Embraco Scroll SE6015GS-O User manual

FOR EMBRACO SCROLL

REFRIGERATION COMPRESSORS

SCROLL

INSTALLATION

INSTRUCTIONS

2

3

SCOPE OF THE COMPRESSOR INSTALLATION INSTRUCTIONS

These installation instructions applies to Embraco scroll compressors for refrigeration applications. The

Country of Origin is indicated on the compressor label.

It is addressed to professional, commercial refrigeration system manufacturers/installers and maintenance

technicians and intends to provide instructions/recommendations on the proper use of Embraco scroll

compressors regarding reliability, performance and safety aspects.

The information of this these installation instructions is limited to the Embraco scroll refrigeration

compressors and to their installation/operation/service. It is not to be considered comprehensive or as a

set of information for training for technicians that need to be qualified by appropriated training nor to replace

the instruction manual of the final equipments provided by the manufacturers.

All the operation on systems, their production, installation use, repairing and disposal must be carried out

according to all the applicable International and National regulations and standards.

DISCLAIMER

All product specifications and data are subject to change without notice; thus customer should always verify its

latest updates on Embraco website (www.embraco.com), catalogues before relying on them.

The information provided herein is correct to the best of Embraco’s knowledge of typical requirements that

are oen requested to Embraco’s products, It is the customer’s responsibility, relying solely on its own testing

and engineering work, to validate that a particular product with the properties described in Embraco’s product

specification is suitable for use in a particular application, Embraco makes no representation concerning the

suitability of its products for incorporation into or use with customer’s applications.

Parameters provided in datasheets and / or specifications may vary in different applications and performance

over time. Therefore Embraco’s statements related to all operating parameters, including typical parameters,

cannot be intended to replace the customer’s validation for each application by the customer’s technical experts.

Product specifications do not expand or otherwise modify Embraco’s terms and conditions of purchase, including

but not limited to the warranty expressed therein.

Embraco rejects any liability for damages and injures caused by its products and/or the applications they are

embedded into being installed or repaired by untrained personnel and/or in discordance with these safety

instructions.

4

GENERAL INDEX

1 SAFETY....................................................................................................p. 07

1.1 Safety notice ...........................................................................................p. 07

1.2 Safety advice ..........................................................................................p. 07

1.3 Safety instructions ................................................................................p. 08

2 PRODUCT INTRODUCTION ........................................................ p. 09

2.1 Compressor test condition ................................................................... p. 11

2.2 Compressor cooling types ....................................................................p. 11

3 COMPRESSOR APPLICABLE STANDARDS AND REGULATIONS.... p. 11

4 EMBRACO RELEVANT DOCUMENTS ......................................... p. 11

5 COMPRESSOR NOMENCLATURE .............................................. p. 12

5.1 Compressor model code ....................................................................... p. 12

5.2 Compressor Bill of material code ........................................................p. 12

5.2.1 Compressor size......................................................................................p. 12

5.2.2 Voltage and frequency supply .............................................................p. 13

5.2 3 External execution .................................................................................p. 13

