EMERGENT EES-101 User manual

EES-101 SeriesUltrasonicFlowmeter

Version:3.0.0

Ultrasonic Flowmeter Instruction Manual

Model: EES-101

Update

Record

Revision 3.0.1

Date 12 . 2021

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page2of65

Notice:

Thisinstruction manualisappropriate forEES-101 seriesultrasonic flowmeter.

Thisultrasonic flowmeteradoptsARM.kernelchip and low-voltage wide-pulse sending technology.

Thisinstruction manualcontainsimportantinformation. Pleaseread carefullybeforethe operation ofthe

flowmeter,avoiding damaging flowmeterand improperuse.

Thisinstruction manualwill introduce howtousetheflowmeterstep-by-step, including productcomponent,

installation, wiring, quick setup etc. to make it easierto operate.

Understanding moreaboutthe menu settingscan fulfill yourhigherrequirementswiththe flowmeters powerful

function option and outputfunction.

Warning

Maycause injury.

Attention

Maydamage the flowmeter.

Someofthe instructionsmaybe differenttothe flowmeters you purchased, dependingonconfiguration

requirements,otherwise, thereisno indication aboutthe productdesign and upgrade requirementinthe

instructions, please referto the version number, aswell asthe appendix.

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page3of65

Product Components

Inspection should be made before installing the Flowmeter. Check to see if the provided parts and components

are in accordance with the packing list. Make sure that there isno damage to the enclosure due to a loose screw

or loose wire, or other damage that mayhave occurred during transportation. Any questions, please contact

Emergent Energy Solutions.

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page4of65

Content

1Transmitter Installationand Connection.................................................................................6

1.1 Inspectionprior toTransmitter Installation........................................................................................................6

1.2 WireConnecting ................................................................................................................................................7

1.2.1 Power supplyoption ..................................................................................................................................7

1.2.2 Transmitter Wiring ....................................................................................................................................7

1.2.3 LengthenedCable Method.........................................................................................................................7

1.3 Powering on.......................................................................................................................................................9

1.4 KeypadFunctions...............................................................................................................................................9

1.5 KeypadOperation..............................................................................................................................................9

1.6 Flowmeter WindowDescriptions.....................................................................................................................10

2PipeParameter EntryShortcuts.............................................................................................11

2.1 Dual functionkeysmenudescription...............................................................................................................11

2.2 Examples..........................................................................................................................................................12

3MeasurementSite Selection.....................................................................................................14

4Transducer Installation............................................................................................................15

4.1 Installingthetransducers..................................................................................................................................15

4.1.1 Transducer Spacing..................................................................................................................................15

4.1.2 Transducer Mounting Methods................................................................................................................15

4.1.3 VMethod.................................................................................................................................................15

4.1.4 ZMethod .................................................................................................................................................16

4.1.5 NMethod (notcommonlyused)..............................................................................................................16

4.2 Transducer Mounting Inspection......................................................................................................................16

4.2.1 Signal Strength.........................................................................................................................................16

4.2.2 Signal Quality(Qvalue)..........................................................................................................................17

4.2.3 Total TimeandDelta Time......................................................................................................................17

4.2.4 Transit TimeRatio...................................................................................................................................17

4.2.5 Warnings..................................................................................................................................................17

5Operating Instructions.............................................................................................................19

5.1 SystemNormal Identification..........................................................................................................................19

5.2 Zero Set Calibration.........................................................................................................................................19

5.3 Scale Factor......................................................................................................................................................19

5.4 SystemLock.....................................................................................................................................................19

5.5 FrequencyOutput.............................................................................................................................................20

5.6 4~20mACurrentLoop OutputVerification(Optional)...................................................................................20

5.7 Recover theFactoryDefault............................................................................................................................20

5.8 4~20mAAnalogOutputCalibration................................................................................................................21

5.9 ESN..................................................................................................................................................................21

6Windows Display Explanations...............................................................................................22

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page5of65

6.1 WindowsDisplayCodes..................................................................................................................................22

6.2 DisplayExplanation.........................................................................................................................................23

7ErrorDiagnoses.........................................................................................................................38

7.1 Table1. Error codesandsolutions....................................................................................................................38

7.2 FrequentlyAskedQuestionsandAnswers.......................................................................................................39

8Product Overview.....................................................................................................................40

8.1 Introduction......................................................................................................................................................40

8.2 FeaturesofEES-101 ........................................................................................................................................40

8.3 Specifications...................................................................................................................................................41

9Appendix1-SerialInterface NetworkUseand Communications Protocol..........................42

9.1 Overview..........................................................................................................................................................42

9.2 Direct connectionvia RS-485 tothehostdevice.............................................................................................42

9.3 Communicationprotocolandtheuse...............................................................................................................42

9.3.1 FUJI Protocol...........................................................................................................................................43

9.3.2 MODBUS CommunicationProtocol.......................................................................................................48

10 Appendix1-W211 InsertionTransducer.................................................................................56

10.1 Overview..........................................................................................................................................................56

10.2 MeasurementPointSelection...........................................................................................................................56

