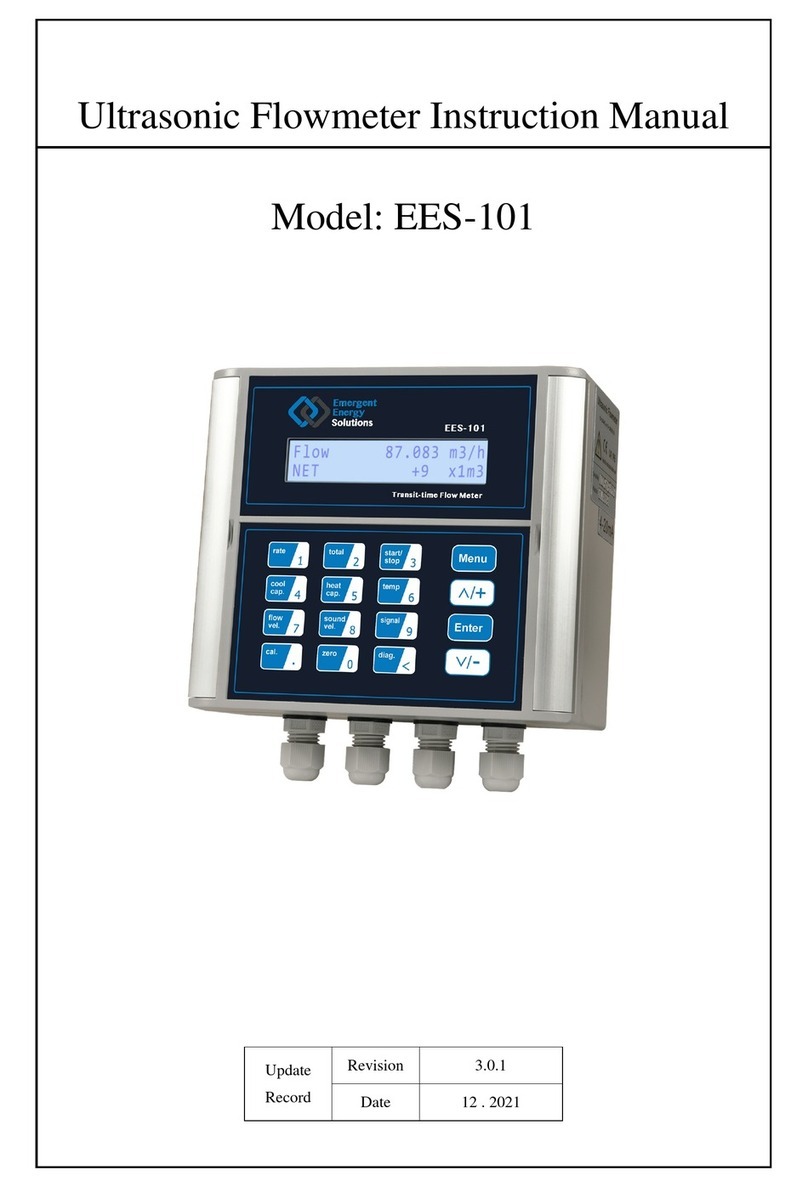

EMERGENT EES-401 User manual

Revision:3.0.0 Page1of90

Ultrasonic Energy Meter Instruction Manual

Model: EES-401

Update

Record

Revision 3.0.1

Date 12 . 2021

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page2of90

Notice

Thankyou forchoosing the EES-401 Ultrasonic EnergyMeterwith ARM.FPGAchip and low-voltage wide-pulse

sending technology.

Thisinstruction manualcontainsimportantinformation. Pleaseread carefullybefore the operation ofthe Energy

Meter, avoiding damaging EnergyMeterand improperuse.

Thisinstruction manualwill introduce howto usethe EnergyMeterstep-by-step, including productcomponent,

installation, wiring, quick setup etc. to make it easierto operate.

Understanding more aboutthe menu settingscan fulfill yourhigherrequirementswith the EnergyMeters

powerfulfunction option andoutputfunction.

Warning

Maycause injury.

Attention

Maydamage the EnergyMeters.

Some ofthe instructionsmaybe differentto the EnergyMeters you purchased,depending on configuration

requirements, otherwise, there isno indication aboutthe productdesign and upgrade requirementin the

instructions, subjectto the EnergyMeterdisplay, lease referto the version number, aswell asthe appendix.