5.2.4 Electrical execution ...............................................................................p. 13

5.2.5 Accessories execution ...........................................................................p. 14

5.2.6 Packaging execution .............................................................................. p. 14

5.3 Compressor label ................................................................................... p. 14

5.3.1 Serial number code ................................................................................ p. 15

6 PRODUCT DESCRIPTION......................................................................p. 15

6.1 Application description ..........................................................................p. 15

6.2 Approved refrigerants.............................................................................p. 16

6.2.1 Refrigerants general information.........................................................p. 17

6.3 External dimensions...............................................................................p. 18

6.4 Hermetic terminal dimensions ............................................................p. 19

6.5 Sight glass ...............................................................................................p. 20

6.6 Free internal volume ..............................................................................p. 20

7 TECHNICAL SPECIFICATIONS.............................................................p. 21

8 OPERATING CONDITIONS....................................................................p. 22

8.1 Ambient temperature.............................................................................p. 22

8.2 Compressor selection.............................................................................p. 22

8.3 Supply voltages and frequencies ......................................................... p. 23

8.4 Operating envelopes ..............................................................................p. 24

8.5 Low ambient operation..........................................................................p. 25

8.6 Refrigerant charge..................................................................................p. 25

8.7 Crankcase heater.................................................................................... p. 26

8.8 Accumulators ..........................................................................................p. 27

8.9 Pump down recommendations.............................................................p. 27

8.10 Compressor On/Off cycling ...................................................................p. 28

8.11 Shell temperrature ................................................................................p. 28

8.12 Maximum discharge gas pressures and temperatures ..................... p. 28

8.13 Discharge line thermostat ....................................................................p. 29

8.13.1 Discharge line thermostat for LBP .......................................................p. 29

8.13.2 Discharge line thermostat for MBP...................................................... p. 29

5

8.14 Pressure controls.................................................................................... p. 30

8.15 Internal pressure relief valve (IPR Valve).............................................p. 30

9 INSTALLATIONS..................................................................................... p. 30

9.1 System components compatibility ...................................................... p. 30

9.2 Painting ...................................................................................................p. 31

9.3 Grommets and sleeves ..........................................................................p. 31

9.4 Mounting for rack systems .................................................................... p. 31

9.5 Screens..................................................................................................... p. 32

9.6 Liquid injection .......................................................................................p. 32

9.7 Solenoid valve ......................................................................................... p. 33

9.8 Current sensing relay ............................................................................. p. 33

9.9 Temperature responsive expansion valve ...........................................p. 33

9.10 Suggested application techniques .......................................................p. 34

9.11 Compressor or valve service ................................................................. p. 34

9.12 Connectors ..............................................................................................p. 35

9.12.1 Compressor pressurization .................................................................... p. 35

9.12.2 Connectors brazing process ..................................................................p. 35

9.12.3 Tube brazing ............................................................................................ p. 36

9.12.4 Tube disconnects .................................................................................... p. 36

9.12.5 Tubing selection .....................................................................................p. 36

9.13 Connections.............................................................................................p. 37

9.14 Rotolock valves ....................................................................................... p. 38

9.15 Adapters...................................................................................................p. 38

10 ELECTRICAL SPECIFICATIONS ....................................................................p. 39

10.1 Electrical motor types ........................................................................... p. 39

10.2 Electrical components types ................................................................p. 40

10.2.1 Electrical components specification of single phase .........................p. 40

10.3 Electrical connections and wiring diagrams ....................................... p. 41

10.4 Motor protection .....................................................................................p. 42

10.4.1 Overload protector parameters.............................................................p. 42

10.5 Degree of protection .............................................................................p. 42

10.6 CSR box .................................................................................................... p. 43

10.7 Fusite pin ................................................................................................p. 43

10.8 Terminal cover mounting and removal ................................................p. 44

10.9 Three-Phase rotation direction ............................................................ p. 44

10.10 Brief power interruptions ......................................................................p. 45

10.11 Electrical supply line and cabinet supply cable ..................................p. 45

10.12 Maximum temperature of electric motor windings ............................p. 45

10.13a Electrical data of three phase motor.................................................... p. 46

10.13b Electrical data of single motor..............................................................p. 47

10.14 Definitions................................................................................................ p. 47

10.15 High potential (Hi-pot) testing ..............................................................p. 47

10.16 Electrical connections ............................................................................ p. 48

10.17 Screws tightening torque ......................................................................p. 48

10.18 Electrical insulation ................................................................................ p. 49

11 STARTING PROCEDURE ............................................................. p. 49

11.1 System cleanliness ................................................................................p. 49

11.2 Moisture removal ................................................................................... p. 49

11.3 System evacuation ................................................................................. p. 50

11.4 Deep vacuum operation ........................................................................p. 50

11.5 Dehydration.............................................................................................p. 50

11.6 Charging process .................................................................................... p. 51

6

11.7 Oil charge ................................................................................................p. 51

11.7.1 Oil Management for rack application ................................................... p. 52

11.8 Scroll functional check .......................................................................... p. 52

11.9 Starting sound level ...............................................................................p. 52

11.10 Sound generation in refrigeration system ........................................... p. 53

12 MAINTENANCE (COMPRESSOR REMOVAL AND REPLACEMENT) .. p. 53

12.1 Compressor replacement procedure ................................................... p. 55

12.2 Unbrazing system components ............................................................p. 55

13 HOW TO RETURN SUPPLIED PRODUCTS TO EMBRACO EUROPE . p. 56

14 COMPRESSOR DISPOSALS ...........................................................p.57

15 COMPRESSOR PACKAGING ............................................................... p.57

15.1 Multiple (industrial) packaging .............................................................p. 57

15.2 Single packaging .................................................................................... p. 57

16 HANDLING. TRANSPORTATION AND STORAGE.............................p.59

16.1 Handling...................................................................................................p. 59

16.2 Storage..................................................................................................... p. 59

16.3 Storage conditions .................................................................................p. 60

16.4 Transportation .......................................................................................p. 60

16.4.1 Shipment by container ..........................................................................p. 60

16.4.2 Shipment by truck ..................................................................................p. 61

16.4.3 Acceptable compressor positions during transportation

of finished product .................................................................................p. 61

16.4.4 Acceleration during transport and handling ....................................... p. 61

APPENDIX 1 – SAFETY RECOMMENDATIONS FOR COMPRESSOR INSTALLATION ......... p. 62

DIGITAL TOOLS ..............................................................................................................p. 67

ATEL: Acute-toxicity Exposure Limit

AHRI: Air-Conditioning, Heating and

Refrigeration Institute (formerly)

CSR (CSCR): Capacitive Start & Run

(Capacitor Start - Capacitor Run)

DTC: Discharge Temperature Control Valve

EN: European Standards

GFCI: Ground Fault Circuit Interrupter

GWP: Global Warming Potential

HFC: HydroFluoroCarbon

HFO: HydroFluoroOlefin

ID: Internal Diameter

IP: International Protection (ratings)

