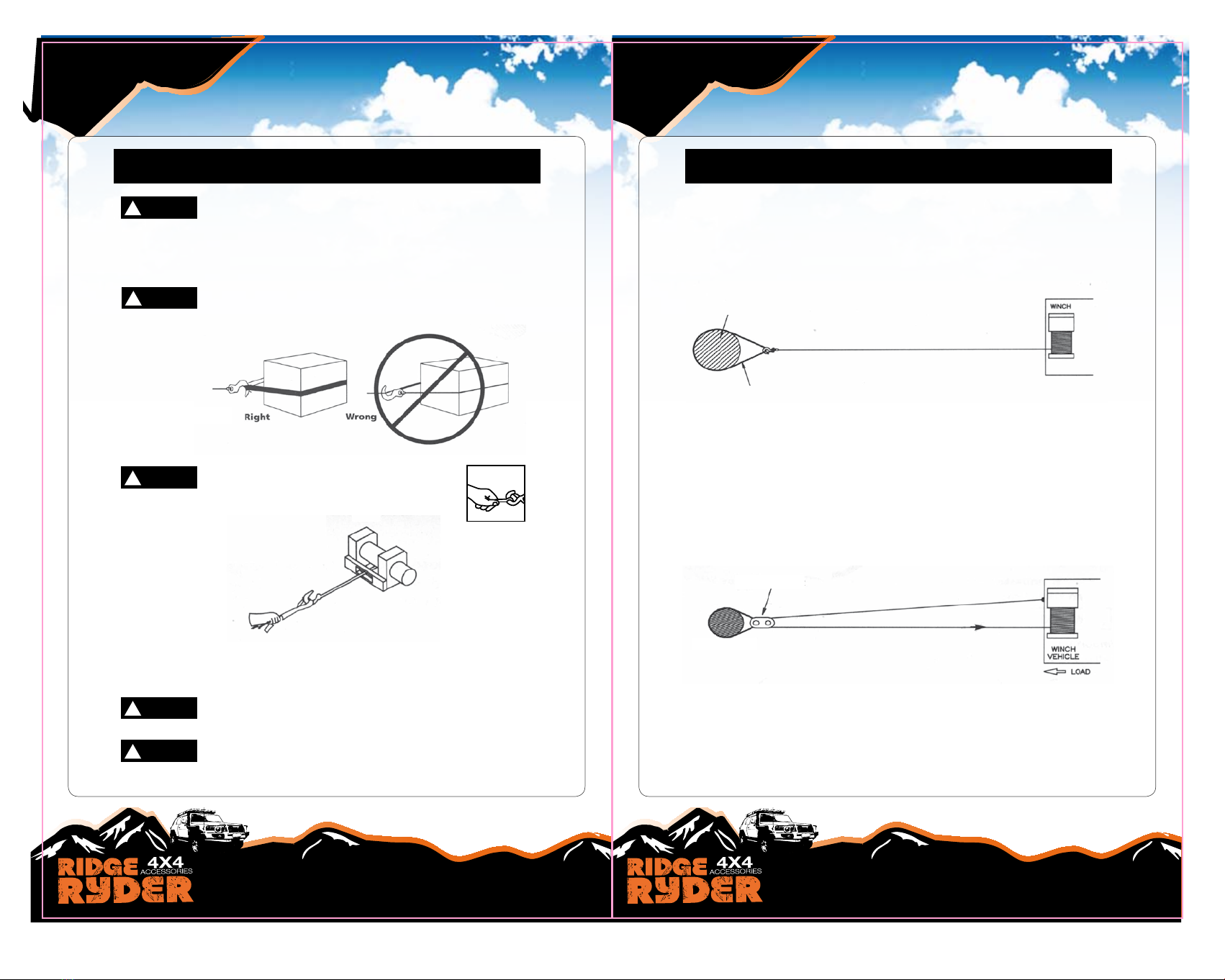

1. Maximum working load capacity is on the winch rope layer closest to the

drum. DO NOT OVERLOAD. DO NOT ATTEMPT PROLONGED PULLS AT

HEAVY LOADS. Overloads can damage the winch and/or the winch rope and

create unsafe operating conditions. FOR LOADS OVER 1/2 RATED

CAPACITY, WE RECOMMEND THE USE OF THE OPTIONAL PULLEY BLOCK

TO DOUBLE LINE THE WINCH ROPE (Figure 2). This reduces the load on the

winch and the strain on the winch rope by approximately 50%. Attach hook

to load bearing part. The vehicle engine should be running during

winch operation. If considerable winching is performed with the engine

o, the battery may be too weak to restart the engine.

