Embraco Fullmotion CF10C User manual

FULLMOTION COMPRESSORS

ELECTRONIC INVERTER

Product Manual

Fullmotion CF10C

www.embraco.com October, 2018 Revision 2.1

BEFORE YOU BEGIN

!!

WARNING

!!

NOTICE

CAUTION

!!

Incorrect operation could result in bod-

ily injury or death due to electrical haz-

ard.

!!

WARNING

!!

NOTICE

CAUTION

!!

Incorrect operation could cause bod-

ily injury or could result in equipment

damage.

!!

WARNING

!!

NOTICE

CAUTION

!!

Contain helpful suggestions or refer-

ences to material not covered in this

document.

Contents

1 INTRODUCTION 1

1.1 Productdescription ............................. 2

1.1.1 Stand alone inverter . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.2 Instituteapproval.......................... 2

1.2 VNE compressor series description . . . . . . . . . . . . . . . . . . . . 3

1.3 FMF and VEG compressor series description . . . . . . . . . . . . . . . 4

1.4 Producthandling............................... 4

1.5 Dimensions(mm) .............................. 5

1.5.1 FMF and VEG compressor series . . . . . . . . . . . . . . . . . 5

1.5.2 VNE compressor series . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Packageinformation............................. 6

2 TECHNICAL SPECIFICATIONS 8

2.1 Nomenclature ................................ 8

2.1.1 Labelinformation.......................... 9

2.2 Productspecications............................ 9

2.3 Inverterenclosure .............................. 11

2.3.1 Product dimensions . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.2 Connectors.............................. 11

2.3.3 Productdiscards .......................... 14

2.4 Information about input inrush current . . . . . . . . . . . . . . . . . . 15

3 INSTALLATION 16

3.1 Assemblyinstructions............................ 16

3.1.1 VEG and FMF compressor cable connection . . . . . . . . . . 17

3.1.2 VNE compressor cable connection . . . . . . . . . . . . . . . . 19

3.1.3 Forced ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.1.4 Optional AC Fan switch control . . . . . . . . . . . . . . . . . . 24

3.1.5 Inverter cables arrangement . . . . . . . . . . . . . . . . . . . 25

3.1.6 Input cable with ferrite lter . . . . . . . . . . . . . . . . . . . . 27

3.2 Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4 OPERATION 29

4.1 Frequency control mode . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2 Drop-Incontrolmode ............................ 31

4.2.1 First time Pull-down . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2.2 Normalcycling............................ 32

4.2.3 Connection.............................. 32

CONTENTS

4.3 Serialcontrolmode ............................. 33

4.3.1 Serial specications and Internal Circuit . . . . . . . . . . . . . 33

4.3.2 Commands.............................. 35

5 DIAGNOSTICS 39

5.1 LEDindication ................................ 39

5.2 Troubleshooting ............................... 40

GENERAL PRECAUTIONS

!!

WARNING

!!

NOTICE

CAUTION

!!

• During instalation the environment must be prop-

erly protected against ESD. The operator and ma-

chines must be properly Earthed.

• Make sure that Fullmotion CF10C Inverter will not

be in direct contact with ames during assembly.

• The location where the Inverter will be installed

must be protected against splashed water from all

directions.

• Do not open the Inverter enclosure. For installa-

tion, remove only the Inverter Cover to make the

electrical connections.

!!

WARNING

!!

NOTICE

CAUTION

!!

• This inverter is for use only with the Fullmotion Em-

braco compressors.

• Read this material carefully before you begin the

Fullmotion CF10C Inverter installation and start up

procedure.

• To prevent damage to your inverter during and af-

ter assembly, avoid contacting with the following

substances: Hydrocarbons; Ester based oils (e.g.:

compressor oil); Phenols; Amines; Ketenes; Au-

tomotive uids such as grease, except glycol and

heavy alcohol.

!!

WARNING

!!

NOTICE

CAUTION

!!

• The protection against access to live parts have

been evaluated according to the relevant require-

ments from IEC 60335-1 and UL 60730-1.

Chapter 1

INTRODUCTION

Embraco’s Fullmotion compressors are ideal for commercial applications where

wide voltage range, fast pull down, better performance, ne temperature control,

lower power consumption and very low noise and vibration levels are required.

