EMERGENT EES-501 User manual

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page1of51

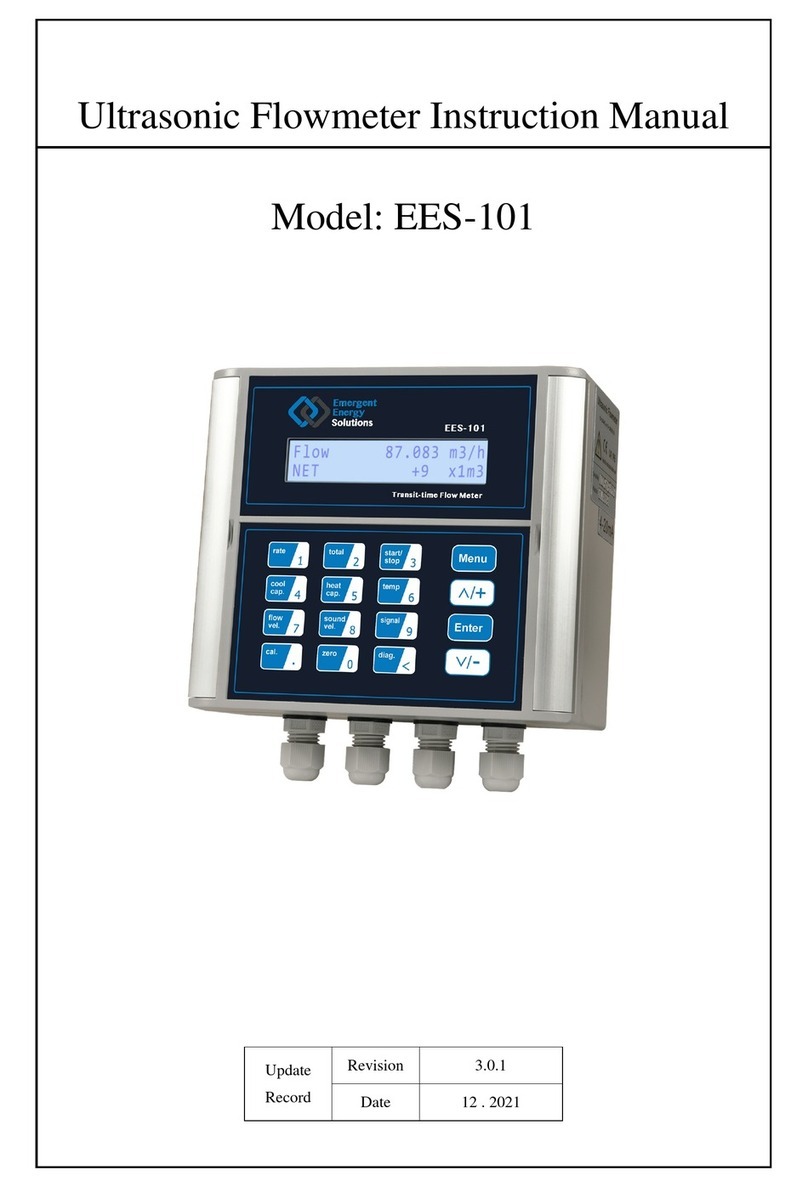

Ultrasonic Flowmeter Instruction Manual

Model: EES-501

Update

Record

Revision

3.0.1

Date 12 . 2021

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page2of51

Notice

Thankyou forchoosing the EES-501 Ultrasonic Flowmeterand Analyzerwith ARMchip and low-voltage

wide-pulse sending technology.

Thisinstruction manualcontainsimportantinformation. Pleaseread it carefullybefore operation the flowmeter

thusavoiding damage to the flowmeterfromimproperuse.

Thisinstruction manualwill advise howto use the flowmeterstep-by-step manner, including productcomponent

description, installation, wiring and quick setupetc. to make it easierto operate.

Aworking knowledgeofthemenu settingswillassistyou in understanding the flowmeters powerfuland output

function.