2. AFTER READING AND UNDERSTANDING THIS MANUAL, LEARN

TO USE YOUR WINCH. After installing the winch, practice using it

so you will be familiar with it when the need arises.

3. DO NOT "move" your vehicle to assist the winch in pulling the load. The

combination of the winch and vehicle pulling together could overload the

winch rope and the winch.

4. ALWAYS STAND CLEAR OF WINCH ROPE, HOOK AND WINCH. IN THE

UNLIKELY EVENT OF ANY COMPONENT FAILURE IT'S BEST TO BE OUT OF

HARM'S WAY.

5. Inspect winch rope and equipment frequently. A Frayed winch rope with

broken strands should be replaced immediately.

Periodically check the winch installation to ensure that all bolts are tight.

6. Use heavy leather gloves when handling winch rope. Do not let winch rope

slide through your hands.

7. Never winch with less than 5 turns of winch rope around the winch drum

since the winch rope end fastener may NOT withstand full load.

The responsibility for safe installation and operation of

the winch and prevention of the winch and prevention of

personal injury and property damage ultimately rests

with you, the operator. There is no subsitute for the use of

good judgement and caution in operating a winch.

Warning

!

The winch rope may break before the winch stalls. For

heavy loads, use a pulley block to reduce the load on the

winch rope.

Warning

!