This is possible thanks to the use of an electronic inverter capable of driving the

compressor at dierent speeds and consequently, controlling its refrigeration ca-

pacity.

Eciency

Fullmotion Compressors technology al-

lows the compressor to operate at dif-

ferent speeds, adjusting it according to

demand. When side by side with a con-

ventional compressor, the energy con-

sumption is up to 45%.

Flexible

Indicated for commercial refrigeration

system, provides more exibility in cus-

tomized solutions through inclusion of

electronics already coupled to the com-

pressor, opening a wide variety of appli-

cations.

1

CHAPTER 1. INTRODUCTION 2

1.1 Product description

1.1.1 Stand alone inverter

1

2

3

4

Figure 1.1: Stand alone view

Composed by

Indicator Description

1 Plastic body

2 Plastic cover

3Compressor cable

output connection

4

Input/ Earth/

Communication

cables connection

!!

WARNING

!!

NOTICE

CAUTION

!!

CF10C inverter series are designed to

be used only in built in appliances, with

not accessible machine compartment.

1.1.2 Institute approval

Institute approval

CF10C Inverter Approved according to

EN 60335-1

CHAPTER 1. INTRODUCTION 3

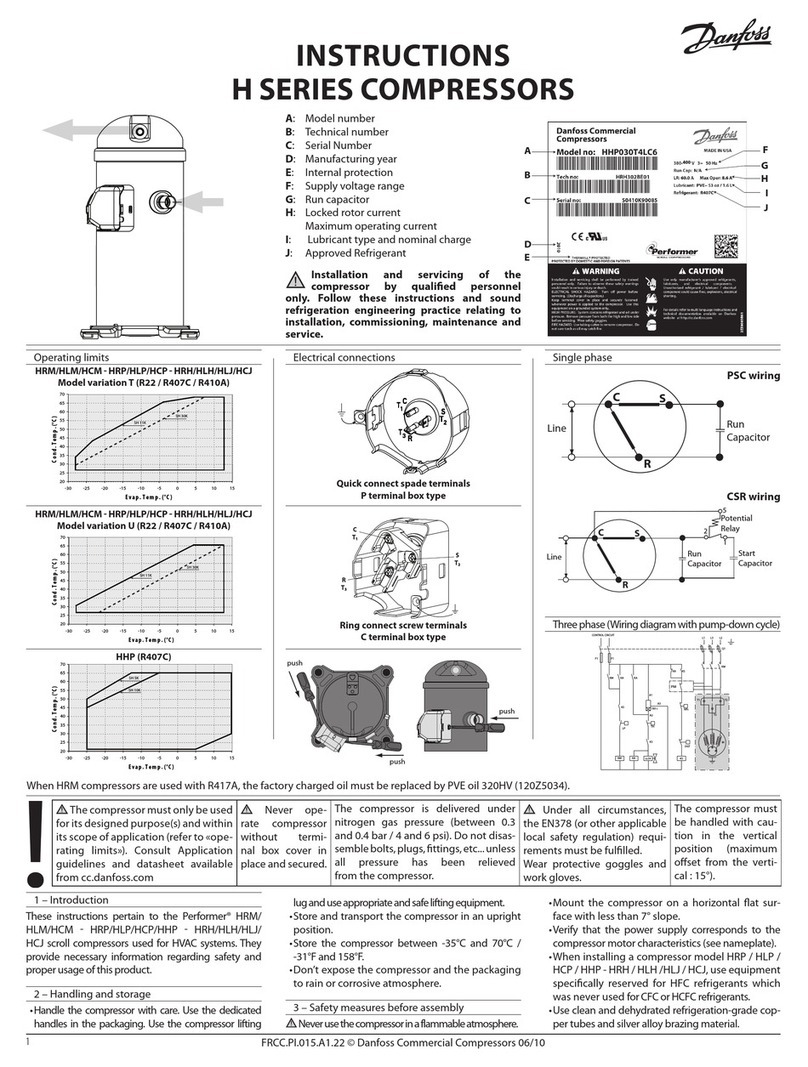

1.2 VNE compressor series description

5

1.Product descripton

9

10

8

6

5

4

1

3

7

2

1- Fence cover

2- OLP

3- 3/4 OLP

4- Cord anchorage

5- Screw

6- Grommets

7- Compressor shell

8- Process tube

9- Discharge tube

10- Suction tube

!!

WARNING

!!

