Emcee SR 30 E User manual

SR 30 E

1004156

Planetary Winches

PURPOSE OF THE MANUAL

This manual has been compiled by the Manufacturer to provide information on the safe transport, handling,

installation, maintenance and repair of winches

Failure to adhere to the information provided herein may result in risk to personal health and safety, and may incur

economic damages.

The documentation must be stored by a person with the correct authority and must always be made available

for consultation. A copy of the users manual can best be kept close the working area of the winch.

The manual reflects the state of the art at the time of commercialization of the winch. The Manufacturer

reserves the right to modify, supplement and improve the manual, without the present publication being for that

reason considered inadequate.

Particularly significant sections of the manual and important specifications are highlighted by symbols whose

meanings are given below.

DANGER

-

WARNING

This symbol indicates situations of serious danger which, if ignored, may result in serious

risks to the health and safety of personnel.

CAUTION

-

ATTENTION

This symbol indicates the need to adopt specific precautions to avoid risks to the health and

safety of personnel and possible economic damages.

IMPORTANT

This symbol indicates import and technical information.

The instructions indicated on a grey background next to theses symbols refer exclusively to

equipment conforming to the “ATEX“ Directive94/9/EC.

The operations highlighted by these symbols must be carried out by qualified professionals

specially trained in the safety requirements for zones characterized by potentially explosive

atmospheres.

Failure to observe these instructions may result in serious risks to personal and

environmental safety.

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

Intellectual property

Winch models, drawings and engineering are of our exclusive property. It is expressly forbidden to copy, use or

hand over to third parties such information without a specific written permission.

Warranty

EMCÉ warrants to the original user its winches to be free of defects in material and workmanship for a period of

one year from the date of purchase. EMCÉ will repair, without cost, any product found to be defective, including

parts and labor charges, or at its option, will replace such products or refund the purchase price less a

reasonable allowance for depreciation, in exchange for the product.

If any product proves defective within its original one year warranty period, it should be returned to any

authorized EMCÉ dealer, transportation prepaid with proof of purchase or winch data sheet / test certificate.

This warranty does not apply to products which EMCÉ has determined to have been misused or abused,

improperly maintained by the purchaser; or where the malfunction or defect can be attributed to the use of non-

genuine EMCÉ parts.

EMCÉ makes no other warranty, and all implied warranties including any warranty of merchantability or fitness

for a particular purpose are limited to the duration of the expressed warranty period as set forth above. EMCÉ´s

maximum liability is limited to the purchase price of the product and in no event shall EMCÉ be liable for any

consequential, indirect, incidental, or special damages of any nature arising from the sale or use of the product,

whether based on contract, tort, or otherwise.

With a missing TAG plate the product is not conform the current CE machine construction

standards and warranty will expire.

The following information is required to ensure reliable delivery of spare parts:

Fabrication number (Fabr. No.).............................................................................(on factory TAG plate)

Product type...........................................................................................................(on factory TAG plate)

Spare part number.............................................................................................................. (from manual)

Additional information such as type and/or description of the parts..................................(from manual)

EMCÉ cannot guarantee a smooth delivery of spare parts unless the above information is not

fully submitted. If the TAG plate is removed or damaged, contact your dealer or supplier.

EMCÉ do reserve the right to modify and upgrade the winches they fabricate at any moment and without

advance notice and will not be liable for any difference between winch features and the specifications of present

use and maintenance manual.

Contact the EMCÉ technical department in case extra information is required about for example maintenance

and repair. This users manual is made with great care. EMCÉ cannot be put responsible for errors in this

publication or for the impact of this.

This users manual is written by EMCÉ in Voorhout.

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

CONTENT

1.

GENERAL SAFETY INSTRUCTIONS

2.

INTRODUCTION

2.1

GENERAL

2.2

SPECIFICATIONS

2.3

OPTIONS

3.

GENERAL DESCRIPTION OF WINCHES

3.1

GENERAL OPERATING PRINCIPLE

3.2

DESCRIPTION OF THE ELECTRIC CIRCUIT

3.3

SAFETY INFORMATION

4.

INSTALLATION

4.1

INSTALLATION

4.2

GEARBOX LUBRICATION

4.3

ROPE

4.4

START UP SEQUENCE

5.

WORKING WITH THE MACHINE

5.1

START, NORMAL OPERATION and STOP

5.2

INSPECTIONS

5.3

TROUBLE SHOOTING

6.

MAINTENANCE

6.1

LUBRICATION

6.2

GEARBOX OIL CHECKS AND CHANGES

6.3

SLEWING GEARS

6.4

BOLT TIGHTENING CHECK

6.5

BRAKE CLEANING

ANNEX I: PRODUCT DATASHEET AND CERTIFICATES

ANNEX II: TECHNICAL INFORMATION COMPONENTS

ANNEX III: DRAWINGS & SCHEMATICS

ANNEX IV: GUIDELINES TO COMPLY WITH THE MACHINERY DIRECTIVE 2006/42/EC

ANNEX V: WINCH CLASSIFICATION ACCORDING TO ISO 4301-1

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

1. GENERAL SAFETY INSTRUCTIONS

THE WINCH MAY NOT BE USED FOR LIFTING OR MOVING PERSONS UNLESS IT IS

CLASSIFIED AS A MAN RIDING WINCH.

Read manual carefully before start, use or carry out any maintenance operation on the winch.

This manual is issued with the scope to be a guide for the correct and safe use of the winch and for its

rational maintenance. After careful reading keep present manual in unabridged condition and near the

winch in order to be always available. In case of non understanding of the manual or parts of such, we

recommend to contact EMCÉ.

For any kind of technical assistance please contact EMCÉ or an official dealer of EMCÉ.

EMCÉ cannot know of, or provide all the procedures by which product operations or repairs may be

conducted and the hazards and/or results of each method. If operation or maintenance procedures not

specifically recommended by the manufacturer are conducted, it must be ensured that product safety is

not endangered by the actions taken. If unsure of an operation or maintenance procedure step,

personnel should place the product in a safe condition and contact supervisors and/or the factory for

technical assistance.

On various parts of the winch warning labels are used. Observe the warnings on these labels, if you

have a question concerning the meaning of a label, then go to your supervisor.

1. Only qualified personnel may operate the winch;

2. The winch operator must read the instructions and familiarize with the product before operation;

3. Only authorized dealers and qualified mechanics may adjust or repair the winch;

4. Before performing any maintenance or close inspection to the winch, ensure that the product is not

under load and that the power supply is switched off and disconnected;

5. Check controls of the product and its operation before operating the winch;

6. Do not operate without testing. (See « Inspection and Testing » procedures).

7. Do not operate winch in a damaged condition.

8. Do not operate winch that has not been properly maintained or equipped.

9. Do not attach winch to unsafe foundation. All bolts and foundations for winch attachment should have a

higher load carrying capacity than the reaction forces of the winch.

10. Do not operate winch with any personnel near the line of force or capable of coming into contact with

moving parts.

11. All signs and warning notices must be posted permanently on the winch.

12. Ease the slack out of the rope when starting a lift. Do not jerk the load.

13. Never leave a suspended load unattended.

14. Do not use limit switch settings to regulate the winch stopping points. Limit switches are designed as a

backup to operator accidental over travel only.

