EMERY MACHINERY CORP. EC-360 User manual

Round Knife Cutter (60mm)

Cordless Electric Shear

OPERATING INSTRUCTIONS

mod. EC-360

Important: Save This Instruction Manual

Charger Operating Instructions Included

Before use

Read this instruction manual

From the library of: Superior Sewing Machine & Supply LLC

SAFETY

INSTRUCTIONS

WARNING! When using

el~ctric

tools, basic safety precautions should always

~e

foll?wed to reduce the rrsk

of

fire, electric shock and personal injury

1nclud1ng the following: '

READ

ALL

THESE INSTRUCTIONS before attempti

ng

to

operate this product

and SAVE THESE INSTRUCTIONS. Keep these operating inst

ru

ctions with this

product.

DOUBLEINSULATED@

The

Do~ble

Insulation @ System replaces the three-wire system e

li

minates

uncertamt~,

.and

all~ws

operation with grounded or ungrounded

p~wer

supp

li

es

While

prov1d1ng

max1mum electrical safety. IMPORTANT! WHEN SERVICING

USE ONLY IDENTICAL REPLACEMENT PARTS! '

1.P<?LARIZED

PLUGS-

This powertool has a

po

l

ari~ed

pl

ug

(one blade is

Wider

t~an

the other) as a feature to reduce the risk

of

electric shock This

plug.wlll fit in

a.

P.olarized outlet only one

way.

If

the plug does not fit,

~ontact

a

qualified electrrc1an to replace the outlet. Never use with an extension cord

unless the plug can be fully inserted. Do not change the plug in any way.

2.KEEP

WORK

AREA

CLEAN -- Cluttered areas and benches invite injuries.

3.

CONSID~R

WORK

AREA

.ENVIRONMENT-- Don't expose powertools to

ram

..Don t use power

t.ools

1n

damp orwet locations Keep work area well l

it.

Don

t use power tools m presence

of

flammable liquids

or

gases.

4.GUARD

AGAINST

ELECTRIC

SHOCK--

Prevent body contact with

grounded surfaces (e.g. pipes, radiators, ranges, refrigerators).

5.

KE~~

CHILDREN AWAY -- Do not let visitors contact tool

or

.extension cord

All

VISitors

should be kept away from work area. ·

6.

~TORE

IDLE

TOOLS

--

When not in use. tools should be stored in a

dry,

h1gh,

or locked-up place, out of the reach

of

children.

7.

DON'~

FORCE

TOOL-

It will do the job better and saferat the rate forwhich

1t was mtended.

8.

USE RIGHT

TOOL-

Don'tforce small tools

or

attachments to do the job

of

a

heav~

duty tool. Don't use tools for purposes not intended; for example, don't

use Circular saw for cutting tree limbs

or

logs.

9.

ORES~

PRO~ERLY-

Do notwear loose clothing orjewel

ry

. They can be

caught m

mov1ng

parts. Rubber gloves and non-skid footwear are

recommended when working outdoors. Wear protective hair covering to

contain long hair.

10. USE SAFETY

GLASSES--

Also use face or dust :nask

if

cutting is dusty.

Al.ways

wear

sa.fety goggles

or

safety glasses with side shields, complying

With

current national standards and a full face shield, when needed.

2

11. DON'T ABUSE CORD

--Never

carry tool by cord

or

yank it to disconnect it

from receptacle. Keep cord away from heat, oil and sharp edges.

12. SECURE

WORK--

Use clamps or a vise to hold work. It's safer than using

your hand and it frees both hands to operate tool.

13.

DON'T

OVERREACH--

Keep proper footing and balance at all times.

14. MAINTAIN TOOLS WITH

CARE--

Keep tools sharp and clean for better

and safer performance. Follow instructions for lubricating and changing

accessories. Inspect tool cords periodically and, ifdamaged, have repair

ed

by Authorized Service Center. Inspect extension cords periodica

ll

y

and

replace if damaged. Keep handles dry, clean and free from oil and grease.

15. DISCONNECT

TOOLS--

When not in use, before servicing, and when

changing accessories such as blades, bits and cutters.

16. REMOVE ADJUSTING KEYS AND

WRENCHES--

Form the habit of

checking to see that keys and adjusting wrenches are removed from to

ol

before tu

rn

ing it on.