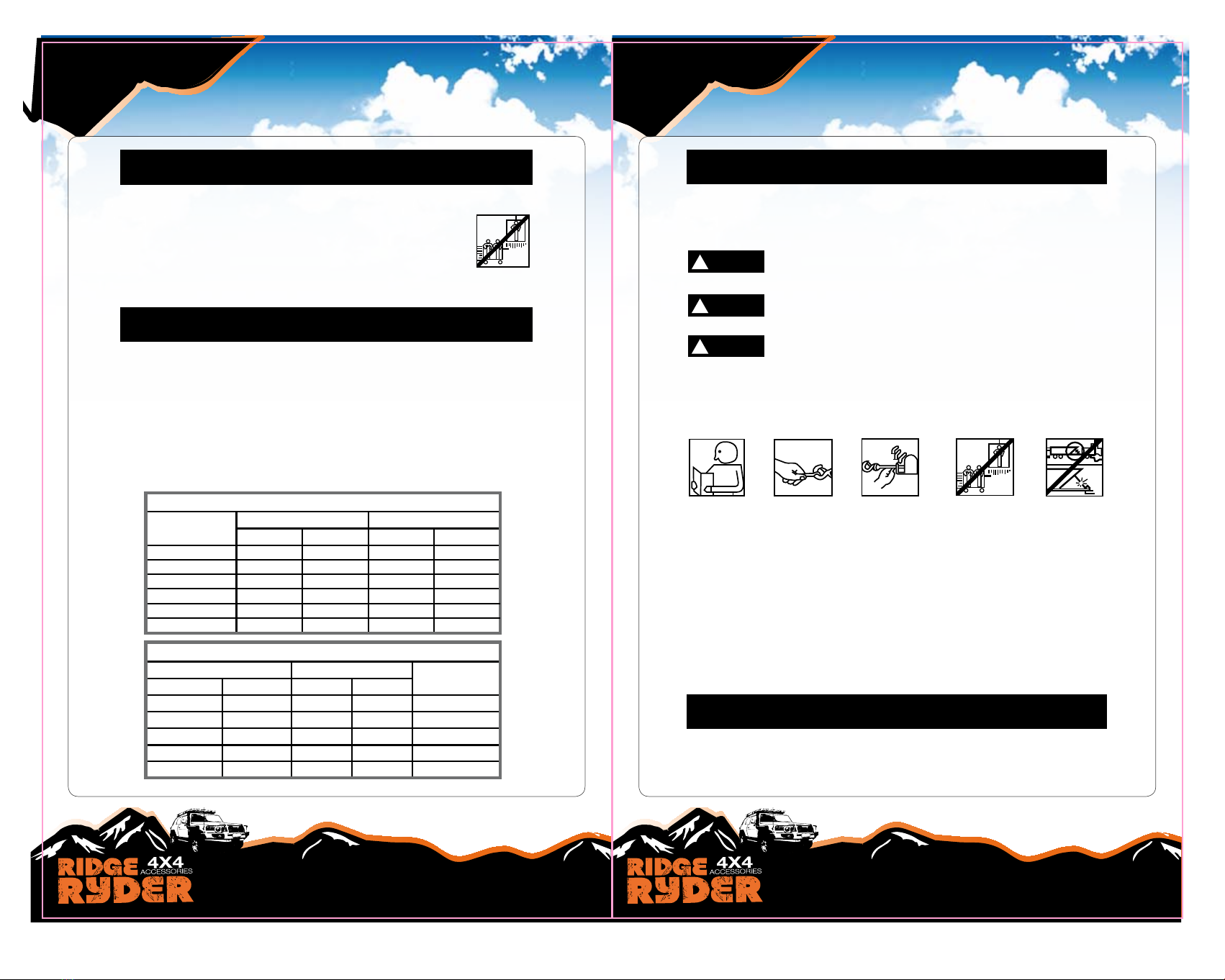

Single Line Double Line

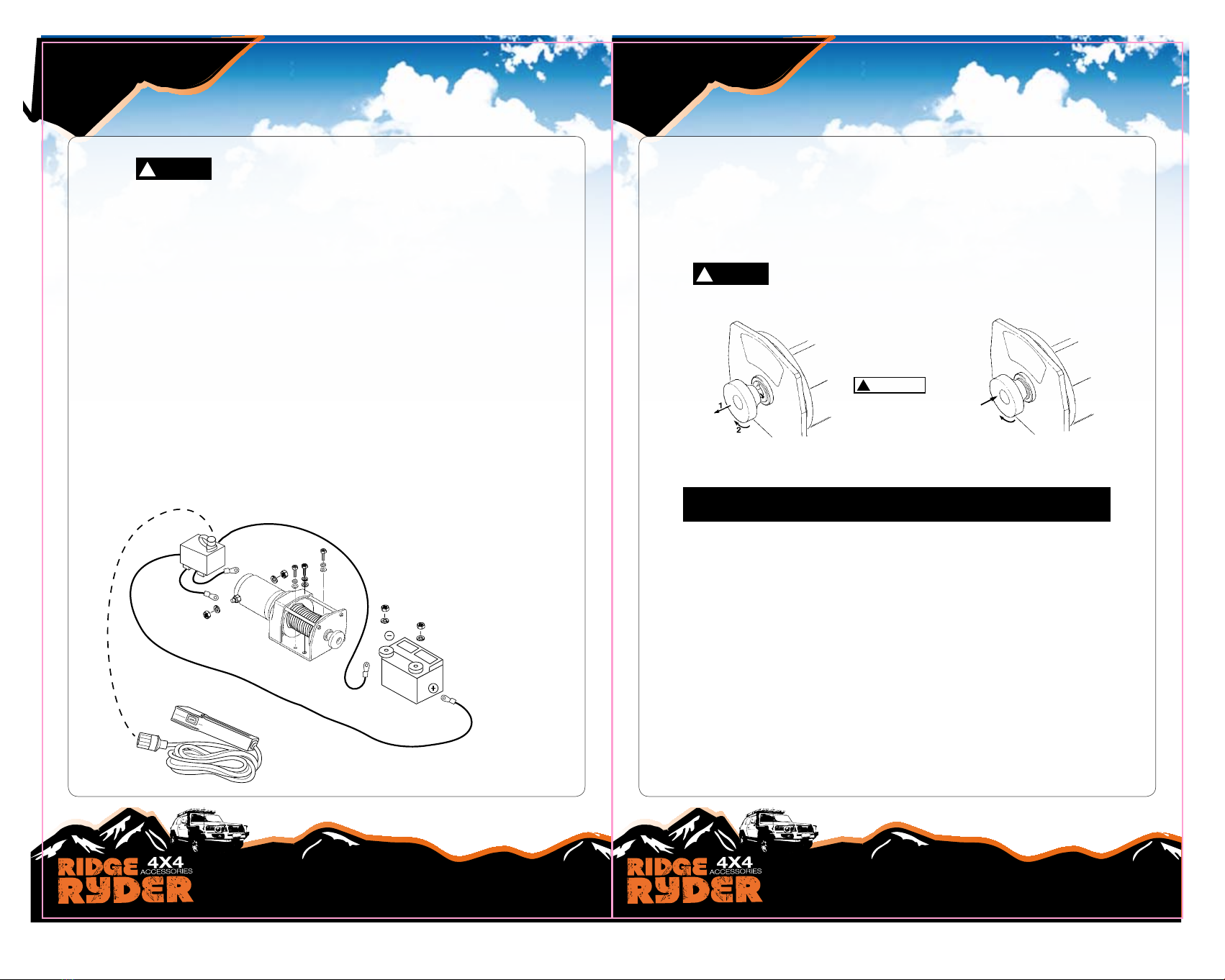

8. Never put your nger through the hook. If your

nger should become trapped in the hook, you

could lose your nger. ALWAYS USE THE

HANDSAVER when guiding the winch rope in or out

(See Figure 3).

12.

NEVER OBSCURE THE WARNING INSTRUCTION LABELS.

13.

Always operate winch with an unobstructed view of the winching

operation.

14.

Equipment such as tackle, hooks, snatch blocks, straps, etc. should be

sized to the winching task and should be periodically inspected for damage

(4)