10.3 Determining Transducer Spacing &Transducer Installation...........................................................................56

10.4 Transducer Mounting Methods........................................................................................................................58

10.4.1 ZMountingMethod.................................................................................................................................58

10.4.2 PipeParameter EntryShortcuts...............................................................................................................58

11 Appendix 2-WiFiOperationInstructions...............................................................................60

11.1 ABriefIntroductiononFunctions...................................................................................................................60

11.2 Flowmeter DistributionNetworkMode...........................................................................................................60

11.3 Flowmeter connectingnetwork........................................................................................................................61

12 Appendix 6-OperationInstructions ofSDCard....................................................................64

12.1 Technical Specifications..................................................................................................................................64

12.2 OnlineInsertandRemoval ofSD Card............................................................................................................65

12.3 OfflineData Reading:......................................................................................................................................65

Update Information:

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page6of65

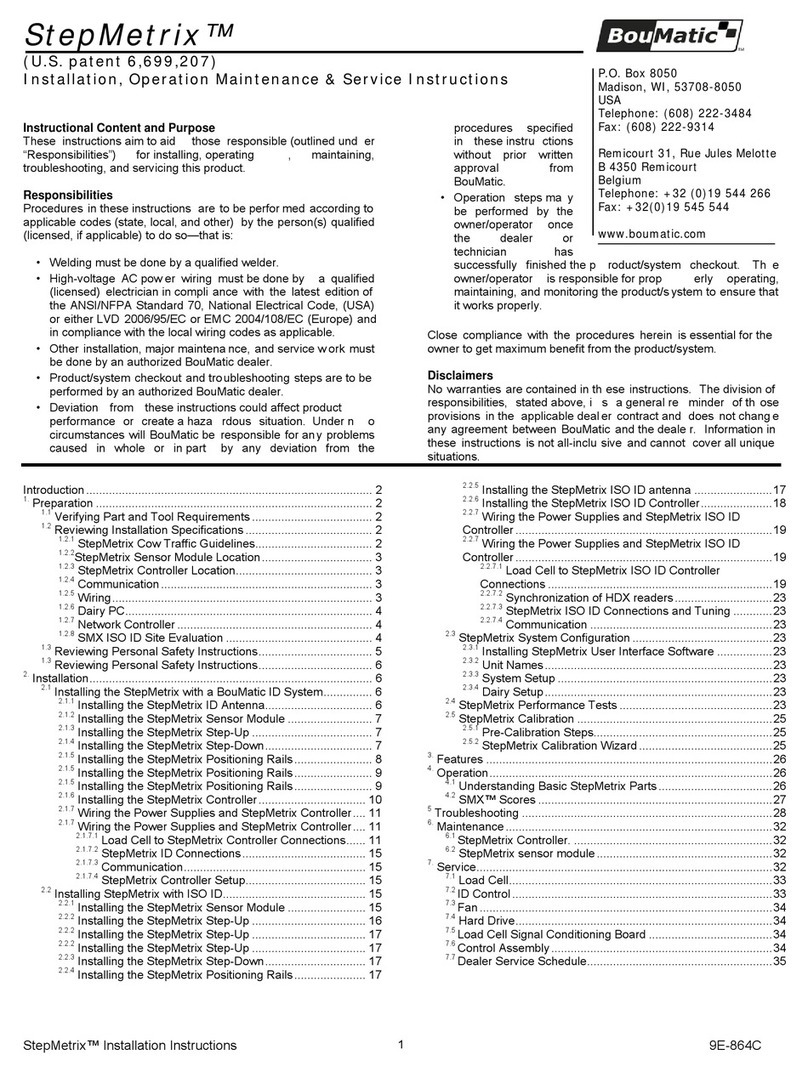

1TransmitterInstallation and Connection

1.1 Inspection prior toTransmitterInstallation

You will find a "Position Drawing" in the

package. Please use it as a template to provide

guidance on product placement as you installthe

flowmeter. Then drill 4 installing holes at the screw

positionsshown on the drawing with the 5.0mm

(0.25") drill.

Attention

When installing please ensure the frontcoverissecure and will notfall open.

86 mm

135 mm

5.32lnch

3.39lnch

Positiondrawing

1.Placethistemplateon thewall anddrill 4

holesof 5mmdiameter&40mmdeep.

2.Insertaplasticbushing intoeachofthe4

holes.

3.Screw4pcsPA4×30mm selftapping

screwsthroughthetransmitter enclosure

baseandattachittothewall.

4.Tightenthescrewsto secureto the

enclosureonthewall.

MODELDCT1188

DigitalCorrelationTransit -TimeFlowmeter

135mm

5.32lnch

86mm

3.39lnch

Take out the enclosed mounting screws and

plastic anchors. Insert the plastic anchors into

the installation holes. Install the flow meter

accordingly.

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page7of65

1.2 WireConnecting

1.2.1 Power supplyoption

Customersshould pay special attention to the specified power supplyoptions when wiring.

Factorystandard power supplyis10~36VDC/1A max.

