PREMIER WINCH DV-6000S User manual

1

Self-Recovery Winch

Thank you for purchasing a PREMIER WINCH. This manual covers operation and

maintenance of the winch. All information in this publication is based on the latest

production information available at the time of printing.

General Safety Precautions

Every PREMIER WINCH is designed to give safe and dependable service if operated

according to the instructions. Read and understand this manual before installation and

operation of winch.

Follow these general safety precautions:

˙Confirm that the winch is suitable for the operation and conditions

˙Ensure that the winch is securely mounted and the rope wound correctly.

˙Don't use unsuitable pulleys or accessories.

˙Genuine replacement parts should only be used.

˙Check the winch for smooth operation without load prior to any recovery.

˙Make sure the wire rope is wound evenly on the first layer on the drum, rewind it if not.

1. The winch is designed as a vehicle self-recovery unit and only rated for

intermittent-periodic duty.

2. The winch is not to be used to lift, support or otherwise transport personnel.

3. A minimum of five (5) wraps of rope must remain on the drum at all times to support

the rated load.

4. When choosing a winch, you need to consider the vehicles size and weight. As a

general guide, you will need a winch with a maximum load rating of at least one to

one and a half times greater than the gross vehicle weight.

5. The rated line pull of the winch must be powerful enough to overcome the added

resistance caused by whatever the vehicle is stuck in.

WARNING

2

Fleet angle

Centre line of anchor

point

I.Safety Precautions

This winch is designed to give safe, dependable service and trouble-free operation. Please read and

understand this Instruction Manual before installing and operating your winch.

Precautions before use:

Confirm that the winch is suitable for the application before use.

Because the maximum load capacity decreases corresponding to the increase in the number of

layers, wind the rope according to the instructions in this manual.

Mount the winch securely and ensure that the rope is attached correctly.

Genuine replacement parts should only be used.

If a hook or pulley blocks are to be used, ensure that they are correct for the application, and

remember that a pulley block should be rated at least twice the capacity of the winch.

Precautions at the time of operation of the winch are listed as follows:

The operator of a winch in some cases, is required to hold qualifications

according to applicable laws and ordinances.

Only a responsible person should operate the winch.

Prior to use, carry out the daily checks without fail, and use only

after confirming the winch is functioning correctly.

Aminimum of 5 wraps of rope must remain on the drum at all times!

Do not use winch to move people

Keep hands clear of wire rope and fairlead opening.

Use leather gloves or a heavy rag when handling the wire rope.

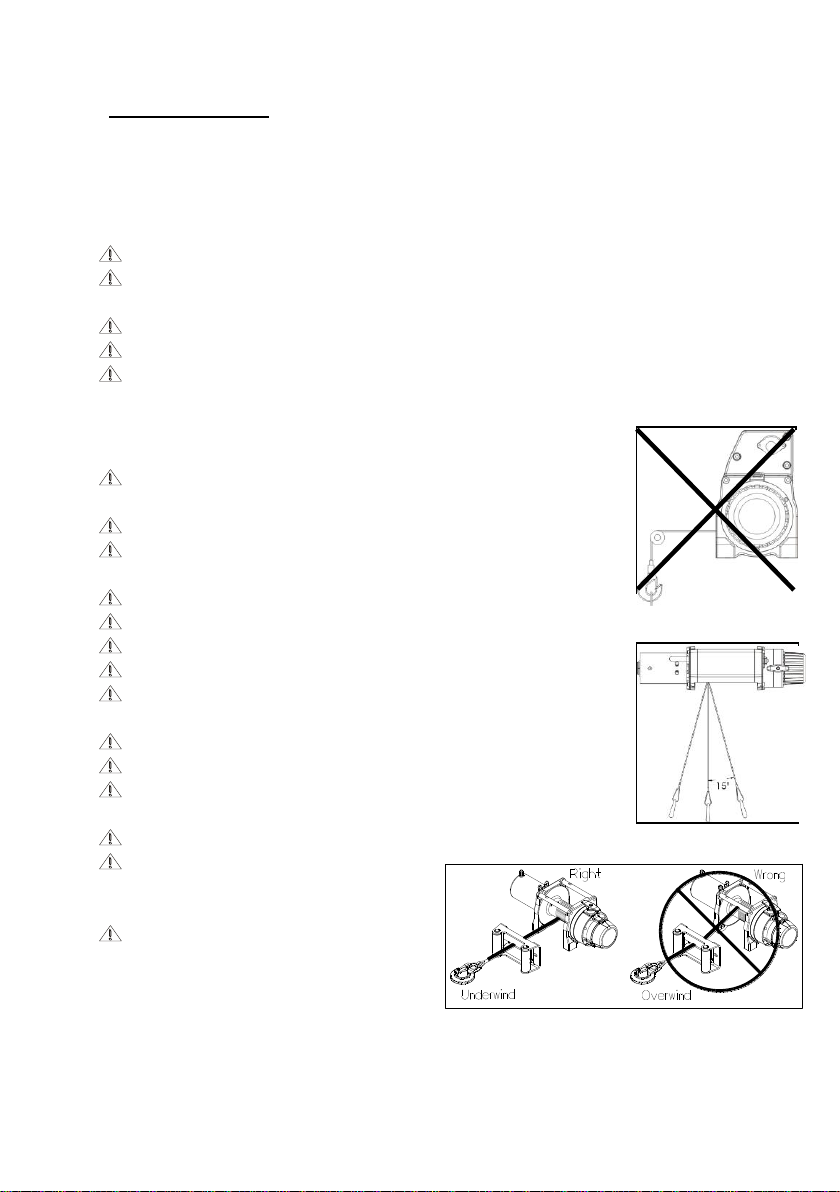

The winch is not to be used as a lifting device or a hoist for vertical lifting

(Fig1)

Do not exceed maximum line pull ratings shown in these instructions.

