Emery Winslow 7600E Quick guide

1

Configuration and Setup

V4.31

Model 7600E

Digital Weight Display

2

TABLE OF CONTENTS

SPECIFICATIONS....................................................4

DIMENSIONS……………………………………………5

INSTALLATION.........................................................6

SETUP ACCESS ......................................................7

MENU LAYOUT........................................................8

CONFIGURATION....................................................9

CALIBRATION........................................................11

REMOTE SERIAL DISPLAY...................................12

SERIAL PORTS ....................................................14

SERIAL COMMANDS.............................................15

ANALOG OUTPUT .................................................17

DIGITAL INPUT/OUTPUT.......................................18

SETPOINTS, BATCHING .......................................19

SERIAL COMMUNICATION (Setpoint/Accumulator).38

TIME & DATE..........................................................39

WEIGH IN/OUT.......................................................40

TEN POINT LINEARIZATION ……………………..43

TOTALIZER (Accumulator) ……………………….…43

SMART SERIAL......................................................44

DISPLAY MESSAGES............................................52

115/220 VAC...........................................................53

SPARE PARTS.......................................................54

DIGITAL CONFIGURATION RECORD...................55

3

Alternate Packaging for

extreme wash-down and with

Totalizer in common enclosure

Emery Winslow Scale Company

73 Cogwheel Lane 4530 North 25th Street

Seymour, CT 06483 Terre Haute, IN 47805

(203) 881-9333 (812) 466-5265

(203) 881-9477 FAX (812) 466-1046 FAX

4

SPECIFICATIONS

LOAD CELL A/D CONVERTER

TYPE: 24 bit delta sigma (1:16,777,216)

EXCITATION: 5 VDC, 120 mA max.

SIGNAL INPUT: 16 mv

SENSITIVITY: 0.1 uV/grad

UPDATE RATE: 30 update/second

DISPLAY: Six (6) Decades, 0.6 inch LED

KEYPAD: Full numeric plus controls

POWER INPUT: 117/217 VAC, 50‑60 HZ, 20 watts, fuse 0.50 A Slo-Blow.

SERIAL PORTS:

Port 1: RS232C or 20ma

Port 2: RS485, RS232C or 20mA.

Smart Serial Setup: 8 custom print files plus 8 macro files, 30 characters each.

Batch Start/Stop: Control from front panel or remote input.

Setpoint Operation: 4 output relays configurable for normal setpoints,

over/under or manual/auto batch modes.

TIME & DATE: 12/24 hr, battery backed.

ENCLOSURE: Stainless Steel, NEMA 4X, Tilt-Stand Base, 7lbs.

CASE: 8.82” (w) x 6.31” (h) x 4” (d) Tilt or panel mount.

NRTL: Met Labs file E112367 certified to UL60950-1, CAN/CSA-C22.2 60950-1-03

NTEP: Class III/IIIL, 10,000 divisions CoC 97-009A4

OPTIONS:

ANALOG OUTPUT: 0-10v, 4-20ma (16 bit D/A).

DIO: 4 AC/DC –inputs, 4 AC/DC outputs (SS Relays, 0.5 amp)

ETHERNET TCP/IP

DUAL CHANNEL

5

DIMENSIONS

6

CalSwitch SW-4

TB-1

———-1——–Signal +

———-2——–Signal -

———-3-——Sense -

———-4—— Excitation -

———-5——-Sense +

——-—6——-Excitation +

SenseJumpers

Option Header

Analog Output

A/DRFIShield

Software Version#

VX.XX

INSTALLATION

POWER WIRING: The indicator is designed to be operated from 117/217 VAC,

50‑60 Hz. The unit power cord must be plugged into a grounded 3 ‑wire polarized

AC wall socket. All normal wiring and grounding precautions should be observed,

including use of a "clean" AC power line.

SCALE WIRING: The unit is equipped with cable gland entry for load cell cable

insertion and internal (pluggable) terminal strip for 4 / 6 wire connection.

Remove sense jumpers P11-8/7, P11-6/5 for six wire.

7

SETUP ACCESS: To access instrument configuration, calibration or to enable op-

tions, depress the “ZERO” key for five seconds.