To ensure the transmitter can work normally, please payattention to the followings when wiring:

Ensure that power connections are made in accordance with the specifications shown on the transmitter.

1.2.2 Transmitter Wiring

Once the electronics enclosure has been installed, the flowmeter wiring can be connected.

Once you open the case, you will find the transmitter interfaces labelsfrom leftto right as follows:

Power supply, Relayoutput, OCTOutput, Upstream transducer, Downstream transducer, 4-20mA, RS485

interface.

Refer to the below diagram for specific connection:

1.2.3 Lengthened CableMethod

Standard cable length of sensor is9 meters (~30 feet);itcan be lengthened to be 300 metersaccording to the

actual need for fluid measurement. Please contact Emergent Energy for specific applications where longer cables

will be needed.

Red Bushing

Flow

DC+ DC- GE

DC10 -36V EUP+UP- EDN+ DN-

TRANSDUCER I+I-

4-20mA

Blue Bushing

Being testedpipe

Black

Red

Shield

PipeStraps

UpstreamTransducer DownstreamTransducer

OCT+OCT-

OCT OUT

RL+RL-

RELAY

Shield

Red

Black

Up-Stream

Down-Stream

10~36VDC

AB

RS485

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page8of65

1.2.3.1 SketchoflengthenedCable

1.2.3.2 JunctionBoxRequirements

The flowmeter usesa sealed waterproof junction box to splice together lengthened transducer cables,installing

62press-connections, the recommended minimum specifications of the junction box is115 90 55mm.

1.2.3.3 Cable Specifications

Name: Shielded Twisted Pair

Administer Standard: JB8734.5-1998

Diameter: Φ5 mm

TwistLine Space: 50 mm

Multi Core Line: 0.4 mm2/radix

Wire Guage: AWG20#

Core Line Color:Red and Black

Shield Floor:128 Intwine

Warning

Wire with poweroff. Theflowmetermustbe reliable grounding before installation.

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page9of65

1.3 Poweringon

Assoon as the flowmeter isswitched ON (powered ON), the self-diagnosisprogram will startto run. Ifany

errorsare detected, an error code will displayon the screen (Refer to -Error Diagnoses if any error appear).

After that self-diagnosis, the systemwillrun automaticallyaccording to the latest stored input parameters.

Ifthe installation isaccomplished when system isswitched on, gain adjustment can be monitored in Window M01

(Access by pressing Menu, 0, 1). Generally, after arriving at this screen, the upper right corner of the

display showstwo steps of *Iand *G, the systemwillactivate the normal measurement condition automatically.

And the upper right corner will show "*R". Ifthe signal isnot ideal, the above processmaycycle several times.

Ifthe meter s being installed for the first time, the customer need to input the new installation parameters. The

systemwill defaultto the laststored settings and automaticallydisplaythemat next power on.

1.4 KeypadFunctions

~ And To inputnumbers.

Backspace ordelete characters to the left.

Selectamenu.Press thiskeyfirst,inputtwo

menu numbers and thenenterthe selected menu. For

example, toinputapipe outside diameter,press

keys,where"11"isthe windowIDto

displaythe parameterforpipe outside diameter.

The keypad shortcuttovisit a specific windowisto pressthe keyatanytime, then inputthe 2-digitwindow

IDcode. Forexample, toinputorcheck the pipe outside diameter,justpress the keysforwindow

IDcode 11.

Anothermethod tovisit aparticularwindowistopress and keystoscroll the screen. Forexample, if

the currentwindowIDcode isM02, press keytoenterWindowM01, press the button againtoenter

WindowM00;then,press the keytoback WindowM01, and pressthe keyagaintoenterWindow

M02.

Windowsareseparated intothree types:(1)DataType,such asM11, M12;(2)Option Type, such asM14;(3)

PureDisplayType, such asM01, M00.

Youcancheckthe correspondingparameters byvisiting theDataType Windows.Ifyou wanttomodifythe

parameters,afterpress ,and thedigits,and thenpress againtoconfirm.

Thiskeypad isdual function keypad:

1. When separatelypressed, isshortcut function,

referring to "2. Quicklyset menu instructions ";

2. Press Menuand Number key, isMenu key,

referring to"6.Menu WindowDescription".

Follow these guidelines when using the Flowmeter

keypad (Refer to Keypad Figure):

0 9 ●

<

^And Return to the lastmenu or to open

the next menu. Actsas "+"and "-"functions when

entering numbers.

1.5 KeypadOperation

The flow meter uses the window software designed access all of the parameters entered, the instrument setup and

measurement parameters are broken down into more than 100 independent operator windows. The operator can

input parameters, modify settings or display measurement results by "visiting" a specific window. These windows

are arranged by 2-digit serial numbers (including "+" sign) from 00~99, then to +0, +1, etc. Each window serial

number, or so-called window ID code, has a defined meaning. For example, Window M11 indicates the

parameter input for pipe outside diameter, while Window M25 indicates the mounting spacing between the

transducers, etc. (Refer – Windows Display Explanations).