15. Periodically check the tightness of all fasteners and tighten if necessary. Replace any damaged

fasteners found;

16. Place the winch in a proper position and secure all fixing points with right size bolts correctly tightened;

17. Check oil level and fill up if necessary;

18. Ensure that all personnel and spectators are clear of the load and winch;

19. Should the winch be easily accessible by third parties, realize the protections stated by CE rules (MC

2006/42/CE);

20. Do not lift loads over people;

21. Use proper crane signals while operating the winch;

22. Ensure safe lifting practices are employed while rigging the cargo for lifting. Do not use untested or

uncertified lifting appendages;

23. Avoid shock loads on the winch, inch the load into engagement before applying full power;

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

24. Limit switches are installed as a safety device; they are not suited to be used as positioning devices;

25. Swinging loads will significantly increase the products load and must be avoided;

26. Do not handle wires without accident prevention gloves and never try to move wires under tension;

27. Make sure that wire size and features are compatible with winch ones and check the correct fastening

of the wire to the drum. Always maintain three or more wraps of rope on the drum:

28. Check the wire winding sense on winch drum for correctness and conformity to the one stated on winch

data sheet. The correct winding contributes to extend wire's operational life;

29. Check wire integrity and absence of broken strands or kinks which may cause wire breaking;

30. Check safety device operation and efficiency;

31. Make sure that working conditions conform to winch features;

32. Never lift loads exceeding maximum safe working load (W.L.L.).

33. Beware of snatch loads on the winch. Any sudden loading can cause excessive acceleration forces on

the winch system, resulting excessive wear or even complete failure. Snatch loads are usually only

found in pulling applications or traversing systems. One way of avoiding them is using a rope leader of

sufficient safety factor (usually SF6) which will stretch when loaded.

34. Some applications such as windlasses, mooring winches and towing winches require significantly

higher than normal break loads. Ensure that the winch is suitable for these applications.

35. When ropes become slack on the drum, they will tend to expend, resulting in: "cutting in" of wire when

the winch is loaded again or the wire coming of the drum and jamming elsewhere on the winch (e.g.

around the winch shaft). Both situations will cause serious damage to the wire requiring replacements.

36. Do not try to move fixed or obstructed loads

37. With winches for lifting and lowering suspended loads, side-pull of load is not allowed.

38. Excessive inching (e.g. giving short pulses to the motor) shall be avoided.

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

2. INTRODUCTION

2.1 GENERAL

Depending on the specifications EMCÉ winches are mend for lifting and/or pulling materials and/of person. The

application of the winches is mentioned on the winch tag plate and the winch datasheet (see annex 1).

Any other use than mentioned on the tag plate or winch datasheet excludes EMCÉ of every responsibility.

2.2 SPECIFICATIONS

Identification data and specifications are mentioned on the identification plate attached to the winch. This data

can be copied to the plate on the back cover of this manual for your reference.

The applicable ATEX classification for the winch can be found on the EMCÉ ATEX certificate (see

annex 1). Although some components of the winch could have higher classifications than on the

EMCÉ ATEX certificate is mentioned the winch may only be used according to the classification on the

EMCÉ ATEX certificate as this certificates is based on the combination off all components on the

winch. In case of doubt please contact EMCÉ or your local dealer.

Standard winches are designed for an ambient temperature of 0°to +40°C. Optional motors can be supplied

for ambient temperatures of -20°to +55°C. Before use check the winch datasheet (see annex 1) for the

applicable design temperature of your winch. In case of doubt please contact EMCÉ.

Standard electric winches have motors with protection class IP 54. These winches are suitable for indoor use.

For outdoor applications onshore IP 55 motors can be supplied. For offshore applications motors with protection

class IP 56 TENV can be supplied.

2.3 OPTIONS

EMCÉ winches can be supplied with a large number of options. The most common options are mentioned

below in this paragraph.

Limit switch:

The safety devices engineered to keep the range of load movements within stated limits. They may be made by

revolution counter or sensors. Limit switches are mandatory for lifting applications but only fitted on request.

Pressure roller:

The device engineered to avoid the loosening and the self unwinding from the drum of a slack wire;

Slack Rope device:

The device engineered to avoid a slack rope by stopping the winch.

Load limiting device:

The safety device engineered to prevent the winch from lifting loads exceeding the allowed maximum or from

being subject to abnormal loads. Before delivery the load limiting device is pre-rated by EMCÉ to the maximum

allowed load stated on the winch datasheet. A load limiter is mandatory for lifting applications but only fitted on

request.

Drum guard:

This option prevents that persons near the winch can touch a rotating winch drum. A drum guard is mandatory

on a winch located in an easily accessible position but only fitted on request.

Bandbrake:

Bandbrakes can be provided manually or failsafe automatically by means of a hydraulic or pneumatic cylinder.

Bandbrakes are used for applications where a second brake, a drum brake is required. By instance for man

riding applications or for applications where the static load is a multiple of the dynamic working load limit. An

application of the second could be a rope anchor winch.

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

Clutches:

With a clutch the winch drum can be disengaged from the winch drive, which allows free running of the cable.

The most common used is the claw clutch, which can’t be operated under load, so that the driveline must first

be freed of the load (for example using a bandbrake on the winch drum). Claw clutches are always manually

operated. Some winches can be equipped with a friction clutch. Friction clutches can be supplied in manual and

remote versions. Note that for most lifting applications the use of a clutch in the driveline is not permitted!

Hand crank:

This option is often used on man riding winches to allow operation of the winch in case the main power source

fails.

Spooling gear:

When it is not possible to work within the maximal advised fleet angle (see section 3.1) a spooling gear is

required on the winch. A standard spooling gear may be used up till a maximum fleet angle of 8°.