The Audit Trail counters (“Pxxxx” and “Cxxxx”) are displayed first followed by access

code request (“AC?”). The initial factory setting is “0000” which is entered with four

numeric “0”’s and enter (“ENT”). If no entry is made, instrument returns to operate

mode. The “Master” access code is “1042”.

The access code can be changed to any four digit combination during setup exit

when display again shows “AC?” or skip with ENT to continue with no change,

The “CHECK” key provides the software version “V X.XX” followed by the display

test routine. Use the “ENT” key to advance to the keyboard test and to exit tests.

After entry, use the “TARE RECALL” key to select a main menu; Configuration

(“SEL.CFG”), Calibration (“SEL.CAL” or “SEL.CL1”), or Options (“SEL.OPX”)

and “START/STOP” to back step.

The “GROSS/NET” key enters selected menu and is used to step through sub

categories. Individual parameter selection is made with the “TARE RECALL” key,

which then steps through the parameter choices (“ZERO” key back steps within the

menu).

The “ENT” key is used at any point to “back” up from categories to menus and to

“save?” and “AC?” and exit.

During the exit steps, if changes were made, the display is “save?” with alternate

“no”. To save changes, use the “UNITS” key to select “yes” and “ENT” to exit.

Calibration numeric entries are entered directly followed with the “ENT” key.

Front panel access is inhibited if conventional “sealing” is applied by setting jumper

J1-1 in the B position. The board mounted “CAL” button is then used for access.

8

MENU LAYOUT (SEL.XXX)

CFG

Configuration: Divisions, count by, decimal, over range, filter, AZM,

zero range, motion, lb/kg, tare select, serial port selection, digital

input enable, remote display, test mode, dual channel sum.

CL1

Calibration: Zero, Span (Earlier units have ‘CAL’ prompt)

OP1

Analog Output

OP2

Setpoint - Digital I/O

OP3

Time and date

OP4

Weigh-IN / Weigh-OUT Truck mode

OP5

10 point linearity, Filter select, Range select

OP6

Accumulator

OP7

Smart Serial

OP8

AC/DC Battery

OP9

Consult Factory

9

CONFIGURATION: “SEL.CFG”

1. Press and hold the ‘ZERO’ button for 10 seconds until a ‘P XX’ is displayed,

then release. [Note: Limited configuration parameters (non-metrological) can

be accessed by pressing and holding ‘PRINT/7’ key for 4 seconds.]

2. Wait for ‘C XX’ prompt, then the Access Code ‘AC ?’ prompt. Enter four (4)

zeros ‘0000’ using the numeric keypad, press ‘ENTER’.

3. Press the ‘TARE RECALL’ button repeatedly until ‘SEL.CFG’ is displayed.

4. Press the ‘GROSS/NET’ button to enter into the Configuration mode. (1_

XXXX will be displayed indicating you are viewing Parameter 1.)

5. Use the ‘GROSS/NET’ button to scroll through Parameters 1 through 50. (All

parameters may not be displayed, depending on setup.)

6. Change any given Parameter with the ‘TARE RECALL’ button. (Scrolling

function, selections wrap around if you have gone past the intended value.)

7. Once all Parameter values have been set, press the ‘ENT’ button to exit Edit

mode. (SEL.CFG’ will be displayed.)

•To exit and save: Press the ‘ENT’ button. ‘Save Y/N’ is displayed – press the

‘UNITS/4’ button to change the selection to ‘Y’, press ‘ENT’ to save, then ‘ENT’

again at the ‘AC ?’ prompt to exit, keeping the Access Code the same. (‘AC’

prompt is not displayed if no changes were made.)

Note: for firmware versions 4.29.0 and earlier, Capacity is the combination of “1”, “2”

and “3”. (Press the CHECK key to view version, ENTER 3 times to escape)

Parameter

Settings

Definition

1

5, 10, 15, 20...100, 120...1000

Number of divisions x100 ,100 =

10,000 divisions

2

1, 2, 5, 10, 20, 50, and 100.

