INTEGRA User Manual Revision 1.1 iv

TABLE OF CONTENTS

1. INTEGRA.........................................................................................................................1

1.1. Introduction.................................................................................................................................................1

1.2. Specifications.............................................................................................................................................1

2. Quick Start Procedure...................................................................................................3

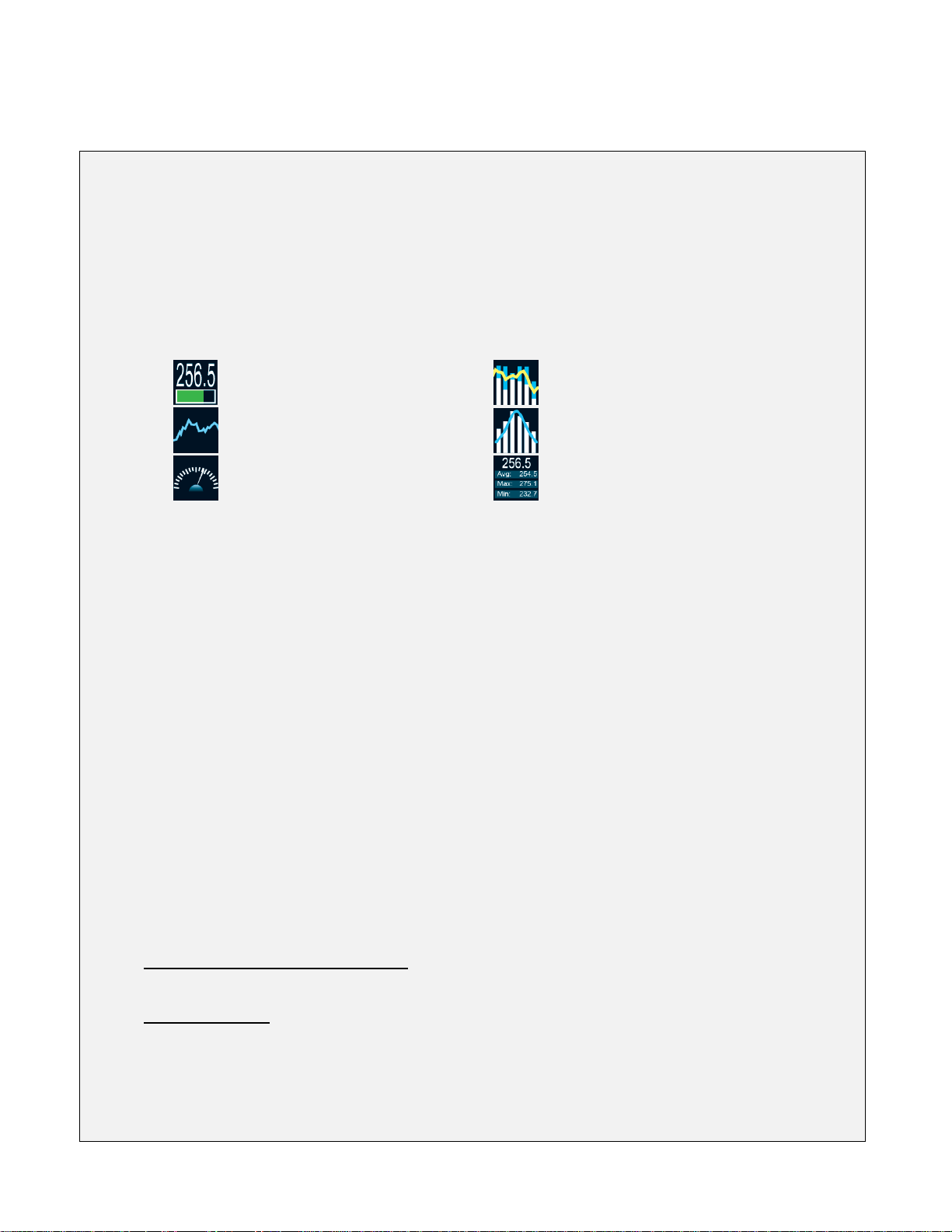

3. User Interface.................................................................................................................4

4. USB Serial Communication ..........................................................................................4

4.1. Description .................................................................................................................................................4

4.2. Setting up Communication to the INTEGRA..............................................................................................4

4.2.1. Verify the COM Port............................................................................................................................4

4.2.2. Connect the INTEGRA........................................................................................................................4

4.2.3. To Echo Commands ...........................................................................................................................5

4.2.4. Test the Connection............................................................................................................................5

4.2.5. HyperTerminal Settings Shortcut........................................................................................................5

4.3. Serial Command Format............................................................................................................................5

4.3.1. Serial Protocol Rules: .........................................................................................................................5

4.3.2. Text Mode Rules:................................................................................................................................5

4.4. Binary Mode OUTPUT Format...................................................................................................................6

4.4.1. Description..........................................................................................................................................6

4.4.2. Codification .........................................................................................................................................6

4.5. List of Serial Commands for the INTEGRA (Summary).............................................................................8

4.6. List of Serial Commands for the INTEGRA (Complete).............................................................................9

4.6.1. Display ................................................................................................................................................9

01 - Set Scale.................................................................................................................................................................9

02 - Set Scale Up.........................................................................................................................................................10

03 - Set Scale Down.....................................................................................................................................................10

04 - Get Current Scale Index........................................................................................................................................10

05 - Set Autoscale........................................................................................................................................................10

06 - Get Autoscale........................................................................................................................................................11

07 - Display Valid Scale ...............................................................................................................................................11

08 - Set Trigger Level...................................................................................................................................................11

09 - Get Trigger Level ..................................................................................................................................................12

10 - Get Mode Display..................................................................................................................................................12

4.6.2. Data Acquisition............................................................................................................................... 12

11 - Query Current Value.............................................................................................................................................12

12 - Send Continuous Transmission of Data................................................................................................................13

13 - Send Continuous Value with Period......................................................................................................................13

14 - Sent Current Value with Frequency ......................................................................................................................13

15 - Stop the CAU Command.......................................................................................................................................14

16 - Query New Value Ready.......................................................................................................................................14

17 - Get Laser Frequency ............................................................................................................................................14

18 - Set Binary Joulemeter Mode.................................................................................................................................15

19 - Get Binary Joulemeter Mode.................................................................................................................................15

4.6.3. Setup................................................................................................................................................ 15

20 - Set Personal Wavelength Correction ....................................................................................................................15

21 - Get Wavelength ....................................................................................................................................................16

4.6.4. Control.............................................................................................................................................. 16

22 - Set Anticipation.....................................................................................................................................................16

23 - Get Anticipation Status..........................................................................................................................................16

24 - Noise Suppression................................................................................................................................................17

25 - Set Zero Offset......................................................................................................................................................17

26 - Clear Zero Offset...................................................................................................................................................17

27 - Get Zero Offset .....................................................................................................................................................17

28 - Set Diode Zero Offset ...........................................................................................................................................18

29 - Set User Multiplier.................................................................................................................................................18