Emico Noah Actuation NA Series User manual

Table of Contents

N

A

1. Caution

2. Storage

3. Actuator Specification

6. Performance

4. Standard Specification

5. Optional Specification

7. Exterior Parts Identification

8. Interior Parts Identification

10. Actuator Mounting Flange

12. Actuator and Valve Assembly

13. Actuator Installation

14. Manual Operation

15. Limit Switch Setting

16. Over Torque Switch Setting

17. Mechanical Limit Stop Bolt

20. Electric Wiring

21. Maintenance

22. Warranty Information

23. Troubleshooting

3

5

6

10

8

9

12

14

11

9. Actuator Nameplate Information

16

11. Actuator Drive Bushing 17

19

25

26

27

28

29

18. Visual Indicator Setting 30

19. Wire Connection 31

32

34

34

35

15

$BVUJPO

3

http://www.emico.co.kr

ELECTRICAL SHOCK HAZARD

To avoid serious personal injury, property damage or death, turn

off all power to the ACTUATOR before removing the cover.

Before installation or use, verify the nameplate information to

insure the correct model number, torque, voltage and enclosure

type.

Be sure to completely review the ACTUATOR manual prior to

operation.

Final limit switch adjustment must be done after mounting the

ACTUATOR to the valve. Incorrect adjustment may cause ACTUATOR

failure.

Over toruque swithes are factory set. Tampering with the over

torque switch settings may damage the ACTUATOR and VOID

the warranty.

.PUJPOJODPOUSPMT

ξ

4

NA SERIES MANUAL

Actuator MUST be properly grounded. Use the grounding lugs

provided on the inside or outside of the ACTUATOR body.

To minimize the possible damage caused by condensation, be

sure to energize the heater.

Care should be taken when wiring 3-phase ACTUATORS.

Confirm proper rotation and limit switch shutoff function during

the initial operation. If the ACTUATOR rotates in the reverse

direction, then the phasing needs to be corrected by switching

two of the 3-phase wires on the terminal block.

Explosion-proof products must be used under the temperature

and environment appropriate for the product spec.

Explosion proof ACTUATORS and wiring must be properly

sealed prior to operation. Improper installation may cause a

hazardous condition and failure of the explosion proof enclo-

sure. The manufacture is not responsible for any losses or

damages caused by incorrect installation.

1. Certified cable entries rated for at least 90℃ must be used

when installed.

2. If conduit is used for cable entry, a seal fitting with setting

compound must be installed as close as possible, within

450mm, to the ACTUATOR.

Ex d IIB T4 -20℃~ +55℃

Flameproof Enclosure Level and Environment of ACTUATOR

4UPSBHF

The ACTUATOR must be stored in a clean, dry, temperature controlled area. The unit shall be

stored with the cover installed and with the conduit openings sealed. Storage must be off the floor.

Care must be taken to guard the ACTUATOR from condensation in extreme temperature variations.

Heaters should be energized as soon as ACTUATORS are installed.

Improper storage of the ACTUATOR will VOID WARRANTY.

Storage Location Indoor

18℃ ± 5℃

Storage Temperature

5

.PUJPOJODPOUSPMT

ξ

The NA-Series ACTUATOR has been designed for the automation of 90ȋdegree rotating

equipment. The ACTUATOR is available in 13 different sizes with torque output from

6kg½m to 250kg½m. The ACTUATOR is suitable for ball valves and butterfly valves as well

as dampers.

Flameproof Enclosure

"DUVBUPS4QFDJGJDBUJPO

&OWJSPONFOUBOE5FNQFSBUVSF

Temperature

Enclosure Type

-20℃ ~ +55℃

IP67 (Option: IP68)

Explosion Proof

Ex d IIB T4 Gb

Certification Body

Ex d IIB T4

-20℃ ~ +55℃

CSA (Canada / USA)

ATEX (EU)

NEPSI (China)

GOST (Russia)

KTL (South Korea)

The ACTUATOR enclosure is made from and anodized

aluminium alloy whitch is also dry powder epoxy painted

to help protect it from oxidation.

6

NA SERIES MANUAL

.BOVBM0WFSSJEF

Hand/Auto declutch type with motor priority, the hand lever engages the manual override

and will automatically reset when the motor is energized.

4FMG-PDLJOH

The self locking worm gear system prevents any valve back drive from occurring

)FBUFS

The 20 watt internal heater helps to minimize condensation due to temperature and humidity

changes.

-JNJU4XJUDI

The mechanical, cam actuated, limit switches are included to accurately calibrate the valve

position.

5PSRVF4XJUDI

The torque switches are cam actuated and factory set to provide over torque portection for

the valve as well as the ACTUATOR. Torque switches are not included in the NA006 and NA009.

.PUPS

The ACTUATOR motor is protected with and embedded 150-degree C thermal protector

designed to protect the motor from overheating.

*OEJBDUPS

The visual indiactor is directly connected to the ACTUATOR output shaft and is designed for

visual indication from a distance.

.FDIBOJDBM-JNJU4UPQT

Mechanical limit stops are designed to protect against the over-travel of quater turn applications

while using the manual override or in the event of a limit switch failure.

"EBQUJPO

Mounting is standardized to the ISO5211 specification and the removable drive bushing can

be machined to match valve stem.