17. AVOID UNINTENTIONAL

STARTING--

Don't carry plugged-in tool with

finger on switch. Be sure switch is offwhen plugging in.

18. OUTDOOR USE EXTENSION CORDS

--When

tool is used outdoors. use

only extension cords intended for use outdoors and so marked.

19. STAY

ALERT--

Watch what you are doing. Use common sense. Do not

operate tool when you are tired.

20. CHECK DAMAGED PARTS

--Before

further use

of

the too

l,

a guard or

other part that is damaged should be carefully checked to determine that it

will operate properly and perform its intended function. Check for alignment

of

moving parts. binding

of

moving parts, breakage of parts. mounting, and

any otherconditions that may affect its operation. A guard or other part that

is damaged should be properly repaired or replaced by Authorized Service

Center, unless otherwise indicated elsewhere in this instruction manual.

Have defective switches replaced by Authorized Service Center. Do not use

tool if switch does not turn it on and off.

If

tool has

.::i

lock-on switch be sure

it

releases freely from lock-on position.

IMPORTANT SAFETY INSTRUCTIONS

FOR BATTERY CHARGER

SAVE THESE INSTRUCTIONS

21

. This manual contains important operating instructions for battery charger

MODEL EC-360-04.

22

. Before

us

i

ng

battery charger, read all instructions and cautionary markings

on (1) battery charger, (2) battery and (3) product using battery.

3

From the library of: Superior Sewing Machine & Supply LLC

23.

CA

UTION • To reduce risk

of

injury, charge only rechargeable

batteries. Othertypes

of

batteries may burst, causing personal injury and

damage.

24.

Do not expose charger to rain

or

snow.

25.

To

reduce risk

of

damage to electric pl

ug

and cord, pull by plug rather than

cord when disconnecting charger.

26.

Make

sure charger cord is located so that

it

will not be stepped on, tripped

over

or

otherwise subjected to damage

or

stress.

27

. An extension cord should

not

be used on the battery charger unless

absolutely necessary.

Use

of

improper extension cord could result in a risk

of

fire and electric shock.

If

extension cord must be used, make sure:

a) that pins on plug

of

extension cord are the same number, size and shape

as those

of

plug on charger.

b)

that extension cord is properly wired and in good electrical condilion, and

b)

that wire size is large enough for AC ampere rating

of

charger as

specified below:

RECOMMENDED MINIMUM AWG SI

ZE

FOR

EXTENSION CORDS FOR BATTERY CHARGERS

L

ength

of c

ord

in meter

(f

eet)

7.6m(25') 15m(50')

30m(1

00') 45m(150')

18

ga.

18

ga.

18

ga.

16

ga.

28. Do notoperate charger with damaged cord

or

plug; have them replaced

immediately.

29. Do notoperate charger

if

it

has received a sharp blow, been dropped

or

otherwise damaged in any way; take it to

an

EMERY Authorized Service

Center.

30.

Do not disassemble charger; take

it

to an Authorized Service

Center when service

or

repairis required. Incorrectreassembly may result in

a risk

of

electric shock

of

fire.

31.

To reduce risk

of

electric shock, unplug charger from outlet before

attempting any maintenance

or

clearing. Turning

off

controls will not reduce

this risk.

SAVE THESE INSTRUCTIONS

SPECIAL SAFETY INSTRUCTIONS FOR THE ROTARY

SHEAR

1. Keep gu

ar

ds in place and in working order •

Neverwedge

or

tie finger guard open. Check operation

of

finger guard before

be

for

e each use. Do not use

if

finger guard does not close over rotary shear

sew blade.

CAUTION:

If

the rotary shear is dropped, finger guard may be bent, restricting

full return. 4

2.

Keep blades clean and sharp •

• Sharp blades minimize stalling.

3.

DANGER: keep hands away from cutting area- .

• Keep hands away from blades. Do not reach beneath workwhile blade 1s

rotating. Do not attempt to remove cut material when blade is moving.

CAUTION: Blade coasts after turn off.

4.

Don't force tool.

• Stay alert; exercise control. . .

• During a cut, don't remove shear from work while the blade IS movmg.