IPRV: Internal Pressure Relief Valve

ISO: International Organization of

Standardization

ISPM: Regulation of Wood packaging

Material in International Trade

LBP: Low Back Pressure

LCL: Less Then Container Load

LFL: Lower Flammability Limit

LRA: Locked Rotor Amps

LVD: Low Voltage Directive

MBP: Medium Back Pressure

MCC: Maximum Continuous Current

MD: Machine Directive

MOC: Maximum Operating Current

MSDSs: Material Safety Data Sheets

OD: Outside Diameter

ODL: Oxygen Deprivation Limit

ODP: Ozone Depletion

OFDN: Oxygen-Free-Dry-Nitrogen

OLP: Overload Protector

PED: Pressure Equipment Directive

POE: Polyolester

RCD: Residual Current Device

REACH: Regulation on Registration,

Evaluation, Authorization and Restriction of

Chemicals

RLA: Rated Load Amperage

RoHS: Restriction of Hazardous Substances

Directive

SH: Superheating

TXV: Thermostatic Expansion Valve

3Ø: Three-phase

Terms and Definitions

For the refrigeration system terms used in these Scroll installation instructions, refer to EN 378-1 or similar

standards.

ACRONYMS USED IN THE TEXT

7

1. SAFETY

1.1 SAFETY NOTICE

Embraco compressors are designed, manufactured and inspected according to the latest European

applicable standards, with particular care on the user’s safety.

Embraco compressors are designed as refrigerant pumping elements on refrigeration machines. Only if they

are used for this purpose and installed according to the instructions of these installation instructions and

the applicable regulations and standards can be put in service, as indicated on the Embraco Manufacturers

Declaration of Incorporation according the 2006/42/EC Machinery Directive.

These instructions should be retained throughout the lifetime of the compressor. You are strongly advised

to follow these safety instructions, and also the local related rules should be obeyed.

Technicians are strongly advised to follow the entire applicable International and National laws and

regulation as well as the instructions of these installation instructions.

1.2 SAFETY ADVICE

WARNING: Indicates Instructions that may result in personal injury or death and

property damage if not carefully followed.

CAUTION: indicates instructions that may results in property damage and possible

personal injury if not carefully followed.

IMPORTANT: indicates instruction to avoid damages/malfunction of the

compressors.

WARNING

CAUTION

IMPORTANT

8

1.3 SAFETY INSTRUCTIONS

Safety statements

• Refrigerant compressors must be used only for their intended use.

• Only qualified/certified and authorized refrigeration technicians are permitted

to perform installation and maintenance of compressors.

• Electrical connections must be made by qualified electrical technicians.

• All valid standards for installing, servicing, and maintaining of electrical and

refrigeration equipment must be observed.

• Usage of personal safety equipment is recommended (goggles, gloves, clothing,

boots and hard hats)

Electrical shock hazard

• Turn off power before servicing.

• Discharge all capacitors.

• Use compressor with grounded system only.

• Molded electrical plug must be used when required.

• Refer to original equipment wiring diagrams.

• Electrical connections must be made by qualified electrical personnel.

• Use only components approved by manufacturer.

• Failure to follow these warnings could result in serious personal injury.

Pressurized system hazard

• System contains refrigerant and oil under pressure.

• Remove refrigerant from both the high and low pressure side before removing

compressor.

• Use appropriate back up wrenches on Rotolock fittings when servicing.

• Never install a system and leave it unattended when it has no charge,

a holding charge, or with the service valves closed without electrically locking

out the system.

• Use only approved refrigerants and refrigeration oils.

• Failure to follow these warnings could result in serious personal injury.

Burn hazard

• Do not touch the compressor until it has cooled down.

• Ensure that materials and wiring do not touch high temperature areas of

the compressor.

• Use caution when brazing system components.

• Failure to follow these warnings could result in serious personal injury or

property damage.

For the compressor connection to the electrical supply line and for maintenance/

repairing operations, refer also to Appendix 1 - Recommendations - safety

instruction for compressor installation.

WARNING

WARNING

9

2. PRODUCT INTRODUCTION

Embraco offers a full range of hermetic reciprocating compressors for refrigeration from fractional

horse power (hp) up to 1.5hp with a long experience in developing innovative solutions for commercial

and professional refrigeration.

With the new range of scroll compressors for refrigeration Embraco complete the product range for

commercial and professional applications with a range of scroll compressors from 2hp up to 13hp

working with R404A, R452A, R449A, R448A and R134a, R513A (MBP only).

By visualizing the whole cycle of a scroll mechanism, we can notice that 3 phases: suction, compression

and discharge are simultaneously made in a continuous movement.

It represents numbers of advantages:

• Less parts in movement versus other compressor technologies; the compression system is

composed by only the mobile and the fix scroll.

• There is no dead space, the volumetric efficiency is close to 1.

• The absence of re-expansion loss makes that there is no reduction of the isentropic efficiency.

• The perfect suction system symmetry by two points diametrically opposed and discharge by

the center of spirals assure a functioning with much lower pulsations and noise.

