EMD EXP-103 User manual

1

PALLET STRETCH WRAPPING MACHINE

MODEL: EXP-103

OPERATION MANUAL

2

TABLE OF CONTENT

1. GENERAL INFORMATION .................................................................................. 3

1.1 NOTE OF INSTALLATION...................................................................................... 3

1.2 NOTICE OF OPERATION........................................................................................ 4

2. SPECIFICATION .................................................................................................. 5

2.1 SPEC. TABLE ......................................................................................................... 5

2.2 MACHINE DIMENSION ......................................................................................... 6

2.3 MACHINE DESCRIPTION ...................................................................................... 7

3. OPERATION DESCRIPTION ...............................Error! Bookmark not defined.8

3.1 INSTALLMENT...................................................................................................... 8

3.2 REMINDER OF INSTALLATION............................................................................. 9

3.3 OPERATION OF CONTROL PANEL.......................................................................10

3.4 OPERATION DESCRIPTION..................................................................................11

3.5 CARRIAGE UNIT..................................................................................................13

4. ELECTRICAL .................................................................................................... 14

4.1 ELECTRICAL CAPACITY......................................................................................14

4.2 ELECTRICAL DIAGRAM ......................................................................................15

5. TROUBLE SHOOTING....................................................................................... 26

5.1 GENERALADJUSTMENT .....................................................................................29

5.2 TROUBLE SHOOTING WITH EXP-108 MACHINE.................................................30

6. PART LIST ..........................................................................................................31

6.1 SEAT.....................................................................................................................31

6.2 TOWER.................................................................................................................33

6.3 CARRIAGE ...........................................................................................................36

3

1. GENERAL INFORMATION

1.1 NOTE OF INSTALLATION

To make sure a safe and correct operation, please check below conditions before

install the machine:

1) Power source capacity must be equal of the machine need.

2) Machine standard power is 110v/220v (+- 10%)

3) Machine standard power Hertz is 50/60 Hz. (+- 2%)

4) Machine is workable under the temperature between O℃- 45℃

5) Make sure the wire is tidy on the ground.

6) There should not have vibration beside the machine during the installment, and

make sure the ground is flat.

7) Read and follow the instruction of the installment.

4

1.2 NOTICE OF OPERATION

To have good protection for the operator, please make sure the following conditions:

1) Before operating, please read the machine operational manual carefully.

2) Make sure there is no object put on the power cable.

3) Make sure there is no object put on the upper elevator unit.

4) Avoid any damp object or water around the electric parts.

5) Avoid film winded into the turntable.

6) Do not stand on or across the machine during operation.