Count by selection10,000 divisions,

count by 2 = 20,000

3

0, 0.0, 0.00, 0.000, and 0.0000

Decimal point selection

Firmware versions 4.30 and later:

Parameter

Settings

Definition

1

1000, 2000, 5000, 10000, etc

Scale Capacity

2

0.001, 0.002, 0.005 …100, 200, 500

Scale Resolution

3

N/A

N/A

4

105P, 9 d (105% or 9 divisions)

Overrange selection

10

5

1, 2, 3, 4, 5, 6, 8, 10, 12, 15...90

Digital filter selection

(averaging)

6

off, 0.5, 1, 3, 5, 10 (divisions)

Auto Zero Maintenance (AZM)

7

1.9, 5, 10, 20, FS (% of capacity)

Zero range selection:1.9% of 2,000 x

0.2 = 38.0 lb

7.1

off, on (ISM)

Zero’s scale on power-up

8

off, 1, 3, 5,10 (divisions)

Motion Band selection

9

lb, kg, con

Units selection and convert

9.1

Of, At, Tr, On

Off, Auto Tare (At), Key Tare (Tr), Both

10

nt, Gtn, n.nt, n.Gtn.

Port 1 serial output selection: nt display

only, Gtn is Gross Tare Net and

n.nt/n.Gtn inhibit negative gross printing

11

off, co, de

Off, Continuous, or Demand

12

7o, 7E, 8n

7- odd, 7- even or 8- none

13

12, 24, 48, 96, 19, 38

Baud rate selection

14

off, 1, 2, 3, 5, 10, 15 (seconds)

Delay between lines or continuous output.

19

A, b

A : adds “STX” in continuous, b : No

“STX” in continuous

20

nt, Gtn, n.nt, n.Gtn

Port 2 serial output selection

21

off, co, de, Ln, IP

Off, Continuous, Demand, Network

22

7o, 7E, 8n

7- odd, 7- even or 8- none

23

12, 24, 48, 96, 19, 38

Baud rate selection

24

off, 1, 2, 3, 5, 10, 15 (seconds)

Delay between lines or continuous output.

25

1 –32 (RS485/RS422)

Network address selection

30

off, on

DIO Inputs

40-46

See page 12

RSD functions

50

nor

Expanded Test resolution (X10)

51

no

Sum, dual channel

11

CALIBRATION

“SEL.CL1 (or SEL.CAL): (CL1/CL2 if dual channels are used):

Note: Scale zero (dead load) and span adjust (single or multi-point) are

independent. Therefore either can be done and repeated as necessary before

exciting calibration. If an error has been made, exiting without “storing” will return

to prior setup.

To ZERO the weight display:

1. Press and hold the ‘ZERO’ button for 10 seconds until a ‘P XX’ is displayed,

then release.

2. Wait for the access code prompt ‘AC ?’, then enter four (4) zeros ‘0000’ and

‘ENTER’.

3. Using the ‘TARE RECALL’ button, press repeatedly until ‘SEL.CL1’is

displayed. (SEL.CAL on older indicators)

4. Press ‘GROSS/NET’ button to enter into the cal mode. (‘C’ will flash indicating

you are in the cal mode).

5. With the scale empty, press the ‘ZERO’ button to set the display to zero. (Or

skip ZERO Cal and procede to SPAN Cal below.)

6. Exit and save (see below) or continue on to SPAN calibration.

To SPAN the weight display:

1. With the scaled loaded with a known weight, enter the weight value using the 0-

9 keypad, press ‘ENTER’.

2. To exit and save: press the ‘ENTER’ button, ‘Save Y/N’ is displayed – press

the ‘UNITS/4’ key to change the selection to ‘Y’, press ‘ENTER’ to save, then

press ‘ENTER’ again at the ‘AC ?’ prompt to exit, keeping the access code the

same.

Note: See OPT 5 for 10 Point Linearity settings.

12

REMOTE SERIAL DISPLAY OPTION

In RSD mode the indicator can be set to work as a master or slave. Communica-

tion is pre-set for Channel 2 only on both units. (RS232, 9600, 8, none)

In RSD, re-access requires using the internal “cal” switch.

Remote unit can have full or partial control of the main unit. RF devices are

available for wireless communication.

RSD “GP” allows Slave unit to use a “Condec” serial input command set.

40

rd.OF, rd.En, rd.re rd.GP

rd.En :Slave,

rd.re

:Master.

rd,GP:Slave for “condec” input.