Figure 5

Right W rong

Figure 6

Figure 4

W rong Right

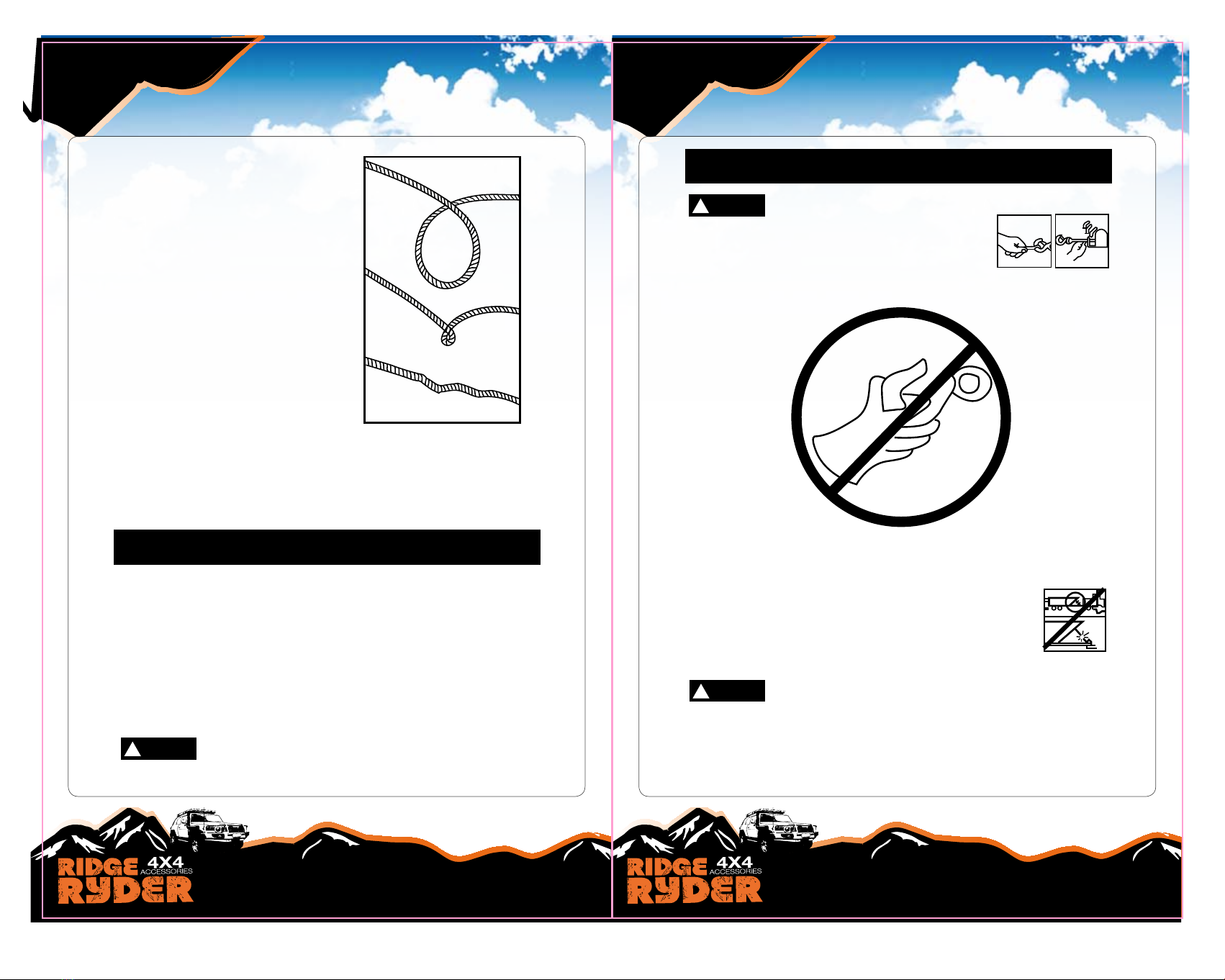

9. NEVER HOOK THE WINCH ROPE BACK ONTO ITSELF because you could

damage the winch rope. Use a nylon sling (Figure 4).

10. It is a good idea to lay a heavy blanket or damper over the winch rope

near the hook end when pulling heavy loads (Figure 5). If a winch rope

failure should occur, the damper will help prevent the rope from whipping.