5.

Finger Guard ·

•

To

avoid accidents never expose excessive blade.

L~wer

the finger guard so

that the material being cut justclears guard.

6.

Adjustments - . .

• Before cutting, be sure the finger guard lock nut IS

t1ght.

7.

Use only the correct blades in

mounting·

· . .

• Do not use blades with incorrect size holes. Never use defective

or

mcorrect

blade washers

or

bolts.

SAVE THESE INSTRUCTIONS

5

From the library of: Superior Sewing Machine & Supply LLC

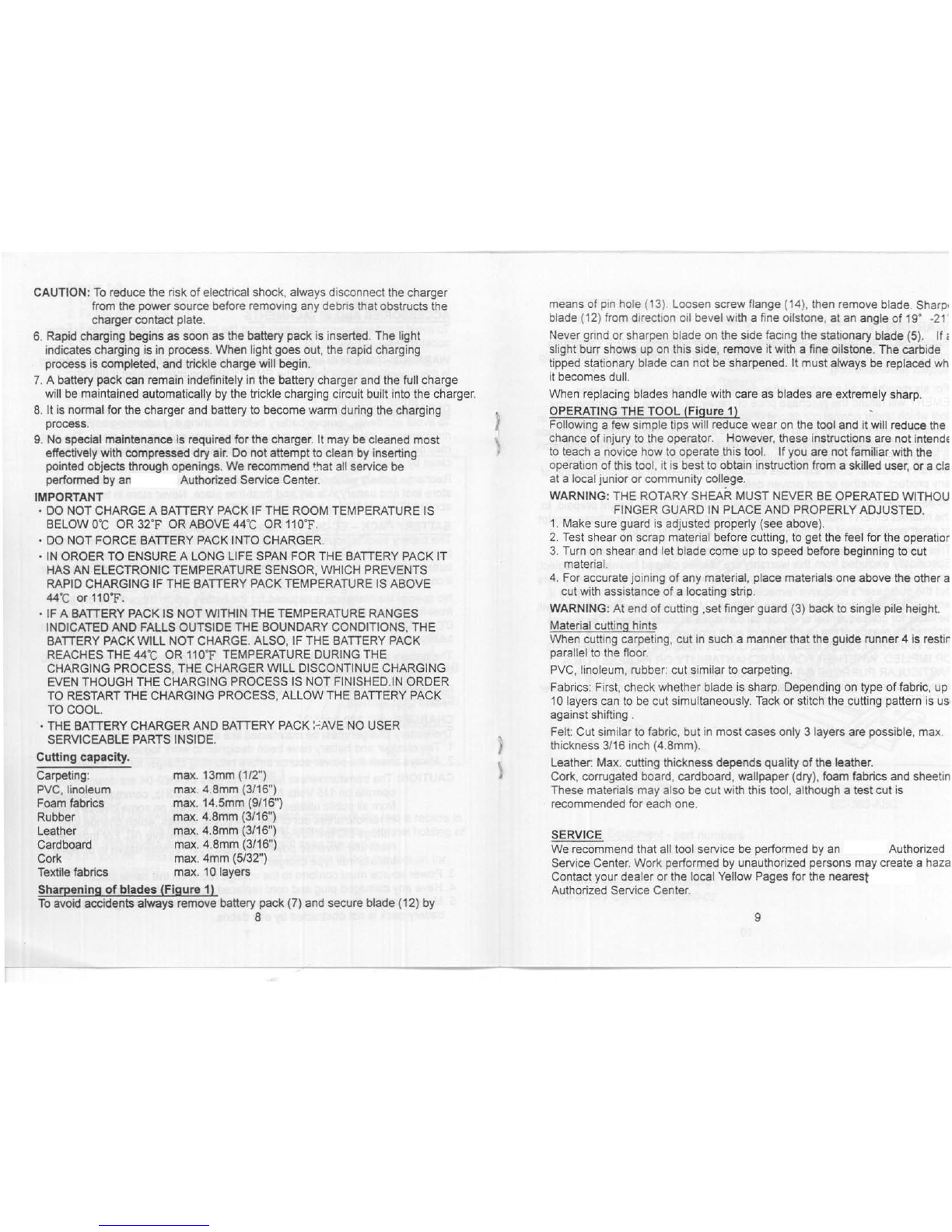

Figure 1-3

1. Oil hole (not illustrated)

2. Finger guard lock nut

3. Finger guard

4.

