5.52.288.00.01.06

9.4 Wire rope........................................................................................................................18

9.5 Limit switch for wire rope path (as option) ..................................................................18

9.6 Slack rope switch (as option) .......................................................................................18

10

Safety check .................................................................................... 18

11

Functional test................................................................................. 19

11.1 Checks before the initial start-up .................................................................................19

12

Maintenance .................................................................................... 19

12.1 General ...........................................................................................................................19

12.2 Monitoring......................................................................................................................19

12.3 Brake motor ...................................................................................................................19

12.4 Overload protection.......................................................................................................20

12.5 Limit switch for wire rope path (as option) ..................................................................20

12.6 Slack rope switch (as option) .......................................................................................21

13

Inspection ........................................................................................ 21

13.1 General Overhaul for motor-driven units.....................................................................21

13.2 Periodic checks .............................................................................................................22

13.3 Wire rope........................................................................................................................22

13.4 Inspection intervals .......................................................................................................22

14

Service ............................................................................................. 22

14.1 Wire rope........................................................................................................................22

14.2 Gearbox..........................................................................................................................23

14.3 Electric motor ................................................................................................................23

14.4 Lubricant selection........................................................................................................23

14.5 Lubricant for food industry – selection (as option*) ...................................................23

15

Trouble............................................................................................. 23

16

Remedy ............................................................................................ 24

17

Decommissioning ........................................................................... 25

17.1 Temporary decommissioning.......................................................................................25

17.2 Final decommissioning/disposal..................................................................................25

18

Additional documents..................................................................... 25

18.1 Electric wiring diagrams ...............................................................................................25

18.2 Radio control (as option) ..............................................................................................25

1 Information

The products meet European Union requirements, in particular the valided EU Machine Directive.

The entire company works acc. to a certified quality assurance system as per ISO 9001.

The production of components at our work is subject to strict, intermediate checks.

After assembly, each product is subject to a final test with overload.

For the operation of hoists, the national accident prevention regulations apply in Germany, amongst others.

The stated performance of the devices and meeting any warranty claims require adherence to all instructions

in this manual.

Before delivery, all products are packed properly. Check the goods after receipt for any damage caused

during transport. Report any damage immediately to the forwarding agent.