7) When problem occurs, please check the section of 5 Trouble shooting

5

2. SPECIFICATION

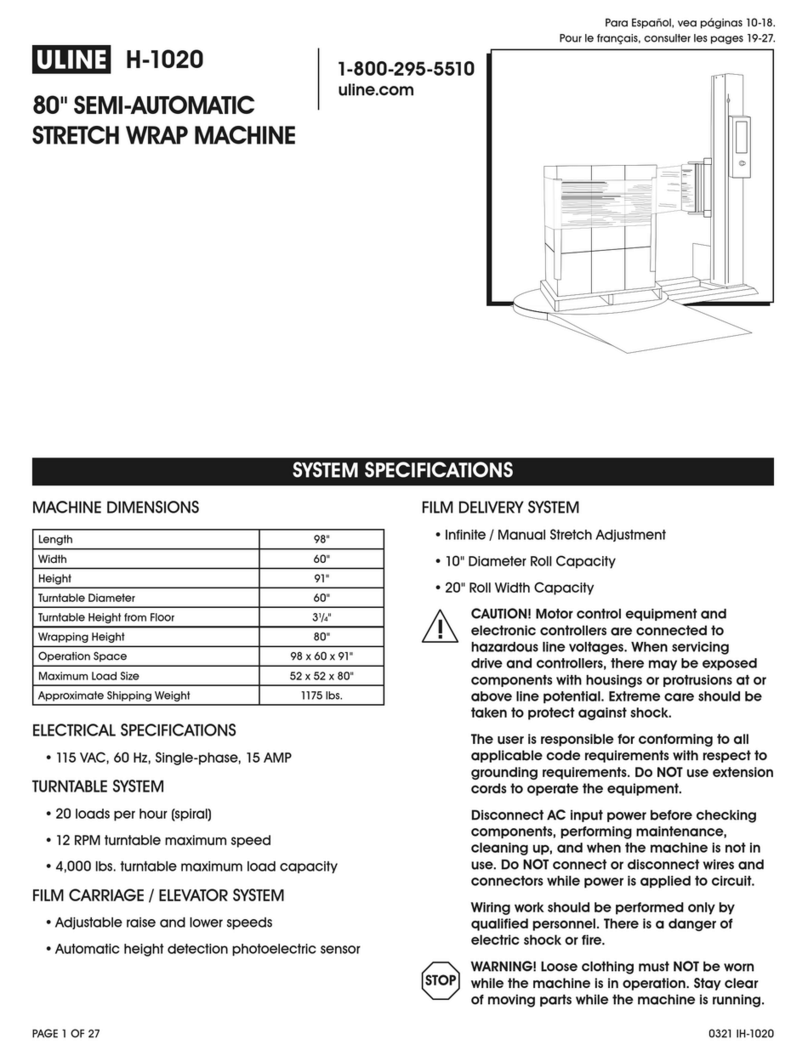

2.1 SPEC. TABLE

Model

EXP-103

Turntable Speed

3 ~ 12 RPM

Turntable dia.

1500mm

Max wrapping height

2200mm

Pallet size

1050x1050mm

Max loading weight

2000kgs

Film stretch (%)

300% & 230% two step change by handle

(250% and 200% option)

Film tension

Adjustable –3 STAGES SETTING

Carriage Unit speed

1.5 ~ 5m/min

Max. film spec.

∮250x500mm

Turntable height

71mm

Machine size

2458x1500x2559mm.

Standard option:

1.65 & 1.80 meters dia. Turntable.