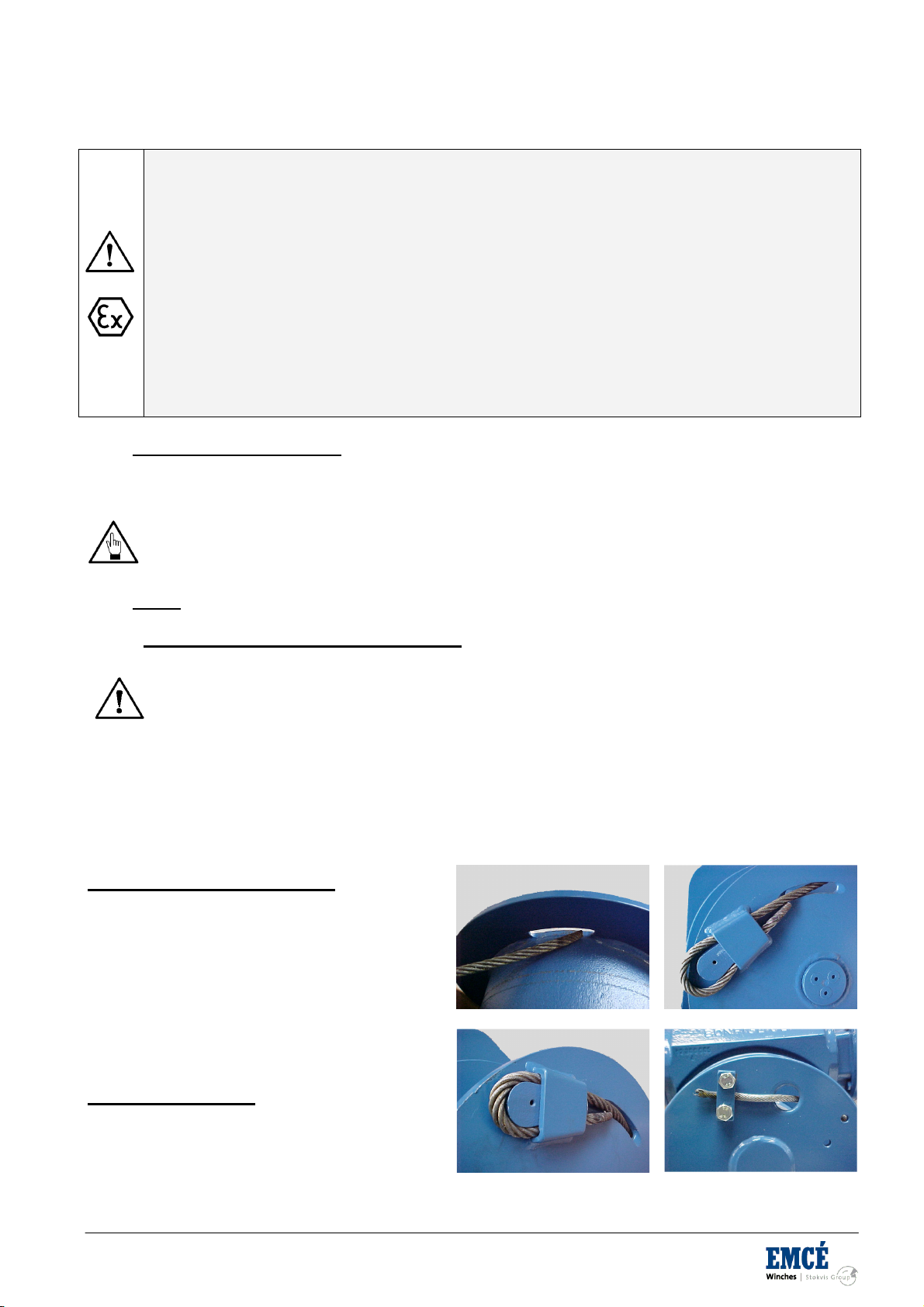

Examples of standard options on EMCÉ winches

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

3. GENERAL DESCRIPTION OF WINCHES

3.1 GENERAL OPERATING PRINCIPLE

Pulling Winch:

A winch is a pulling winch when transporting a load in horizontal sense. If the wire

were to be cut during operation the load would stop moving.

Lifting Winch:

A lifting winch is any winch which moves a load vertically during part or all of its

operation. This may be directly vertical or up a slope. If the rope were to be cut during

any part of the operation, the load will move.

Fleet angle.

To allow the wire to spool correctly it is imperative that the wire comes off the drum at

a sufficiently low fleet angle. In the below table the minimal and maximal fleet angles

are given for plain and grooved drums. Higher fleet angles will result in excessive

wear, grinding noise and bad spooling. To obtain a correct fleet angle, line out the

products drum at a right angle to the wire, and centralize to the first sheave. A piece of

rope can be useful in determining the correct angle.

Plain drum

Grooved drum

1 layer cable only

Grooved drum

multi-layer spooling*

Min.

Recom.

max. Max. Min.

Recom.

max. Max. Min.

Recom.

max. Max.

Standard cables 0,5° 1,5° 2,0° 0° 2,5° 4,0° 0,5° 1,5° 2,5°

Rotating free cables 0,5° 1,2° 1,5° 0° 1,5° 2,0° 0,5° 1,5° 2,0°

* For spooling > 3 layers cable on a grooved drum the max. fleet angle should be limited to the values for a plain drum

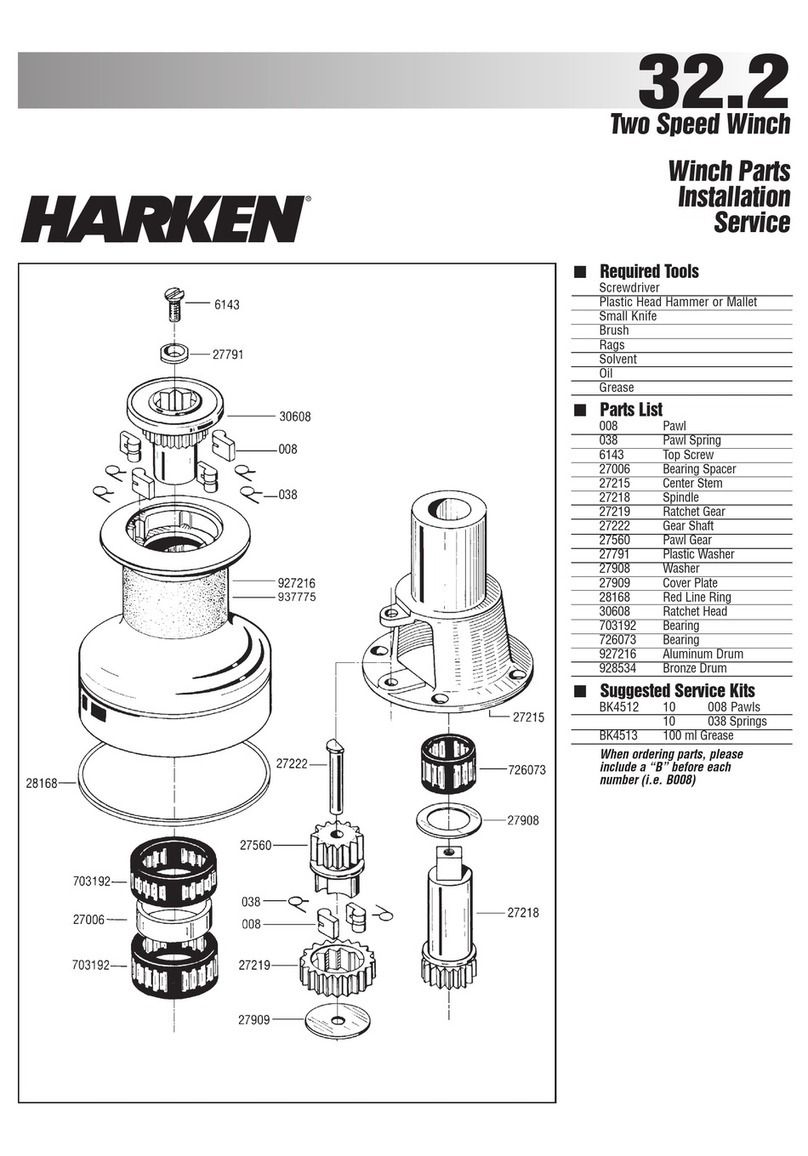

Main components of EMCÉ winches

Motor:

The part delivering the torque for driving the load.

Brake:

The safety device delivering the torque opposite to the load when the motor is not feeded. The brake acts on the

input torque and normally features 1.5 times the driving torque. A further safety brake, directly acting on the

drum, can be delivered on request.

Reduction gear:

The part which multiplies the torque delivered by the motor to obtain the necessary torque to drive the load.

Drum:

The part which winds the rope. Use of a grooved drum smoothens spooling of the rope. Drum boundaries are

the flanges. For safety reasons the diameter of the flanges is equal to the outer diameter of the upper allowed

wire layer increased by two wire diameters.

Frame:

The structure which supports drum and other winch parts.