41

En.On

Allow remote keypad operation (Slave)

42

Zr.On

Enable/Disable zero key (Slave)

43

OF,At, Tr, On

Off, Auto Tare (At), Keyboard Tare (Tr), Both (On)

(Slave).

44

Un.On

Enable/Disable unit key (Slave)

45

Pr.On

Print function with MASTER parameter “11” see below

46

Fn.On

Enable/Disable all other functions

11.P1.xx

45.Pr.xx

RSD Serial Port 1

RSD Print Key

off

off

Disabled

Disabled

off

on

Disabled

Sends print cmd to weigh meter

co

off

Sends co serial

Disabled

co

on

Sends co serial

Sends print cmd to weigh meter

dE

off

Disabled

Disabled

dE

on

See right .......

Outputs demand format from RSD serial

port 1 (No T&D)

13

Master/Slave sample configuration:

(Master) Parameters

(Slave) Parameters

CONFIGURATION

PARAMETER

DEFAULT

CUSTOM

DEFINITION

40

Rd.re

REMOTE SERIAL DISPLAY

rd.of, rd.re, rd.En

11

OFF

PRINT SELECTION

SEE BELOW

CONFIGURATION

PARAMETER

DEFAULT

CUSTOM

DEFINITION

40

Rd.En

REMOTE SERIAL DISPLAY

rd.of, rd.re, rd.En

41

En.On

Allow remote keypad operation

42

Zr.On

Enable/Disable zero key

43

tr.On

Enable/Disable tare key

44

Un.On

Enable/Disable unit key

45

Pr.On

Enable/Disable print key

46

Fn.On

Enable/Disable all other functions

14

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

GND

Tx1, RS232

Rx1, RS232

Tx2, RS232

Rx2, RS232

Tx1, -20mA

Tx1, Tx2, +20mA

Tx2, -20mA

Rx2, +20mA

Rx2, -20mA

B, RS485, RS422-Tx

A, RS485, RS422-Tx

B, RS422-Rx

A, RS422-Rx

GND

SERIAL PORTS

Port 1: RS232 duplex (Rx, Tx), 20ma (Tx). See OPT 2 for additional commands

Port 2: RS232 duplex (Rx, Tx), 20ma (Rx,Tx), RS485, or RS422. Basic functions only

(Z, N, T, etc.)

Note: Position jumper on J2 for Port 2 receive mode.

J2

A-RS232

B-20ma

C-RS485

D-RS422

(Under DIO card if installed)

Header for DIO Option

TB-2

15

SERIAL COMMANDS

<Z><cr> Zero Scale “Gross” mode, no motion, inside zero range.

<N><cr>Switch to Net From “Gross” mode with Tare stored.

<G><cr>Switch to Gross From “Net” mode.

<T><cr> Auto Tare Switch to Net, no motion, not at “Gross” zero.

<P><cr>Print Valid display, No motion

<U><cr>Units Selects alternate units

Data Formats

Demand Mode: <stx><pol><DATA><sp><lb/kg><sp><GR/NT><cr/lf>

Continuous Mode: <stx><pol><DATA><L/K><G/N><status><cr/lf>

(Brackets “<>” are not sent)

stx:“Start of Text” character (ASCII 002) (can be removed in continuous: cfg 19)

pol: Polarity sign, “SPACE” (ASCII 032) for positive or (-) sign (ASCII 045)

for negative

sp: Space character (ASCII 032)

DATA: Seven (7) digit data field including decimal point or fixed (dummy) zero if

selected. “Leading Zero Suppression” with leading zeros transmitted as

“space” characters.

lb/kg: Two (2) character field data identification for weight units, in demand

(printer) mode.

Weight in lb = “lb” (ASCII 108,098), weight in kg = “kg” (ASCII 107,103)

L/K: One (1) character field data identification for weight units in continuous

(computer) mode.

Weight in lb = “L” (ASCII 076), weight in kg = “K” (ASCII 075)

GR/NT: Two (2) character field data identification for weighing mode in demand

(printer) mode.

Gross Mode = “GR” (ASCII 071,082), Net Mode = “NT” (ASCII 078,084)

16

G/N: One (1) character field data identification for weighing mode in continuous

(computer) mode.