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page3of90

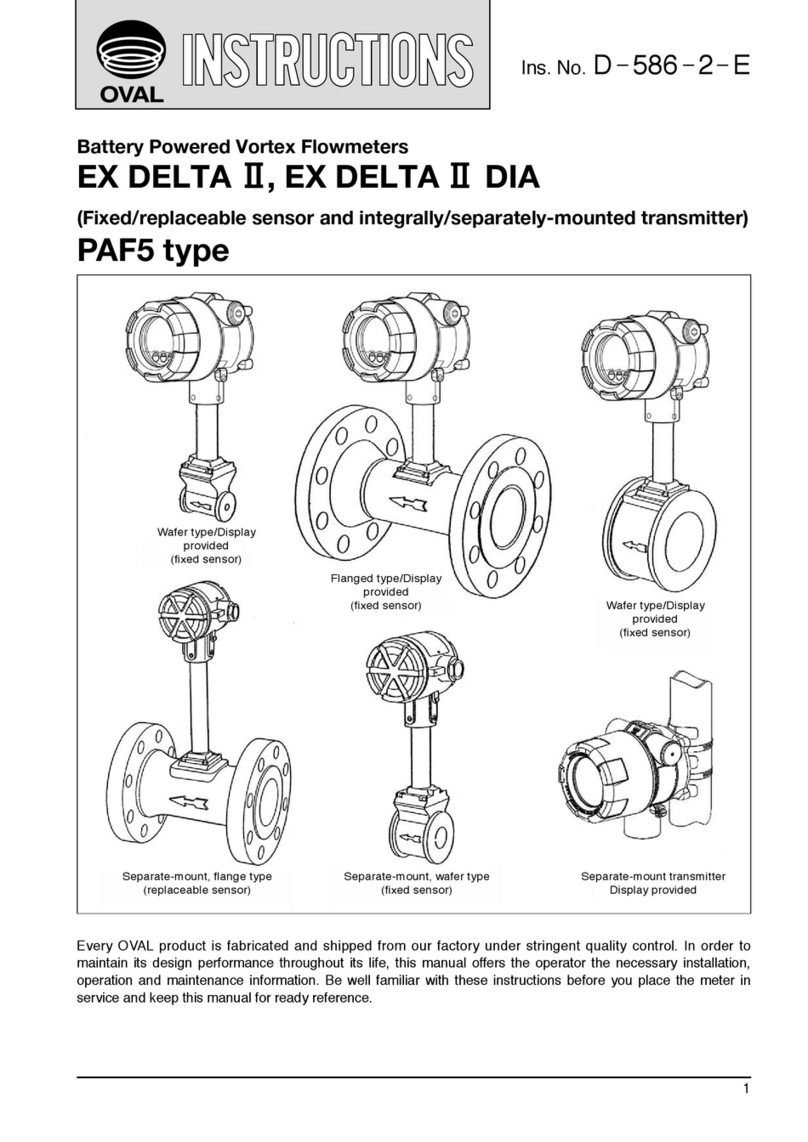

Product Components

Inspection should be made before installing the EnergyMeter. Check to see if the spare parts are in accordance

with the packing list. Make sure thatthere isno damage to the enclosuredue to aloose screworloose wire, or

otherdamage thatmayhave occurred during transportation. Anyquestions, please contactyourrepresentative as

soon aspossible.

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page4of90

Content

1Transmitter Installationand Connection.................................................................................7

1.1 InspectionPrior toTransmitter Installation..........................................................................................................7

1.2 WireConnecting...................................................................................................................................................8

1.2.1 Power SupplyOption......................................................................................................................................8

1.2.2 Transmitter Wiring..........................................................................................................................................8

1.3 Powering On.........................................................................................................................................................9

1.4 KeypadFunctions.................................................................................................................................................9

1.5 KeypadOperation.................................................................................................................................................9

1.6 EnergyMeter WindowDescriptions..................................................................................................................10

2PipeParameter EntryShortcuts.............................................................................................11

2.1 Dual FunctionKeysMenuDescription ..............................................................................................................11

2.2 Examples............................................................................................................................................................13

3MeasurementSite Selection.....................................................................................................14

4Transducer Installation............................................................................................................16

4.1 Transducer Installation.......................................................................................................................................16

4.2 Transducer Spacing.............................................................................................................................................16

4.3 Transducer Mounting Methods...........................................................................................................................16

4.3.1 VMethod ......................................................................................................................................................16

4.3.2 ZMethod.......................................................................................................................................................16

4.3.3 NMethod (notcommonlyused)...................................................................................................................17

4.4 Transducer Mounting Inspection........................................................................................................................17

4.4.1 Signal Strength..............................................................................................................................................17

4.4.2 Signal Quality(Qvalue)...............................................................................................................................17

4.4.3 Total TimeandDelta Time...........................................................................................................................18

4.4.4 Transit TimeRatio........................................................................................................................................18

4.4.5 Warnings.......................................................................................................................................................18

5TemperatureSensorInstallation.............................................................................................19

5.1 Selectionofmeasuring point..............................................................................................................................19

5.2 Installationoftemperaturesensor.......................................................................................................................19

6Operating Instructions.............................................................................................................20

6.1 SystemNormal Identification.............................................................................................................................20

6.2 LowFlowCutoff Value......................................................................................................................................20

6.3 Zero Settings.......................................................................................................................................................20

6.4 Scale Factor ........................................................................................................................................................20

6.5 SystemLock.......................................................................................................................................................20

6.6 4~20mACurrentLoop Output..........................................................................................................................21

6.7 FrequencyOutput...............................................................................................................................................21

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page5of90

6.8 TotalizerPulseOutput........................................................................................................................................22

6.9 AlarmProgramming...........................................................................................................................................22

6.10 BatchController..................................................................................................................................................23

6.11 4-20mAAnalogOutputCalibration...................................................................................................................23

6.12 SD Card Operation..............................................................................................................................................23

6.12.1 Specifications................................................................................................................................................23

6.12.2 Install or RemovetheSD Card while theMeter isPoweredOn...................................................................24

6.12.3 OfflineData Reading....................................................................................................................................25

6.13 ESN.....................................................................................................................................................................25

7Windows Display Explanations...............................................................................................26

7.1 WindowsDisplayCodes.....................................................................................................................................26

7.2 DisplayExplanations..........................................................................................................................................28

8ErrorDiagnoses.........................................................................................................................51

8.1 Table 1. Error CodesandSolutions(DuringOperation)....................................................................................51

8.2 FrequentlyAskedQuestionsandAnswers.........................................................................................................52

9Product Overview.....................................................................................................................53

9.1 Introduction.........................................................................................................................................................53

9.2 FeaturesofEES-401...........................................................................................................................................53

9.3 Operating principle.............................................................................................................................................53

9.4 Applications........................................................................................................................................................54

9.5 Specifications......................................................................................................................................................55

10 Appendix1 W211 InsertionTransducer ..............................................................................56

10.1 Overview............................................................................................................................................................56

10.2 MeasurementPointSelection .............................................................................................................................56

10.3 Determining Transducer Spacing &Transducer Installation..............................................................................56

10.4 Transducer Mounting Methods...........................................................................................................................58

10.4.1 ZMountingMethod......................................................................................................................................58

10.5 PipeParameter EntryShortcuts..........................................................................................................................58

11 Appendix2 W110 InsertionTransducer ...............................................................................60

11.1 Overview............................................................................................................................................................60

11.2 MeasurementPointSelection .............................................................................................................................60