Guide runner

5.

Stationary blade

6.

Holding spring clip

7. Battery pack

8.

On I

Off

switch

9. Spring

10

. Blade lubricating felt

3---.../

4 ------'"-..:..--/"

5------J

SWITCHES

11

. Drive flange

12. Blade

13. Pin hole

14. Screw flange

15.

Upperguard bushing

16. Upper guard

17. Screw

18. Sharpening stone

19. Sharpening stone holder

20. Bracket

..........

~~FY

------

8

.---

----9

10

----

--

11

Figure

1

16 17

Pull back on the switch (8) to start tool. Switch trigger will slip into a recess in

motor housing. This helps hold it on against spring tension. Normal holding

of

the tool with fingers around switch trigger will keep the switch on.

To

turn tool off, release switch. There is no provision to lock the tool on for

continuous running.

6

ACCESSORIES AND ATTACHMENTS

To

avoid accidents, remove battery from the tool while installing blade or other

accessories.

WARNING

-The

use of any accessory or attachment other than recommende

in this operating instruction catalog may present a risk of

personal injury.

CLEANING AND CARE

To

avoid accidents, remove battery before cleaning or performing any

maintenance. Always see that the ventilation openings are kept clean. The too

may be cleaned most effectively with compressed dry a

ir.

Do notattempt to

clean by inserting pointed objects through openings

Recharge battery periodically to keep ready for operation. When not

in

use,

store tool and battery in a dry and frost-free place. Never store in temperature!

above44

·c

or

110·F or below o·c or 32.F.

BATTERY PACK -EC-360-03 (Figure

1,

position 7)

The battery pack

1s

housed 1n the handle

of

the motor housing.

To

remove the

battery pack, release the holding spring clip (Figure 1 -position 6) and pull the

battery pack out. Do not force the battery pack out.

If

the battery pack is hot.

le

it cool before removing from the housing.

No special maintenance is required for the battery pack. Store it in a dry and

frost-free place. Never store in temperatures above 44•c or 110•F or below

o·c or 32"F.

If

the battery pack has a warped or swollen plastic housing, it

mw

be replaced.

The battery pack will charge in about 1 hour. It can be recharged more than 30

times: however, misuse or abuse can shorten its life expectancy.

IMPORTANT: DO NOTTRY TO CHARGE BATTERY PACK IF

IT

IS HOT

FROM DISCHARGE.

CHARGER -EC-360-04

The battery charger must be maintained like any electronic device.

1. The charger and battery have been designed to work together.

2. Always check the power source before returning charger for any repair.

CAUTION: The transformerless battery chargers EC-360-04 are designed to

operate on 115 Volts AC, 60Hz, or

230\1,

50Hz, commonly available

from all public utilities. They will notoperate on some inverters foun

in remote areas out

of

reach of public utilities, which change low-

voltage

DC

to 115V or 230V modified sine-wave AC. Forthose whc

must use "inverted power", contact your representative to obtain a

transformer type charger.

3. Power source must conform to the voltage rating on the name place.

4. Have any damaged plug and cord replaced immediately by a service center.

5. Make sure that the contact plate connection between the charger and the

battery pack is not obstructed by any debris.

7

From the library of: Superior Sewing Machine & Supply LLC

CAUTION:

To

reduce the risk

of

electrical shock, always disconnect the charger

from the powersource before removing any debris that obstructs the

chargercontact plate.

6.

Rapid charging begins as soon as the battery pack is inserted. The light

indicates charging is in process. When lightgoes out, the rapid charging

process is completed, and trickle charge will begin.

7.

A battery pack can remain indefinitely in the battery charger and the full charge

will be maintained automatically by the trickle charging circuit built into the charger.

8.

It is normal forthe charger and battery to become warm during the charging

process.

9. No special maintenance is required forthe charger.

It

may be cleaned most

effectively with compressed dry air. Do not attemptto clean by inserting

pointed objects through openings.

We

recommend

~~at

all service be

performed by an Authorized Service Center.