LBP section MBP section

Figure 2.0 Product sections

10

DESIGN FEATURES

• Dynamic valve specially designed for

MBP/LBP working conditions - allows

high compression ratio reducing

compression.

• Instant shutdown.

• More efficient for pump down control.

• Designed for higher motor efficiency in different condition.

• Designed to ensure uniform three phase motor winding temperature.

• Build-in overload protector.

• Unique design with dual compliance – radial

and axial.

• Effective control of discharge temperature

to improve compressor reliability.

• Specially designed for Mid/Low

temperatures compression ratio.

• Height-thickness ratio to assure strength

of involutes.

• High isentropic efficiency design.

Figure 2.0.1. Discharge valve

Figure 2.0.2 Involutes

2.0.3 Motor

11

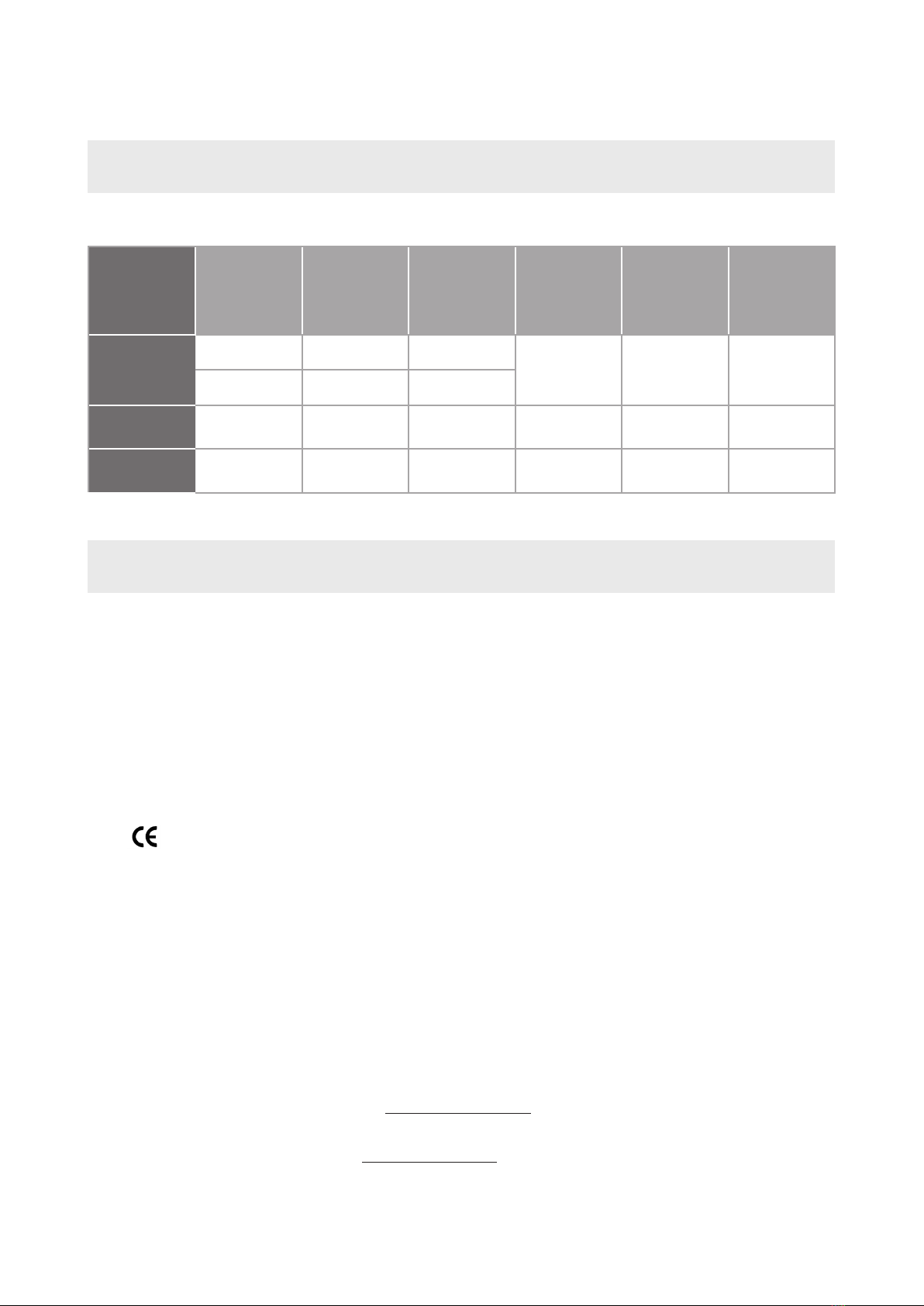

2.1 COMPRESSOR TEST CONDITION

Table 2.1 Test condition

TEST

CONDITIONS

RATING POINT

APPLICATION

EVAPORATING

TEMPERATURE

°C

CONDENSING

TEMPERATURE

°C

RETURN GAS

TEMPERATURE

°C

SUBCOOLING

AMBIENT

TEMPERATURE

°C

EN 12900

LBP -35 40

20 NO

SUBCOOLING 35

MBP -10 45

ARI 540

2015 LBP -31.6 40.6 4.4 NO

SUBCOOLING 35

ARI 540

2004 HBP -6.7 54.4 48.9 NO

SUBCOOLING 35

2.2 COMPRESSOR COOLING TYPES

Scroll compressors are designed as static, not requiring forced ventilation cooling. Its cooling is secured by

refrigerant. Ambient temperature has very little impact on compressor performance.