Main components of an SB series electric winch

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

3.2 DESCRIPTION OF THE ELECTRIC CIRCUIT

EMCÉ electric winches are standard supplied without controls. The required voltage can be found on the winch

datasheet (see annex 1) and on the winch tag plate. The connection details of the motor can be found on the

inside of the terminal box cover of the motor. Technical details about the electric components can be found in

annex 2.

In case the winch is delivered including control panel the electric diagram of the controls can be found on the

inside of the door of the electrical panel.

A control panel is standard supplied with test wires between the panel and the winch. The

testing wires must be replaced by suitable permanent wires during installation of the winch by

a skilled electrical engineer. In cause of doubt of the correct wires please contact EMCÉ or

your local dealer.

3.3 SAFETY INFORMATION

3.3.1 General

EMCÉ winches should be considered “part machines”, as they are intended for incorporation into an assembly

consisting of a platform, a suspensions system, etc… Therefore, they are delivered without the CE mark, but

with a Declaration of Incorporation. However, since they are equipped with selected safety options, when the

user applies for EC compliance of the entire system, the winch “part” will meet the EC requirements. It’s the end

users responsibility to install the winch in such a way that it complies with all safety regulations.

3.3.2 Emergency stops

The winch controls must be equipped with an emergency stop that allows to switch of the winch in case of an

emergency situation. The operators of the winch must be instructed about the location of the emergency stop(s).

The emergency stop(s) may only be used during emergency situations.

The functioning of the emergency stop(s) must be checked frequently.

3.3.3 Safety guards

Drum and other running parts of a winch located in an easily accessible position shall be protected by opportune

guards, only removable when the machine is stopped, according to safety rules in force (MC 2006/42/EC).

Drum guards can be optional supplied by EMCÉ.

3.3.4 Safety precautions during maintenance and repair

During maintenance and repair the winch must be isolated from the main supply.

Electric winches must be isolated from the supply voltage with for example a main switch on

the controls.

Pneumatic and hydraulic winches must have an isolation ball valve before the motor inlet.

Before starting with the maintenance and repair on the winch the users must make sure that

there is no pressure left on the components by shortly operating the winch up till the winch

does not respond anymore on the controls.

The motor and gearbox can become hot during operation. Before starting any maintenance or

repair on these components they first must cool down.

If the winch is to be serviced in a potentially explosive atmosphere, the operator must first

witch off power to the gear unit and ensure that it is out of service, as well as taking all

necessary precautions against it being accidentally switched on again or its parts moving

without warning.

Furthermore, all additional environmental safety precautions must be taken (e.g. elimination of

residual gas or dust, etc.).

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

3.3.5 Handling of the winch

For lifting the winch following possibilities should be used, starting

from the top.

1. Use the lifting lugs on the frame (if applied)

2. Use the holes in the main plate (if applied)

3. Use a sling around the drum

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

4. INSTALLATION

Every winch is delivered completely assembled, tested and packed on a pallet, unless specified otherwise.

Check product integrity on delivery and immediately notify found damages to the transport company.

For winch handling see section 3.5.6.

All tenders and contracts for the performance of deliveries by us inside and outside the Netherlands are

governed by the FME General Conditions for the sales and supply for mechanical and electrical industry of

October 19

th

1998 filed under reference nr. 119/1998 at the district court in The Hague.

If the winch is to be serviced in a potentially explosive atmosphere, the operator must first

switch off power to the gear unit and ensure that it is out of service, as well as taking all

necessary precautions against it being accidentally switched on again or its parts moving

without warning.

Furthermore, all additional environmental safety precautions must be taken (e.g. elimination of

residual gas or dust, etc.).

4.1 INSTALLATION

EMCÉ winches are standard supplied for placement on a horizontal floor unless otherwise specified in

the purchase order and winch drawings. Most winches can also be used in different positions with some

small adjustments to the gearbox. In case of doubt about the installation position of the winch please

contact EMCÉ or your local dealer.

Winch foundation shall be flat and stiff to avoid anomalous tensions which could cause the quick wear

of internal parts;

Position the winch onto the foundation and check winch foundation feet for perfect sticking to;

Fit opportune shim plates before foundation bolt tightening should any gap be found between

foundation and winch feet;

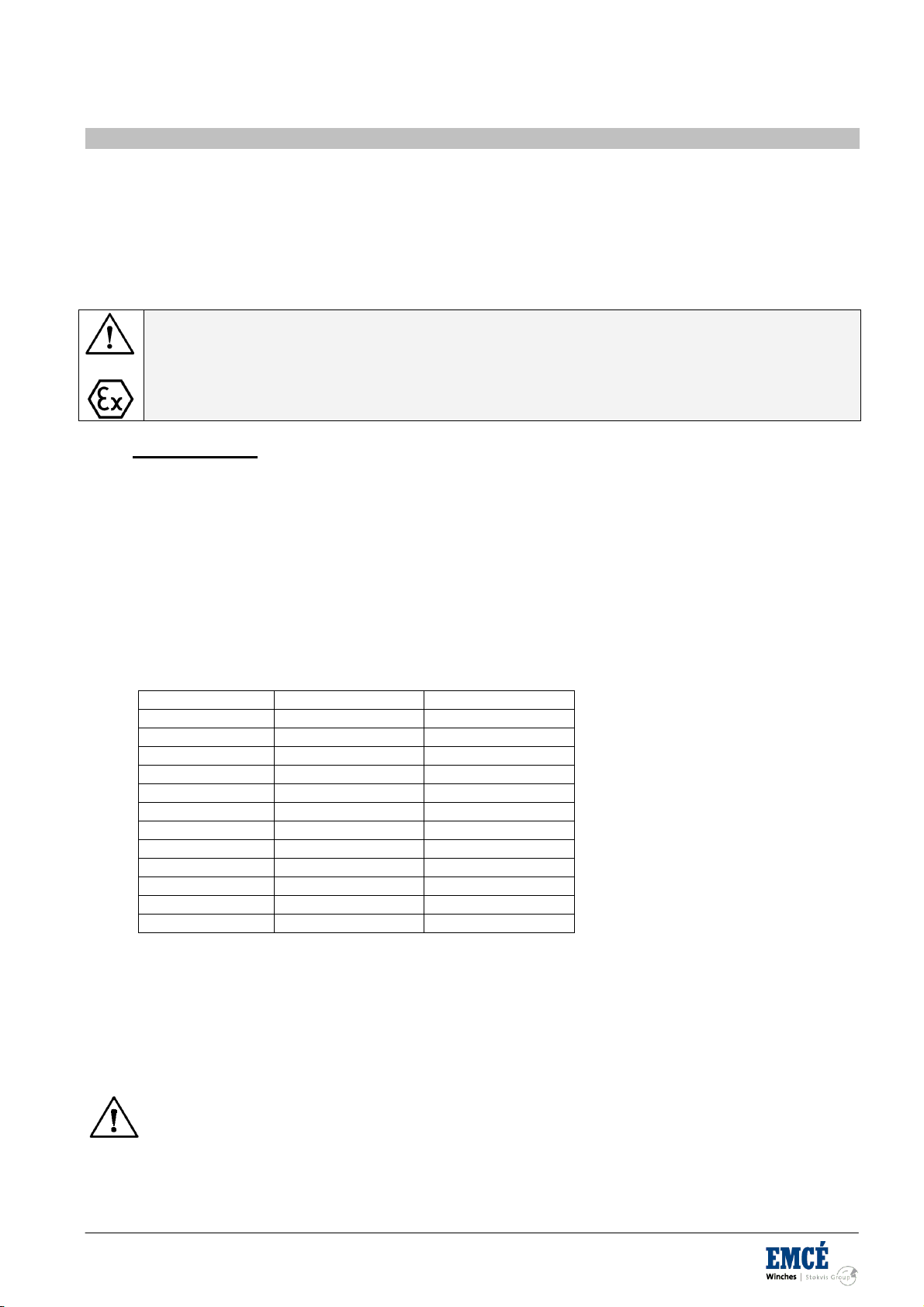

Use grade 8.8 or higher foundation bolts through all existing foundation holes and tighten all bolts with

due torque;

Size (mm)

torque 8.