Warning

Maycause injury.

Attention

Maydamage the flowmeter.

Some ofthe instructionsmaybe differentfromthe flowmeterand analyzeryou havepurchased. Thatdependson

the configuration requirements. It also maybe due to changesin productdesign, modification and upgrade .You

will find the flowmeterdisplayinterface intuitive and easyto understand and it shall prevail when there isno

indication ofthe instructions.Please referto the version numberand the appendix formore information.

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page3of51

ProductComponents

Inspection should be made before installing the flowmeter. Check to see if the spareparts are in accordance with

the packing list. Make sure thatthere isno damage to theenclosure due to loose screworwiresorotherdamage

thatmayhave occurred during transportation. Anyquestions, please contactyourrepresentative assoon as

possible.

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page4of51

Content

1Transmitter Installationand Connection.................................................................................6

1.1 Power SupplyConnections................................................................................................................................6

1.1.1 TypeofPower Supply...............................................................................................................................6

1.1.2 Wiring........................................................................................................................................................6

1.1.3 Data OutputWiring ...................................................................................................................................7

1.2 Powering On......................................................................................................................................................8

1.3 KeypadFunctions...............................................................................................................................................8

1.4 KeypadOperation..............................................................................................................................................9

1.5 Flowmeter Menu Descriptions.........................................................................................................................10

2TheQuickSetupDescription...................................................................................................11

2.1 Double FunctionKeysMenuDescription........................................................................................................11

2.2 For example......................................................................................................................................................15

2.3 MeasurementSite Selection.............................................................................................................................17

3Transducer Installation............................................................................................................19

3.1 InstallingtheTransducer..................................................................................................................................19

3.1.1 Transducer Mounting Methods................................................................................................................19

3.1.2 VMethod.................................................................................................................................................19

3.1.3 ZMethod .................................................................................................................................................19

3.1.4 NMethod (notcommonlyused)..............................................................................................................20

3.2 Transducer InstallationandFixing...................................................................................................................20

3.3 Transducer Mounting Inspection......................................................................................................................20

3.3.1 Signal Strength.........................................................................................................................................21

3.3.2 Signal Quality(Qvalue)..........................................................................................................................21

3.3.3 Total TimeandDelta Time......................................................................................................................21

3.3.4 Transit TimeRatio...................................................................................................................................21

3.3.5 Warnings..................................................................................................................................................21

4Operating Instructions.............................................................................................................23

4.1 SystemNormal Identification..........................................................................................................................23

4.2 LowFlowCutoff Value...................................................................................................................................23

4.3 Zero Settings....................................................................................................................................................23

4.4 Scale Factor......................................................................................................................................................23

4.5 4~20mACurrentLoop Output.......................................................................................................................23

4.6 4~20mAAnalogOutputCalibration................................................................................................................24

4.7 TFCard Operation...........................................................................................................................................24

4.7.1 Specifications...........................................................................................................................................24

4.7.2 ReadingtheTFData Offline....................................................................................................................25

4.7.3 TFCard StorageOperationGuide...........................................................................................................25

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page5of51

4.8 ESN..................................................................................................................................................................26

5WindowDisplay Explanations.................................................................................................27

5.1 WindowDisplayCodes....................................................................................................................................27

5.2 DisplayExplanation.........................................................................................................................................28

6ErrorDiagnoses........................................................................................................................46

6.1 Table 1. Error CodesandSolutions(during operation)....................................................................................46

6.2 FrequentlyAskedQuestionsandAnswers.......................................................................................................47

7Product Overview.....................................................................................................................48

7.1 Introduction......................................................................................................................................................48

7.2 FeaturesofFlowmeter......................................................................................................................................48

7.3 TheoryofOperation.........................................................................................................................................48

7.4 Applications.....................................................................................................................................................49

7.5 Specifications...................................................................................................................................................49

8Appendix 1 -FlowApplicationData.......................................................................................50

8.1 SoundVelocityandViscosityfor FluidsCommonlyUsed.............................................................................50

8.2 SoundVelocityfor VariousMaterialsCommonlyUsed..................................................................................50

8.3 SoundVelocityInWater (1 atm)AtDifferentTemperatures..........................................................................51

Update Information:

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page6of51

1TransmitterInstallation and Connection

1.1 PowerSupplyConnections

1.1.1 TypeofPower Supply

The factoryoffers one rechargeable 11.1VLithiumbatteryand matching batterycharger.