3. COMPRESSOR APPLICABLE STANDARDS AND

REGULATIONS

4. EMBRACO RELEVANT DOCUMENTS

• Embraco Product Selector on www.embraco.com

• Scroll Installation instructions.

Check available documents on www.embraco.com or contact Embraco Technical support team.

Compressors comply with the latest European standards and regulations and are marked with

mark.

• Low Voltage Directive 2014/35/EU.

• Machinery Directive 2006/42/EC.

• Pressure Equipment Directive (PED) 2014/68/UE.

• RoHS II Directive 2011/65/EU.

• REACH Regulation (EC) 1907/2006.

12

5. COMPRESSOR NOMENCLATURE

Information printed on compressor label: model, voltage and frequency supply, bill of material.

5.1 COMPRESSOR MODEL CODE

COMPRESSOR SCROLL

TYPE

PACKAGING EXECUTION

ACCESSORIES EXECUTION

VOLTAGE & FREQUENCY SUPPLY

COMPRESSOR SIZE

EXTERNAL EXECUTION

ELECTRICAL EXECUTION

MODEL CODE

30 1A C 01 01 AA

COMPRESSOR FAMILY

SE = Scroll Embraco

VOLTAGE & FREQUENCY SUPPLY

C - 220V 50Hz 1~

O - 380-420V 50Hz/460V 60Hz 3~

NOMINAL CAPACITY

In Btu/h at 60 Hz x 1000

ARI conditions

E.g. 015=15000 Btu/h

APPLICATION CODE

2 = LBP

6 = MBP

REFRIGERANT

R404A, R452A, R449A, R448A, R134a, R513A

SE 2015 GK C

5.2 COMPRESSOR BILL OF MATERIAL CODE

5.2.1 COMPRESSOR SIZE

1– MBP models for 2-6hp

2– MBP models for 7-13hp

3– LBP models for 2-6hp

4– LBP models for 7-13hp

13

5.2.3 EXTERNAL EXECUTION

Table 5.2.4

5.2.4 ELECTRICAL EXECUTION

5.2.2 VOLTAGE AND FREQUENCY SUPPLY

Table 5.2.2

VOLTAGE CODE RATED VOLTAGE & FREQUENCY

C220V 50HZ 1~

O380420V 50HZ / 460V 60HZ 3~

Table 5.2.3

EXTERNAL

EXECUTION

COMPRESSOR

SIZE

APPLICATION CONFIGURATION TYPE

01 2-6 hp MBP Brazing connection; discharge tube ID Ø12.92mm ±5; suction tube ID Ø22.4mm ±5;

oil sight glass.

02 2-6 hp LBP Brazing connection; discharge tube ID Ø12.92mm ±5; suction tube ID Ø22.4mm ±5;

Liquid Injection with DTC valve; oil sight glass.

03 7-13 hp LBP Brazing connection; discharge tube ID Ø22.47mm; suction tube ID Ø28.83mm; Liquid

Injection with DTC valve; oil sight glass.

04 7-13 hp MBP Brazing connection; discharge tube ID Ø22.47mm; suction tube ID Ø28.83mm; oil sight

glass.

11 2-6 hp MBP Rotolock connection; threaded discharge connection 3/4“-16 UNF 2A, ID Ø9mm; threaded

suction connection 1 1/4“-12 UNF 2A, ID Ø19.2mm; oil sight glass.

12 2-6 hp LBP

Rotolock connection; threaded discharge connection 3/4“-16 UNF 2A, ID Ø9mm;

threaded suction connection 1 1/4“-12 UNF 2A, ID Ø19.2mm; Liquid injection with DTC

valve; oil sight glass.

13 7-13 hp LBP

Rotolock connection; threaded discharge connection 1 1/4“-12 UNF 2A, ID Ø19.2mm;

threaded suction connection 1 3/4“-12 UNF 2A, ID Ø26.4mm. Liquid Injection with DTC

valve; oil sight glass.

14 7-13 hp MBP Rotolock connection; threaded discharge connection 1 1/4“-12 UNF 2A. ID Ø19.2mm;

threaded suction connection 1 3/4“-12 UNF 2A, ID Ø26.4mm; oil sight glass.

EXECUTION

MOTOR TYPE CONFIGURATION TYPE

01 3 PHASE Internal overload protector, terminal cover with gasket and wiring diagram, grounding screw.

04 1 PHASE CSR CSR box with start and run capacitor, Internal overload protector, terminal cover with gasket and wiring diagram,

grounding screw.

