23

www.ronstan.com

USER INSTRUCTIONS

t

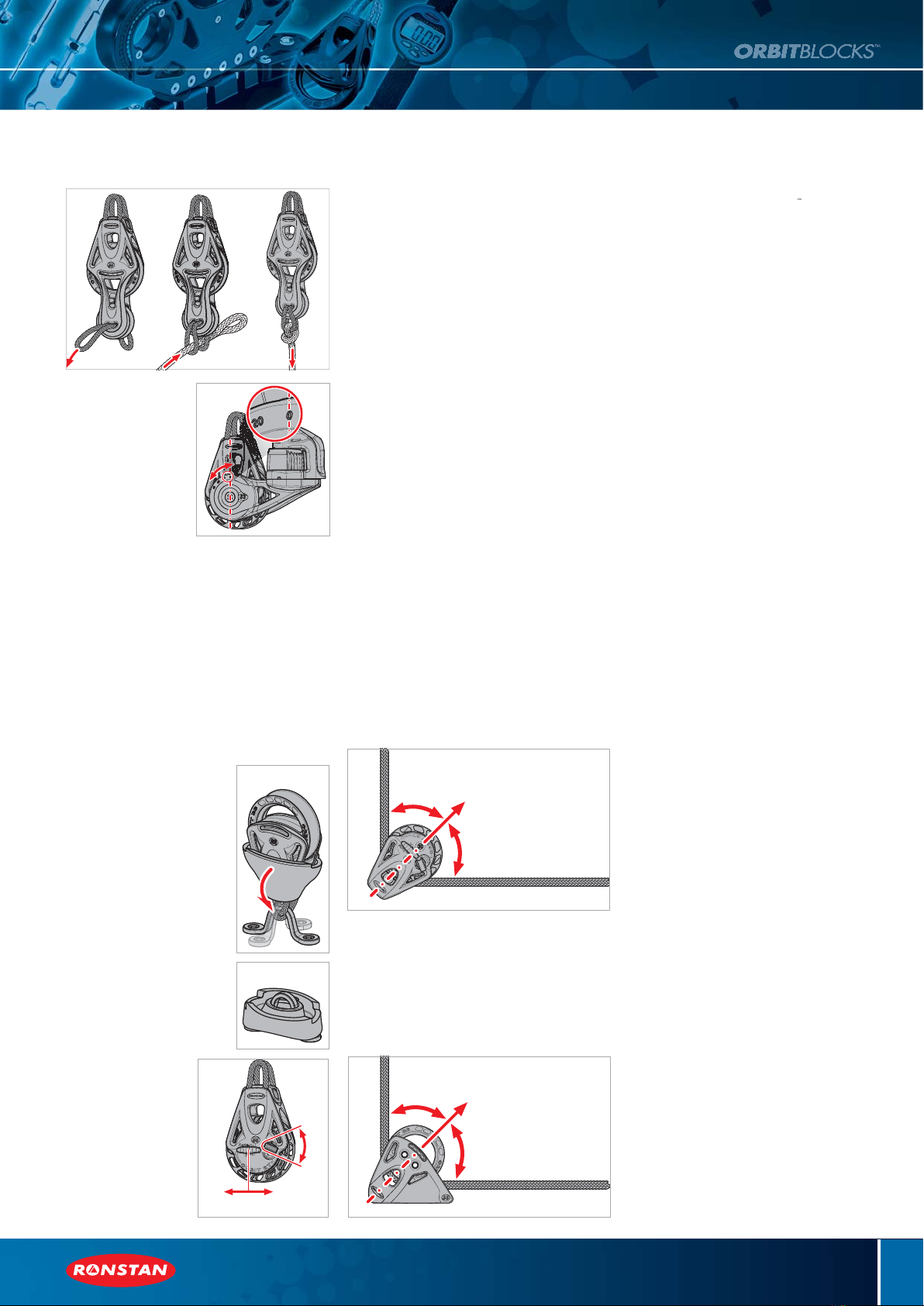

(Diagrams 2.3B)

I

using a pre-spliced sheet, secure with a cow

hitch through both loops o

the Link

.

(Diagram 3.0)

Ad

ustment of

leat arm an

le

.

.

n t

r

w at t

ntr

f th

l

at arm

n each side of the block

approximately 1 ½ turns

3.0.

djust the cleat arms to the re

uired an

le. The

cleatin

an

le can be adjusted

rom

de

rees

when

the sheet is coming out o

the block at right angles to

the centre line of the block

to 60 degrees

40 degrees

n RT triple, becket

cleat). The cleat arm angle is

ndicated by the number aligned with the centre line of

t

.

3.0.

e-ti

hten the screw at the centre of the cleat arm on

ach side of the block

.

tand-up kit

.0.

se the method described in

.

ab

v

t

t th

link f

r

°

transverse

or

°

in-line

.

.

.

rn t

r

r

t

n

t

nd place it over the head of

t

e

oc

so t

e

n

rotru

es

t

rou

t

e sma

en

.

.0.3 (Diagram 4.0.3)

ass the saddle throu

h the lin

n the re

uired orientation.