11.3 Determining Transducer Spacing andInstallationMethod.................................................................................60

11.4 Menu SetupInstructions.....................................................................................................................................61

11.5 InstallationMethod.............................................................................................................................................63

11.5.1 ZMountingMethod......................................................................................................................................63

11.5.2 VMountingMethod......................................................................................................................................63

12 Appendix3 WH101 InsertionTransducer ...........................................................................64

12.1 Overview............................................................................................................................................................64

12.2 MeasurementPointSelection .............................................................................................................................64

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page6of90

12.3 Determining Transducer Spacing &Transducer Installation..............................................................................64

12.4 WHTypeInsertionTransducer PipeParameter EntryShortcuts........................................................................65

12.5 WHTypeTransducer Mounting Methods..........................................................................................................67

12.5.1 ZMountingMethod......................................................................................................................................67

12.5.2 VMountingMethod......................................................................................................................................67

13 Appendix4 SerialInterface NetworkUseand Communications Protocol.......................68

13.1 Overview............................................................................................................................................................68

13.2 Direct connectionvia RS-485 tothehostdevice................................................................................................68

13.3 Communicationprotocolandtheuse.................................................................................................................68

13.3.1 FUJI Protocol................................................................................................................................................69

13.3.2 MODBUS CommunicationProtocol.............................................................................................................75

14 Appendix5 RTDModuleand PT1000 Wiring (ModuleOptional)......................................83

14.1 RTDEnergyMeter Function..............................................................................................................................83

14.2 Wiring (PT1000).................................................................................................................................................83

14.3 EnergyMeasurementMethods...........................................................................................................................84

14.4 TemperatureCalibrationMethods......................................................................................................................84

15 Appendix6-FlowApplicationData.........................................................................................85

15.1 SoundVelocityandViscosityfor FluidsCommonlyUsed................................................................................85

15.2 SoundVelocityfor VariousMaterialsCommonlyUsed....................................................................................85

15.3 SoundVelocityinWater (1 atm) at DifferentTemperatures..............................................................................86

16 Appendix 6-WiFiOperationInstructions...............................................................................87

16.1 ABriefIntroductiononFunctions......................................................................................................................87

16.2 EnergyMeter DistributionNetworkMode.........................................................................................................87

16.2.1 Automatic Access .........................................................................................................................................87

16.2.2 ManualAccess..............................................................................................................................................87

16.3 EnergyMeter connectingnetwork......................................................................................................................88

16.3.1 DownloadWeChat........................................................................................................................................88

16.3.2 SearchSMARTMETERSpublic cloudnumber...........................................................................................88

16.3.3 Clickonfollowingbutton .............................................................................................................................89

16.3.4 InstrumentDistributionNetwork..................................................................................................................89

16.3.5 Configurationofequipmentfor Internet access............................................................................................90

16.3.6 Visit SMARTMETERS...............................................................................................................................90

Update Information:

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page7of90

1TransmitterInstallation and Connection

1.1 Inspection Prior toTransmitterInstallation

Youwill find a"Position Drawing"inthe

packing. Pleaseuseit asatemplateinthe

place thatyou aregoing toinstall the

EnergyMeter.Then drill 4installation

holesatthescrewposition shownonthe

drawing with the 5.5mm drill.

Take outthe enclosed screwsand plastic

bushings.Insert the plasticbushingsinto

the installing holes.Then open thetwo

aluminumpieceson the twosidesofthe

top cover.PuttheEnergyMeterintothe

position and screwit in.

Attention

When installing please ensure the frontcoverissecure and will notfall open.

120 mm

182 mm

7.17lnch

4.72lnch

Position drawing

Instrutions:

1.Place thistemplateon thewall anddrill4holesof 8mm

2. Insertaplasticbushingintoeachofthe4holes.

3. Screw4pcsST5.5X50mm self tapping screwsthrough the

4. Tightenthescrewstosecuretotheenclosureon thewall.

transmitter enclosurebaseand attachit tothewall.

diameter &50mmdeep.

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page8of90

1.2 WireConnecting

1.2.1 Power SupplyOption

Customers should payspecialattention to specifythe desired powersupplywhen wiring.

Factorystandard powersupplyis90 ~245 VAC.

To ensure the transmittercanwork normally, please payattention to the followingswhen wiring:

Ensure thatpowerconnectionsare made in accordance with the specificationsshownon the transmitter.

Transmitters can be poweredbytwo differentpowersupplies:90 ~245VACor10-36VDC.

1.2.2 Transmitter Wiring

Once the electronicsenclosure hasbeeninstalled, the EnergyMeterwiring can be connected.

Openthe case, you will find the Powerboard wiring ports, fromup to down, fromleft to right, are asfollows;

Connectto the,AC power(90-245V),DC power(10-36V), RelayOutput, OCT Output, RTDTemperature Sensor

input, Transducerwiring, 4-20mAOutput, RS485 Output.

Fordouble-shielded transducercable:"-"on the black wire, "+"on the red wire and "shield"on the shield wire.

Referto the belowdiagramforspecific connection:

Warning

Wire when it ispower-off. Reliable grounding mustbe taken forthe instrumentbefore installation

and use .

Use eitherACorDC powersupply. Do notconnectthemboth atthe same time.

Blackwire

Shieldwire

Redwire

Shieldwire

Down-Stream

Redwire Blackwire

BlueBushing

RedBushing

Up-Stream

Flow

ACPower

LNE

AC 90~245V

DC+ DC- E

DC10~36V

I+ I-

4~20mA

DL1DL2

RELAY

OCT+OCT-

OCTOUT

A1 B1B1 A2B2B2

RTDINPUT

E UP+UP- E DN+DN-

TRANSDUCER

AB

RS485

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page9of90

1.3 PoweringOn

AssoonastheEnergyMeterisswitched on, the systemwillrun automaticallyaccording tothe lastinput

parameters.Ifthe installation isaccomplished when systemisswitched on,gainadjustmentcan bemonitored in

WindowM01. Aftercode "*R"aredisplayed on the upperleft cornerofthe screen,the systemwill activatethe

normalmeasurementcondition automatically.Itisindicated bycode "*R"on the upperleft cornerofthe screen.