Gross Mode = “G” (ASCII 071), Net Mode = “N” (ASCII 078)

status: One (1) character data identification used in the continuous (computer) out-

put mode to identify the status of the indicator. Characters are listed below in order

of priority.

Calibration/configuration <D> (ASCII 068)

Over/Under Range <O> (ASCII 079)

Motion <M> (ASCII 077)

Center of Zero <C> (ASCII 067)

None of the above <sp>(ASCII 032)

cr/lf: Two (2) character field, “Carriage Return” (ASCII 013), “Line Feed” (ASCII

010)

Guidelines for Serial Output:

Demand format will inhibit “print” when scale is in “motion” or with negative “Gross”

weight, even in “Net” mode (based on setting “CFG 10”).

Local Network Protocol (RS485)

Command to the indicator:

<*><DD><00><cmd><data entry><CR>

Response from indicator:

<:><00><DD><cmd echoed><data resp><CR>

Where: (<,> brackets not sent)

* = Message from master (2AH)

DD = Indicators address

00 = Master address (fixed at 00)

CR = Message terminator (ODH)

: = Response from indicator (3AH)

Cmd = Command to indicator

cmd echoed = Command echoed from indicator

data entered = Data entered into indicator

data resp = Data response from indicator

17

J1,2: set jumper position 1-2 for 0-10 vdc

set jumper position 2-3 for 4-20 ma

-

+

Output

OPTION 1: Analog Output

Option 1 Analog Output: “SEL.OP1”

Use Gross/Net to enter the menu and step to each category, Tare Recall to select

parameters. ENT to return to menu selection.

1.1__Gr

Gr, Net, DSP

Analog tracks Gross, Net, Display.

1.5__Zr

Ex. 000

Flashes current analog starting point. Adjust value and

ENT to adjust starting point. (Normally set to zero)

1.6_FS

Ex. 5000

Flashes current analog span point. Adjust value and

ENT to adjust full scale weight value. (Normally set to

scale capacity.)

1.7_ZRa

Analog Zero

output adjust

While monitoring the output, use Start/Stop to decrease

or Tare Recall to increase the analog output value.

1.8_FSA

Analog Full

Scale output

adjust

While monitoring the output, use Start/Stop to decrease

or Tare Recall to increase the analog output value.

ENT to exit OP1. (Digital) Analog Output is updated with the display filter setting P5.

18

OPTIONS 2: Digital IN/OUT (DIO)

AC Inputs: D1, D2 are not installed, J1 = short (underside), J2 = open,

R1 –R4 = 18k (3w, 5%, flame proof). (STANDARD)

DC Inputs: D1, D2 are installed, J1 = open (cut trace), J2 = short,

R1 –R4 = 1.5k (1/2w, 5%, carbon film). (OPTIONAL)

AC Outputs: Solid State Relays, 120VAC, 0.5A. (Relays PS646,PS1201, PS2401, CPC1945Y)

DC Outputs: (Optional) Solid State Relays, 12~24VDC, 0.5A. (Relays PS540, PS541, CPC1726Y)

TB 30

TB 31

K1

K2

K3

K4

COM

COM

IN1

IN2

IN3

IN4

19

(SEL.OP2) SETPOINT CONFIGURATION

__________________________________________________________________________

The 7600E Digital Weight Indicator is available with four (4) control inputs and four (4) control outputs

when equipped with the optional Digital Input/Output (DIO) module. Setpoint outputs can be configured in

the following modes:

•Four independent setpoints with pre-act. (V3.98.0 and later)

•Two Setpoints and zero band.

•Two Setpoints, with pre-act, and zero band.

•Two Setpoints, with dribble control.

•Two Setpoints, with pre-act and dribble control.

•One setpoint with pre-act, dribble control, tolerance and Zero Band output.

•"HI - LO" Alarm Control.

•"OVER/UNDER" Check Weigh Control.

Setpoints can be used in a straight setpoint system or as part of either a "Manual Batching" or

"Automatic Batching" system. When configured for batching, the setpoints are de-energized except

when the batch is in process. When setpoint cutoff is reached, the setpoints are latched OFF and will

not reactivate until the next batching sequence.

A "Zero Band" (ZBD), around GROSS ZERO is available for monitoring an "empty scale" - in certain

setpoint configurations.