14

5.3 COMPRESSOR LABEL

Figure 5.3 Label

Table 5.2.5

Table 5.2.6

5.2.5 ACCESSORIES EXECUTION

5.2.6 PACKAGING EXECUTION

EXECUTION

CONFIGURATION TYPE

AGrommets, sleeves, tube plug, DTC valve included for LBP

EXECUTION

PCS PER PALLET

A9

B12 (for compressors 7-13 hp)

C16 (for compressors 2-6 hp)

Note: See Chapter 15 for detailed information about packaging.

* Manufacturing Date is part of Serial Number Code.

Compressor model

Displacement

Compressor protection

Bill of Materials code

Serial Number Code*

Oil initial

charge

Oil type

Maximum Operating Pressures

(Low and High Side)

Rated Load Amps (RLA)

Locked Rotor Amps (LRA

Voltage & Frequency Supply

15

YEAR / MONTH / DAY

PRODUCTION LINE

5.3.1 SERIAL NUMBER CODE

C170503 0061

SEQUENCE NUMBER

6. PRODUCT DESCRIPTION

6.1 APPLICATION DESCRIPTION

Each compressor model is intended for specific refrigerant and application. Their

use in different application and/or with different refrigerant may result in significant

impact to motor-compressor performance, life expectancy or even may result in

personal injury and damages.

LBP (Low Back Pressure) scroll compressors are designed to correspondent to the latest scroll technology

of refrigeration for low temperature application; including special scroll set design, dynamic discharge valve

and injection system. These special designs result in a compressor that is suitable for the most demanding

refrigeration applications with efficiencies comparable to the semi-hermetic piston compressors.

LBP models are optimized for low temperature applications with discharge

temperature management, working down to -40°C of evaporating temperature;

for instance commercial and professional refrigeration application, frozen food

cabinets, frozen food display cases, cold rooms, frozen products, environmental

test chambers.

MBP (Medium Back Pressure) scroll compressors are designed to correspondent to the latest scroll

technology of refrigeration for medium temperature applications.

MBP models are optimized for medium temperature applications, able to run

down to -30°C of evaporating temperature without injection solution; for instance

commercial and professional cabinets, fresh products cabinets, ice machines, milk

coolers and cold room.

WARNING

16

Table 6.2 Approved refrigerants

6.2 APPROVED REFRIGERANTS

Usage of different refrigerants can generate abnormal working conditions, excessive

pressure in the refrigeration system, damages of the compressor and explosions.

All operations related to the use of refrigerants shall be performed only by trained

and qualified technicians and in accordance with applicable International and

National standards, laws and regulations related to this subject.

Users must have available and understand the applicable HFCs Material Safety

Data Sheets (MSDSs).

When selecting the refrigerant, it is important to measure different aspects the environment would require:

legislations, standards, cost, availability, and surely the applications. Thanks to its specific technology, the

scroll allows the compressor to run as multi refrigerant product, Embraco has therefore qualified the range

with the following refrigerants:

WARNING

WARNING

APPLICATION

REFRIGERANTS

R404A R452A R449A R448A R134a R513A

LBP ✓ ✓ ✓ ✓ X X

MBP ✓✓✓✓✓✓

R404A is an HFC refrigerant without any ozone depletion (ODP=0) and suitable for medium temperature and

low temperature applications, it is near an azeotropic mixture and the glide effect is negligible. It has to be

charged in liquid phase.

R452A is a HFC/HFO blend, it contains R125/R32/R1234yf, but belong to A1 safety class (GWP: 2140; ODP:

0), originally developed for transport application, it can also be used in commercial refrigeration in both

medium and low temperature applications with similar performances than R404A. It can therefore be used in

new installations as well as retrofit of existing installations.

R449A is a HFC/HFO blend, it contains R125/R32/R134a/R1234yf, low GWP (1397), no ozone depletion

(ODP=0) and belong to A1 safety class. It can be used for medium and low applications.

The impact of its glide (6,1K) and higher discharge temperature has to be taken consideration for retrofit; an

audit of the heat exchangers, expansion devices has to be done before final decision.

R448A is a non flammable HFC/HFO blend. It contains R125/R32/R134a/R1234yf/R1234ze, low GWP (1387),

no ozone depletion (ODP=0) and belong to A1 safety class. It can be used for medium and low applications.

The impact of its glide (6,3K) and higher discharge temperature has to be taken consideration for retrofit;

an audit of the heat exchangers, expansion devices has to be done before final decision.

R134a is a pure refrigerant with zero glide and low GWP (1430), it is only qualified for medium temperature

application.

R513A is a HFO refrigerant, it contains R1234yf/R134a, low GWP (631), no ozone depletion (ODP=0) with

zero glide and belong to A1 safety class. It is qualified for medium temperature application, suitable for new

installations as well as retrofit of existing installations.

17

6.2.1 REFRIGERANTS GENERAL INFORMATION

Table 6.2.1

Refrigerant glide - Single component refrigerants evaporates and condense at constant temperature,

bubble point temperature and dew point temperature are the same. Some refrigerants mixtures, classified

as zeotropic refrigerants, have a measurable temperature change during evaporation or condensing process.