Ifitisthe firsttime to use orinstall on a newsite, the customerneed to inputthe newinstallation site parameters.

Anyparameters which are setbyuserwill be saved permanentlyuntil theyare changed bythe user.

When the usermodifiesthe parameters and removesthe transducers, the meterwill recalculate automatically, and

operate normallywith the parameters.

The EnergyMetercan alwayscompleteall tasksatthe sametime. The tasks(Including measurement,output,etc)

will be carried outasusual,no matterinwhich displaywindow.The systemwilldefault tothelastwindow

settingsand automaticallydisplaythemwhen the EnergyMeterispower-on.

1.4 KeypadFunctions

Followthese guidelineswhen using the dualfunction keypad (Referto Keypad Figure):

~ and InputNumbers or

Menu Code.

Backspace ordelete characters to the left.

and Returntothe lastmenu oropen the

nextmenu. Actsas"+"and "-"areused toenter

numbers.

Selectamenu. Press thiskeyfirst,then input

twomenu numbers todisplaythe selected menu. For

example, ToInputapipeoutside diameter,press

keys,where"11"isthe window

IDto displaythe parameterforpipe outside diameter.

、、、、、

areshortcutstothe windowsforFlowRate, Velocity,

SignalStrengthand SignalQuality,Totalizer,Velocity,

Transit Time Ratio, and SystemErrorCodes.

1.5 KeypadOperation

The flowmeteradoptsthe windowsoftwaredesign toconsolidateorsubdivide all ofthe parameters entered, the

instrumentsetup and measurementresult displaysintomorethan 100 independentwindows.The operatorcan

inputparameters,modifysettingsordisplaymeasurementresultsby"visiting"aspecificwindow.Thesewindows

arearranged by2-digit serialnumbers (including "+"sign)from00 ~99, then to+0, +1, etc. Each windowserial

number,orso-called windowIDcode,hasa definedmeaning. Forexample, WindowM11 indicatesthe parameter

inputforpipe outside diameter,whileWindowM25 indicatesthe mounting spacing between the transducers,etc.

(Refer –WindowsDisplay Explanations).

The keypad shortcuttovisitaspecificwindowistopress the keyatanytime, then inputthe 2-digit

windowIDcode. Forexample, toinputorcheckthe pipeoutside diameter,justpress the

keysforwindowIDcode 11.

Anothermethod tovisit aparticularwindowistopress and keystoscroll the screen.For

example, if the currentwindowIDcode isM02, press keytoenterWindowM01, press the

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page10of90

button againtoenterWindowM00;then,pressthe keytoback WindowM01,andpress the key

again to enterWindowM02.

Windowsareseparated intothree types:(1)DataType,such asM11, M12;(2)Option Type, such asM14;(3)

PureDisplayType, such asM01, M00.

Youcancheckthe correspondingparameters byvisiting theDataType Windows.Ifyou wanttomodifythe

parameters, afterpress , andthe digits, and then press again to confirm.

Example1:Toenterapipe outside diameterof200, the

procedure isasfollows:

Press keystoenterWindowM11(the

numericalvalue displayed currentlyisapreviousvalue).Now

press key.The symbol">"and the flashing cursorare

displayed atthe left end ofthe second line onthe Screen. Then

inputthe value parameters .

Youcan checkthe selectedoption byvisiting Option Type

Windows.Ifyou wanttomodifyit,youmustpress

first,the symbol">"and theflashing cursoraredisplayedatthe

left ofthe Screen. Operatorcan usethe and to

scroll the screen and getthe required value then press to

confirm.

Forexample, if the pipe materialis"Stainless Steel",Press

toenterWindowM14, press to

modifythe options.Selectthe "1. Stainless Steel"option by

pressing and , then press toconfirmthe

selection.

Attention

Generally, press keyfirstif operatorwantsto enter"modify" status.Ifthe "modify" isstill

notpossible even afterpressing the key, itmeansthatsystemislocked bya password. To

"Unlock"it, select"Unlock"in WindowM47 and enterthe originalpassword.

1.6 EnergyMeterWindow Descriptions

These windowsareassigned asfollows:

00 ~09Displaymenus:todisplayflowrate, positivetotal,negativetotal,nettotal,velocity,date&time,

presentanalog output, presentoperation and flowresultstoday, etc.

10 ~29 InitialParameterSetup:toenterpipe outside diameter,pipe wall thickness,fluidtype, transducertype,

transducermounting method and spacing, etc.

30 ~38FlowUnitsOptions:toselectthe flowunit such ascubicmeter,literorotherunits,can turntotalizers

on/off and resettotalizers, etc.

40 ~51Setup options:Scale factor, systemlock (WindowM47),etc.

52 ~89Inputand outputsetup:CLmode select, CL4mA/20mAoutputvalue, serialport parameter,etc.

PipeOuter Diameter

>_

PipeMaterial[14

>1.Stainless Steel

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page11of90

90 ~98Diagnoses:Signalstrengthand signalquality(WindowM90),TOM/TOS*100 (WindowM91),flow

sound velocity(WindowM92),totaltimeand deltatime(WindowM93),Reynoldsnumberand factor

(WindowM94),etc.

+0~-2Appendix:poweron/off time, totalworking hours, on/off timesand a single-accuracyfunction

calculator.

Attention

The otherwindowsforhardware adjustmentare reservedbythe manufacturer.

2PipeParameterEntryShortcuts

2.1 DualFunction KeysMenu Description

Press key.

DisplayFlowRate. The function isthe same with

WindowM02.

Press key.

DisplayVelocity. The function isthe same with

WindowM01.

Press key.

DisplaySignalStrength and SignalQuality. The

function isthe same with WindowM90.

Press key.