^

Menu

Menu

1 1

Menu

Menu 1 1

^

^

^ ^

^^

Enter Enter

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page10of65

Example1:Toenterapipe outside diameterof219.234, the

procedure isasfollows:

Press keystoenterWindowM11 (the

numericalvalue displayed currentlyisapreviousvalue).Now

press key.The symbol">"and the flashing cursorare

displayed atthe left end ofthe secondline on theScreen.Then

inputthe value parameters

.

You cancheckthe selected option byvisiting Option Type

Windows.Ifyou wanttomodifyit,you mustpress first,

the symbol">"and the flashing cursoraredisplayed atthe left

ofthe Screen. Operatorcanusethe and toscroll

the screen and getthe required value then press to

confirm.

Forexample, if the pipe materialis"StainlessSteel",Press

toenterWindowM14, press tomodify

the options.Selectthe "1. Stainless Steel"option bypressing

and , then press to confirm the selection.

Attention

Generally,press keyfirstifoperatorwantstoenter"modify"status.Ifthe "modify" isstill not

possibleeven afterpressingthe key,itmeansthatsystemislocked byapassword. To

"Unlock"it, select"Unlock"in WindowM47 and enterthe originalpassword.

1.6 FlowmeterWindowDescriptions

These windowsareassigned asfollows:

01~08 FlowTotalizerDisplay:todisplayflowrate, positivetotal,negativetotal,nettotal,velocity,date&

time, presentoperation andflowresultstoday, etc.

10~29InitialParameterSetup:toenterpipe outside diameter,pipe wall thickness,fluidtype, transducertype,

transducermounting method and spacing, etc.

30~38 FlowUnitsOptions:toselectthe flowunit such ascubicmeter,literorotherunits,can turntotalizers

on/off and resettotalizers, etc.

40~49 Setup options:Scaling factor, systemlock (WindowM47), etc.

55~89 Inputand outputsetup:dateand time, ESN,communication baud rate setting, etc.

90~98 Diagnoses:Signalstrengthand signalquality(WindowM90),TOM/TOS*100 (WindowM91),flow

sound velocity(WindowM92),totaltimeand deltatime(WindowM93),Reynoldsnumberand factor

(WindowM94),etc.

+0~+5Appendix:poweron/off time, totalworking hours, on/off timesand a single-accuracyfunction calculator.

Attention

The otherwindowsforhardware adjustmentare reservedbythe manufacturer.

Menu 1 1

Enter

219●234

5Enter

Pipe OuterDiameter

>_

Enter

^

^

Enter

Menu 14Enter

^

^

Enter

Pipe Material[14

>1.StainlessSteel

Enter

Enter

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page11of65

2PipeParameterEntryShortcuts

2.1 Dualfunction keysmenu description

Press key

DisplayNetFlowToday/FlowMax /FlowMin/The

Average/CurrentRate in turn.

Press key

DisplayDayTotalizerFlow/MonthlyTotalizerFlow

/YearlyTotalizerFlowin turn.

Press key

DisplayTotalizerStart and Stop in turn.

Press key

Displayinstantaneouscoolcapacityand coolcapacity

totalizer.

Press key

Displayinstantaneousheatcapacityand heatcapacity

totalizer.

Press key

Displaythe temp in, outand temperature difference .

Press key

DisplayFlowRate and Velocity.

Press key

DisplayFlowSound Velocity.

Press key

DisplaySignalStrength and SignalQuality.

FlowMax. 6.56m3/h

DayTotalizer

700.00m3/h

Timing1525sec

ON5.858m3

EFR0.0000KW*R

ENT0x1KWh

EFR0.0000KW*R

EPT0x1KWh

In-Out-DeltaC[07

6.218.21-

2.00

Flow20.112m3/h*R

Vel 1.0415m/s

FluidSoundVelocity

0.00m/s

Strength+Quality[90

UP:00.0DN:00.0Q=00

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page12of65

Press key

Press Enttostart ManualTotalizer,then press Entto

end ManualTotalizer,press EnttoinputStandard

TotalizertogetthefinalKfactor.Completethe

calibration with pressing Entto store.

Press key

Set"Zero Point"and the same asMenu 42.

Press key

DisplaySystemErrorCodes.

2.2 Examples

Forexample, measuring the diameterof219mmand pipe wall thickness of6mm, measuring mediumiswater,

PipeMaterialiscarbon steel,No Liner, can be operated asfollows:

Step1. Pipe outside diameter:

Press the keystoenterWindow

M11, and enterthe pipe outside diameter,and

then press the keyto confirm.

Step2. Pipe wall thickness

Press the keytoenterWindow

M12, and enterthe pipe wall thickness,and

press the keyto confirm.

Step3. Pipe Material

Press the keystoenterWindow

M14, press the key,pressthe or

keytoselectPipeMaterial,andpress the

keyto confirm.

Step4. Transducertype

(The transmitterisavailableforvarious

transducertypes.)

Press the keytoenterM23, and

then press ,nextpress or to

selectflowtransducertype1. CP037, finally

press to confirm.