1.1.2 Wiring

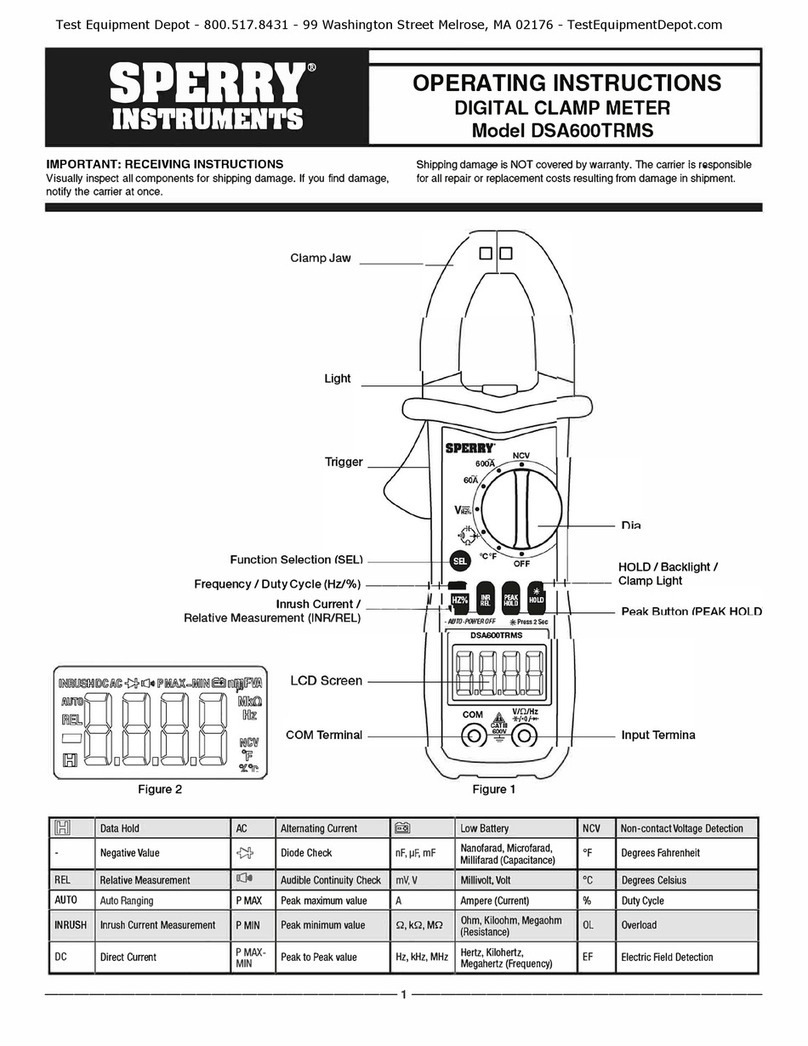

Openthe hinged top coverofthe electronics. The wiring ports ofthe EES-501, fromleft to right, are asfollows:

Downstreamtransducerconnector, upstreamtransducerconnector,SDcard slot, powerswitch, data output

connectorand batteryrecharge port.

Warning

Wiring connectionsshould be made when powerisoff.

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page7of51

1.1.3 DataOutputWiring

Data outputwiring asshownbelow: Firstconnectthe 8-pin plug with the data outputport; afterthese connectthe

ABwith the RS485 Communication, finallygetthe Iwith the 4 ~20mAcurrentoutput.