IMPORTA

NT

•

DO

NOT CHARGE A BATTERY PACK IF THE ROOM TEMPERATURE IS

BELOW

o·c

OR 32•F OR ABOVE 44•c OR 110

·F.

• DO NOT FORCE BATTERY PACK INTO CHARGER.

• IN OROER TO ENSURE A LONG LIFE SPAN FOR THE BATTERY PACK IT

HAS AN ELECTRONIC TEMPERATURE SENSOR, WHICH PREVENTS

RAPID CHARGING IF THE BATTERY PACK TEMPERATURE IS ABOVE

44·c

or

110r.

• IF A BATTERY PACK IS NOTWITHIN THE TEMPERATURE RANGES

INDICATED AND FALLS OUTSIDE THE BOUNDARY CONDITIONS, THE

BATTERY PACK

WILL

NOT

CHARGE. ALSO, IF THE BATTERY PACK

REACHES THE 44•c OR 110•F TEMPERATURE DURING THE

CHARGING PROCESS, THE CHARGER WILL DISCONTINUE CHARGING

EVEN THOUGH THE CHARGING PROCESS IS NOT FINISHED.IN ORDER

TO RESTART THE CHARGING PROCESS, ALLOW THE BATTERY PACK

TO COOL.

• THE BATTERY CHARGER AND BATTERY PACK :-:AVE

NO

USER

SERVICEABLE PARTS INSIDE.

Cutting

capacity.

Carpeting:

PVC, linoleum

Foam fabrics

Rubber

Leather

Cardboard

Cork

Textile fabrics

max. 13mm (1/2")

max. 4.8mm (3/16")

max. 14.5mm (9/16")

max. 4.8mm (3/16")

max. 4.8mm (3/16")

max. 4.8mm (3/16")

max. 4mm (5/32")

max. 1

0 layers

Sharpeni

ng

of

blades

(Figur

e

1)

To

avoid accidents always remove battery pack (7) and secure blade (12) by

8

means

of

pin hole (13

).

Loosen screw flange (14), then remove blade. Sharp•

blade (

12

) from direction oil bevel with a fine oilstone, at an angle of 19•

-21

Never

gr

ind or sharpen blade on the side facing the stationary blade (5). If<

slight burrshows up on this side, remove it with a fine oilstone. The carbide

tipped stationary blade can not be sharpened. It must always be replaced

wh

it becomes dull.

When replacing blades handle with care as blades are extremely sharp.

OPERATI

NG

THE TOOL (F

igure

1)

Following a few simple tips will reduce wearon the tool and itwill reduce the

chance of injury to the operator. However, these instructions are not i

ntendE

to teach a novice how to operate this tool.

If

you are not familiar with the

operation of this tool, it is best to obtain instruction from a

sk

illed user,

or

a

cia

at a local junioror community college.

WARNING: THE ROTARY SHEAR MUST NEVER BE OPERATED WITHOU

FINGER GUARD IN PLACE AND PROPERLY ADJUSTED.

1.

Make sure guard is adjusted properly (see above).

2.

Test shear on scrap material before cutting, to get the feel for the operatior

3.

Turn on shear and let blade come up to speed before beginning to cut

material.

4.

Foraccurate joining of any material, place materials one above the other a

cut with assistance

of

a locating strip.

WARNING: At end

of

cutting ,set finger guard (3) back to single pile height.

Material cutting hints

When cutting carpeting, cut in such a manner that the guide runner 4 is rest

ir

parallel to the floor.

PVC, linoleum, rubber: cut similar to carpeting.

Fabrics: First, check whether blade is sharp. Depending on type

of

fabric, up

1

0 layers can to be cut simultaneously. Tack or stitch the cutting pattern is

us

•

against shifting .

Felt: Cut similar to fabric, but in most cases only 3 layers are possible, max.

thickness 3/16 inch (4.8mm).

Leather: Max. cutting thickness depends quality

of

the leather.

Cork, corrugated board, cardboard, wallpaper (dry), foam fabrics and sheetin

These materials may also be cutwith this tool, although a testcut is

recommended for each one.