8 (Nm)

torque 10.9 (Nm)

M 8 25 35

M 10 50 70

M 12 87 122

M 16 211 299

M 18 289 412

M 20 412 578

M 24 711 1000

M 27 1049 1481

M 30 1422 2010

M 33 1932 2716

M 36 2481 3491

M 39 3223 4530

Winch installation shall be such to warrant that the line connecting the middle of the drum to the first

wire pulley is perfectly perpendicular to drum shaft. Small deviations may cause bad winding of the wire

on the drum;

The distance between winch and first pulley shall be such to warrant the correct fleet angle of installed

wire.

EMCÉ winches should be considered “part machines”, as they are intended for incorporation

into an assembly consisting of a platform, a suspensions system, etc… Therefore, they are

delivered without the CE mark, but with a Declaration of Incorporation. However, since they

are equipped with selected safety options, when the user applies for EC compliance of the

entire system, the winch “part” will meet the EC requirements.

Drum and other running parts of a winch located in an easily accessible position shall be

protected by opportune guards, only removable when the machine is stopped, according to

safety rules in force (MC 2006/42/EC).

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

Installation of gear units classified under Directive 94/9/EC

Category 2D gear units must be installed in compliance with the provisions of standards EN

1127-1 and EN 50281-1-2. The installer must, therefore, be fully informed and trained for this

application.

The installation technician must be aware of the ATEX class of the installation area, as well

as the risks associated with the presence of a potentially explosive atmosphere, with

particular attention to explosion and fire hazards, and thereby adopt the necessary safety

precautions.

All maintenance, assembly and disassembly work must be done outside the explosion ha-

zard area by trained personnel.

Check that all accessory components (cables, joints, cable glands, cooling units, etc.) comply

with the Essential Health and Safety Requirements of the ATEX directives. Handle them with

extreme care to avoid altering their characteristics.

Clean the gear unit thoroughly after installation.

4.2 GEARBOX LUBRICATION

Check the winch datasheet (annex 1) for the type of oil used for your winch.

EMCÉ winches are usually delivered with lubricating oil. Nevertheless check oil level at

installation and fill up if necessary. For further details see section (7).

Lubricating oil temperature shall never exceed 100 °C.

4.3 ROPE

4.3.1 Fitting the fiber rope to the winch drum

Before fitting the rope the cable anchor on the drum should be positioned to an

easily accessible position. During fitting of the rope the winch must be isolated from

the main supply.

On winches with a pressure roller the spring tensions must be removed before and

during the installation of the rope.

Changing the winch rotation by reversing the wire dead end connection is only possible when the winch is

equipped with two wedge pockets or two cable clamp mounting positions.

Fit wire dead end from the inside of the drum to the outside through the slotted hole in one of the drum flanges

(see picture 4.3.1)

Fastening with pocket and wedge

The wire dead end shall be fitted in the pocked as

to make an eye around the wire wedge with free

end fitted backwards through the pocket (see

picture 4.3.2).

Pull the wire from the opposite side to press wire

and wedge into the pocket (see picture 4.3.3). The

free end of the wire end shall at al times be 5

times the rope diameter and the rope end shall be

prevented from fraying.

Fitting with wire clamp

Fit the wire as shown on picture 1 and through the

wire clamp on the drum flange.

Tighten wire clamp bolts according to the table in

section 4.1(see picture 4.3.4).

Picture 4.3.1 Picture 4.3.2

Picture 4.3.3 Picture 4.3.4

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

Other possibilities

In some cases a different fastening of the rope than mentioned before is provided. In these cases the rope is

fastened by means of:

A hole in the drum with several fixing bolts

Special wire clamps on the drum

Always keep a minimum of 6 wire coils winded around the drum to warrant a safe winch load

holding. The wire dead end fastening alone is not sufficient to hold the winch load.

Make sure that wire clamp bolts don't pass over the flange plate. If it happens, shorten the

bolts to avoid rope damage.

Never fit a wire longer than the maximum allowed to avoid excess wire layers non conforming

to safety rules.

The first winding of the wire to the drum shall be such to obtain a perfect compactness of the

wire coils and leave no space between the coils. Keep the wire under tension during the first

winding operation. The wire can be easily damaged should it be wedged under load between

non compacted under laying coils.

4.3.2 Handling and installation of the rope

Handling and installation of the rope should be carried out in accordance with a detailed plan and should be

supervised by a competent person.

Incorrectly supervised handling and installation procedures may result in serious injury to

persons in the vicinity of the operation as well as those persons directly involved in the

handling and installation.

Wear suitable protective clothing such as overalls, industrial gloves, helmet, eye protectors and safety footwear

Failure to wear suitable protective clothing and equipment may result in skin problems from

over exposure to certain types of rope lubricants and dressing

Ensure that the correct rope has been supplied by checking to see that the description on the Certificate is in

accordance with that specified in the purchaser’s order.

Check by measurement that the nominal diameter of the new rope conforms to the nominal size stated on the

Certificate. Examine the rope visually to ensure that no damage or obvious signs of deterioration have taken

place during storage or transportation to the

installation site.

Check the working area around the equipment for any potential hazards which may affect the safe installation of

the rope.

Check the condition of the rope-related equipment in accordance with the OEM’s instructions. Include the

following:

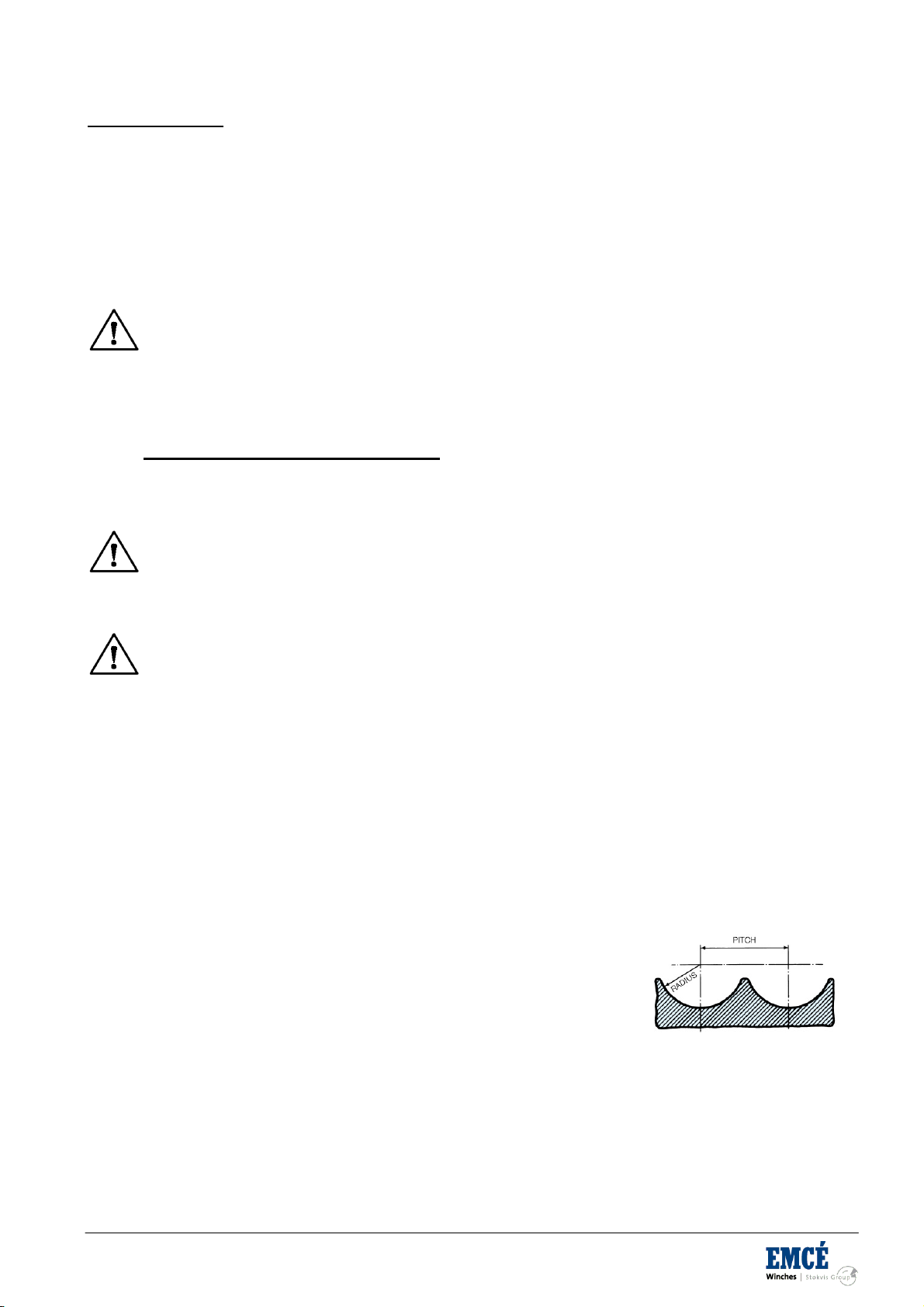

Drum

Check the general condition of the drum.

If the drum is grooved, check the radius and pitch and ensure that the

grooves will satisfactorily accommodate the size of the new rope (see

Fig 3)

Sheaves

Ensure that the grooving is of the correct shape and size for the new rope

Check that all sheaves are free to rotate and in good condition.

Rope Guards

Check that any rope guards are correctly fitted and are in good condition.

Check the condition of any wear plates or rollers which are protecting structural members.

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

Failure to carry out any of the above could result in unsatisfactory and unsafe rope

performance.

Coils

Place the coil on the ground and roll it out straight ensuring that it does

not become contaminated with dust/grit, moisture or any other harmful

material.

If the coil is too large to physically handle it may be placed on a ‘swift’

turntable and the outside end of the rope pulled out allowing the coil to

rotate.

Never pull a rope away from a stationary coil as

this will induce turn into the rope and kinks will

form. These will adversely affect rope

performance.

Reels

Pass a shaft through the reel and place the reel in a suitably anchored stand which allows it to rotate

and be braked to avoid overrun during installation. Where multi-layer coiling is involved it may be

necessary for the reel to be placed in equipment which has the capability of providing a back tension in

the rope as it is being transferred from reel to drum. This is to ensure that the underlying (and

subsequent) laps are wound tightly on the drum.

Position the reel and stand such that the fleet angle during

installation is limited to 1.5 degrees.

If a loop forms in the rope ensure that it does not tighten

to form a kink.

Ensure that the reel stand is mounted so as not to create a

reverse bend during reeving (i.e. for a winch drum with an overlap

rope, take the rope off the top of the reel).

Ensure that any equipment or machinery to be roped is correctly and safely positioned and isolated

from normal usage before installation commences. Refer to the OEM’s instruction manual and the

relevant ‘Code of Practice’.

When releasing the outboard end of the rope from a reel or coil, ensure that this is done in a controlled manner.

On release of the bindings and servings used for packaging, the rope will want to straighten itself from its

previously bent position. Unless controlled, this could be a violent action. Stand clear.

Failure to control could result in injury.

Ensure that the as-manufactured condition of the rope is maintained during installation.

If installing the new rope with the aid of an old one, one method is to fit a rope sock (or stocking) to each of the

rope ends. Always ensure that the open end of the sock (or stocking) is securely attached to the rope by a

serving or alternatively by a clip (See Fig. 9). Connect the two ends via a length of fibre rope of adequate

A kink can severely affect the strength of a six

strand rope and can result in distortion of a

rotation- resistant or low rotation rope leading

to its immediate discard.

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

strength in order to avoid turn being transmitted from the old rope into the new rope. Alternatively a length of

fibre or steel rope of adequate strength may be reeved into the system for use as a pilot/messenger line. Do not

use a swivel during the installation of the rope.

Monitor the rope carefully as it is being pulled into the system and make sure that it is not obstructed by any part

of the structure or mechanism which may cause the rope to come free.

Failure to monitor during this operation could result in injury.

This entire operation should be carried out carefully and slowly under the supervision of a competent person.

When coiling a rope on a plain (or smooth) barrel drum ensure that each lap lies tightly against the preceding

lap. The application of tension in the rope greatly assists in the coiling of the rope.

Any looseness or uneven winding will result in excessive wear, crushing and distortion of the

rope.

When multi layer coiling has to be used it should be realized that after the first layer is wound on a drum, the

rope has to cross the underlying rope in order to advance across the drum in the second layer. The

points at which the turns in the upper layer cross those of the lower layer are known as the cross-over points

and the rope in these areas is susceptible to increased abrasion and crushing. Care should be taken when

installing a rope on a drum and when operating a machine to ensure that the rope is coiled and layered

correctly.

Limit switches, if fitted, must be checked and re-adjusted, if necessary, after the rope has been installed.

Record the following details on the Certificate after installation has been completed: type of equipment, location,

plant reference number, duty and date of installation and any re-rating information/signature of competent

person. Then safely file the Certificate.

Run in’ the new rope by operating the equipment slowly, preferably with a low load, for several cycles. This

permits the new rope to adjust itself gradually to working conditions.

Unless otherwise required by a certifying authority, the rope should be in this condition before

any proof test of the equipment or machinery is carried out.

Check that the new rope is spooling correctly on the drum and that no slack or cross laps develop. Apply a back

tension in the order of 2% to 5% of the strength of the rope in order to achieve tight and even coiling especially

on the first layer..

Where multi-layer coiling is unavoidable, succeeding layers should coil evenly on the preceding layers of rope.

Irregular coiling usually results in severe surface wear and rope malformation, which in turn is

likely to cause premature rope failure.

Ensure that the as-manufactured condition of the rope is maintained throughout the whole of the handling and

installation operation.