OCT+OCT- RL1RL2

Dataoutputportto

thetransmitter(8-pin)

ABI+ I-

RS485and4~20mA

Output

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page8of51

1.2 PoweringOn

When the meterispowered on, it will start with the following screen, the Version NumberVer:1.01 andthe Serial

numberS/N:v5200355 will be shown atthe bottomrightcorner.

Ifitisthe firsttime ofuse oran installation on a newsite,the customerneedsto inputthe newinstallation site

parameters. Anyparameters which are setbythe userwillbe saved permanentlyuntil theyare changed bythe

user.

When the usermodifiesthe parameters orremovesthe transducers, the meterwill recalculate automatically, and

operate normallywith the newlysetparameters.

1.3 KeypadFunctions

Followthese guidelineswhen using the flowmeterkeypad:

~and :Inputnumbers.

:Backspace ordelete characters to the left.

and :Return to the lastMenu or

open the nextMenu. Actsas"+"and "-"are used to

enternumbers.

:Selecta Menu. Press thiskeyfirst, inputa

two-digit Menu numberand the selected Menudata

will be displayed. Forexample, in orderto inputa

pipe outside diameter, press

where "11"isthe windowIDto displaythe

pipe outside diameter.

:Enter/Confirm.

:Enter/Exit SDcard storage interface.

are shortcutstothe windowsforFlowRate,

Velocity, SignalQuality, POS Totalizer, waveform, and Diagnosis.

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page9of51

1.4 KeypadOperation

The instrumentsetup and measurementdisplaysare subdivided into more than 100 independentMenus.The

operatorcan inputparameters, modifysettingsordisplaymeasurementresultsby"visiting"a specific Menu.

These Menusarearranged by 2-digit serialnumbers from00~99, then using +0, +1, etc. Each Menu IDcode hasa

defined meaning. Forexample, Menu 11 indicatesthe pipe outside diameter, while Menu 25 indicatesthe

mounting spacing between the transducers.EachMenu will be discussed laterin thismanual.

1.To visit a specific Menu, press the keyatanytime exceptthe SDCard Storage Interface, then inputthe

2-digit Menu IDcode and thatMenu will be displayed. Forexample, to inputorcheck the pipe outside diameter,

press the keysforwindowIDcode 11.

Anothermethod to visit a particularMenu isto press the , and keysto scroll through the

Menus. Forexample, if the currentMenu is30, press key to enterMenu 31, press the button

again to enterMenu 30.

The Menusaredivided into three types:1)Data Type, such asM11, M12;2)Selection Type, such asM14;3)

DisplayType, such asM00, M01.

Visit Data Type Menusto check specific parameters.

Ifparameterchange isneeded, justpress

first, then inputthe valuesand press to

confirm.

Example 1:To enterapipe outerdiameterof

200mm, the procedure isasfollows:

Press to enterMenu11 (the

numericalvalue displayed currentlyisthe previous

pipe outerdiameter). Nowpress the key. The

symbol">"and a flashing cursorisdisplayed on the

screen.The newvalue can nowbe entered.

Visit Selection Type Menusto check the related

options. Ifneed to modifyit,press first to

enterthe revised selection when the symbol">"is

displayed on the screen;orinputnumbers directlyto

selectthe option when the symbol">"and a flashing

cursorare displayed.

Example 2:Ifthe pipe materialis"Carbon Steel",

press to enterMenu 14,

then press to modifythe option. Then,

select"0. Carbon Steel"fromthe drop-down Menu

(you maycycle through the choicesbypressing the

and keys)and then press

to confirmthe selection.

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page10of51

1.5 FlowmeterMenu Descriptions

These windowsareassigned asfollows:

00~09DisplayMenus:Usedtodisplay flowrate, positive total,negativetotal,nettotal, velocity,date

&timeetc.

10~29Setup Menus:Used to enterpipe outerdiameter, pipe wall thickness, fluid type, transducer

type, transducermounting and spacing, etc.

30~38Flowunitsselection and totalizeroperating Menus:Used to selectunitsofmeasurement. OtherMenusset

/resetthe varioustotalizermodes.