DisplayNetTotalizer. The function isthe same with

WindowM00.

Press key.

DisplayTransit Time Ratio. The function isthe same

with WindowM91.

Press key.

DisplaySystemErrorCode. The function isthe same

with WindowM08.

Press key.

EnterPipe OuterDiameterin WindowM11.

Press key.

EnterPipe Wall Thickness in WindowM12.

Flow0.1129m3/h*R

POS 0x1m3

Flow0.1129m3/h*R

Vel 1.0415m/s

Strength+Quality[90

UP:00.0DN:00.0Q=00

Flow0.1154m3/h*R

NET0x1m3

TOM/TOS*100[91

0.00%

*R-------------[08

SystemNormal

PipeOuterDiameter

60.00mm

PipeWallThickness

2.00mm

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page12of90

Press key.

EnterPipe Materialin WindowM14.

Press key.

EnterFluid Type in WindowM20.

Press key.

EnterTransducerMounting in WindowM24.

Press key.

Enterto start and stop ManualTotalizerin turn.

Press key.

Displaythe Display/Hold Totalizerin turn.

Press key.

DisplayDynamic /NormalFlowRate and Velocityin

turn.

Press key.

EnterFluid Sound Velocityin WindowM92.

Press key

DisplayDate and Time in WindowM60.

Press key

Press to start ManualTotalizer, then press

to end ManualTotalizer, press to input

StandardTotalizerto getthe finalKfactor. Complete

the calibration with pressing to store.

Press key

Press , andenterZero Cut, the same asMenu 42

Pipe Material[14

0. CarbonSteel

FluidType[20

0. Water

TransducerMounting

0.V

Timing10SEC

ON10.123m3

Flow0.1129m3/h*R

POS1.1m3

Flow0.1129m3/hDyn

Vel 1.0415m/s

FluidSound Velocity

1443.4 m/s

YYYY-MM-DDHH:MM:SS

2021-01-0910:05:06

ManualCalibrate

PressEntWhenReady

SetZero[42

PressENTWhenReady

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page13of90

2.2 Examples

Forexample, letusyou havea pipe of219mm outerdiameterand 6mm wallthickness, measuring mediumis

water, Pipe Materialiscarbon steelwith no Liner, These parameters should be operated asfollows:

Step1. Pipe outer diameter:

Press keysto enterWindow

M11, and enterthe pipe outside diameter, and then

press the keyto confirm.

Step2. Pipe wall thickness

Press the keyto enterWindow

M12, and enterthe pipe wall thickness, and press the

keyto confirm.

Step3. Pipe Material

Press the keysto enter

WindowM14, press the key, press the

or keyto selectPipe Material, and press the

keyto confirm.

Step 4. Liner MaterialParameters

(including thickness and sound velocity, if needed ):

Press the keyto enterMenu

16, press the key, use the or

keyto selectlinermaterialfromthe drop-down Menu,

and then press the key.

Step 5. FluidType

Press the keyto enterMenu

20, press the key, use the or

keyto selectfluid type fromthe drop-down Menu, then

press the key.

Step6. Transducer Type

(The transmitterisavailableforvarioustransducer

types.)

Press the keyto enterWindow

M23, press the key, move the or

keyto selecttransducertype, and press the

keyto confirm.

PipeOuterDiameter

219.00mm

PipeWall Thickness

6mm

PipeMaterial[14

0.CarbonSteel

LinerMaterial[16

0.None,NoLiner

FluidType [20

0. Water

Transducer Type [23

0.Standard

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page14of90

Step 7. Transducer Mounting Methods

Press the keyto enterMenu

24, press the key, use the or key

to selecttransducer-mounting fromthe drop-down

Menu, thenpress the key.

Step 8. Adjust Transducer Spacing

Press the keyto enterMenu

25, accuratelyinstallthe transduceraccording to the

displayed transducermounting spacing and the selected

mounting method.

Step 9. Display MeasurementResults

Press to enterMenu 01 to

displayflowrate. (Subjectto the realmeasurement. )

3MeasurementSiteSelection

The installation ofthisultrasonic flowmeteristhe simplestone ofall kindsofEnergyMeters. Onlyone suitable

measuring site needed, plug the transducers on the pipe and then start the measurement.

When selecting ameasurementsite, it isimportantto selectan area where thefluid flowprofile isfullydeveloped

to guarantee a highlyaccurate measurement. Use the following guidelinesto selecta properinstallation site:

lChoosea section ofpipe thatisalwaysfullofliquid, such asa verticalpipe with flowin the upwarddirection

ora full horizontalpipe.

lEnsure enough straightpipe length atleastequalto the figure shown belowforthe upstreamand downstream

transducers installation. Tryto avoid Ensure enough straightpipe length atleastequalto the figure shown

belowforthe upstreamand downstreamtransducers installation.

lOn the horizontalpipe, thetransducershould be mounted on the 9 and 3 ofthe pipe, avoiding the position of

6 and 12, in caseofthe signalattenuation caused bypipe atthe bottomsedimentorbubble、cavitation on the

pipe.

lEnsure thatthe measuring site temperature isunderthe transducertemperature limits.

lConsiderthe inside condition ofthe pipe carefully.Ifpossible, selecta section ofpipewhere the inside is

free ofexcessive corrosion orscaling.

lChoosea section ofsound conducting pipe.

Transducer Mounting

0. V

TransducerSpacing

176.48mm

Flow0.1129m3/h*R

Vel 1.0415m/s

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page15of90

Pump

Valve

Reduce

Diffuser

Tee

90

o

bend

Straightlengthof

downstream piping

Straightlengthofupstream

piping

Name

Detector

10Dmin

0.5D min

L≥5D

L ≥5D

L≥10D

Flowcontrolleddownstream

10D min

L ≥10D

L ≥5D

L ≥10D

10Dmin

L ≥50D

L ≥30D

D

5Dmin

L≥10D

L≥30D

Flowcontrolledupstream

L≥50D

P

Check valve

Stopvalve

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page16of90

4TransducerInstallation

4.1 TransducerInstallation

Before installing the transducers, clean the pipe surface where the transducers are to be mounted. Remove anyrust,

scale orloose paintand make a smooth surface. Choose asection ofsound conductingpipe forinstalling the

transducers.Applya wide band ofsonic coupling compound down thecenterofthe face ofeach transduceras

well ason the pipe surface, ensure there are no air bubblesbetween the transducers and the pipe wall, and then

attach the transducers to the pipe with the strapsprovided and tighten themsecurely.