ManualCalibrate

PressEntWhenReady

SetZero[42

PressENTWhenReady

*R-------------[08

SystemNormal

Menu 1 1

Enter

PipeOuterDiameter

219.00mm

Menu 12

Enter

Pipe WallThickness

6mm

Menu 14

Enter ^

^

Enter

Pipe Material[14

0. Carbon Steel

Menu 2 3

Enter ^

^

Enter

TransducerType [23

1.CP037

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page13of65

Step5. Transducermounting methods

Press the keytoenterWindow

M24, press the key,pressthe or

keytoselecttransducer-mounting

method, and press the keyto confirm.

Step6. AdjustTransducerspacing

Press the keytoenterWindow

M25, accuratelyinstall the transduceraccording

tothe displayed transducermounting spacing

and the selected mountingmethod (Referto

Installing the Transducers inthischapter).

Step7. Displaymeasurementresult

Press the keystoenterWindow

M01 todisplaymeasurementresult.(Baseon

the actualmeasurement)

Menu 2 4

Enter ^

^

Enter

Transducer Mounting

0. V

Menu 2 5 TransducerSpacing

179.55mm

Menu 0 1Flow0.1129m3/h*R

Vel 1.0415m/s

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page14of65

3Measurement Site Selection

When selecting a measurement site, itisimportant to select an area where the fluid flow profile isfullydeveloped

(achieved laminar flow) to guarantee a highlyaccurate measurement. Use the following guidelines to select a

proper installation site:

Choose a section of pipe that isalwaysfullof liquid, such as a vertical pipe with flow in the upward direction or a

fullhorizontal pipe.

Ensure enough straight pipe length at leastequal to the figure shown below for the upstream and downstream

transducersinstallation.

Ensure that the pipe surface temperature at the measuring point iswithin the transducer temperature limits.

Consider the inside condition of the pipe carefully. Ifpossible, select a section of pipe where the inside isfree of

excessive corrosion or scaling. This is especially applicable on galvanized rigid piping that might have

significant rust on the inside of the pipe.

10D min

L ≥10D

L ≥5D

10D min

10D min

L ≥50D

L ≥10D

L ≥30D

D

5D min

0.5D min

L≥5D

L≥10D L ≥5D

L≥50D

P

L≥30D L≥10D

StraightlengthofUpstream

piping

Name Straightlengthof Downstream

piping

Pump

Value

Diffuser

Tee

90obend

Reducer

Detector

FlowcontrolleddownstreamFlowcontrolledupstream

CheckValue

CheckValue

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page15of65

4TransducerInstallation

4.1 Installingthetransducers

Before installing the transducers, clean the pipe surface where the transducers are to be mounted. Remove anyrust,

scale orloose paintand make a smooth surface. Choose asection ofsound conductingpipe forinstalling the

transducers.Applya wide band ofsonic coupling compound down thecenterofthe face ofeach transduceras

well ason the pipe surface, ensure there are no air bubblesbetween the transducers and the pipe wall, and then

attach the transducers to the pipe with the strapsprovided and tighten themsecurely.

Note:

The two transducers shouldbe mounted atthe pipe’scenterline on horizontalpipes.

Make sure thatthe transducermounting direction isparallelwith the flow.

During the installation, thereshould be no air bubblesorparticlesbetween the transducerand the pipe wall. On

horizontalpipes, the transducers should bemounted in the 3 o’clock and 9o’clock positionsofthe pipe section in

orderto avoid anyair bubblesinside the top portion ofthe pipe. (Referto TransducerMounting). Ifthe

transducers cannotbe mounted horizontallysymmetricallydue to limitation ofthe localinstallation conditions, it

maybe necessarytomountthe transducers ata location where there isa guaranteed full pipe condition (the pipe is

alwaysfull ofliquid).

4.1.1 TransducerSpacing

Afterentering the required parameters, the spacing between the ENDSofthe two transducers isconsideredasthe

standard transducerspacing (Referto Top Viewon transducermounting methods). Check the datadisplayed in

WindowM25and space the transducers accordingly.

4.1.2 TransducerMountingMethods

Three transducermounting methodsare available. Theyare respectively:Vmethod, Zmethod and Nmethod. The

Vmethod isprimarilyused on small diameterpipes(DN100~300mm, 4〞~12〞).TheZmethod isused in

applicationswhere the Vmethod cannotwork due topoorsignalorno signaldetected. In addition, the Zmethod

generallyworksbetteron largerdiameterpipes(overDN300mm, 12〞)orcastiron pipes.

The Nmethod isan uncommonlyused method. Itisused on smallerdiameterpipes(belowDN50mm, 2〞).

4.1.3 VMethod

The Vmethod isconsidered asthe standard method. Itusuallygivesa more accurate reading and isused on pipe

diameters ranging from25mmto 400mm(1"~16〞)approximately. Also, it isconvenientto use, butstill

requiresproperinstallation ofthe transducers, contacton the pipe atthe pipe’scenterline and equalspacing on

eitherside ofthe centerline.