40~45Setup Menus:Zero SetCalibration menu, Scale Factormenu, etc.

46~81Inputand outputsetup Menus:currentloop mode select, 4mAor20mAoutputvalue, etc.

90~96Diagnostics:signalstrength quality(Menu 90), TOM/TOS*100 (Menu 91),sound velocity

(Menu 92), totaltime anddelta time ofthe measured signal(Menu 93), Reynoldsnumberand

Kfactor(Menu 94).

-04~20mAcorrection Menu.

Attention

"Hidden"Menusare forhardware adjustment(retained bythe manufacturer).

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page11of51

2TheQuickSetup Description

2.1 DoubleFunction KeysMenu Description

Press to display FlowRate with large font.

Press to display Velocitywith large font.

Press to display SignalQualitywith large font.

Press to displayPOS Total with large font.

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page12of51

Press to displayMetric/English.The function is

the same with .

Press to displaythe CurrentState ofthe

System.

Press to displayPipe Outside Diameter. The

function isthe same with .

Press to displayPipe Wall Thickness.The

function isthe same with .

Menu

3

0

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page13of51

Press to displayPipe Material. The function is

the same with .

Press to displayFluid Type. The function is

the same with .

Press to displayTransducerMounting Methods.

The function isthe same with .

Press to Start /Stop ManualAccumulation

Totalin turn.

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page14of51

Press toDisplay/Hold Totalin turn.

Press to displayTOM/TOS. The function is

the same with .

Press to displayFluid Sound Velocity. The

function isthe same with .

Press to displayDate and Time. The function

isthe same with .

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page15of51

Press to enterManualCalibrate.Afterthe flow

velocitybecomessteady, input standard totalizerto get

the Kfactor. Then press to complete the

calibration.

Press to inputthe password1234 to resetzero.

2.2 For example

ForExample:Letusassume you have a DN150(6")pipe, measuring mediumiswater, Materialiscarbon steel

with no liner. These parameters should be operated asfollows:

Step 1. Pipe OuterDiameter

Press keysto enterMenu 11,

enterthe Pipe Outside Diameter, then press the

key.

Step 2. Pipe Wall Thickness

Press the keyto enterMenu

12 the Pipe Wall Thickness,then press the

key.

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page16of51

Step 3. Pipe Material

Press the keyto enterMenu

14, press the key, use the or

keyto selectthe pipe materialfromthe drop-down

Menu, thenpress the key.

Step 4. Liner MaterialParameters

(including thickness and sound velocity, if needed ):

Press the keyto enterMenu

16, press the key, use the or

keyto selectlinermaterialfromthe drop-down Menu,

and then press the key.

Step 5. FluidType

Press the keyto enterMenu

20, press the key, use the or

keyto selectfluid type fromthe drop-down Menu, then

press the key.

Step 6. Transducer Mounting

Press the keyto enterMenu

24, press the key, use the or

keyto selecttransducer-mounting fromthe drop-down

Menu, thenpress the key.

(Detailson Chapter3.1.1 ).

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page17of51

Step 7. Transducer Spacing

Press the keyto enterMenu

25, accuratelyinstallthe transduceraccording to the

displayed transducermounting spacing and the selected

mounting method.

(Detailson Chapter2.3 ).

Step 8. Display MeasurementResults

Press to enterMenu 01 to

displayflowrate. (Subjectto the realmeasurement. )