Note: The two transducers should be mounted atthe pipe scenterline on horizontalpipes.

Make sure thatthe transducermounting direction isparallelwith the flow.

During the installation, thereshould be no air bubblesorparticlesbetween the transducerand the pipe wall. On

horizontalpipes, the transducers should bemounted in the 3 o clock and 9o clock positionsofthe pipe section in

orderto avoid anyair bubblesinside the top portion ofthe pipe. (Referto TransducerMounting). Ifthe

transducers cannotbe mounted horizontallysymmetricallydue to limitation ofthe localinstallation conditions, it

maybe necessarytomountthe transducers ata location where there isa guaranteed full pipe condition (the pipe is

alwaysfull ofliquid).

4.2 TransducerSpacing

The spacing between the ENDSofthe two transducers isconsidered asthestandard transducerspacing (Referto

MENU25 ).Afterentering the required parameters, Check the data displayed in WindowM25 and adjustthe

transducers spacing according to the data displayed in WindowsM25.

4.3 TransducerMounting Methods

Three transducermounting methodsare available. Theyare respectively:Vmethod, Zmethod and Nmethod.

The Vmethod isprimarilyused on small diameterpipes(DN100 ~300mm, 4〞~12〞). The Zmethod isused

in applicationswhere the Vmethod cannotwork dueto poorsignalorno signaldetected. In addition, the Z

method generallyworksbetteron largerdiameterpipes(overDN300mm, 12〞)orcastiron pipes.

The Nmethod isan uncommonlyused method. Itisused on smallerdiameterpipes(belowDN50mm, 2〞).

4.3.1 VMethod

The Vmethod isconsidered asthe standard method. Itusuallygivesa more accurate reading and isused on pipe

diameters ranging from25mmto 400mm(1"~16〞)approximately. Also, it isconvenientto use, butstill

requiresproperinstallation ofthe transducers, contacton the pipe atthe pipe scenterline and equalspacing on

eitherside ofthe centerline.

4.3.2 ZMethod

The signaltransmitted in a Zmethod installation hasless attenuation than a signaltransmitted with the Vmethod

when the pipesaretoo large,there are some suspended solid in the fluid, orthe scalingand linerare too thick .

Thisisbecausethe Zmethod utilizesa directlytransmitted (ratherthan reflected)signalwhich transversesthe

liquid onlyonce. TheZmethod isable to measure on pipediameters ranging from100mmto 5000mm(4 inch to

200 inch )approximately. Therefore, we recommend the Zmethod forpipe diameters over300mm(12 inch).

DownstreamTransducer

UpstreamTransducer

Flow

TransducerSpace

Flow

SideView TopViewSection

PipeStrap

Transducer

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page17of90

4.3.3 NMethod(not commonlyused)

With the Nmethod, the sound wavestraverse the fluid three timesand bounce twice offthe pipe walls. Itis

suitable forsmallpipe diametermeasurement. The measurementaccuracycan be improved byextending the

transit distance with the Nmethod (uncommonlyused ).

4.4 TransducerMounting Inspection

Checkto see if the transducerisinstalled properlyand if there isan accurate and strong enough ultrasonic signal

to ensure properoperation and high reliabilityofthe transducer. Itcan be confirmed by checking the detected

signalstrength, totaltransit time, delta time aswell astransit time ratio.

The "mounting"condition directlyinfluencesthe flowvalue accuracyand systemlong-time running reliability.In

mostinstances, onlyapplya wide band ofsonic coupling compound lengthwise on theface ofthe transducerand

stick it to the outside pipe wall to getgood measurementresults. However, the following inspectionsstill need to

be carried outin orderto ensure the high reliabilityofthemeasurementand long-termoperation ofthe instrument.

4.4.1 SignalStrength

Signalstrength (displayed inWindowM90)indicatesa detected strength ofthe signalboth fromupstreamand

downstreamdirections. The relevantsignalstrength isindicated bynumbers from00.0 ~99.9. 00.0 representsno

signaldetected while 99.9 representsmaximumsignalstrength. Normally,the strongerthe signalstrength

detected, the longerthe operation ofthe instrumentreliably, aswell asthe more stable the measurementvalue

obtained.

Adjustthe transducerto the bestposition and check to ensure thatenough sonic coupling compound isapplied

adequatelyduring installation in orderto obtain themaximumsignalstrength.

Systemnormallyrequiressignalstrength over60.0, whichisdetected fromboth upstreamand downstream

directions. Ifthe signalstrength detected istoo low, the transducerinstallation position and the transducer

mounting spacing should bere-adjusted and the pipe should be re-inspected. Ifnecessary, change the mounting

method to be Zmethod.

4.4.2 SignalQuality(Qvalue)

Qvalue isshort forSignalQuality(displayed in WindowM90). Itindicatesthe levelofthe signaldetected. Q

value isindicated bynumbersfrom00 ~99. 00 representsthe minimumsignaldetected while 99 representthe

maximum. Normally, the transducerposition should be adjusted repeatedlyand coupling compound application

should be checked frequentlyuntil the signalqualitydetected isasstrong aspossible.

