EMBLEM EASYLAM 140 C User manual

Operating instructions

Laminator

Version 1.0

140 C

- 2 -

Please read this operating instructions before installation and keep this

for later use

technical information

model..............................................................................................................EASYLAM 140C

length .............................................................................................................177 cm

width ..............................................................................................................48 cm

height .............................................................................................................135 cm

height working area .......................................................................................97 cm

max. media width ...........................................................................................143 cm

usable roll length ............................................................................................1420 mm

max. opening of rolls......................................................................................40 mm

power supply .................................................................................................110 - 230 V

internal power supply .....................................................................................12 V

.....................................................................................................................50/60 Hz max. 4,5A

INSTALLATION

The laminator is delivered in wooden box.

size .................................................................................................................2000 x 900 x 600 mm

weight in total kg ...........................................................................................115 kg

To open the box we recommend to use a cordless screwdriver. Further you need a open-end wrench, size 17

Further advises for installation:

Power supply:

The connection sockets have to be close to the machine.

• single-phase current 110 V - 230 V

• frequency: 50 – 60 Hz

• strength of electric current: 4,5 A

Location

The location to place the machine must provide enough space to work. Don’t forget that space is also

needed to insert and remove the material. Please consider the dimensions of the pictures and sheets

used.

Place

Prepare a flat location suited to the size of the machine and also consider its accessories.

Lighting

Good lighting (300 – 600 lux) is indispensable to operating and maintaining the machine safely.

Room properties:

The laminator has to be placed in a closed room and has to be protected against weather effect.

• Permissible room temperature: 18°C to 35°C.

• Humidity range permitted: 30% to 80%

Electricity connection

Check that the electrical supply corresponds with the machine performance.

With connecting to the electricity supply, the laminator must be earthed.

To connect the laminator with electric supply system:

• Interrupt the current supply.

• Connect the connection cable to a suitable plug or directly to the main (capsule rail, junctionbox, etc.).

• Turn on the electricity with main switch (10).

Test before use

Before the actual initial operation, carry out a few test runs of the different functions of the device.

- 3 -

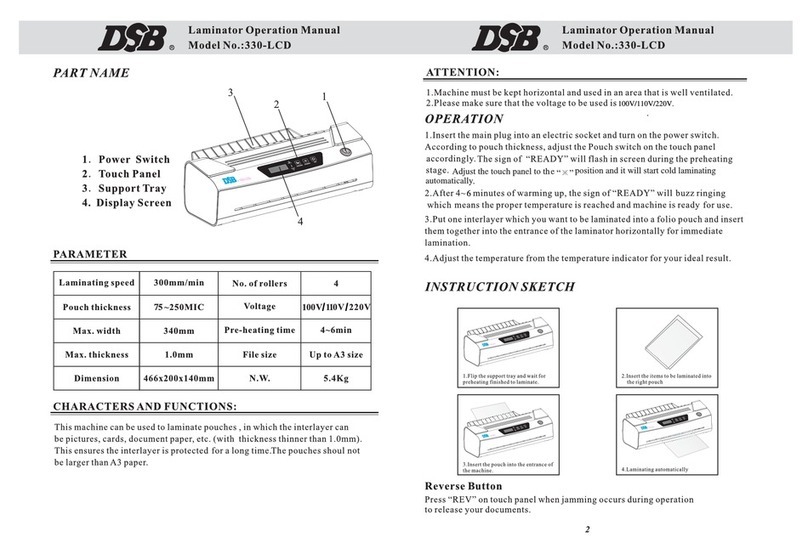

9) Roll-down axle R1

10) Main switch

7) Textile basket

8) Adjustment of the brake for R1

1) keyboard/operating panel

15) Pressure rollers

16) Supply plate with guide roller

5) Roll-down axle R4

6) Lever to set up the height of the

supply plate

3) Adjustment of the brake for R4

2) Adjustment of the strength of the

roll-up coupling R3

4) Roll-up axle R3

17) Side casing

12) Roll-up axle R2

18) Wheel with brake

11) connection for the footpedal

14) Adjustment of the strength pf the roll-up

coupling for R2

13) Cable inlet

- 4 -

19) Foot switch “FILM“

foot switch on backside

The keyboard:

The laminator is controlled (apart from footpedal) by the following keyboard:

- 5 -

● adjustable brakes and

clutches

Safety devices

The machine includes the following safety devices:

Left safety cover

right safety cover

safety system (slip clutch)

Make sure that your hands do not get between the rolls while the machine is opera-

ting. EMBLEM EASYLAM 140C is eqipped with a safety mechanism which uses a

slip clutch to stop the rotation of the rollers. In this way serious injuries or pinching of

the fingers are avoided. During running the machine the user has to make sure that

no parts of the body or other unknown objects get between the rolls.The manufac-

turing company will not accept any liability - especially in case of any mechanical or

electrical alteration of the mechanism by the user.