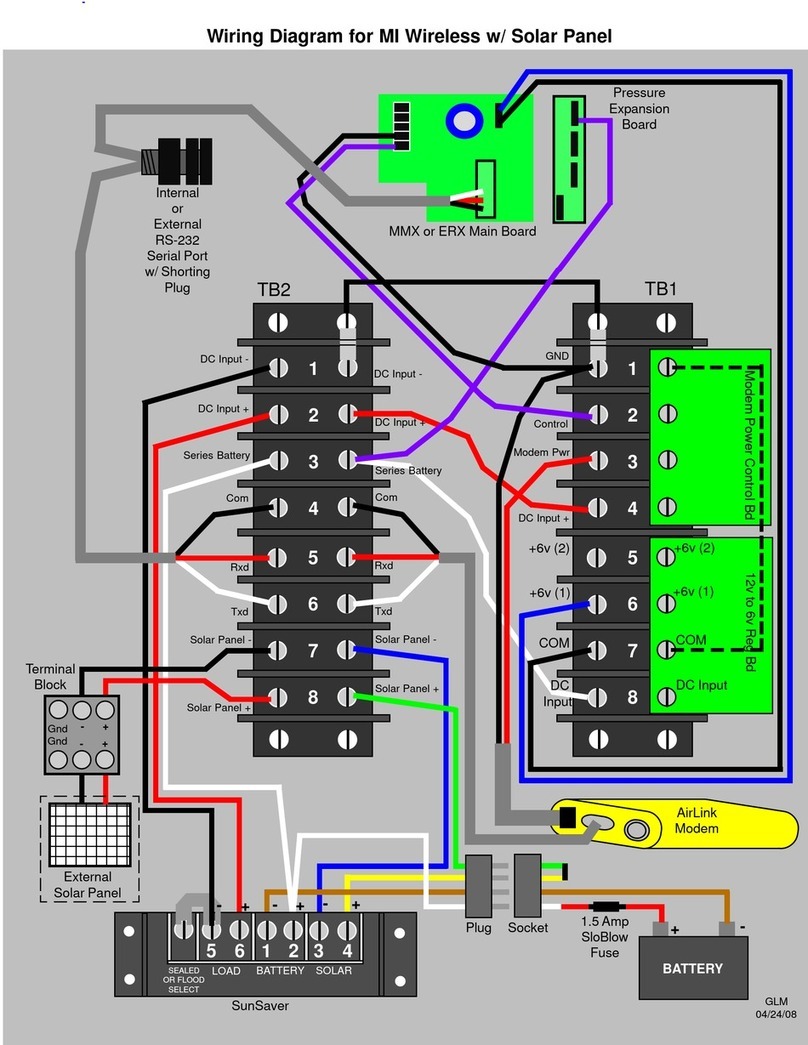

2.3 MeasurementSiteSelection

Compared with otherkindsofflowmeters, Ultrasonic Flowmeteristhe simplestone to install. Choose a proper

measurementsite, enterthe pipe sparameters into the flowmeter.Install and fix the transducers on the pipe as

instructed bythe meterand start the measurement.

When selecting ameasurementsite, it isimportantto selectan area where thefluid flowprofile isfullydeveloped

to guarantee a highlyaccurate measurement. Use the following guidelinesto selecta properinstallation site:

lChoosea section ofpipe thatisalwaysfullofliquid, such asa verticalpipe with flowin the upwarddirection

ora full horizontalpipe.

lEnsure enough straightpipe length atleastequalto the figure shown belowforthe upstreamand downstream

transducers installation.

lOn the horizontalpipe, thetransducershould be mounted on the 3 o clock and 9 o clock position ofthe pipe

section, avoid the 6 o clock and 12 o clock position, in orderto avoid the signalattenuation caused bythe

sedimentatthe bottom, orair bubblesorcavitation.

lEnsure thatthe pipe surface temperature atthe measuring pointiswithin the transducertemperature limits.

lConsiderthe inside condition ofthe pipe carefully.Ifpossible, selecta section ofpipewhere the inside is

free ofexcessive corrosion orscaling.

lChoosea section ofsound conducting pipe.