This temperature change is described as "glide“. The "glide“ depends on the mixture substances and their

compositions. As a consequence of "glide“, different temperatures are measured at inlet and outlet of heat

exchangers. For correct performance evaluation of zeotropic refrigerants with the glide more than 1K, the

average evaporator temperature and average condenser temperature shall be considered.

ACCORDING TO

EN378 R404A R452A R449A R448A R134aR513A

CHEMICAL

NAME

Mixture

R125/R143a/

R134a

Mixture

R32/R125/

R1234yf

Mixture

R32/R125/

R1234yf/ R134a

Mixture

R32/R125/

R1234yf/R134a/

R1234ze (E)

1,1,1,2

tetrafluoro-

ethane

Mixture

R134a/R1234yf

MOLECULAR

FORMULA

Weight %

(44/52/4)

Weight %

(11/59/30)

Weight %

24.3/24.7/

25.3/25.7

Weight %

(26/26/20/21/7) CH2FCF3 Weight %

(44/56)

SAFETY CLASS A1 A1 A1 A1 A1 A1

PED FLUID GROUP 2 2 2 2 2 2

PRACTICAL LIMIT

[kg/m3] 0.52 0.423 0.357 0.388 0.25 0.319

ATEL/ODL

[kg/m3]0.52 0.423 0.357 0.388 0.21 0.319

LFL [kg/m3]NF * NF * NF * NF * NF * NF *

VAPOUR DENSITY

25°C,

101.3 KPA [kg/m3]

3.99 4.30 3.62 3.58 4.17 4.256

MOLECULAR MASS

[g/mol] 97.6 103.51 8 7. 21 86.28 102 108.4

NORMAL BOILING

POINT

°C

46.5 to 45.7 47 to 43.2 46 to 39.9 45.9 to 39.8 26 29.05

ODP 0 0 0 0 0 0

GWP

[100 yr ITH] 3922 2140 1397 1387 1430 631.4

AUTOIGNITION

TEMPERATURE

°C

728 ND ND ND 743 ND

CRITICAL

TEMPERATURE

°C

72.12 74.9 81.5 83.7 101.06 96.5

CRITICAL PRESSURE

[kPa abs] 3734.9 4001.7 4447 4660 4059.3 3766

TEMPERATURE

GLIDE AT 1 BAR ABS

PRESSURE K

0.75 0.38 0.61 0.63 00.1

(*) NF signifes non-flammable.

Note: HFC refrigerants (R404A, R452A, R449A, R448A, R134a and R513A) are classified in Safety Class A1 -

lower toxicity, no flame propagation, (according to ISO817).