NOTICE

CAUTION

!!

• Before you begin your installation observe

technical specications and proper connec-

tions.

• Check if product is properly identied and if

it’s enclosure is without cracks.

CHAPTER 1. INTRODUCTION 4

1.3 FMF and VEG compressor series description

5

1

23

4

6

7

8

1-Fence cover

2-Cord anchorage

3-Screw

4-Grommets

5-Compressor shell

6-Process tube

7-Discharge tube

8-Suction tube

1

23

4

5

6

7

8

1.4 Product handling

!!

WARNING

!!

NOTICE

CAUTION

!!

• Inverter is sensitive to Electrostatic Dis-

charges. Take care with product handling

until nal assembly.

• Special care must be taken to avoid me-

chanical impacts on the inverter during

assembly process.

• The environment must be properly pro-

tected against ESD.

• The workers that handle the inverter must

be Earthed through adequate ESD wrist

strap and must wear ESD gloves.

• Do not hold by the wiring.

• Do not use the inverter if it drops during

handling.

CHAPTER 1. INTRODUCTION 5

1.5 Dimensions (mm)

1.5.1 FMF and VEG compressor series

173.3

85.5

133.3

217.3

(INVERTER)

199.5

241

202

CHAPTER 1. INTRODUCTION 6

1.5.2 VNE compressor series

21

4.7. Dimensions (mm)

MADE IN

SLOVAKIA

1997423

LX

NB0CB9BX

SUCTION

NO START WITHOUT STARTING DEVICE

VNEK609GK

100-300 V

33-75 Hz

THERMALLY PROTECTED

R-404A

3 PH

POE OIL 500

CC

100-300 V

33-75 Hz

THERMALLY PROTECTED

R-404A

3 PH

POE OIL 500

CC

20

4.7 Dimensions (mm)

216

80 162

192.6

101.6

269

199

165

4.8 Compressor label

Voltage and

frequency

defined by

the inverter

Refrigerant

Oil type and

quantity

Strip, indicating voltage

and frequency

Engineering

code

Production

date letters

Serial

number

Model

Three-phase

89.5 77

71.75

214

189.5

137.5

4.8. Compressor label

MADE IN

SLOVAKIA

1997423

LX

NB0CB9BX

SUCTION

NO START WITHOUT STARTING DEVICE

VNEK609GK

100-300 V

33-75 Hz

THERMALLY PROTECTED

R-404A

3 PH

POE OIL 500

CC

100-300 V

33-75 Hz

THERMALLY PROTECTED

R-404A

3 PH

POE OIL 500

CC

Voltage and

frequency

defined by

the inverter

Refrigerant

Oil type and

quantity

Strip, indicating voltage

and frequency

Engineering

code

Production

date letters

Serial

number

Model

Three-phase

21

4.7. Dimensions (mm)

MADE IN

SLOVAKIA

1997423

LX

NB0CB9BX

SUCTION

NO START WITHOUT STARTING DEVICE

VNEK609GK

100-300 V

33-75 Hz

THERMALLY PROTECTED

R-404A

3 PH

POE OIL 500

CC

100-300 V

33-75 Hz

THERMALLY PROTECTED

R-404A

3 PH

POE OIL 500

CC

20

4.7 Dimensions (mm)

216

80 162

192.6

101.6

269

199

165

4.8 Compressor label

Voltage and

frequency

defined by

the inverter

Refrigerant

Oil type and

quantity

Strip, indicating voltage

and frequency

Engineering

code

Production

date letters

Serial

number

Model

Three-phase

89.5 77

71.75

214

189.5

137.5

4.8. Compressor label

MADE IN

SLOVAKIA

1997423

LX

NB0CB9BX

SUCTION

NO START WITHOUT STARTING DEVICE

VNEK609GK

100-300 V

33-75 Hz

THERMALLY PROTECTED

R-404A

3 PH

POE OIL 500

CC

100-300 V

33-75 Hz

THERMALLY PROTECTED

R-404A

3 PH

POE OIL 500

CC

Voltage and

frequency

defined by

the inverter

Refrigerant

Oil type and

quantity

Strip, indicating voltage

and frequency

Engineering

code

Production

date letters

Serial

number

Model

Three-phase

21

4.7. Dimensions (mm)

MADE IN

SLOVAKIA

1997423

LX

NB0CB9BX

SUCTION

NO START WITHOUT STARTING DEVICE

VNEK609GK

100-300 V