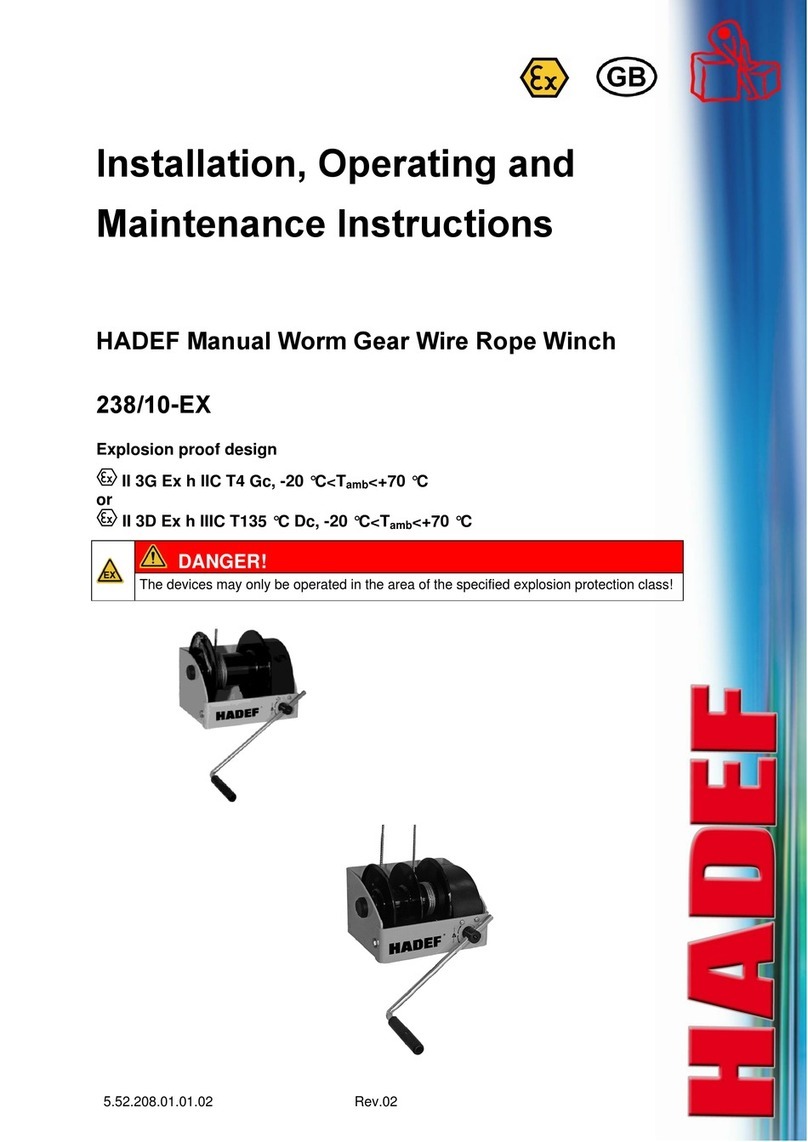

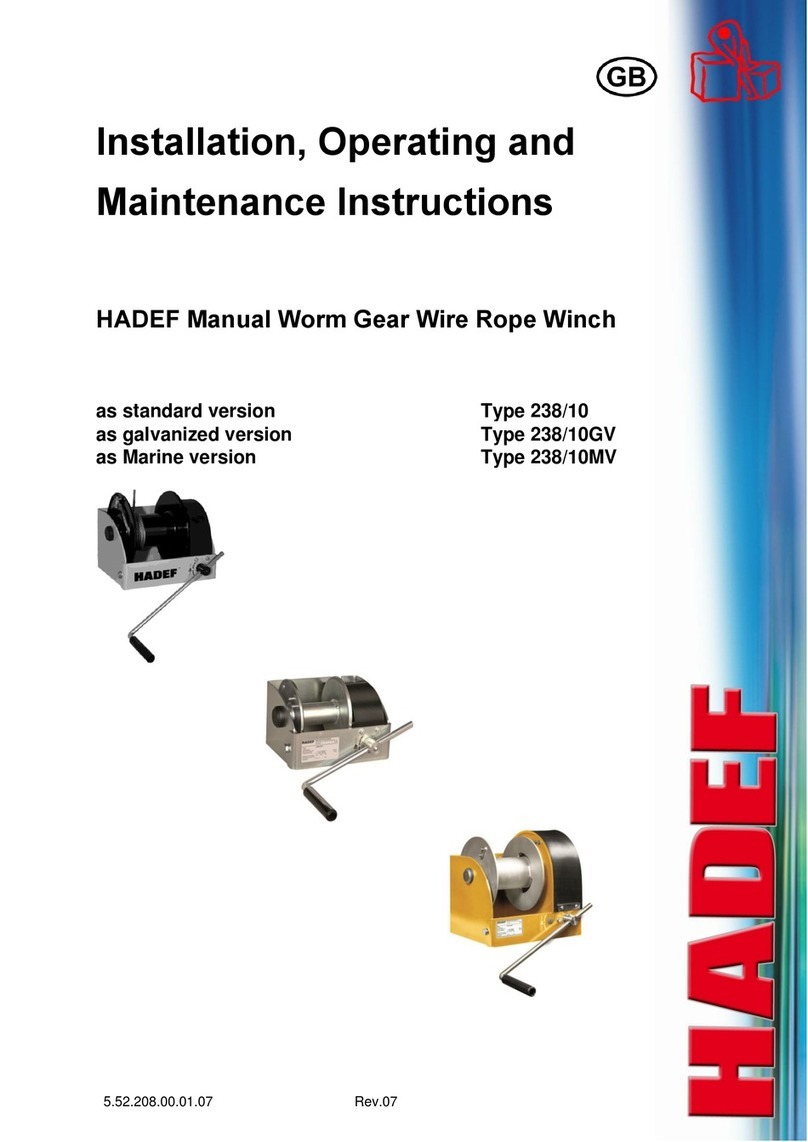

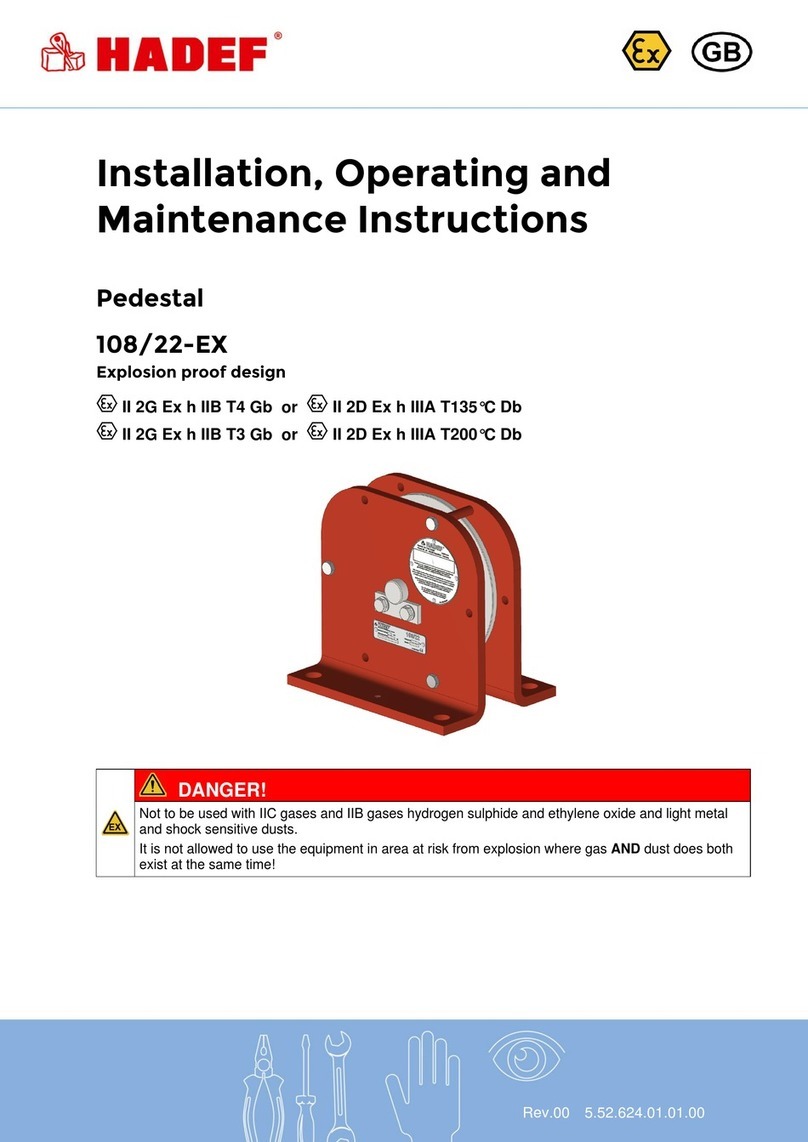

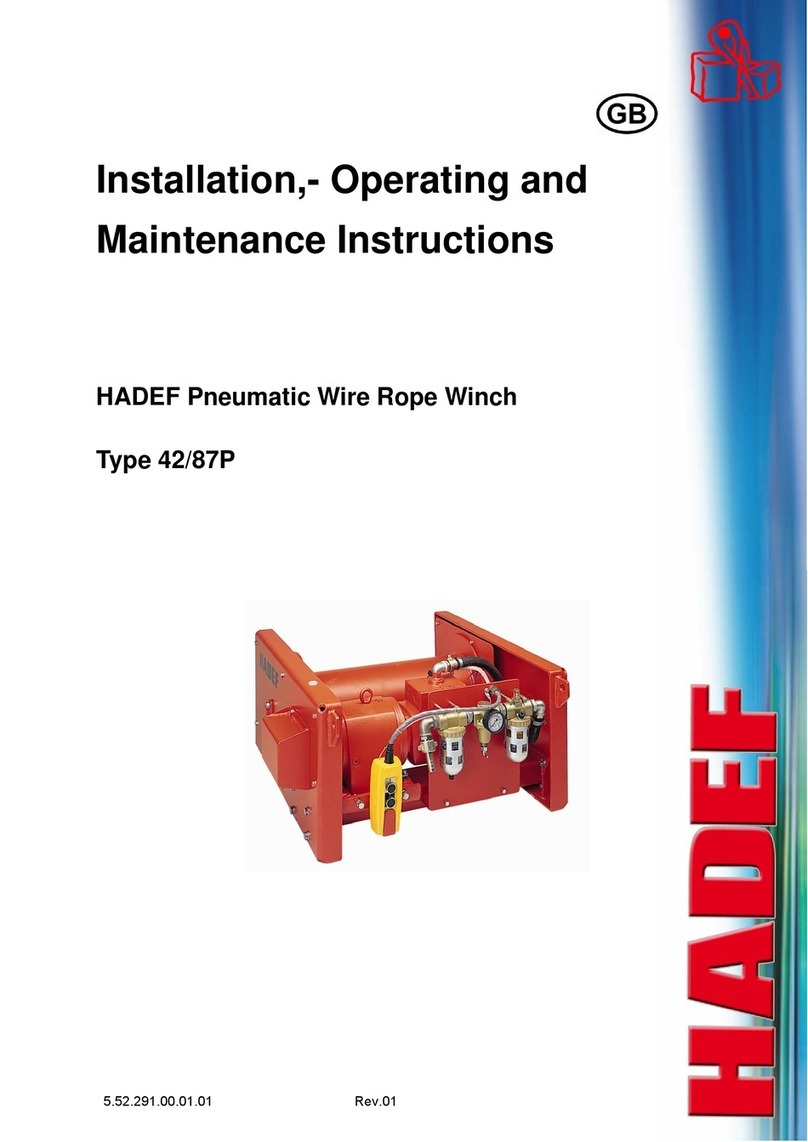

This manual allows a safe and efficiently use of equipment. Images of this manual are for a principle

understanding and can be different from the real design.