5601-80 Clean Out Cover Gasket

8 5601-90 Clean Out Cover

9 5604-35 Dip Tube Spring Assembly

10 5604-83 Spacer

11 5605-20 Cam Pin (2-required)

12 5607-00 Slide Channel Rivetment

13 5608-50 Food Pan Grid

14 5609-00 Water Pan Weldment

15 5613-00 Cabinet Top

16 5615-02 Pump Handle

17 5616-90 Strain Relief

18 5622-00 Steam Range Name Plate

19 5626-00 Food Pan

20 5648-00 Pilot Light Assembly

21 2608-10 Discharge Plate

22 5655-00 120V Generator

23 5658-00 Steam Chamber Weldment

24 5658-60 Steam Chamber Bottom Rivetment

25 5658-80 Food Drawer Rivetment

26 5659-20 Door Liner/Cusset Weldment

27 5659-60 Crank

28 5659-90 Rear Leg

29 5660-00 Pump/Check Valves

30 5660-10 Pump Chassis Weldment

31 5660-50 Cabinet Back

32 5660-60 Upper Switch Panel

33 5660-70 Food Door

34 5660-80 Left Cabinet Side

35 5660-81 Right Cabinet Side

36 5660-90 Riser Tube

37 5661-05 Pump Tube Assembly

38 5661-30 Bulb Clamp

39 5661-40 Heyco Mount

40 5661-50 Upper Switch Panel Spacer

41 5661-60 Spring Anchor

42 5661-70 Left Water Pan Support

43 5661-71 Right Water Pan Support

44 5661-80 Rear Foot (2-Required)

45 5661-90 Steam Deflector

46 5663-00 Pump Rod End

47 5663-10 Slide Channel Stop

48 5663-20 Pump Line (2-Required)

49 5663-90 Food Drawer Nut Plate (2-Required)

50 8423-14 Rocker Switch

51 8452-08 Thermostat

52 8445-00 Ball Knob

53 8445-01 Cover Knob

54 8445-04 Black Vinyl Grip

55 8450-11 3/32 x 5/8Woodruff Key

PART NUMBER DESCRIPTION

56 8450-19 3/8Nyliner

57 8450-25 Socket Tip (4-Required)

58 8451-36 10-24 x 1/2Stainless Steel Carriage Bolt (16-Required)

59 8451-44 Strainer

60 8480-17 74B Wire Nut (2-Required)

61 8483-00 1/8M x 1/4T Compression El

62 8496-11 1/8Brass Pipe Fitting

101 6-32 x 1/8Slotted Round Head Zinc Plated (2-Required)

102 6-32 x 1 Slotted Oval Head Nickel Plated (2-Required)

103 6-32 Hex Nut Zinc Plated (2-Required)

104 No. 6 Split Lockwasher Stainless Steel (2-Required)

105 No. 8 x 3/8Phillips Round Washer Head (13-Required)

106 10-24 x 3/8Slotted Round Head Stainless Steel (13-Required)

107 10-32 x 1/4Slotted Pan Head Stainless Steel (2-Required)

108 10-24 Hex Nut Zinc Plated (23-Required)

109 No. 10 Flat Washer Zinc Plated (16-Required)

110 10-24 x 7/8Slotted Round Head Stainless Steel (2-Required)

111 No. 10 Split Lockwasher Stainless Steel (16-Required)

112 10-24 x 1/4Slotted Pan Head Stainless Steel

113 10-32 x 3/8Phillips Truss Head Stainless Steel (4-Required)

114 1/4-20 Hex Nut Zinc Plated

115 1/4Split Lockwasher Zinc Plated

116 1/8x 1 Cotter Pin Zinc Plated

117 Hitch Pin (2-Required)

118 3/32 x 3/16 Aluminum Pop Rivet (2-Required)