Do not impose shock loads on the winch.

Pull from an angle below 15 degree when straightening up the vehicle or

load. (Fig 2)

Run the engine during winching operations to keep battery charged.

When winching a heavy load, lay a heavy

blanket or jacket over the wire Rope, near to

the hook end.

Always operate your winch in an

underwound orientation only. (Fig3)

(Fig 1)

(Fig2)

(Fig3)

3

II.Performance Data

Specifications

Model

DV-6000S

DV-9000ES

DV-9000i

DV-12 light

DV-12000ES

DV-15000ES

Line Pull (first layer)

2,722kg / 6,000lb

4,082kg / 9,000lb

5,443kg/12,000lb

5,443kg/12,000lb

6,803kg/15,000lb

Line Speed (first layer, no load)

8.0mpm / 26.2fpm

13.4mpm / 44fpm

8.0mpm / 26.2fpm

8.3mpm/27fpm

6.9mpm/22fpm

Line Speed (first layer, full load)

2.0mpm / 6.5fpm

2.0mpm / 6.4fpm

1.0mpm / 3.3fpm

1.2mpm/4.0fpm

0.8mpm/2.5fpm

Amp. Draw

no load 12V

60A

55A

50A

60A

60A

full load 12V

300A

350A

350A

440A

460A

no load 24V

35A

30A

30A

50A

50A

full load 24V

200A

210A

210A

290A

340A

Motor

Type

Series wound

Output

12V

2,390w / 3.2hp

3,430w / 4.6hp

3,430w / 4.6hp

4,175w/5.6hp

24V

1,490w / 2.0hp

1,940w / 2.6hp

1,940w / 2.6hp

2,684w/3.6hp

Gear Train

Type

3 stage planetary

Ratio

216:1

156:1

211:1

261:1

315:1

Clutch

Rotating ring-gear

Brake

Automatic, full load CBS (Cone Brake Structure)

Control

Detachable control

box

Detachable

control box

Bridge

control box

Detachable control

box

Detachable control box

Wire Rope

Type

Galvanized aircraft A7 x 19

6 x 29-IWRC

Length

24.4m / 80ft

30.5m / 100ft

25m / 82ft

38m / 125ft

27m / 89ft

Size

7mm / 9/32”

8mm / 21/64”

9.5mm / 3/8”

9.5mm / 3/8”

11mm / 7/16”

Performance

Layer

Model

DV-6000S

DV-9000ES

DV-9000i

DV-12 light

DV-12000ES

DV-15000ES

1st

Layer

Line Pull

kg / lb

2,722 / 6,000

4,082 / 9,000

4,082 / 9,000

5,443 /

12,000

5,443 /

12,000

6,804 /

15,000

Total Rope on

the Drum m/ft

3.8 / 12.5

6.1 / 20.0

6.1 / 20.0

5.4 / 17.7

6.6 /21.5

5.7 / 18.6

2nd

Layer

Line Pull

kg / lb

2,266 / 4,995

3,316 / 7,310

3,316 / 7,310

4,319 /

9,522

4,563 /

10,060

5,569 /

12,277

Total Rope on

the Drum m/ft

8.4 / 27.5

13.6 / 44.7

13.6 / 44.7

12.2 / 40.0

14.4 / 47.2

12.6 / 41.4

3rd

Layer

Line Pull

kg / lb

1,941 / 4,279

2,792 / 6,154

2,792 / 6,154

3,580 /

7,893

3,928 / 8,659

4,713 /

10,391

Total Rope on

the Drum m/ft

13.7 / 45.0

22.6 / 74.0

22.6 / 74.0

20.5 / 67.3

23.5 / 77.0

20.8 / 68.3

4th

Layer

Line Pull

kg / lb

1,697 / 3,742

2,410 / 5,314

2,410 / 5,314

3,056 /

6,737

3,448 / 7,601

4,086 / 9,007

Total Rope on

the Drum m/ft

19.8 / 65.1

30.5 /100

30.5 /100

25.0 / 82.0

33.8 / 110.9

27.1 / 89

5th

Layer

Line Pull

kg / lb

1,508 / 3,325

3,072 / 6,774

Total Rope on

the Drum m/ft

24.4 / 80

38.1 / 125

4

Main Components

5

This manual suits for next models

5

Table of contents

Popular Winch manuals by other brands

Comeup

Comeup DV-9 manual

Orvea

Orvea Italwinch 805 Installation and user manual

Prowinch

Prowinch PWJTHF300 user manual

Clas Ohlson

Clas Ohlson LD2000-A manual

Runva

Runva EWD8000 Assembly & operating instructions

Ingersoll-Rand

Ingersoll-Rand LIFTSTAR FG 1500/CN Series Parts, operation and maintenance manual