4.4 START UP SEQUENCE

1. Check lubricating oil level and fill up if necessary;

2. Make a few trials without load before fitting the wire to check a correct operation of the system;

3. Fit the wire as described in section (4.3);

4. Make a few lifting trials with reduced load to check the correct operation of the brake and the limit

switches (optional), pay attention to excessive or unexplained noises;

5.

Check for correct working of the load limiting device (optional).

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

5. WORKING WITH THE MACHINE

5.1 START, NORMAL OPERATION AND STOP

5.1.1 Check list for prestart preparation

1. Perform the frequent inspection (see chapter 5.2) at the beginning of each shift.

2. Do not operate winch with any personnel near the line of force or capable of coming into contact with

moving parts.

3. Ease the slack out of the rope when starting a lift. Do not jerk the load.

4. Ensure that all personnel and spectators are clear of the load and winch;

5. Make sure that working conditions conform to winch features;

5.1.2 Operating instructions

The following descriptions cover the functional operation of the winch controls only. It does not cover any

operations performed using the winch. It is the operators responsibility to understand all facets of the operation.

The operator must be physically capable and mentally alert. They must have good hearing,

vision and depth perception. The operator must make sure all conditions are safe for operations. If the operator

feels that anything is unsafe, or even questionable, do not proceed until properly evaluated or corrected.

Standard our products are delivered without control. Below an operating instruction is given about the optional

controls EMCÉ can deliver. In case controls are obtained from another supplier please use the instruction

manual from the supplier for safe use.

On winches with an optional manual operated bandbrake, the bandbrake must first be

released before the below operation of the winch can be performed.

On winches with an optional manual operated clutch, the clutch must be engaged before the

below operation of the winch can be performed.

Before start up

Turn speed control potentiometer on main control panel in position “0” (only applicable for controls with

a frequency inverter).

“Paying in”

Press the “in” button on the main control panel. Check if the cable is spooling correct and if the load in

the winch wire is stable.

Turn the speed control potentiometer on main control panel up till the winch is slowly rotating. Before

increasing the speed of the winch check if the cable is spooling correct and if the load in the winch wire

is stable (only applicable for controls with a frequency inverter).

“Paying out””

Press the “out” button on the main control panel. Check if the cable is spooling correct and if the load in

the winch wire is stable.

Turn the speed control potentiometer on main control panel up till the winch is slowly rotating. Before

increasing the speed of the winch check if the cable is spooling correct and if the load in the winch wire

is stable (only applicable for controls with a frequency inverter).

For winches with frequency inverters that do not have motors with forced ventilation the

running times of the winch at slow speed are limited due to the reduced cooling capacity of the

motor at slow speeds. For such winches we recommend to use the winch mainly on slow

speed during starting, stopping and positioning.

To stop the winch

Turn speed control potentiometer on main control panel in position “0” (only applicable for controls with

a frequency inverter).

Release “in” or “out” button

Emergency stop (optional)

Turn the button for normal operation (button in upper position). To stop the winch push the button down. To

reset the emergency stop turn the button to the upper position.

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

Manual operated bandbrake (optional)

The bandbrake on a winch can be used to lock the winch drum

during maintenance or when the disengagement clutch on the

drum is released. When a load remains in the cable after the job

with the winch is finished the bandbrake should also be engaged

to prevent that the loads remains on the winch drive when the

winch is not in use. Before the winch is taken back into service the

bandbrake must first be released. Below the instructions for the

bandbrake operation are given.

Closing

Push the handle towards it’s outer limit in the direction of

the bandbrake rim (overcentre type bandbrake)

Rotate the handle (clockwise) up till the bandbrake is

firmly locked (wind-on type bandbrake)

Opening

Pull the handle towards you up till it’s outer limit

(overcentre type bandbrake)

Rotate the handle (counter clockwise) up till the

bandbrake is fully free of the brake rim (wind-on type

bandbrake)

Manual operated clutch (optional)

With a clutch the winch drum can be disengaged from the winch

drive, which allows to walk out the cable. Below the instructions

are given for the operation of the clutch.

Closing

Close the bandbrake (when available)

Turn the drum shaft up till the pins/claws of the clutch are

placed before the corresponding openings on the winch

drum. Depending on the type of winch the shaft can be

rotated as follows

oWith a hand wheel on the winch drive

oBy operating the winch at a slow speed

When the above methods are not possible the last option

is to rotate the drum manually up till it is in the correct

position compared to the pins/claws of the clutch.

Move the handle in the direction of the winch drum up till

the clutch is fully closed.

Open the bandbrake before the winch is used (when

available).

Opening

Close the bandbrake (when available)

Turn the drum shaft up till the pins/claws of the clutch are

not making contact anymore with the corresponding

openings on the winch drum. Depending on the type of

winch the shaft can be rotated as follows

oWith a hand wheel on the winch drive

oBy operating the winch at a slow speed

When the above methods are not possible the last option

is to rotate the drum manually up till it is in the correct

position compared to the pins/claws of the clutch.

Move the handle in the drum support bearing up till the

clutch is fully free of the winch drum.

Open the bandbrake before the winch is used (when

available).

Overcentre type bandbrake

Wind-on bandbrake

Manual operated clutch

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

On a winch without bandbrake the clutch may only be operated when there is no load in the

cable.

The winch drum may only be rotated manually when there is no load in the cable.

Before rotating the winch drum manually, the winch must be isolated from the main supply. A

dangerous occurrence is likely to occur if the motor is powered.

Emergency hand crank (optional)

Before engaging the emergency hand crank, the winch must be isolated from the main

electrical, hydraulic or air supply. A dangerous occurrence is likely to occur if the motor is

powered with the crank handle engaged.

The crank handle is connected to the winch frame by mean of a wing nut. Remove the handle from

the winch frame.

Depending on the winch type the hand crank should be fitted as follows

oOn the gearbox input shaft opposite to the motor is a recessed shaft protected by a nylon

plug. Remove the plug and slot the crank handle onto the keyway.

oOn the back of the motor is a recessed shaft protected by a nylon plug. Remove the plug

and slot the crank handle onto the keyway.

Ascertain the direction of rotation by turning the crank handle two or three revolutions.

Thereafter, continue to wind in the direction required to recover the load or person suspended from

the winch rope.

In case the winch is supplied with one or more brakes, carefully release the brakes before us

e of the emergency hand crank. To make sure that the load not drops when releasing the

brakes, the emergency crank must be locked during release of the brakes or hold tight by an

operator.

In case a self braking hand crank is fitted the opening on the side of the crank should be

placed over the locking pin.

In case the winch is equipped with a self braking worm gearbox (reduction of 80 to 100) the

load will be sustained by the gearbox even when the brakes are released.

5.2 INSPECTIONS

Before use, free the unit from snow, ice, sand, gravel or other interfering matter.

All new, altered or modified equipment should be inspected and tested by personnel instructed

in safety, operation and maintenance of this equipment to ensure safe operation at rated

specifications before placing equipment in service.

Never use a winch when inspection indicates is damaged. Frequent and periodic inspections

should be performed on equipment in regular service.

Observe the routine inspection and maintenance schedule to ensure suitable operating

conditions and the effective explosion protection of the unit.