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page18of51

Pump

Valve

Reduce

Diffuser

Tee

90

o

bend

Straightlength of

downstreampiping

Straightlengthofupstream

piping

Name

Detector

10Dmin

0.5D min

L≥5D

L ≥5D

L≥10D

Flowcontrolleddownstream

10D min

L ≥10D

L ≥5D

L ≥10D

10Dmin

L ≥50D

L ≥30D

D

5Dmin

L≥10D

L≥30D

Flowcontrolledupstream

L≥50D

P

Check valve

Stopvalve

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page19of51

3TransducerInstallation

3.1 InstallingtheTransducer

Before installing the transducers, clean the pipe surface where the transducers are to be mounted. Remove anyrust,

scale orloose paintand make a smooth surface. Choose asection ofsound conductingpipe forinstalling the

transducers.Applya wide band ofsonic coupling compound down thecenterofthe face ofeach transduceras

well ason the pipe surface, ensure there are no air bubblesbetween the transducers and the pipe wall, and then

attach the transducers to the pipe with the strapsprovided and tighten themsecurely.

Note:

1. The two transducers shouldbe mounted atthe pipe scenterline on horizontalpipes.Make sure thatthe

transducermounting direction isparallelwith the flow.

2. During the installation, thereshould be no air bubblesorparticlesbetween the transducerand the pipe wall.

On horizontalpipes, the transducers shouldbe mounted in the 3 o clock and 9 o clockpositionsofthe pipe

section in orderto avoid anyair bubblesinside the top portion ofthe pipe.

3. Referto 2.15 forthe TransducerMounting Spacing.

4. Ifthe transducers cannotbe mounted horizontallysymmetricallydue to limitation ofthe localinstallation

conditions, it maybe necessarytomountthe transducers ata location where there isa guaranteed full pipe

condition (the pipe isalwaysfull ofliquid).

3.1.1 TransducerMountingMethods

Three transducermounting methodsare available. Theyare respectively:Vmethod, Zmethod and Nmethod.

The Vmethod isprimarilyused on small diameterpipes(DN100~300mm, 4"~12"). The Zmethod isused in

applicationswhere the Vmethod cannotwork due topoorsignalorno signaldetected. In addition, the Zmethod

generallyworksbetteron largerdiameterpipes(overDN300mm, 12")orcastiron pipes.

The Nmethod isan uncommonlyused method. Itisused on smallerdiameterpipes(belowDN50mm, 2").

3.1.2 VMethod

The Vmethod isconsidered asthe standard method. Itusuallygivesa more accurate reading and isused on pipe

diameters ranging from25mmto 400mm(1"~16")approximately. Also, it isconvenientto use, butstill requires

properinstallation ofthe transducers, contacton the pipe atthe pipe scenterline and equalspacing on eitherside

ofthe centerline.

3.1.3 ZMethod

The signaltransmitted in a Zmethod installation hasless attenuation than a signaltransmitted with the V

method

when the pipesaretoo large,there are some suspended solid in the fluid, orthe scalingand linerare too thick .

Thisisbecausethe Zmethod utilizesa directlytransmitted (ratherthan reflected)signalwhich transversesthe

liquid onlyonce. TheZmethod isable to measure on pipediameters ranging from100mmto 5000mm(4"to

200")approximately. Therefore, we recommend the Zmethod forpipe diameters over300mm (12").

DownstreamTransducer

UpstreamTransducer

Flow

TransducerSpace

Flow

SideView TopViewSection

PipeStrap

Transducer

EES-501 Ultrasonic Flowmeter

Reversion:3.0.1Page20of51

3.1.4 NMethod (notcommonlyused)

With the Nmethod, the sound wavestraverse the fluid three timesand bounce twice offthe pipe walls. Itis

suitable forsmallpipe diametermeasurement. The measurementaccuracycan be improved byextending the

transit distance with the Nmethod (uncommonlyused ).

3.2 TransducerInstallation andFixing

Transducers can be installed onto the pipe with itsmagnetic racks. Ifyou need to fasten them, then you can use

the chainsto make it firm. Showasbelow:

3.3 TransducerMounting Inspection

Confirmthe transducerisinstalled properlybychecking the detected signalstrength,totaltransit time, delta time

aswell astransit time ratio Key9.