DownstreamTransducer

UpstreamTransducer

Flow

TransducerSpace

Flow

SideView TopViewSection

PipeStrap

Transducer

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page16of65

4.1.4 ZMethod

The signaltransmitted in a Zmethod installation hasless attenuation than a signaltransmitted with the Vmethod

when the pipesaretoo large,there are some suspended solid in the fluid, orthe scalingand linerare too thick .

Thisisbecausethe Zmethod utilizesa directlytransmitted (ratherthan reflected)signalwhich transversesthe

liquid onlyonce.

The Zmethod isable to measure on pipe diameters ranging from100mmto 800mm(4〞~32〞)approximately.

Therefore, we recommend the Zmethod forpipe diametersover300mm(12〞).

4.1.5 NMethod (notcommonlyused)

With the Nmethod, the sound wavestraverse the fluid three timesand bounce twice offthe pipe walls. Itis

suitable forsmallpipe diametermeasurement.

The measurementaccuracycan be improved byextending the transit distance with the Nmethod (uncommonly

used).

4.2 TransducerMounting Inspection

Checkto see if the transducerisinstalled properlyand if there isan accurate and strong enough ultrasonic signal

to ensure properoperation and high reliabilityofthe transducer. Itcan be confirmed by checking the detected

signalstrength, totaltransit time, delta time aswell astransit time ratio.

The "mounting"condition directlyinfluencesthe flowvalue accuracyand systemlong-time running reliability.In

mostinstances, onlyapplya wide band ofsonic coupling compound lengthwise on theface ofthe transducerand

stick it to the outside pipe wall to getgood measurementresults. However, the following inspectionsstill need to

be carried outin orderto ensure the high reliabilityofthemeasurementand long-termoperation ofthe instrument.

4.2.1 SignalStrength

Signalstrength (displayed inWindowM90)indicatesa detected strength ofthe signalboth fromupstreamand

downstreamdirections. The relevantsignalstrength isindicated bynumbers from00.0~99.9. 00.0 representsno

signaldetected while 99.9 representsmaximumsignalstrength.

Normally, the strongerthe signalstrength detected, the longerthe operation ofthe instrumentreliably, aswell as

the more stable the measurementvalue obtained.

Adjustthe transducerto the bestposition and check to ensure thatenough sonic coupling compound isapplied

adequatelyduring installation in orderto obtain themaximumsignalstrength.

DownstreamTransducer

UpstreamTransducer

Flow

TransducerSpacing

Flow

SideView Top ViewSection

PipeStrap

Transducer

DownstreamTransducer

UpstreamTransducer

Flow

TransducerSpacing

Flow

SideView TopViewSection

PipeStrap

Transducer

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page17of65

Systemnormallyrequiressignalstrength over60.0, whichisdetected fromboth upstreamand downstream

directions. Ifthe signalstrength detected istoo low, the transducerinstallation position and the transducer

mounting spacing should bere-adjusted and the pipe should be re-inspected. Ifnecessary, change the mounting

method to be Zmethod.

4.2.2 SignalQuality(Q value)

Qvalue isshort forSignalQuality(displayed in WindowM90). Itindicatesthe levelofthe signaldetected. Q

value isindicated bynumbersfrom00~99. 00representsthe minimumsignaldetected while 99 representthe

maximum.

Normally, the transducerposition should be adjusted repeatedlyand coupling compound application should be

checkedfrequentlyuntil the signalqualitydetected isasstrong aspossible.

4.2.3 TotalTimeand DeltaTime

"TotalTime and Delta Time", which displaysin WindowM93, indicatesthe conditionofthe installation. The

measurementcalculationsin the Flowmeterare based upon these two parameters. Therefore, when "DeltaTime"

fluctuateswidely, the flowand velocitiesfluctuate accordingly, thismeansthatthe signalqualitydetected istoo

poor. Itmaybe the resulted ofpoorpipe-installation conditions, inadequate transducerinstallation orincorrect

parameterinput.

Generally, "Delta Time"fluctuation should be less than ±20%.Onlywhen the pipe diameteristoo smallor

velocityistoo lowcan the fluctuation be wider.

4.2.4 Transit TimeRatio

Transit Time Ratio indicatesif the transducermounting spacing isaccurate. Thenormaltransit time ratio should

be 100+/-3 if the installation isproper. Check it in WindowM91.

4.2.5 Warnings

(1) Pipeparameters entered mustbe accurate;otherwise the Flowmeterwill notwork properly.

(2) During the installation, applyenough coupling compoundsin orderto stick the transducers onto the

pipe wall. While checking the signalstrength and Qvalue, move the transducers slowlyaround the

mounting site until the strongestsignaland maximumQvalue can be obtained. Make sure thatthe

largerthe pipe diameter, the more the transducers shouldbe moved.

(3) Checkto be sure the mounting spacing isaccordance with the displayin WindowM25 and the

transducerismounted atthe pipe’scenterline on the same diameter.