Frequent inspections are visual examinations performed by operators or service personnel during routine winch

operation. Periodic inspections are thorough inspections performed by personnel trained in inspection of the

winch. Inspection intervals depend upon the nature of the critical components of the equipment and the severity

of usage. Careful inspection on a regular basis will reveal potentially dangerous conditions while still in the early

stages, allowing corrective action to be taken before the condition becomes dangerous. Deficiencies revealed

through inspection, or noted during operation, must be reported to an appointed person. A determination must

be made as to whether a deficiency constitutes a safety hazard before resuming operation of the winch.

Records and Reports

Some form of inspection record must be maintained for each winch, listing all points requiring periodic

inspection. A written report should be made monthly on the condition of the critical parts of each winch. These

General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

reports should be dated, signed by the person who performed the inspection, and kept on file where they are

readily available for review.

Rope Reports

Records should be maintained as part of a long-range rope inspection program. Records should include the

condition of rope removed from service. Accurate records will establish a relation ship between visual

observations noted during frequent inspections and the actual condition of rope as determined by periodic

inspections.

Frequent Inspection

On equipment in continuous service, frequent inspection should be made by operators at the beginning of each

shift. In addition, visual inspections should be conducted during regular operation for indication of damage or

evidence of malfunction (such as abnormal noises).

1. WINCH. Prior to operation, visually inspect winch housings, controls, brakes and drum for indications of

damage. Do not operate the winch unless the rope feeds into the drum smoothly. Any discrepancies

noted must be reviewed and inspected further by authorized personnel instructed in the operation,

safety and maintenance of this winch.

2. FIBER ROPE. Visually inspect all rope which can be expected to be in use during the day's operations.

Inspect for wear and damage indicated by distortion of rope such as kicking, "birdcaging", core

protrusion, main strand displacement, corrosion, broken or cut strands. If damage is evident, do not

operate winch until the discrepancies have been reviewed and inspected further by personnel

instructed in the operation, safety and maintenance of this winch.

The full extent of rope wear cannot be determined by visual inspection. At any indication of

wear inspect the rope in accordance with instructions in "Periodic Inspection."

3. ELECTRIC SYSTEM: Check connections of power supply. Electric wiring connections, if in doubt check

phase cycle, voltage dip during operation and current supply. (Fix loose wiring or exposed wiring or

connections).

4. CONTROLS. During operation of winch, verify response to control is quick and smooth. If winch

responds slowly or movement is unsatisfactory, do not operate winch until all problems have been

corrected.

5. BRAKES. During winch operation test brakes. Brakes must hold load without slipping. Automatic brakes

must release when winch motor throttle is operated. If brakes do not hold load, or do not release

properly, the brakes must be adjusted or repaired.

6. ROPE REEVING. Check reeving and ensure rope is properly secured to the drum.

7. LUBRICATION. Refer to section 7 for recommended procedures and lubricants.

Periodic Inspection

Frequency of periodic inspection primarily depends on the severity of usage :

NORMAL : semi-annually

HEAVY : quarterly

SEVERE : monthly

Keep accumulative written records of periodic inspections to provide a basis for continuing evaluation. Inspect

all items listed in "Frequent Inspection". Also inspect the following :

1. FRAME and UPRIGHT. Check for deformed, or cracked or corroded main components. If external

evidence indicates the need for additional inspection return winch to your nearest EMCÉ service repair

center.

2. FASTENERS. Check retainer rings , split pins, cap screws, nuts, and other fasteners on winch,

including mounting bolts. Replace if missing or damaged and tighten if loose.

3. DRUM AND SHEAVES. Check for cracks, wear or damage. Replace if necessary.

4. FIBER ROPE. In addition to Frequent Inspection requirements, also inspect for the following:

a. Build-up of dirt. Remove dirt and corrosion if necessary.

b. Loose or damaged end connection. Replace if loose or damaged

c. Check whether the fiber rope is secured properly to the drum.

d. Verify fiber rope diameter. Measure the diameter of the fiber rope from crown-to-crown

throughout the life of the rope. Recording of the actual diameter should only be done with the

fiber rope under equivalent loading and in the same operating section as accomplished during

This manual suits for next models

1

Table of contents

Popular Winch manuals by other brands

Sherpa

Sherpa 4x4 Stallion owner's manual

RIDGE RYDER

RIDGE RYDER 341685 instructions

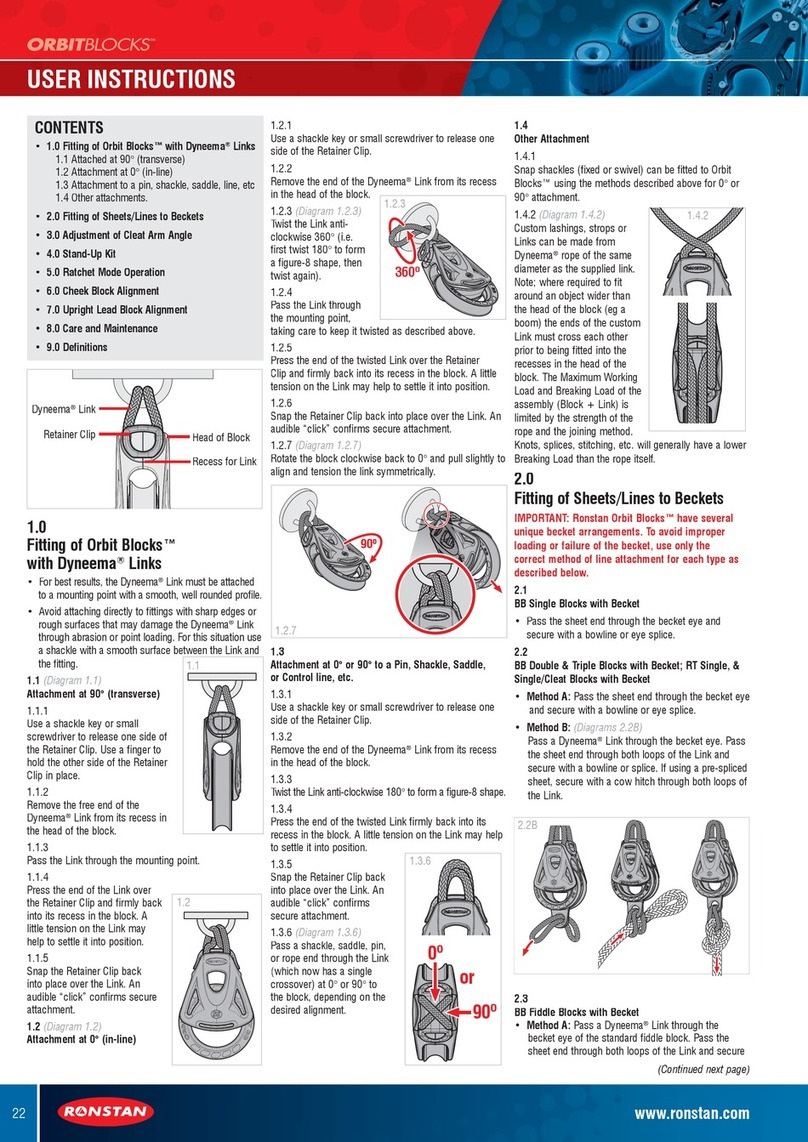

Ronstan

Ronstan ORBITBLOCKS User instructions

PREMIER WINCH

PREMIER WINCH DV-6000S manual

HADEF

HADEF 46/21E Installation, Operating and Maintenance Instruction

Ramsey Winch

Ramsey Winch 600 Series Operating, Service and Maintenance Manual