2.6 & 3.0 meters wrapping height

Top pressure plate driven by motor

Ramp

Mechanical roping

6

2.2 MACHINE DIMENSION

7

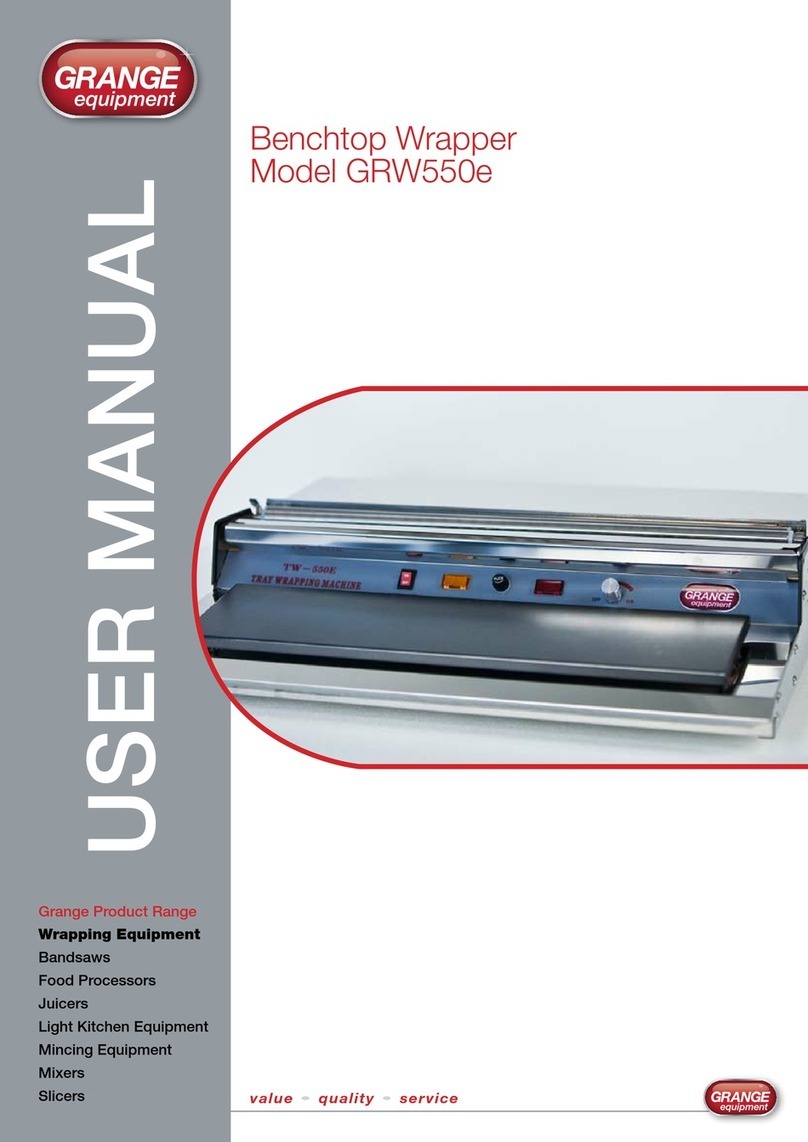

2.3 MACHINE DESCRIPTION

TURNTABLE

SEAT

CARRIAGE

TOWER

CONTROL BOX

MOTOR COVER

8

OPERATION DESCRIPTION

3.1 INSTALLMENT

1) Apart all the wooden package. Avoid damaging the machine.

2) Move the machine to an installment position by fork lift.

3) Install master cover and tighten screws on both side.

4) Lift up the tower.

5) Fix and tighten the tower by M8 screws. Total 6 screws on each side.

6) Connect the sensor wires.

Proximity Switch: “―”&4.

7) Install the motor cover and support brackets.

Total 4 screws required.

Connect the power cable with the socket by a 110V/230V power.

9

3.2 REMINDER OF INSTALLATION

Tower Installation

Engineers must ensure all screws are properly installed underneath the tower, and

evenly lay out.

Control Panel Installation

Engineers must make sure the control panel is removed from supporting bracket,

and is installed properly.

10

3.3 OPERATION OF CONTROL PANEL

11

3.4 OPERATION DESCRIPTION

Up & Down

Up Only

Top Sheet

Turntable Speed

Carriage Speed

Up or Down

Film Force -

Top wraps

During Cycle

Bottom Wraps

Top Wraps Adj.

Btm Wraps Adj.

Film Enforce -

No. of wraps.

Height from.

Manual Turntable

Manual Carriage

Up or Down

Reset

Key Lock

Start

Stop

Setting Dial/Enter

Clockwise “+”

Counterclock “–“

Press to “Enter”

12

START BUTTON

Press this button to start operation.

Note: After all of function been setting press this button to re start the

program

PAUSE BUTTON

Press the button; the machine will be stop whether it is under automatic

or manual mode. Press the START button to complete the rest program.

EMG. STOP

Pressing this button to make emergency stop.

MAIN POWER

This is the main power cut switch.