(4) Payspecialattention to those pipesthatformed bysteelrolls(pipe with seams), since such pipe is

alwaysirregular.Ifthe signalstrength isalwaysdisplayed as0.00, thatmeansthere isno signal

detected. Thus, it isnecessaryto check thatthe parameters (including all the pipe parameters) have

been entered accurately.Check tobe surethe transducermounting method hasbeen selected properly,

the pipe isnotworn-out, andthe linerisnottoo thick. Make sure there isindeed fluid in the pipe or

the transducerisnottoo close to a valve orelbow, and there are nottoo manyair bubblesin the fluid,

etc. With the exception ofthese reasons, if there isstill no signaldetected, the measurementsite has

to be changed.

Attention

Ifthe transittime ratio isover100±3,it isnecessaryto check:

(1) Ifthe parameters (pipe outside diameter, wall thickness, pipe material, liner, etc.)have

been enteredcorrectly,

(2) Ifthe transducermounting spacing isaccordance with the displayin WindowM25,

(3) Ifthe transducerismounted atthe pipe’scenterline on the same diameter,

Ifthe scale istoo thick orthe pipe mounting isdistorted in shape, etc.

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page18of65

(5) Make sure thatthe Flowmeterisable to run properlywithhigh reliability. The strongerthe signal

strength displayed, the higherthe Qvalue reached. The longerthe Flowmeterrunsaccurately, the

higherthe reliabilityofthe flowratesdisplayed. Ifthere isinterference fromambientelectromagnetic

wavesorthe signaldetected istoo poor, the flowvalue displayed isnotreliable;consequently,the

capabilityforreliable operation isreduced.

(6) Afterthe installation iscomplete, poweron the instrumentand check the result accordingly.

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page19of65

5Operating Instructions

5.1 SystemNormalIdentification

Press the keys.Ifthe letter"*R"displayson the screen, it indicatessystemnormal.

Ifthe letter"G"isdisplayed,it indicatesthatsystemisadjusting the signalgain priorto the measurement. Also, it

meanssystemnormal. Onlywhen the adjustmenttakestoo long(>2min)withoutstopping can systembe

identified asabnormal.

Letter"I"indicatesno signalisbeing detected. Check thetransducerwiring connectionsare correct, the

transducers are installed firmly, etc.

5.2 Zero SetCalibration

Once zero flowoccurs, a zero pointmayindicate on eachmeasuring instrument, butthe displayed measuring

value isnotequalto "0", thisvalue indicates"Zero". To anymeasuring instrument, thesmallerthe "Zero"is, the

betterthe qualityis. Conversely, if the Zero istoo big, thatindicatesthe qualityofthe instrumentispoor.

Ifthe zero setpointisnotattrue zero flow, a measurementdifference mayoccur. Thesmallerthe physical

measurementcapacityis, thelargerthe measurementdifference fromthe zero pointwill exist. Onlywhen zero

pointreduced toa definite degree, ascompared with the physicalmeasurementcapacity, can the measuring

difference fromzero pointbe ignored.

Foran ultrasonicFlowmeter,the measurementdifference fromzero pointcannotbe ignored atlowflow. Itis

necessaryto performa staticzero setcalibration to improve lowflowmeasurementaccuracy.

Press WindowM42 to setthe Zero, press first, and then wait the readingsdisplayisfinished. Ifthisis

carried outwith flow, the flowwill be displayed as"0",M43 can help to restore settings.

5.3 ScaleFactor

Scale factorrefers to the ratio between "actualvalue"and "reading value".Forexample, when the measurement

and is2.00, and it isindicated as1.98on the instrument, the scale factorreadingis2/1.98. Thismeansthatthe

bestscale factorconstantis1.

However, it isdifficult to keep the scale factoras"1"on the instrumentespeciallyin batch productions.The

difference iscalled "consistency".

During operation, there still existspossible difference inpipe parameters, etc. The "scale factor"maybe necessary

when used on differentpipes. Thus, scale factorcalibration isspeciallydesigned forcalibrating the differences

thatresult fromapplication on differentpipes. The scale factorentered mustbe one thatresultsfromactual

calibration. The scale factorcan be inputin WindowM45.

5.4 SystemLock

Systemlock isreadable butnotmodifiable to preventoperation errordue to unauthorized tampering by

unauthorized personnel.

Press the keys,if displays"Unlock"on the screen, thenpress the key, enter6 numerically

long password, and then pressthe keyto confirm.

Unlockit byusing the selected password only. Press , if "lock"isdisplayed on the screen, then

press the keyand enterthe correctpassword, then press to confirm.

Keep the password in mind orrecorded in a safe place, otherwise the instrumentcannotbe used.

Menu 0 8

Enter

Menu 4 7 Enter

Enter

Menu 4 7

Enter Enter

EES-101 SeriesUltrasonicFlowmeter

Revision:3.0.1Page20of65

5.5 Frequency Output

The Flowmeterisprovided with a frequencyoutputtransmitterfunction. The high orlowfrequencyoutput

displayed indicatesthe high orlowflowrate reading. The usercan resetthe frequency outputaswell asflowrate

ashisrequirements.