20

DEFINING SETPOINT PARAMETERS

PARAMETER

DESCRIPTION

ID

OUTPUT CHANGE

Setpoint

(Target)

Weight value desired

at end of weighing

operation.

SP

WT > or = SP

Pre-act

Weight value which is set to

allow for material in suspen-

sion

Pr

WT > or = SP - Pr

Dribble

Weight value at which

material flow changes,

usually from "fast" to "slow"

feed.

dr

WT > or = SP-(dr)-Pr

Tolerance

Band

Weight band around

setpoint

HI,Lo

trG -LO > WT > trG +HI

Zero

Band

Weight band (±) around

GROSS ZERO used to

define "empty scale".

ZBD

0 - x > WT > 0 + x

NOTES:

1. Front panel LED's for setpoints 1 and 2 are ON when respective outputs are ON.

2. In Batching modes (BAT1 & BAT2) the setpoint outputs are latched while running.

Other manuals for 7600E

1

Table of contents

Popular Accessories manuals by other brands

Balluff

Balluff BVS ID-M1280-F1 Series user guide

DigiDesign

DigiDesign 96 I/O Guide

Larson Electronics

Larson Electronics IND-HL-HDB-FUVC-EX-1L-120V-15C instruction manual

Lightolier

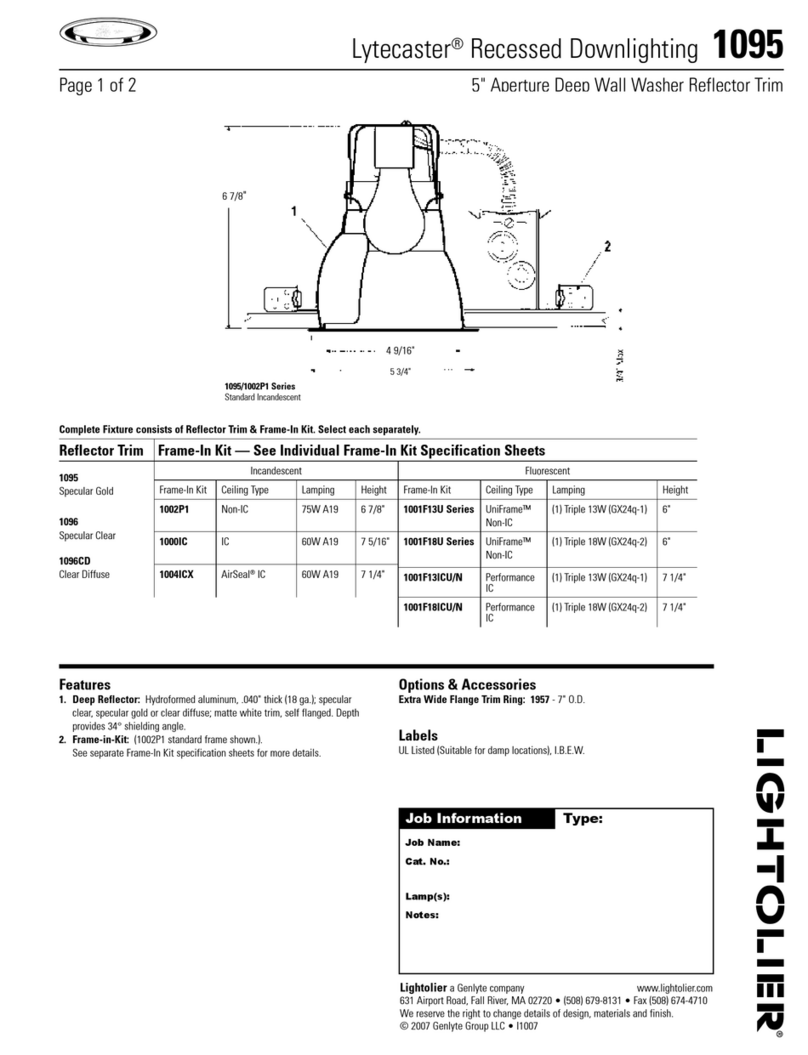

Lightolier Lytecaster 1095 specification

Clas Ohlson

Clas Ohlson 36-7285 quick start guide

Makita

Makita DFJ206 instruction manual