FloBoss S600 Instruction Manual

Rev Sep/04 Table of Contents iii

TABLE OF CONTENTS

SECTION 1 – GENERAL INFORMATION....................................................................................1-1

1.1 Scope of Manual........................................................................................................................1-1

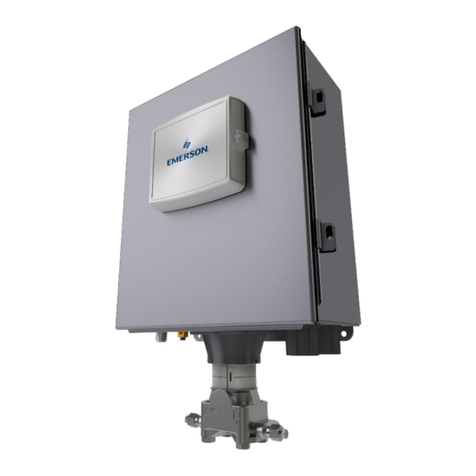

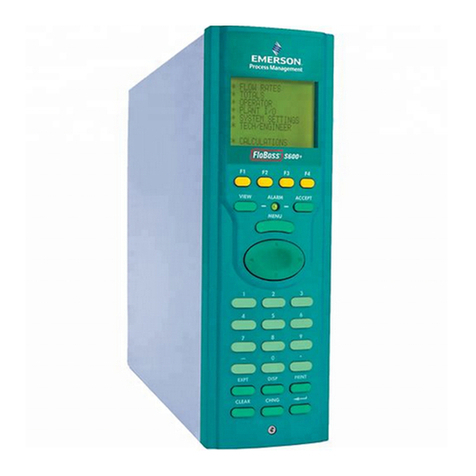

1.2 FloBoss S600 Flow Computer...................................................................................................1-2

1.3 Config 600 Software..................................................................................................................1-5

1.4 FloBoss S600 Specifications.....................................................................................................1-7