.

.

ix the saddle to the mounting

rfa

.

.

(Diagram 4.0.5)

f attaching the block to a fitting

that is alread

fixed in

ace, ro

u

t

e

ottom

alf of the boot to sim

lify

ttachment of the Link

nd unroll it a

ain when

ini

h

d

5.

(Diagram 5.0)

atchet mode

peratio

ome RT

rbit Blocks™

an

t t

t

mat

o

e or

anua

mo

e to su

t t

e a

cat

on or user

s

reference. RT blocks with cleats are fully automatic

onl

.

.

M

n

lM

.

.

T blocks leave the

actory in Manual mode, with

he black MODE switches on both sides of the block

ositioned away from the red

N

FF knob.

.1.

se the red

N

FF knob to turn the ratchet

N or

FF.

5.2

Auto Mod

.

.

With the block in Manual mode, turn the ratchet o

by

otating the red ON/OFF knob to the OFF position

.

.

lide the black MODE switch firmly toward the red

N

FF knob until it locks into the recess in the knob.

epeat with the M

DE switch on the other side of the

oc

.

.

e

oc

s now

n

uto mo

e

.

.4

o return to Manual mode, slide the black MODE

switches on both sides o

the block

irmly away

rom

he red ON

OFF knob. Now use the red ON

OFF knob to

urn the ratchet ON and OFF.

.