119 Black Switch Tip

120 1/2-20 Pal Nut 1220 Zinc Plated

121 Celsidot 450°F Label

122 5/16-24 Hex Jam Nut

The Following Kits Are Available

2608-80 (16) 8451-36 Stainless Steel Carriage Bolts

with nuts and washers

5604-35 (1) 5604-30 Dip Tube Spring Assembly with nut

5605-90 (2) 5605-20 Cam Pin with (2) hitch pins

5609-50 (2) 2619-30 Water Pan Baffles

5615-10 (1) 5615-02 Pump Handle with 8450-19 Nyliner,

8450-11 Woodruff Key and 1/8x 1 cotter pin

5627-20 (1) 5601-90 Clean Out Cover, (2) 5602-20 Clean Out

Cover Gasket with (2) 10-24 x 3/8slotted round head

screws, (2) No. 10 split lockwashers and Celsidot label

5659-65 (1) 5659-60 Crank with 1/8x 1 cotter pin and (1)

8450-11 Woodruff Key (order part no. 5605-20 cam

pins and hitch pins separately)

5661-05 (1) 5661-00 Pump Tube Assembly with 5/16 nut and

ferrule

5663-25 (2) 5663-20 Pump Links only

5663-50 (1) 5660-00 Pump/Check Valves (1) 5560-10 Pump

Chassis Weldment (1) 5659-60 Crank (2) 5663-20

Pump links (3) 5605-20 Cam Pins (1) 5663-00 Pump

Rod End (2) hitch pins (1) 1/4-20 hex nut (1) 1/4split

lockwasher and (1) 5/16-24 hex nut

5663-60 (1) 8543-13 Wire Assembly Black (1) 8543-14 Wire

Assembly Black (1) 8551-17 Wire Set White and (1)

8551-18 Wire Set Black

5663-70 (1) 5660-90 Riser Tube with (2) each tube sleeves and

tube nuts

Parts

Avoid error in parts selection. When ordering, use complete Ember-Glo part number and description. Furnish model number,

bill of material number and date code or serial number from specification plate.

IMPORTANT: Availability of parts as well as specifications are subject to change without notice.

Please consult factory for item availability.

4

Exploded View

120V 12.5A 1500W

5

Heating and Cooking Guide

These suggestions are made only to help the operator get started. Since each location will

have different portions and different requirements, each operator must determine his own

operation habits. Please remember that the steamer conserves its steam in the drawer and

therefore does not often need repeated shots. The main exception is when frozen product

must be defrosted.

If a product is at room temperature or refrigerated, start with 2 shots (operate lever

twice). This ensures that the food pan is full of steam.

If a product is frozen, start with 3 shots because condensation on the cold product

eliminates the steam quickly.

Cooking Instructions

Meats

Sliced meats

Hamburger patties (precooked)

Cheeseburger (precooked)

patty with cheese

patty with cheese on bottom bun

Hot Dogs

Bacon (precooked)

Link Sausage (precooked)

1/2Chicken (1lb)

Ribs (precooked)

Poached

Soft Boiled

Buns (open)

Buns (closed)

Rolls

Macaroni and Cheese (casserole)

Rice (precooked)

Spaghetti (precooked)

Vegetables (precooked)

Chop Suey (casserole)

Shrimp (unfrozen)

2

2

2

2

2

2

2

2

2

1

2

2

3

2

2

2

3

3

10-20

30

30

90

60-90

45

60

60

30

10

20

20

90-120

45-60

45-60

30-45

90-120

90

Shots Seconds

Eggs

Bread

Pasta

2 shots/60 sec. then

2 shots/30 sec.

2 shots/60 sec. then

2 shots/90 sec.

Excellent results can also be achieved with many other precooked or frozen foods such as any

non-breaded seafood… clams… lobster tails… scallops… red snapper… crab legs… all breads

and rolls… french bread loaves… hoagies… onion buns… many specialty foods… tortillas…

enchiladas… pizza slices… and much more!

6

Other manuals for AR30

2

Table of contents

Other EmberGlo Electric Steamer manuals