The side covers are designed to protect the electric equipment of the machine and

may be removed by qualified personal only or by service technicians authorised by the manufactor.

● FILM,FOAM-keysfor

preset modes of roller

pressure.

● SPEED1-2,5m/min.

SPEED 2 - 3,5 m/min.

● START/STOP–Startandstoprunning

the rolls.

● REVERSE–themachinestopsand

goes back (after 2 seconds).

● OPENkeyforautomatic

open of the rollers

● MANUALOPENkey

● MANUALCLOSEkey

Operation of the machine

When you start working stay directly in front of the machine. The laminator has to be turned on with the

main switch (right down, inside the machine). The main switch is lighted in green.

With the keys SPEED I or SPEED II you decide the speed of lamination. You can also use the footpedal

to adjust the speed of the laminator.

General operation advice

AxlesR1-R4areequippedwithadjustablebrakesandclutches.Allmediumshavetheirownspecifi-

cations, which differ by temperature, humidity, used glue, type of film and more. The best condition is,

when the lamination film is tensioned at the upper roll and can be applied without wrinkles. To find the

best adjustment you start with low brake condition. If necessary you can increase the break power.

We recommend not to use too much brake to get not too much tension. The lamination film would

warptoomuchandthelaminatedproductwouldgettoomuchtension.Usingthetakeupforlineryou

need low tension. Please notice to adjust the clutches properly.

Operation of the machine

The machine may be used only by trained and qualified personel.

Tosetthepressurecorrectlyyoucaneitherusethepre-setfunctions„FILM“or„FOAM“.Youcanuse

alsothemanualfunctionwitharrow-keysupordown.„FOAM“isforfoamboardsorothernotrigidmedia.

„FILM“ is for paper, film and self adhesive vinyl. To get the correct right pressure, we recommend to make

tests sample.

When the roller pressure is exceeded to a damaging extent, the machine stops automatically.

To avoid tension and pushing, the material to be worked with should be placed in the middle, i.e. at an

equal distance from both sides; the same applies to small formats (e.g. for a roller width of 1,450 mm and

a material of 450 mm).

When laminating thin foils or paper, it is important to choose the width of the laminate according to the

dimensions of the picture. It should not protrude too far over the print to be laminated as otherwise it

could stick to the lower roller. It is perfect if the paper to be laminated or the base is bigger than the lami-

nate to be applied.

If this is not possible, the size difference between the laminate and the paper has to be kept as small as

possible (no more than 2–3 cm per page) to avoid creases.

Material supply

Themediaaxles(R1-R4)couldbeequippedwithlaminationfilm,linerordoublesidedadhesionfilm.To

place the axes, please notice the pictures and do the following:

Removing the scroller

• Lift up the scroller at the left side.

• pull it from its right fastener

Insert the scroller into the core of the roll of media you want to use which is easy thanks to autogrip mate-

rial insertion. As soon as the machine starts operating, the autogrip function will lock with the media inside

its core and it will rotate with the scroller.

Inserting the scroller

Thescrollerhastwodifferentends.Oneendislabeledbluewitharedcircle.Thispartisfortherightcon-

nection.

- 6 -

- 7 -

Operating priciples:

Adhesives without protective liner (application tape, double-sided adhesive film):

•OpenthelaminationrollerbypressingthebuttonMANUALÇ/Èand put on the laminate flatly. Ensure that the

film is completely flat on the roller and there are no folds or waves. Secure the film by fastening (tape) it slightly

onto the back workspace.

•UsethebuttonMANUALÇ/Èto put the upper roller about 1 cm off the lower roller. Meanwhile the foil might

come loose during this time and no longer stick to the roller perfectly. Pull the foil straight again so that it is

slightly under tension.

• After you have put the base to be used under the laminating roller, use Çand Èto adjust the rollers comple-

telytoposition0oruse„FILM“or„FOAM“toshuttherollers.Iftheprintmediumisnotstiff,putonthelaminate

that it extends to the work surface via the rubber roller and the slit so it sticks when the machine starts up.

LINER-ROLL-UP DEVICE

PRINT MEDIUM

RUBBER ROLLER

LAMINATE

Laminating single prints

Insert the scroller into the right

connection. Move the scroller that

way, so the pin fits into the holding

fixture.

insert this end of the scroller into

the left connection

label on the side

with pin.

right end of scroller

with pin

• Autogrip material insertion

to equip self-adhesive

ToequipyourlaminatorwithlaminationlminasimpleandeconomicalwaywerecommendourEASYLAM-CUTTER

(Art.-Nr.:24959).

Its knife has a special blade to minimize the danger of getting hurt or of damaging the rolls considerably.