13

3.3 CARRIAGE UNIT

1) Illustration for film threading

1. OPEN THE SECURITY DOOR FIRST.

2. Pull the film across the film carriage.

3. CLOSE THE SECURITY DOOR

Cling Inside

Cling Outside

FILM

FILM

SECURITY DOOR

14

4. ELECTRICAL

4.1 ELECTRICAL CAPACITY

1 ) Power Consumption

Pre-stretch motor

0.2 KW

Turntable motor

0.75 KW

Elevator Motor

0.4KW

Control & wiring box

DC 24V 50W

Machine Power Use

1.5 KW

Power Socket need

1.7 KW

2) Power Cable ---------------------- 1.25 ㎜2

3) Machine input -------------------- 110V / 230V 1-PHASE

15

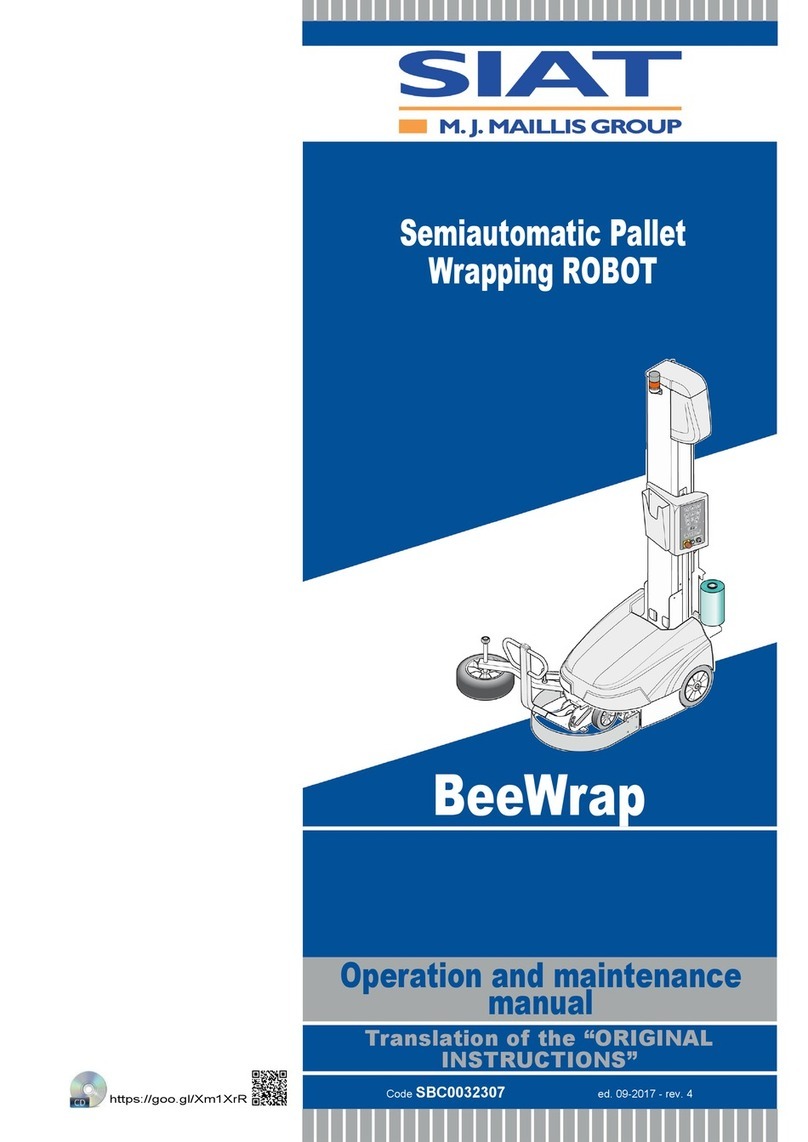

4.2 ELECTRICAL DIAGRAM

Sensor / limit switch location

16

KEY NO

PART NO

DESCRIPTION

Q'TY

3S9B

P0311-060001400

LIMIT SWITCH ML-7312

1

3S9C

P0311-060001400

LIMIT SWITCH ML-7312

1

4S2

P0311-060001100

LIMIT SWITCH TZ-8108

1

4S3

P0311-060001100

LIMIT SWITCH TZ-8108

1

4B4

P0302-020000200

PHOTO SENSOR A3R-2MX

1

4S5

P0311-060001210

LIMIT SWITCH TZ-8108

1

4B10

P0302-010001600

PROX SWITCH XS4-P18-AB110

1

6K7

P0301-0000300

SOLENOID SH-1585 (DC24V)

1

4S5

4B4

6K7

3S9B

3S9C

4S2

4S3

4B10

17

18

19

20

Table of contents