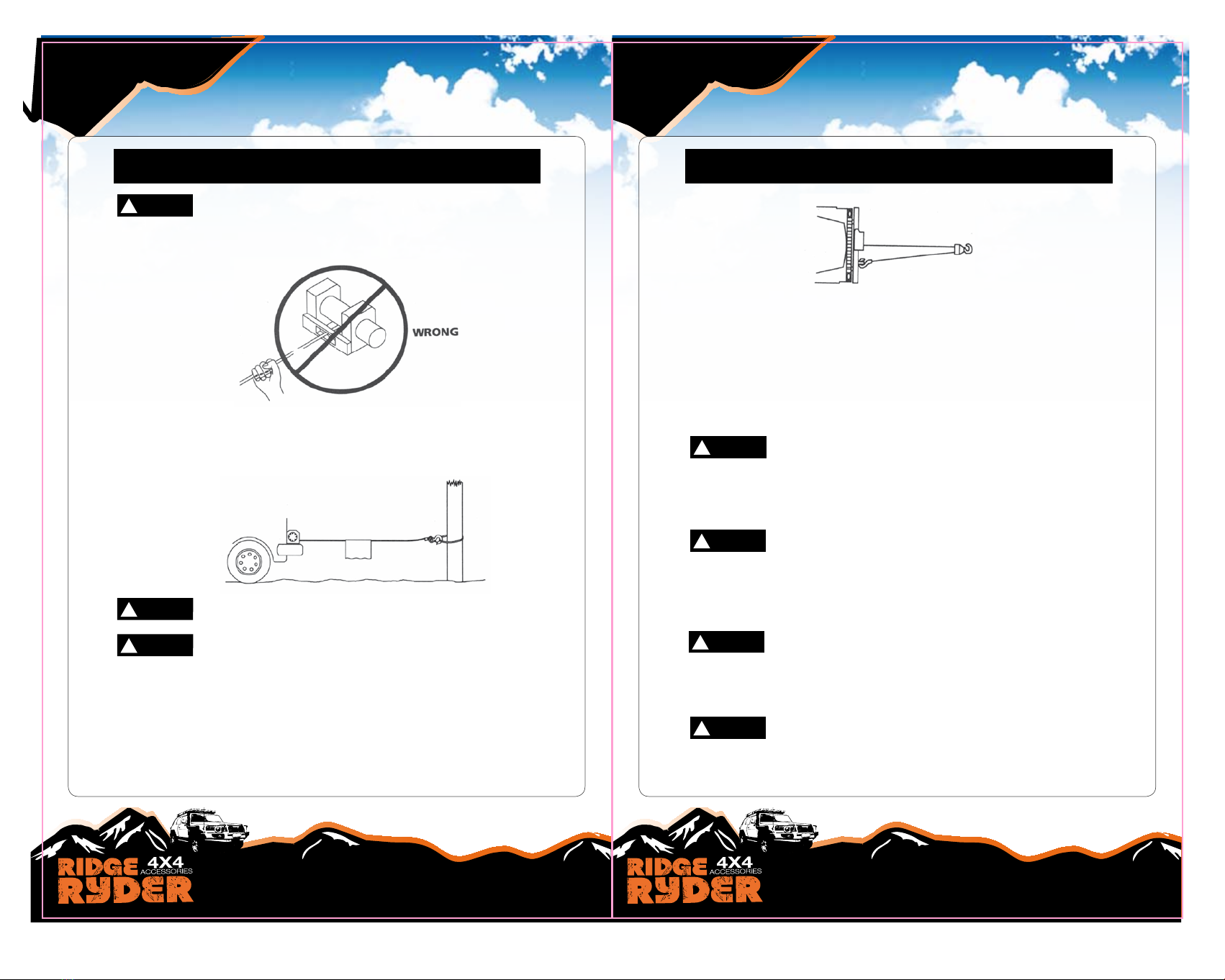

11. AVOID CONTINUOUS PULLS FROM EXTREME ANGLES as this will cause

the winch rope to pile up on one end of the drum (Figure 6). This can jam

the winch rope in the winch, causing damage to the rope or the winch.

Figure 3

1. Maximum working load capacity is on the winch rope layer closest to the

drum. DO NOT OVERLOAD. DO NOT ATTEMPT PROLONGED PULLS AT

HEAVY LOADS. Overloads can damage the winch and/or the winch rope and

create unsafe operating conditions. FOR LOADS OVER 1/2 RATED

CAPACITY, WE RECOMMEND THE USE OF THE OPTIONAL PULLEY BLOCK

TO DOUBLE LINE THE WINCH ROPE (Figure 2). This reduces the load on the

winch and the strain on the winch rope by approximately 50%. Attach hook

to load bearing part. The vehicle engine should be running during

winch operation. If considerable winching is performed with the engine

o, the battery may be too weak to restart the engine.

2. AFTER READING AND UNDERSTANDING THIS MANUAL, LEARN

TO USE YOUR WINCH. After installing the winch, practice using it

so you will be familiar with it when the need arises.

3. DO NOT "move" your vehicle to assist the winch in pulling the load. The

combination of the winch and vehicle pulling together could overload the

winch rope and the winch.

4. ALWAYS STAND CLEAR OF WINCH ROPE, HOOK AND WINCH. IN THE

UNLIKELY EVENT OF ANY COMPONENT FAILURE IT'S BEST TO BE OUT OF

HARM'S WAY.

5. Inspect winch rope and equipment frequently. A Frayed winch rope with

broken strands should be replaced immediately.

Periodically check the winch installation to ensure that all bolts are tight.

6. Use heavy leather gloves when handling winch rope. Do not let winch rope

slide through your hands.

7. Never winch with less than 5 turns of winch rope around the winch drum

since the winch rope end fastener may NOT withstand full load.

(3)

The responsibility for safe installation and operation of

the winch and prevention of the winch and prevention of

personal injury and property damage ultimately rests

with you, the operator. There is no subsitute for the use of

good judgement and caution in operating a winch.

Warning

!

The winch rope may break before the winch stalls. For

heavy loads, use a pulley block to reduce the load on the

winch rope.

Warning

!

Single Line Double Line

8. Never put your nger through the hook. If your

nger should become trapped in the hook, you

could lose your nger. ALWAYS USE THE

HANDSAVER when guiding the winch rope in or out

(See Figure 3).

12.

NEVER OBSCURE THE WARNING INSTRUCTION LABELS.

13.

Always operate winch with an unobstructed view of the winching

operation.

14.

Equipment such as tackle, hooks, snatch blocks, straps, etc. should be

sized to the winching task and should be periodically inspected for damage

Figure 5

Right W rong

Figure 6

Figure 4

W rong Right

9. NEVER HOOK THE WINCH ROPE BACK ONTO ITSELF because you could

damage the winch rope. Use a nylon sling (Figure 4).

10. It is a good idea to lay a heavy blanket or damper over the winch rope

near the hook end when pulling heavy loads (Figure 5). If a winch rope

failure should occur, the damper will help prevent the rope from whipping.

11. AVOID CONTINUOUS PULLS FROM EXTREME ANGLES as this will cause

the winch rope to pile up on one end of the drum (Figure 6). This can jam

the winch rope in the winch, causing damage to the rope or the winch.

280 x 215mm