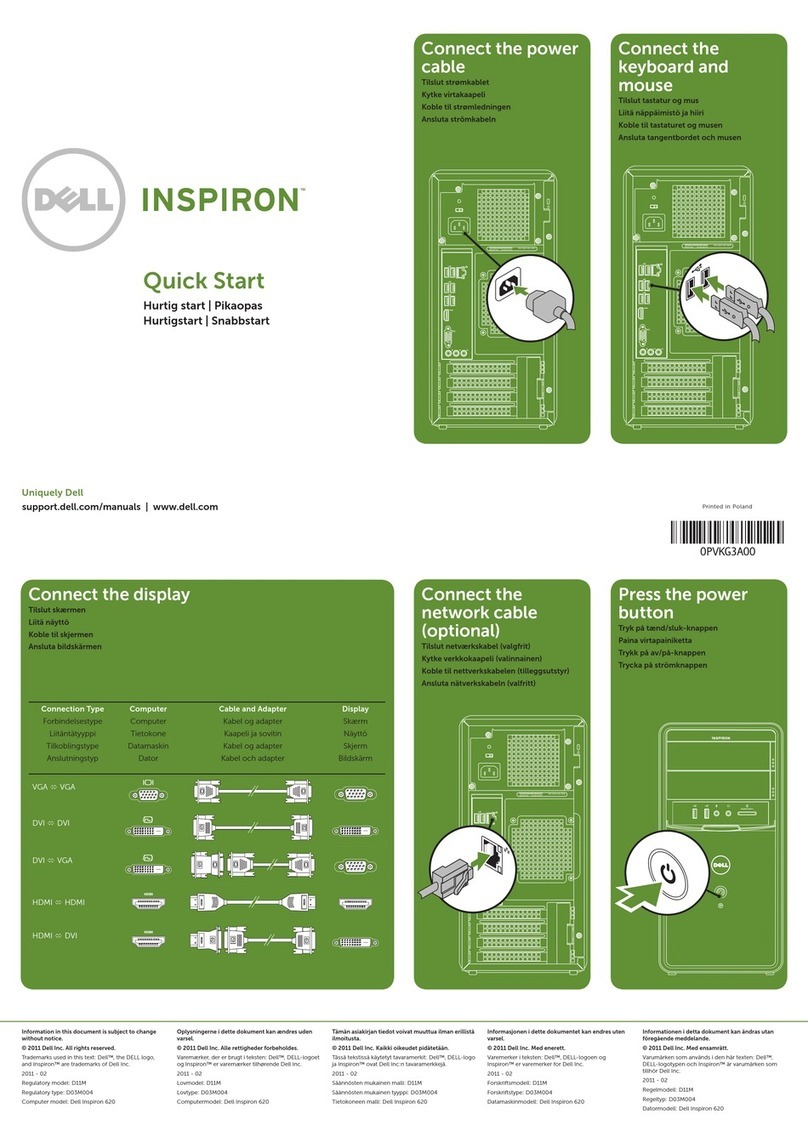

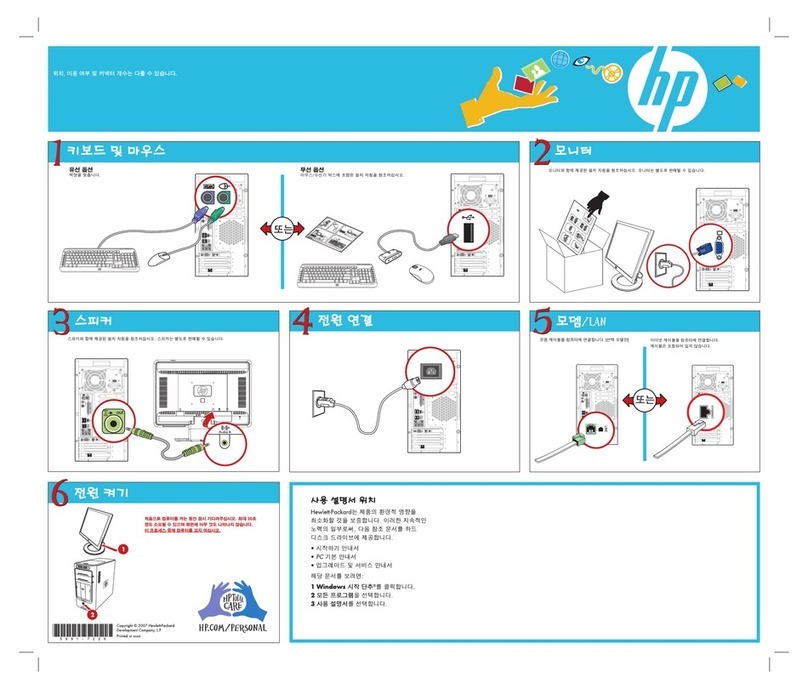

SECTION 2 – INSTALLATION .......................................................................................................2-1

2.1 Preparing for Installation...........................................................................................................2-1

2.2 Environmental Considerations ..................................................................................................2-2

2.3 Required Tools for Installation..................................................................................................2-2

2.4 Installing the FloBoss S600.......................................................................................................2-3

2.5 Installation and Removal of the Boards ....................................................................................2-7

SECTION 3 – CPU..............................................................................................................................3-1

3.1 P152 CPU Board .......................................................................................................................3-1

3.2 Power Supply.............................................................................................................................3-2

3.3 Communication Ports................................................................................................................3-4

3.4 CPU On-Board Connectors.......................................................................................................3-8

3.5 CPU Bit Links (Jumpers) ..........................................................................................................3-8

3.6 Dual Ethernet LAN Port..........................................................................................................3-10

SECTION 4 – I/O ................................................................................................................................4-1

4.1 P144 I/O Board..........................................................................................................................4-1

4.2 P154 Prover Board ..................................................................................................................4-17

4.3 P188 HART Board..................................................................................................................4-24

SECTION 5 – FRONT PANEL..........................................................................................................5-1

5.1 Description ................................................................................................................................5-1

5.2 Front Panel Port.........................................................................................................................5-2

5.3 Keypad.......................................................................................................................................5-2

5.4 Alarm LED and Alarm Keys.....................................................................................................5-3

5.5 Display.......................................................................................................................................5-4

5.6 Navigating the Display..............................................................................................................5-5

5.7 Entering Data.............................................................................................................................5-6

5.8 Assigning a Default Page ..........................................................................................................5-8

5.9 Assigning a Page to a Function Key..........................................................................................5-8

5.10 Using the Exponential Key........................................................................................................5-8

5.11 Using the Print Key...................................................................................................................5-9

SECTION 6 – WEB SERVER ACCESS...........................................................................................6-1

6.1 How to Access the FloBoss S600..............................................................................................6-1

6.2 How to Navigate the Web Server Interface...............................................................................6-2

SECTION 7 – STARTUP ...................................................................................................................7-1

7.1 Starting the FloBoss S600.........................................................................................................7-1

7.2 Warm Start.................................................................................................................................7-1