The "mounting"condition directlyinfluencesthe flowvalue accuracyand systemlong-termoperation reliability.

Inmostinstancesit isonlynecessaryapplya wide band ofsonic coupling compound lengthwise on the faceofthe

transducerand stick it to the outside pipe wall to getgood measurementresults. However, the following checks

still need to be carried outinorderto ensure ahigh reliabilityofthe measurementand long-termoperation ofthe

instrument.

DownstreamTransducer

UpstreamTransducer

Flow

TransducerSpacing

Flow

SideView Top ViewSection

PipeStrap

Transducer

DownstreamTransducer

UpstreamTransducer

Flow

TransducerSpacing

Flow

SideView TopViewSection

PipeStrap

Transducer

Table of contents

Other EMERGENT Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Omron

Omron H7CX-R11-N instruction manual

Hanna Instruments

Hanna Instruments HI96709C instruction manual

Applent Instruments

Applent Instruments AT525 user guide

Ludlum Measurements

Ludlum Measurements 700e Series manual

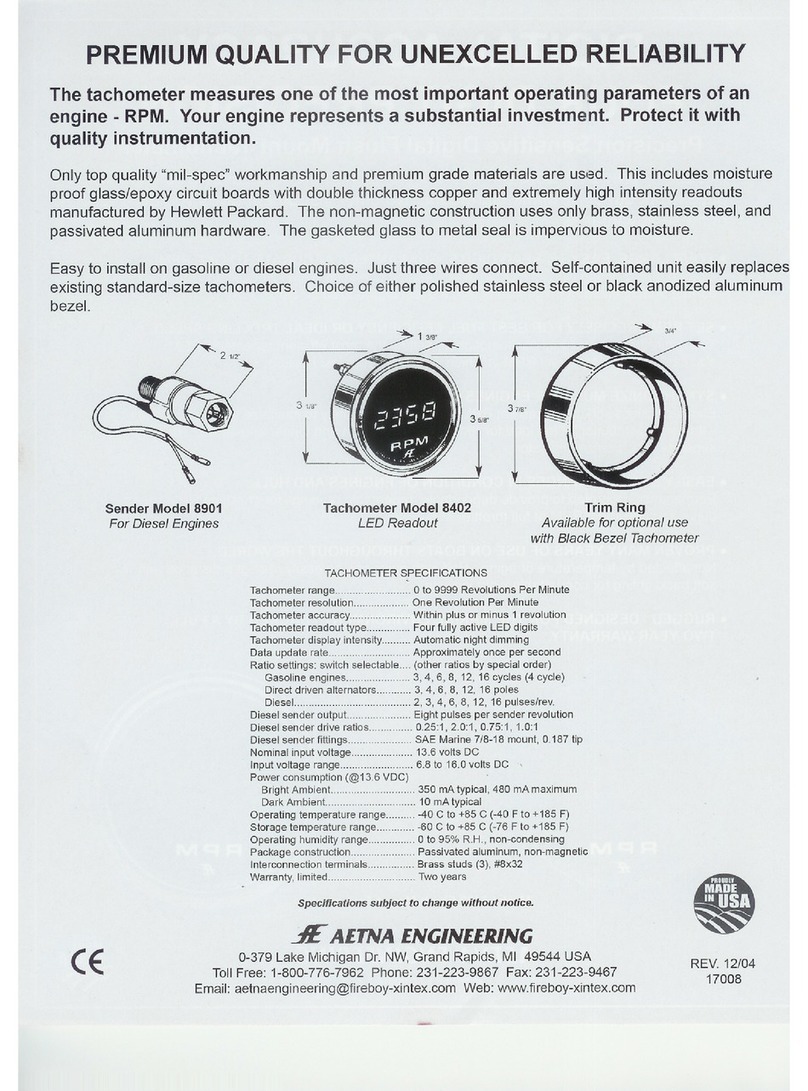

AETNA ENGINEERING

AETNA ENGINEERING 8402 Specifications

Sony

Sony DCR-PC115 Service manual