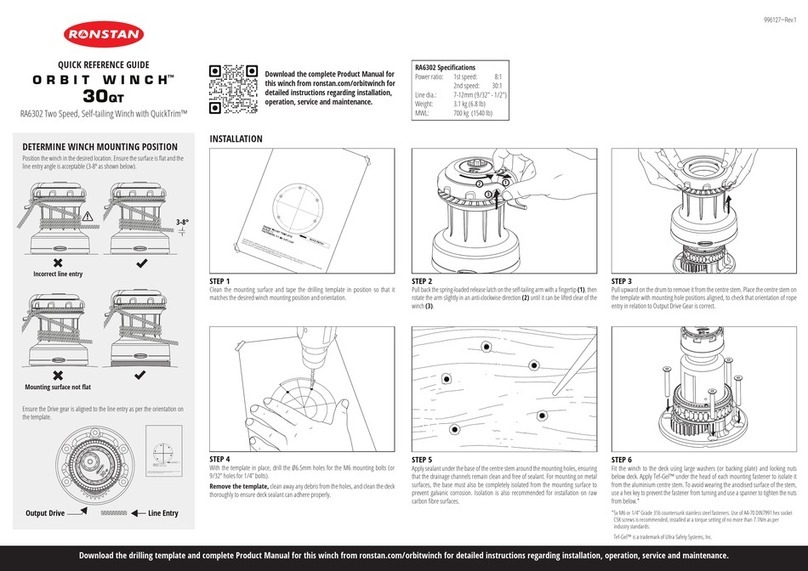

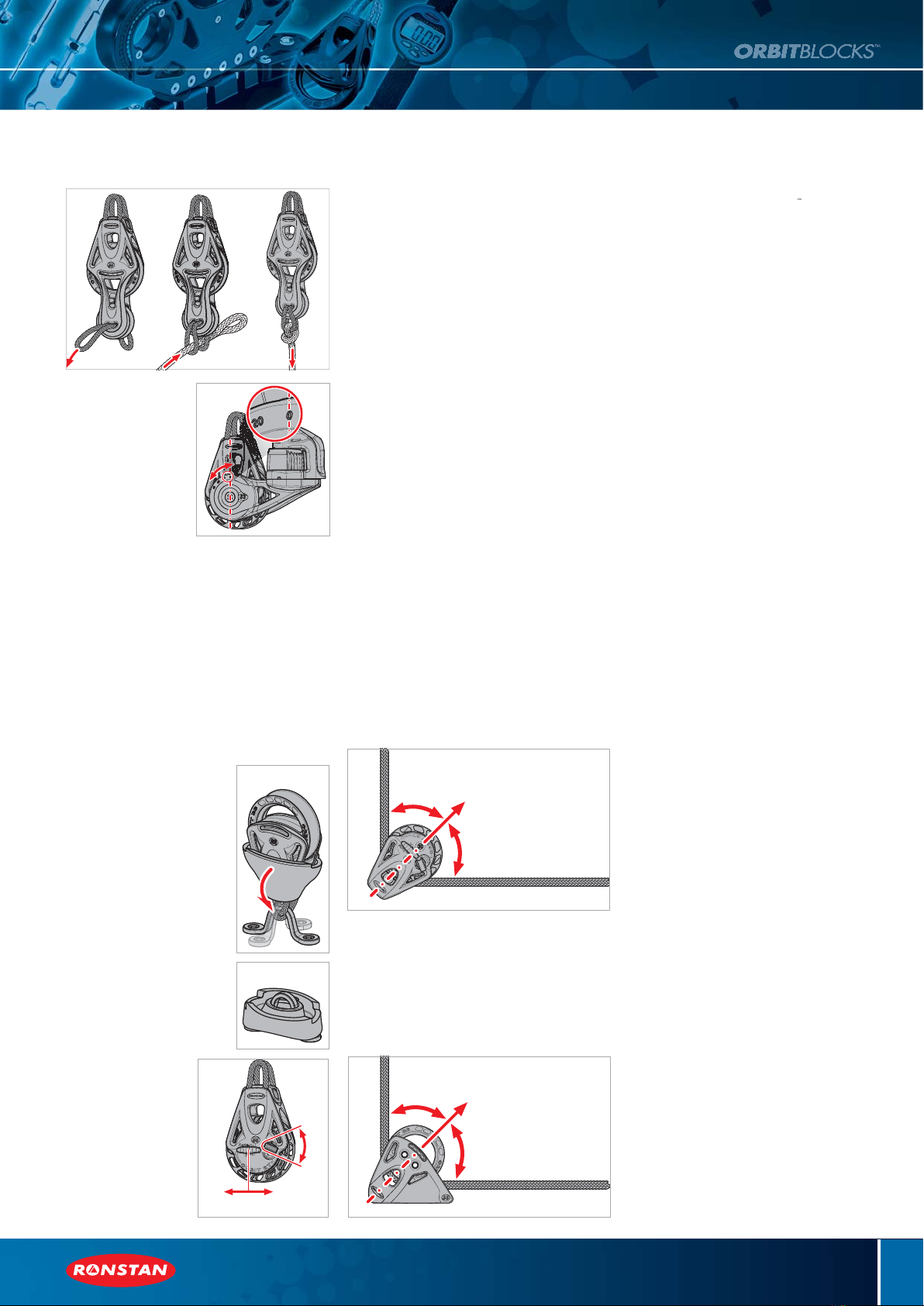

(Diagram 6.0)

heek block ali

nment

heek blocks must be properly aligned so that the

axis of the block bisects the angle between line entry

an

ex

t, w

c

must

e approx

mate

y

n t

e same

ane. Misalignment or improper installation will reduce

the load capacity of the block.

7.

(Diagram 7.0)

pr

g

t

ea

oc

a

gnment

The U

ri

ht Lead block is desi

ned to

rovide a

0

de

ree chan

e in line direction, with line entry at

0

degrees to the base and line exit parallel to the base.

ny variation on these line angles will reduce the load

capacity of the block

8.

are and maintenanc

neem

®Link

Ronstan BB and RT Orbit Blocks

feature a unique

yneem

n

ea

.

u

ng on t

e

atest tren

s

n gran

pr

x

ng

y an

ocean rac

ng,

t rep

aces

he steel head

ost and shackle arran

ement of

ra

t

ona

oc

s.

onstan

neema

n

s are

ade from hi

hest

uality F

E Robline

cean 3000

lait Dyneema

SK75 line, treated with S.Y.I.S.

mpregnation

or high resistance to abrasion and UV

rotection. Dyneema

is a super strong polyethylene

ibre that offers maximum strength combined with

n

mum we

g

t.

yneem

fibre’s high tenacity

allows it to match the strength of steel at one tenth

of the wei

ht. It is more durable than

olyester and

as a s

ecific stren

th that is 40

ercent

reate

han aramid fibre.

To receive the maximum

erformance benefit from

he Dyneem

Link, it must be used correctly,

nspected regularly and replaced when required.

The Dyneema

Link must be attached to a mounting

oint with a smooth, well rounded profile without

sharp edges or burrs. If in doubt, use a shackle

ith a

m

th

rfa

b

tw

n th

Link and th

ount

n

o

nt.

• The Dyneema®Link will eventually suffer

degradation from fatigue, wear and UV exposure.

Like all running and standing rigging, the Link should

be inspected regularly and replaced it if it shows

significant amount of wear or fibre damage, or as a

part of your regular boat maintenance program.

Orbit Block

Grit and sand will damage bearing systems.

onstan

rbit Blocks™ have a precisely engineered

bearing system that should be kept clean and free of

sand and

rit to ensure o

timum

erformance and

service life. Blocks, in

articular the bearin

areas,

should be flushed with fresh water re

ularly and

eriodically cleaned with a mild deter

ent and water.

Dry lubricants such as Ronstan Sailfast silicon

spray may be used to lubricate the bearing system

and rat

h

t

ntr

l

. Oil/petrochemical based

lubricants must not be used.

Ronstan

rbit Blocks™ are designed and

anufactured for applications on sailboats.

ee

he Info section of the Ronstan web site and our

catalo

ue for im

ortant customer considerations

and warrant

information

.

initi

n

B = Ball Bearin

T = Rat

h

t

WL = Maximum Working Loa

L = Breaking Load

yneem

is a trademark of Royal DSM NV.

M is the inventor and manufacturer of Dyneem

he world’s strongest fibre™.

Dyneema

an

D

neem

, the world’s stron

est fibre™” are

rademark

s

applications

owned by Royal D

M NV.

4.0.3

4.0.5

E

Q

U

A

L

E

Q

U

A

L

6.0

E

Q

U

A

L

E

Q

U

A

L

7.0

3.0

2.3B

ON

OFF

AUTOMANUAL

5.0