Forexample:if a pipe flowrange is0~3000m3/h, the relative frequencyoutputrequired is0~5000Hz, and the

configuration isasfollows:

In WindowM68 (lowlimitfrequencyoutputflowvalue),input0;

In WindowM69 (high limit frequencyoutputflowvalue), input3000;

TypicalOCTOutputwiring diagramasbelow:

OCTOutputWiring Diagram

5.6 4~20mA CurrentLoop OutputVerification(Optional)

Processing a currentloop outputexceeding an accuracyof1%, the flowmeterisprogrammable and configurable

withmultiple outputmodessuch asflowrate orfluid velocity. Selectin WindowM55.Fordetails, please referto

"WindowsDisplayExplanations".

In WindowM56, entera 4mAflowrate orfluid velocityvalue. Enterthe 20mAflowrate orfluid velocityvalue

in WindowM57. Forexample, if the flowrange in a specific pipe is0~1000m3/h, enter0 in WindowM56 and

1000 inWindowM57.

Calibrating and testing the currentloop isperformed in WindowM58. Complete the stepsasfollows:

Press , move or to display"0mA","4mA","8mA", "12mA","16mA", "20mA"

readings, connectan ammeterto testthe currentloop outputand calculate the difference. Calibrate it if the

difference iswithin tolerance. Ifthe difference iswithouttolerance, referto the "Analog OutputCalibration"to

calibrate the currentloop.

Checkthe presentcurrentloop outputinWindowM59 asit changesalongwith change in flow.

5.7 RecovertheFactory Default

Press keysto Windowm37, press or keyto choose"Reset"keysto recoverthe

factorydefault.

OCT+OCT-

OCTOUT

COM

RL1RL2

RELAY EUP+ UP-

TRANS

5~10K1/4w Vcc

Sig

Menu 5 8 Enter ^

^

Menu 37Enter ^

^

Table of contents

Other EMERGENT Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

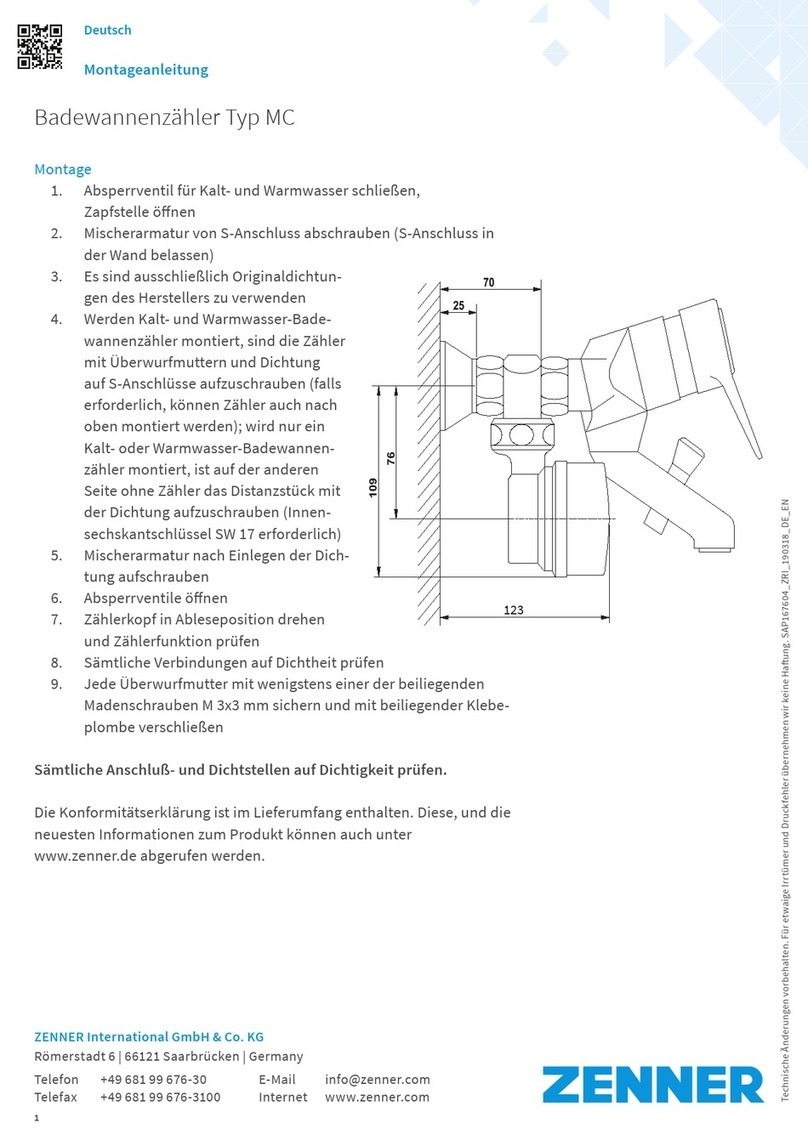

Zenner

Zenner MC Assembly instructions

Packet Power

Packet Power BGS72 Installation, operation and maintenance manual

EINHELL

EINHELL NKL 90/4 operating instructions

Boumatic

Boumatic StepMetrix Installation, Operation Maintenance & Service Instructions

NanoSense

NanoSense enocean EP5000E installation manual

Campbell

Campbell cs215 instruction manual