18

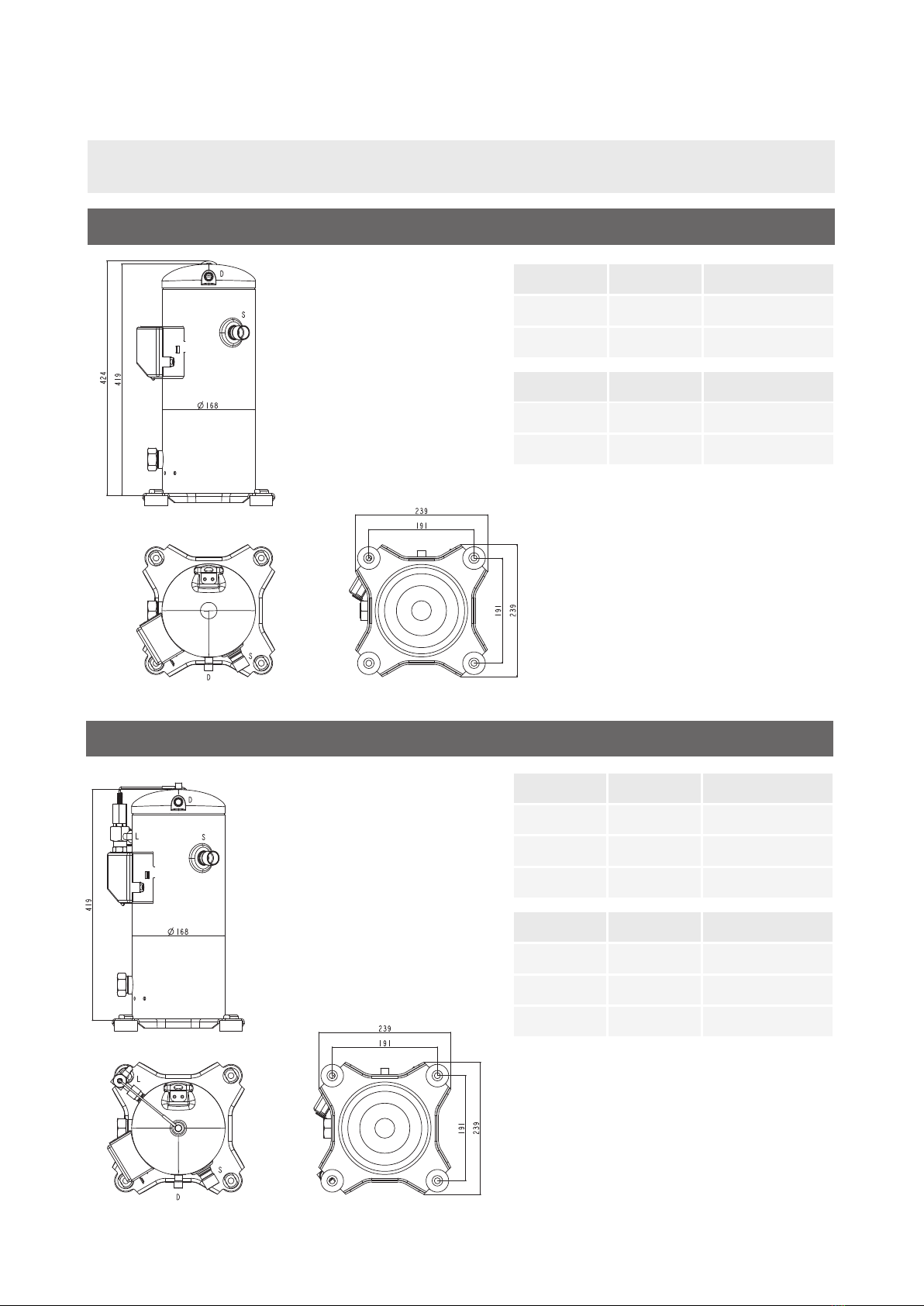

6.3 EXTERNAL DIMENSIONS

MBP_2-6 HP

BRAZING I.D. mm MATERIAL

S - SUCTION 22.35-22.45 COPPER PLATED STEEL

D - DISCHARGE 12.87-12.97 COPPER PLATED STEEL

ROTOLOCK I.D. inches MATERIAL

S - SUCTION 1 1/4"12UNF2A STEEL

D - DISCHARGE 3/4"16UNF2A STEEL

LBP_2-6 HP

BRAZING I.D. mm MATERIAL

S - SUCTION 22.35-22.45 COPPER PLATED STEEL

D - DISCHARGE 12.87-12.97 COPPER PLATED STEEL

L - LIQUID INJ. 3/8" COPPER PLATED STEEL

ROTOLOCK I.D. inches MATERIAL

S - SUCTION 1 1/4" 12UNF 2A STEEL

D - DISCHARGE 3/4" 16UNF 2A STEEL

L - LIQUID INJ. 3/8" STEEL

19

6.4 HERMETIC TERMINAL DIMENSIONS

Figure 6.4 Hermetic terminal

BRAZING I.D. mm MATERIAL

S - SUCTION 22.35-22.45 COPPER PLATED STEEL

D - DISCHARGE 12.87-12.97 COPPER PLATED STEEL

ROTOLOCK I.D. inches MATERIAL

S - SUCTION 1 1/4"12UNF2A STEEL

D - DISCHARGE 3/4"16UNF2A STEEL

MBP_7-13 HP

BRAZING I.D. mm MATERIAL

S - SUCTION 28.83 COPPER PLATED STEEL

D - DISCHARGE 22.47 COPPER PLATED STEEL

ROTOLOCK I.D. inches MATERIAL

S - SUCTION 1 3/4" 12UN STEEL

D - DISCHARGE 1 1/4" 12UNF 2A STEEL

20

Table 6.6b Compressor free internal volume for 1 phase motor

Table 6.6a Compressor free internal volume for 3 phase motor

6.5 SIGHT GLASS

Compressors are equipped and delivered with threaded

oil sight glass of size 1 ¼” 12UNF.

It can be used for visual check of oil, its quantity,

composition or used for parallel multi compressor

connections. Recommended size of wrench for sight

glass nut is 36mm applying torque 55÷60Nm.

6.6 FREE INTERNAL VOLUME

COMPRESSOR SIZE

FREE INTERNAL VOLUME L

LOW SIDE HIGH SIDE

2 HP 4.1 1

2.5 3 HP 3.8 1

3.5 5 HP 3.6 1

6 HP 3.2 1

7 HP 7.3 0.9

8 9 HP 6.5 0.9

10 13 HP 6.3 0.9

COMPRESSOR SIZE

FREE INTERNAL VOLUME L

LOW SIDE HIGH SIDE

2 3 HP 3.6 1

3.5 4 HP 3.2 1

Figure 6.5 Sight glass

This manual suits for next models

29

Table of contents

Other Embraco Air Compressor manuals

Popular Air Compressor manuals by other brands

DeWalt

DeWalt DXCMH1608WB instruction manual

Bitzer

Bitzer 0 operating instructions

Gardner Denver

Gardner Denver ELECTRA-SAVER II Operating and service manual

Craftsman

Craftsman 921.152150 owner's manual

Parkside

Parkside PVKO 50 A1 Translation of the original instructions

Panasonic

Panasonic DA73C12RCU6 Specification sheet