DownstreamTransducer

UpstreamTransducer

Flow

TransducerSpacing

Flow

SideView Top ViewSection

PipeStrap

Transducer

DownstreamTransducer

UpstreamTransducer

Flow

TransducerSpacing

Flow

SideView TopViewSection

PipeStrap

Transducer

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page18of90

4.4.3 TotalTimeand DeltaTime

"TotalTime and Delta Time", which displaysin WindowM93, indicatesthe conditionofthe installation. The

measurementcalculationsin the EnergyMeterare based upon these twoparameters. Therefore, when "Delta

Time"fluctuateswidely,the flowand velocitiesfluctuateaccordingly, thismeansthatthe signalqualitydetected

istoo poor. Itmaybe the resulted ofpoorpipe-installation conditions, inadequate transducerinstallation or

incorrectparameterinput.

Generally, "Delta Time"fluctuation should be less than ±20%.Onlywhen the pipe diameteristoo smallor

velocityistoo lowcan the fluctuation be wider.

4.4.4 TransitTimeRatio

Transit Time Ratio indicatesif the transducermounting spacing isaccurate. Thenormaltransit time ratio should

be 100+/-3 if the installation isproper. Check it in WindowM91.

Attention

Ifthe transittime ratio isover100±3,it isnecessaryto check:

(1) Ifthe parameters (pipe outside diameter, wall thickness, pipe material, liner, etc.)have

been enteredcorrectly,

(2) Ifthe transducermounting spacing isaccordance with the displayin WindowM25,

(3) Ifthe transducerismounted atthe pipe scenterline on the same diameter,

(4) Ifthe scale istoo thick orthe pipe mounting isdistorted in shape, etc.

4.4.5 Warnings

(1) Pipeparameters entered mustbe accurate;otherwise the EnergyMeterwillnotwork properly.

(2) During the installation, applyenough coupling compoundsin orderto stick the transducers onto the

pipe wall. While checking the signalstrength and Qvalue, move the transducers slowlyaround the

mounting site until the strongestsignaland maximumQvalue can be obtained. Make sure thatthe

largerthe pipe diameter, the more the transducers shouldbe moved.

(3) Checkto be sure the mounting spacing isaccordance with the displayin WindowM25 and the

transducerismounted atthe pipe scenterline on the same diameter.

(4) Payspecialattention to those pipesthatformed bysteelrolls(pipe with seams), since such pipe is

alwaysirregular.Ifthe signalstrength isalwaysdisplayed as0.00, thatmeansthere isno signal

detected. Thus, it isnecessaryto check thatthe parameters (including all the pipe parameters) have

been entered accurately.Check tobe surethe transducermounting method hasbeen selected properly,

the pipe isnotworn-out, andthe linerisnottoo thick. Make sure there isindeed fluid in the pipe or

the transducerisnottoo close to a valve orelbow, and there are nottoo manyair bubblesin the fluid,

etc. With the exception ofthese reasons, if there isstill no signaldetected, the measurementsite has

to be changed.

(5) Make sure thatthe EnergyMeterisable to run properlywith high reliability. The strongerthe signal

strength displayed, the higherthe Qvalue reached. The longerthe EnergyMeterrunsaccurately, the

higherthe reliabilityofthe flowratesdisplayed. Ifthere isinterference fromambientelectromagnetic

wavesorthe signaldetected istoo poor, the flowvalue displayed isnotreliable;consequently,the

capabilityforreliable operation isreduced.

(6) Afterthe installation iscomplete, poweron the instrumentand check the result accordingly.

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page19of90

5TemperatureSensor Installation

Standard configuration PT1000 temperature sensor.

Before the temperature sensortransducerisinstalled, it isnecessaryto selectthe appropriate measuring point

to ensure the accuracyofmeasurement.

5.1 Selection of measuring point

The installation position ofthe temperature sensorshall be selected according to the following principles:

1. The installation position ofthe temperature sensorshall be selected atthe place with sensitive and

representativemediumtemperature change, notnearthe resistance parts such asvalves, weldsand the

dead angle ofmediumflowrate.

2. Installed in a place convenientforoperation andmaintenance.

3. The temperature ofthe measured fluid doesnotexceed the rated working temperature, and the

working temperature range ofthe temperature sensoris0-100 ℃.

4. The installation ofthe temperature sensorshall notaffectthe installation ofthe ultrasonic sensor

because it will become a resistance part forthe fluid in the pipeline afterthe temperature sensoris

installed , which will cause turbulence ofthefluid flow). Itshallbe installed downstreamofthe

ultrasonic sensor.

5.2 Installationof temperaturesensor

Before installing the clamp on temperature sensor, the area to be installed on the surface ofthe pipeline shall

be cleaned and the rustand paintshall be removed, and then the clamp on temperature sensorshall be tightly

bound on the pipe wall. Notethatthe waterinlettemperature sensorisinstalled on the waterinletpipe wall, and

the wateroutlettemperaturesensorisinstalled on the wateroutletpipe wall.

temperaturesensor

EES-401 SeriesUltrasonicEnergyMeter

Revision:3.0.1 Page20of90

6Operating Instructions

6.1 SystemNormalIdentification

Press the keys.Ifthe letter"*R"displayson the screen, it indicatessystemnormal.

Ifthe letter"G"isdisplayed,it indicatesthatsystemisadjusting the signalgain priorto the measurement. Also, it

meanssystemnormal. Onlywhen the adjustmenttakestoo long (>2min)withoutstopping, cansystembe

identified asabnormal.

Letter"I"indicatesno signalisbeing detected. Check thetransducerwiring connectionsare correct, the

transducers are installed firmly, etc.

Forfurtherinformation, please referto "ErrorDiagnosis".

6.2 Low Flow Cutoff Value

The data inM41 isLowFlowCutoff Value. Ifthe flowrate fallsbelowthe lowflowcutoff value, the flow

indication isdriven to zero. Thisfunction can preventthe flowmeterfromdisplayingflowas"0"aftera pump was

shutdown, butthere isstill liquid movementin the pipe, which will result in cumulative error. Generally, 0.01m/s

isrecommended to enterasthe lowflowcutoff point.

The lowflowcutoff value hasno relation to the measurementresultsonce the velocityincreasesoverthe lowflow

cutoff value.