SERVICE

We

recommend that all tool service be performed by an Authorized

Service Center. Work performed by unauthorized persons may create a haza

Contact yourdealer or the local Yellow Pages for the nearest

Authorized Service Center.

9

From the library of: Superior Sewing Machine & Supply LLC

WARRANTY

Applicable to all countries. Supersedes any other warranty. warrants

new power tools sold by itto be free from defects

in

material and workmanship

subject to the following:

For six months

in

all countries, after delivery to the first using purchaser,

will refund the purchase price of, repair, or replace, at its option, any

tool which under normal conditions

of

use and service proves to be defective

in

material orworkmanship at no charge to the purchaser. No charge will be made

for labor with respect to defects covered by this warranty, provided that the work

1s done by or any

of

its authorized service facilities. However, this

warranty does not coverexpenses incurred

in

the removal and reinstallation

of

any product, whether or not proven defective.

To

obtain performance of this warranty, return the tool intact, freight prepaid, to

the

nearest Authorized Service Centeralong with the purchase receipt

or other positive proof that the tool is within the warranty period.

This warranty is limited to the first using purchaserana is not transferable.

Specifically excluded from this warranty are failures caused by misuse, neglect,

abuse. improper operation, or unauthorized service or parts. This warranty sets

out the purchaser's exclusive remedies with respect to products covered by

it,

whether for negligence or otherwise. Neither nor any of its affiliates will

be liable for consequential or incidental damages orother losses or expenses

mcurred by reason

of

the use of sale

of

such products.

THIS WARRANTY

IS

IN

LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR

IMPLIED, WHETHER FOR MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE OR OTHRWISE. No attempt

to

alter, amend or

extend this warranty shall be effective unless authorized

in

writing by an Officer

of company.