33-75 Hz

THERMALLY PROTECTED

R-404A

3 PH

POE OIL 500

CC

100-300 V

33-75 Hz

THERMALLY PROTECTED

R-404A

3 PH

POE OIL 500

CC

20

4.7 Dimensions (mm)

216

80 162

192.6

101.6

269

199

165

4.8 Compressor label

Voltage and

frequency

defined by

the inverter

Refrigerant

Oil type and

quantity

Strip, indicating voltage

and frequency

Engineering

code

Production

date letters

Serial

number

Model

Three-phase

89.5 77

71.75

214

189.5

137.5

4.8. Compressor label

MADE IN

SLOVAKIA

1997423

LX

NB0CB9BX

SUCTION

NO START WITHOUT STARTING DEVICE

VNEK609GK

100-300 V

33-75 Hz

THERMALLY PROTECTED

R-404A

3 PH

POE OIL 500

CC

100-300 V

33-75 Hz

THERMALLY PROTECTED

R-404A

3 PH

POE OIL 500

CC

Voltage and

frequency

defined by

the inverter

Refrigerant

Oil type and

quantity

Strip, indicating voltage

and frequency

Engineering

code

Production

date letters

Serial

number

Model

Three-phase

1.6 Package information

The inverters are packed in a carton box. Figure 1.2 shows the used box to pack the

product. The quantity of products inside the box may change due to internal or ex-

ternal requirements. Box dimensions can be changed without previous information.

CHAPTER 1. INTRODUCTION 7

536±5

227±5

385±5

*Dimensions are in mm.

Figure 1.2: Product package

Chapter 2

TECHNICAL SPECIFICATIONS

2.1 Nomenclature

CF 10 C KK X U.Y VV W ZZ

CF Driver Type

10 Family

C Generation

KK Subversion

X Power Supply

U.Y Protective Function

VV Eletronic Conguration

W Enclosure

ZZ Cables and Peripherals

Example: CF 10 C02 N 0.1 01 A 00

CF Fullmotion controller

10 High power series (500 W - 1000 W)

C3rd generation

02 Product subversion

N Single Voltage 50 - 60 Hz

0.1 HW PEC version 1

01 Eletronic conguration version 01

A Stand Alone

00 Cable conguration version 00

8

CHAPTER 2. TECHNICAL SPECIFICATIONS 9

2.1.1 Label information

Next image shows the product label description.

Manufacturer code ↑ ↑ Batch code / Serial number

Production site Production date

2.2 Product specications

General Specications

Input rated voltage range 220 V-240 V

Input operating voltage

range 160 V-264 V

Input frequency range 50 Hz to 60 Hz

Control mode Frequency, Drop-in and Serial

Parameter VEG VNE FMF

Maximum input current 2.62 A 5.00 A 5.00 A

Maximum input power 540 W 1100 W 1100 W

Output frequency range 60 Hz to 150 Hz 33 Hz to 75 Hz 60 Hz to 150 Hz

Maximum output current 3.3 A 6.5 A 6.5 A

Compressor speed range 1800 rpm to

4500 rpm

2000 rpm to

4500 rpm

1800 rpm to

4500 rpm

Storage and Operating conditions

Storage humidity < 85%

Storage ambient

temperature -20 ºC to 85 ºC

Operating humidity < 85%

Operating ambient

temperature*-20 ºC to 60 ºC

Air forced ventilation (min) †2 m/s

Ingress Protection Grade ‡IPX0

CHAPTER 2. TECHNICAL SPECIFICATIONS 10

!!

WARNING

!!

NOTICE

CAUTION

!!

• Do not connect the Fullmotion CF10C In-

verter to a power supply above 264 V.

!!

WARNING

!!

NOTICE

CAUTION

!!

• For operation below the rated voltage, the

maximum compressor cooling capacity

can be reduced as consequence of speed

limitation.

• Conrm compressor type and speed rota-

tion at compressor datasheet.

• In order to avoid loss of performance,

make sure to operate the inverter inside

the temperature range of -20 °C to 50 °C.

• Ambient operation temperature above 50

°C may activate inverter thermal protec-

tion.

!!

WARNING

!!

NOTICE

CAUTION

!!