6.3 Zero Settings

Once zero flowoccurs, a zero pointmayindicate on eachmeasuring instrument, butthe displayed measuring

value isnotequalto "0", thisvalue indicates"Zero". To anymeasuring instrument, thesmallerthe "Zero"is, the

betterthe qualityis. Conversely, if the Zero istoo big, thatindicatesthe qualityofthe instrumentispoor.

Ifthe zero setpointisnotattrue zero flow, a measurementdifference mayoccur. Thesmallerthe physical

measurementcapacityis, thelargerthe measurementdifference fromthe zero pointwill exist. Onlywhen zero

pointreduced toa definite degree, ascompared with the physicalmeasurementcapacity, can the measuring

difference fromzero pointbe ignored.

Foran ultrasonic EnergyMeter, the measurementerrorfromzero pointcannotbe ignored underlowflow

conditions. Itisnecessarytoperforma static zero setcalibration to improve lowflowmeasurementaccuracy.

Press WindowM42 to setthe Zero, press first, and then wait the readingsdisplayisfinished. Ifthisis

carried outwith flow, the flowwill be displayed as"0",M43 can help to restore settings.

6.4 ScaleFactor

Scale factorrefers to the ratio between "actualvalue"and "reading value".Forexample, when the measurementis

2.00, and it isindicated as1.98 on the instrument, the scale factorreading is2/1.98.Thismeansthatthe bestscale

factorconstantis1. However, it isdifficultto keep the scale factoras"1"on the instrumentespeciallyin batch

productions.The difference iscalled "consistency".

During operation, there still existspossible difference inpipe parameters, etc. The "scale factor"maybe necessary

when used on differentpipes. Thus, scale factorcalibration isspeciallydesigned forcalibrating the differences

thatresult fromapplication on differentpipes. The scale factorentered mustbe one thatresultsfromactualflow

calibration. The scale factorcan be inputin WindowM45.

6.5 SystemLock

Systemlock isintended to preventoperation errordue to tampering byunauthorized personnel.

Press the keys,move or keyto select"Lock", press the

key, entera 1 ~4 numericallylong password, and then press the keyto confirm.

Table of contents

Other EMERGENT Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

GTE

GTE CoboSafe-Scan operating manual

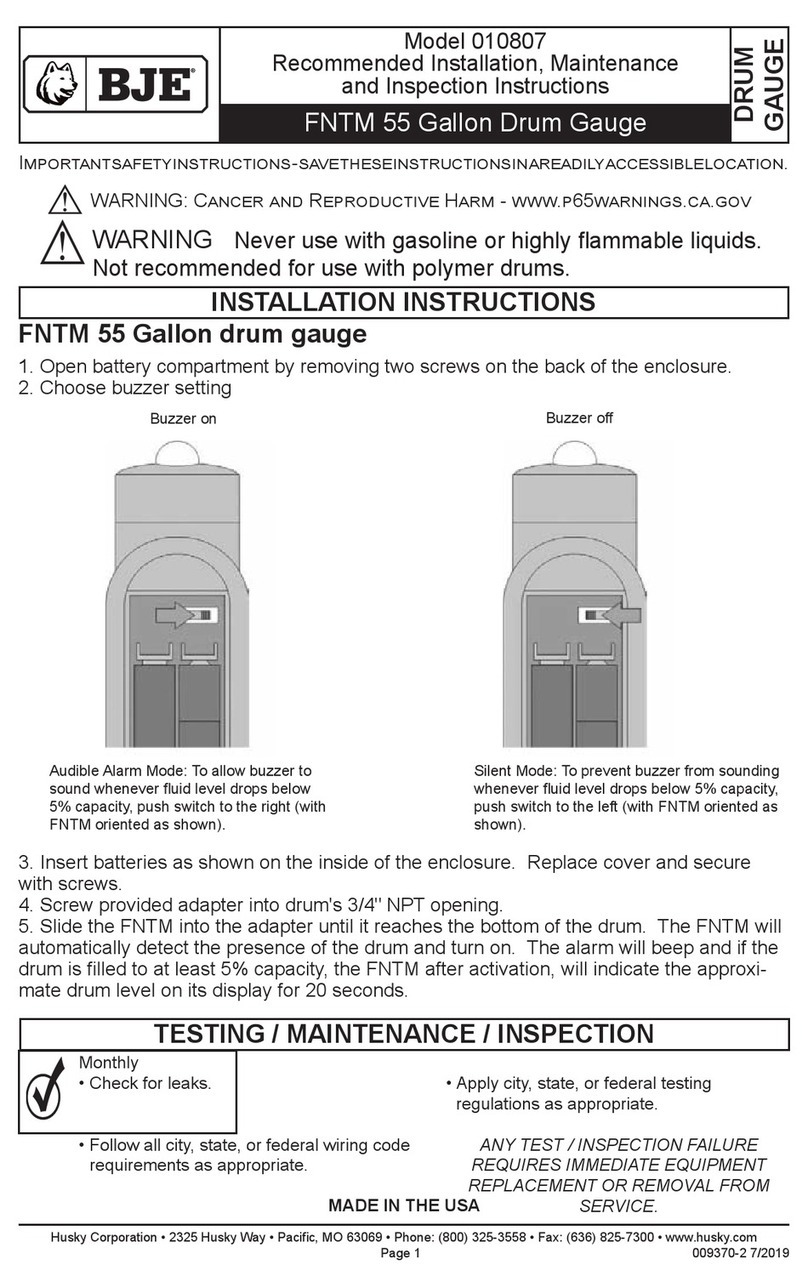

BJE

BJE 010807 Recommended Installation, Maintenance and Inspection Instructions

Lorentz

Lorentz PV Combiner 1000-125-4 Manual for installation and operation

Sony

Sony ICD-B200RS Service manual

WAGNER

WAGNER TITANUS SUPER-SENS Technical manual

Levenhuk

Levenhuk Wezzer Air MC20 user manual