10

S

PE

CIFICATIO

NS

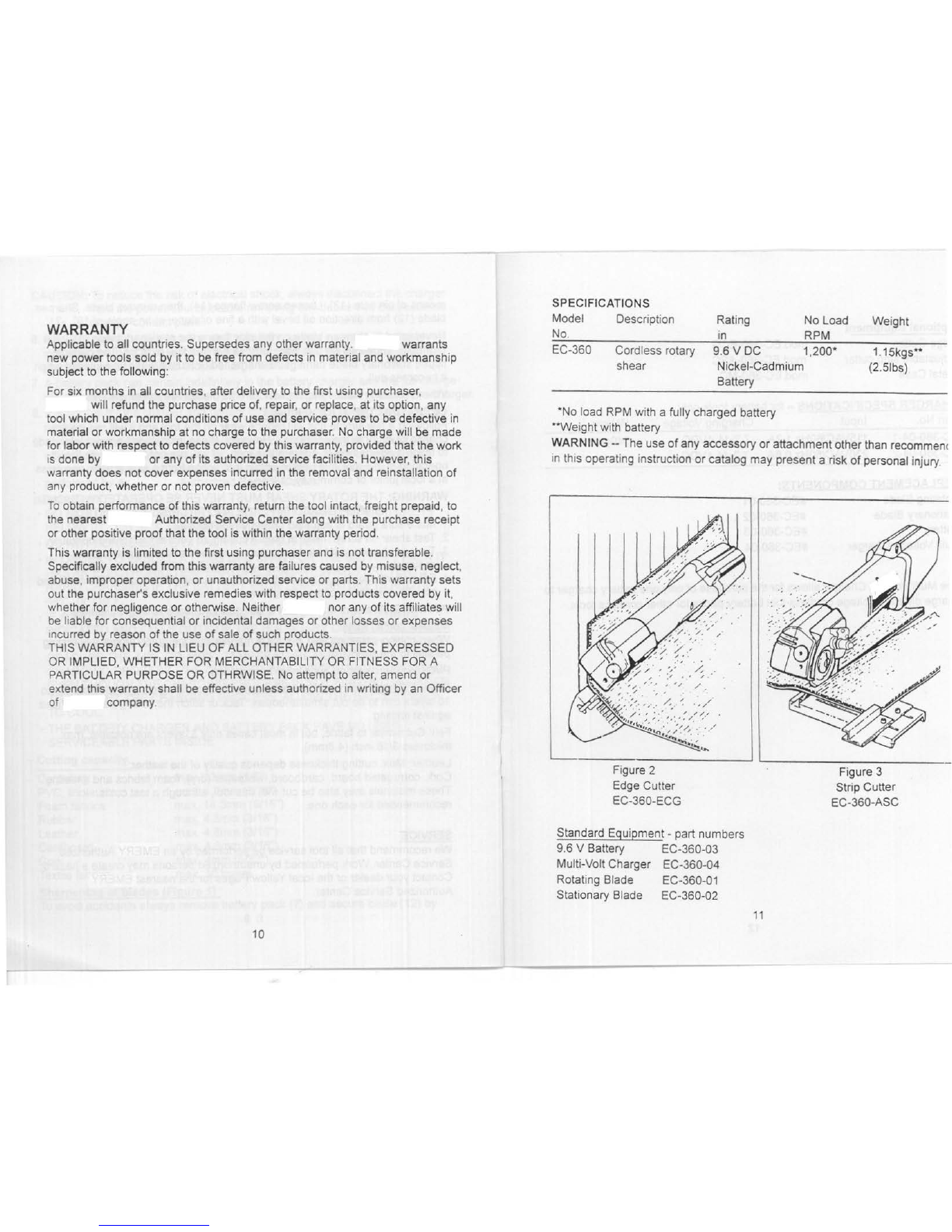

Model Description Rating

No. in

EC-360 Cordless rotary 9.6 V

DC

shear Nickel-Cadmium

Battery

·No load RPM with a fully charged battery

··weight

with battery

No Load Weight

RPM

1,200" 1.15kgs

....

(2.51bs)

WA

RN

ING

--The

use ofany accessory or attachment other than recommenc

in

th

is operati

ng

instruction

or

catalog may present a risk

of

personal injury.

Figure 2

Edge Cutter

EC-360-ECG

Standard Equipment -part numbers

9.6 V Battery EC-360-03

Multi-Volt Charger EC-360-04

Rotating Blade EC-360-01

Stationary Blade EC-360-02

11

Figure 3

Strip Cutter

EC-360-ASC

From the library of: Superior Sewing Machine & Supply LLC

Optional

Equipment

Edge Cutter

Adjustable strip cutter

Metal Case

mod

EC-360-ECG

mod.EC-360-ASC

mod

EC-360-MC

CHARGER SPECIFICATIONS -for battery tools only

Part No. Input Charging Voltage

EC-360-04-1 115VAC/60Hz.1.2A 7.2-14.4VDC

EC-360-04-2 230VAC/50Hz.0.6A 7.2-14.4VDC

REPLACEMENT COMPONENTS:

Rotating Blade #EC-360-01

Stationary Blade #EC-360-02

Battery #EC-360-03

Multi Voltage Charger #EC-360-04

Weight

340grams

The Multi Voltage Chargerallows for the purchase of only one battery charger to

charge differentvoltage cordless tool battery packs for othercordless tools.

12

From the library of: Superior Sewing Machine & Supply LLC

Nickel

Cadmium

Battery

Care

&

Disposal

@

Ni-Cd

This nickel c:::dmium battery must

be

collected,recycled.

or

disposed

of

in an environmentally sound manner.

Do

not

place used batteries in your regular trash. The

incineration,landfilling,or mixing of nickel cadmium bat-

teries with municipal solid waste streams

is

prohibited

by law

in

most areas.

Return depleted batteries

to

an authorized power tool

service center

or

other State Municipal approved battery

collection center. Contact your local waste management

Item

No.EC-360-03

(9.6VDC)

author

ity for

specific

locations and additional informa-

tion

regarding

the

environmentally

sound

collection,

recycling, and disposal

of

nickel cadmium batteries.

~~

Do not expose the tool or battery

to

fire

~

or

high

heat

as

batteries

may

ex-

plode. Care must

be

t

CJken

not

to

short terminals together

with mental objects; jewel

ry,

keys, nai

ls,

screws, etc.

Do

not attempt to disassemble battery. .Fire

or

injury may

result.

Prior

to

disposal

protect

terminals

with

heavy

insulating tape to prevent shorting.

...

-----------------------------------------------------------------------------------------------~

From the library of: Superior Sewing Machine & Supply LLC

Table of contents