Advantages:

- yousavetimeandmaterialwhileinsertingthelaminationlmincludingliner

- no exposed knife point

Thefollowingdescriptionoftheprocedureallowsaneconomicalconsumptionofthelaminationlmwhileequippingthelamina-

torwithfoil.Thecuttersimpliesthepreparationofthemachineandhelpstolearnitfaster.

You can get this tool at your local dealer or at www.dataplot.de.

EASYLAM-CUTTER

- 8 -

Place the lamination film between

the rollers

Hold the film tight and clamp the

rollers

Make sure the lamination film is

rolled tight

Feed foreward approx. 5cm of

lamination film

Position the blund part of the knife

between film and liner

Cut the liner carefully

Usethesharpendinfrontofthe

knife too

Fix the liner to the core Start Laminating

- 9 -

Procedure - EASYLAM CUTTER

- 10 -

Laminate with backing paper:

•OpenthelaminationrollerbypressingthebuttonOPENkeyandputinthelaminateasshowninthepicture.

Pushanemptyrollercoreontotheroll-upaxleR3sothattheprotectiveliner/backingpapercanberolledup.

•Afteryouhaveattachedthelaminatetotheroll-downaxleR4,separatethebackingpaperandusetapetofas-

tenittothecardboardcoreontheroll-upaxleR3.Ensurethattheprotectivelinerhasbeenfasteneduniformly

without cross creases. Pull the laminate between the rollers and stick it onto the upper roller with tape. When

doing this ensure that the foil is spread out evenly across the whole width. If there are creases or folds, repeat

the steps until the material is perfectly positioned.

•Byadjustingthecouplingoftheroll-upaxlesthepulloftheR3axlecanbestopped.Onlyasmallamountof

power is required to roll up the liner. Therefore, do not select a very high value.

• The required breaking power is normally low unless the protective liner has much more power than the vinyl. In

this case the tensile force has to be increased accordingly.

•UsethebuttonMANUALÈ/Çto put the upper roller about 1 cm apart the lower roller. The laminate might

come loosen during this time and no longer stick to the roller properly. Correct the film again.

•Puttheprinttobelaminatedbetweenthelaminatingrollersasshowninthepicture.UseÇand Èto adjust the

rollerscompletelytoposition0oruse„FILM“or„FOAM“toshuttherollersorusefootswitchatbackside.

•Releasethefilmthatyouhavefixedwithtapetotheupperrollerandstartrunningthemachine.

Laminating with backing paper:

LINER-AUFROLLVORRICHTUNG

DRUCKMEDIUM GUMMIWALZEN

LAMINAT

FERTIGES PRODUKT

Mounting on rigid boards with EASYLAM

There are different technics professional users execute. First you have to face two requirements:

a) Mounting a print on a self adhesive board

b) Mounting a self adhesive print on board

General:

Openthegapbetweentheaxlesatthathighoftheboard.

Adjust the high of the supply plate to the high of the board.

Move the board between the axles and close the gap by “FILM”-key.

Removetheboardoutsidebyusing“REVERSE”–key.

Nowthegapisadjusted.

For requirement a) Mounting a print on a self adhesive board

Pull of 3-4 cm of the liner of the adhesive board and stick the print to the board manually.

Move the board between the axles and place print on top of the upper axle like shown in graphic I.

Start mounting by some push of the board to move between the axles and push “start”- key.

Move away liner manually during mounting process.

- 11 -

- 12 -

For requirement b) Mounting a self adhesive print on board:

Pull of 3-4 cm of the liner of the self adhesive print and stick the print onto the board manually.

Move the board between the axles and place the print on top of the upper axle like shown in graphic II.

Start mounting by some push of the board to move between the axles and push “start”- key.

Move away liner manually during mounting process.

Alternative technique:

Place the print on the board

Move this both into the open axles in the middle of the board and close axles to fix position of board and print.

Print should be some larger then board to adjust easy.

- 13 -

Cut the liner of one half of the self adhesive media and mount this half by using the laminator pushing “start” key.

Turn around and insert the board again.

- 14 -

CE DECLARATION OF CONFORMITY

Us, DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Company manufacturerof the brand EMBLEM, declares under our own responsility, that the machine:

Brand: EMBLEM

Model: Easylam Expert 140C

Easylam Expert 160C

Easylam 140C

Easylam 160W

Easylam 160C

is in conformity with:

The requirements of EU Directive 2006/42/EC.s

The requirements of EU Directive 2004/108/EC.

The safety requirements of EU Directive 2006/95/EC.

- 15 -

DataplotGmbH•Gutenbergstraße15•D–24558Henstedt–Ulzburg•Germany

Tel. +49 41 93 995 0 • Fax +49 41 93 995 220

Table of contents

Other EMBLEM Laminator manuals