• Voltage range relates to product robust-

ness, not institute approval.

• Maximum power is not reached under all

input voltage range.

• Output frequency and motor speed may

have reduced range based on maximum

working conditions of the respective com-

pressor.

*VDE agency approval temperature.

†Air ow over the inverter heat sink, as shown in Figure 3.9.

‡Ingress Protection grades are described in IEC 60529 (Degrees of protection provided by

enclosures).

CHAPTER 2. TECHNICAL SPECIFICATIONS 11

2.3 Inverter enclosure

2.3.1 Product dimensions

199.5

170.2

119.5

39

100.4

160

128.40.5

0.5

110.2

Figure 2.1: Stand alone dimensions

Stand alone dimensions

Dimensions 170,2 mm x 199,5 mm x 119,5 mm

2.3.2 Connectors

This section presents the available connectors of Fullmotion CF10C Inverter, as well

as their propper connections. The nal enclosure without plastic cover is presented

CHAPTER 2. TECHNICAL SPECIFICATIONS 12

to improve understanding. The manufacturer part number of each connector can

be found in the following table.

1 2

4

3

5

6

7

Figure 2.2: Connectors

Connectors part numbers

Indicator Description Part number Insulation

1Serial

Communication

S3P-VH (LF)

(SN) Reinforced

2 Frequency input S2P-VH (LF)

(SN) Reinforced

3 Drop in 1217754-1 Functional

4 AC input (L+N) 1217754-1 Functional

5 AC Fan*

MSLO 9402 -

002 - 00A - 960

- 000 - 00

–

6Additional Drop

in (optional) 1217754-1 Functional

7 Safety Earth 63849-1 Basic

*Mates with 1/4” faston receptacle. Fan connector assemble is optional.

CHAPTER 2. TECHNICAL SPECIFICATIONS 13

Figure 2.3: Motor cable for

VEG and FMF compressor

series

Figure 2.4: Motor cable for VNE

compressor series with OLP

Figure 2.5: EMI Earth and

Safety Earth Cable

Cable Specication

Indicator Description Part Specication Color

Figure 2.3 Standard

Motor Cable UL STYLE 2586 105°C 600 V Black, Blue and

Brown

Figure 2.4 Motor Cable

With OLP UL STYLE 2586 105°C 600 V Black, Blue and

Brown

Figure 2.5 Safety Earth

Cable UL STYLE 1015 105°C 600 V Green/Yellow

Figure 2.5 EMI Earth

Cable UL STYLE 1015 105°C 600 V White

Inside the inverter enclosure, the compressor motor and Earth cables must be con-

nected as shown in Figure 2.6. Earth cables shall always be connected rst to avoid

ESD.

CHAPTER 2. TECHNICAL SPECIFICATIONS 14

Figure 2.6: Motor cable

2.3.3 Product discards

!!

WARNING

!!

NOTICE

CAUTION

!!

• Do not remove the inverter from its case.

• Do not incinerate any Embraco’s inverter.

Contact your local authorities, if you need

to incinerate this product for disposal.

• Inverters should not be mixed with general

waste.

!!

WARNING

!!

NOTICE

CAUTION

!!

• If you wish to discard this product, please

contact your local authorities or dealer for

the correct method of disposal, for proper

treatment, recovery and recycling.

• This device is RoHS compliant, neverthe-

less the correct disposal of this product

will help to save valuable resources and

prevent any potential negative eects on

human health and the environment (e.g.:

to avoid ground disperse) which could oth-

erwise arise from inappropriate handling.

CHAPTER 2. TECHNICAL SPECIFICATIONS 15

2.4 Information about input inrush current

Inrush Specications

Allowed inrush events 1 per day

Inrush current (cold state) 235 A peak

Inrush current (hot state) 357 A peak

Input fuse melting (i²t) 209 A²s

Inrush current refers to a transient phenomenon that occurs rarely and only when

the power supply cord is connected to the power grid or in the case of power grid

shutdown. CF10C inverter series are designed accordingly and can reliably with-

stand this current along the expected product lifespan. Excessive inrush current

events may damage the inverter. Regarding inverter installation, Embraco recom-

mends to have the appliance supply cord directly connected to inverter power input

without any disconnection means. Please, contact Embraco Technical Support for

any assistance or application assessment needed.

Table of contents

Other Embraco Air Compressor manuals