7

.PUJPOJODPOUSPMT

ξ

4UBOEBSE4QFDJGJDBUJPO

Watertight Ingress Protection 67

Nema 4 and 6

Option : IP68

Option : Ex d IIB T4

-20℃to +70℃ 150℃ /1hr

Option : -40℃ to +70℃

90% RH Max (Non Condensing)

110 / 230V AC 50/60Hz

DC24V

380 / 440V AC 50/60Hz

Option : AC24V

Open / Close Torque Switch

(Except NA006 , NA009)

Open / Close Limit Switch

Thermal Protection ( Open 150℃)

90±5℃

Continuous Position Indicator

Hand / Auto Declutching Mechanism

Provided by Means of Worm Gearing

External Adjustable Screws

20W

2-M20 , 2-NPT 3/4

Shell Gadus S2 V220 2

Aluminium

Anodizing

Polyester

AC1800V / 1min

DC500V more Than 100M Ohm

X, Y, Z log, 10Hz~57Hz 0.15mm 30min

Enclosure

Ambient Temperature

Ambient Humidity

Power Supply

Torque Switches

Limit Switches

Stall Protection

Travel Angel

Indicator

Manual Override

Self Locking

Mechanical Stops

Space Heater

Cable Entries

Lubrication

Materials

Surface Treafment

External Coating

Dielectric Strength

Insulation

Anti Vibration

8

NA SERIES MANUAL

5. Optional Specification

Flameproof Enclosure Ex d IIB T4 Gb

CSA, ATEX, NEPSI, GOST, KTL

Watertight Enclosure IP68

1 bar 72h (KTL)

Auxiliary Open, Close Limit Switches (Dry Contact)

Auxiliary Open, Close Over Torque Switches (Dry Contact)

Travel Angle (120˚, 135˚, 180˚, 270˚)

Potentiometer 1K Ohm

Current Position Transmiter

Output : DC 4-20mA

Proportional Control Unit

Input DC 4-20mA, DC1~5V, DC2~10V

Output : DC 4-20mA

Local Control Unit

Material : Plastic (IP66)

Local Control Unit

Material : Aluminium (IP67~68)

Integral Motor Starter (On-Off Action)

Continuous Modulating (Duty 100%)

With Speed Controls

Rechargeable Battery Pack

EXP

IP68

ALS

ATS

EXT

PIU

CPT

PCU

LCU 1

LCU 2

IMS

NAC

RBP

9

9

.PUJPOJODPOUSPMT

ξ

1FSGPSNBDF

10

NA SERIES MANUAL

11 11 14 14 17 17 17 24 25 25 64 65 65

8.5 8.5 10 10 12.5 12.5 12.5 14.5 14.5 14.5 43.5 43.5 43.5

F07 F07 F07

/F10

F07

/F10

F10

/F12

F10

/F12

F10

/F12

F12

/F14

F12

/F14

F12

/F14 F16 F16 F16

20 20 20 20 26 26 26 34 34 34 65 65 65

22 22 22 22 32 32 32 42 42 42 75 75 75

50 50 50 50 50 30 25 25 25 25 25 25 25

FFFFFFFFFFFFF

15 25 40 40 40 60 90 90 180 180 90 180 180

IIB T4 IIB T4 IIB T4 IIB T4 IIB T4 IIB T4 IIB T4 IIB T4 IIB T4 IIB T4 IIB T4 IIB T4 IIB T4

67/68 67/68 67/68 67/68 67/68 67/68 67/68 67/68 67/68 67/68 67/68 67/68 67/68

Type

Max

Output

Torque

Operating

Time

(90/sec)

Enclosure

Flameproof

Enclosure

Motor

Duty Cycle

(CSA)

Max

Stem

Dia(mm)

Mounting

Base

Handle

Turns

Weight

W

Class

S4

(%)

key

Squ

-are

ISO

5211

kg

kg½m6 9 15 19 28 38 50 60 80 100 150 200 250

60 90 150 190 280 380 500 600 800 1000 1500 2000 2500

1750Hz

60Hz

IP

EX

17 20 20 24 24 24 29 29 29 87 87 87

14 14 17 17 20 20 20 24 24 24 72 72 72

Nm

NA

006

NA

009

NA

015

NA

019

NA

028

NA

038

NA

050

NA

060

NA

080

NA

100

NA

150

NA

200

NA

250

65

43.5

F16

65

75

25

F

180

IIB T4

67/68

300

3000

116

96

NA

300

3BUFE4UBSUJOH$VSSFOU

9

11

Type

110V

50Hz

Rated

Current(A)

Starting

Current(A)

Rated

Current(A)

Starting

Current(A)

Rated

Current(A)

Starting

Current(A)

Rated

Current(A)

Starting

Current(A)

Rated

Current(A)

Rated

Current(A)

Starting

Current(A)

Starting

Current(A)

Rated

Current(A)

Starting

Current(A)

Rated

Current(A)

Starting

Current(A)

Rated

Current(A)

Starting

Current(A)

Rated

Current(A)

Starting

Current(A)

110V

60Hz

220V

50Hz

220V

60Hz

380V

50Hz

230V

50Hz

380V

60Hz

440V

50Hz

440V

60Hz

DC

24V

NA

006

NA

009

NA

015

NA

019

NA

028

NA

038

NA

050

NA

060

NA

080

NA

100

NA

150

NA

200

NA

250

NA

300

WU^ XUX XU] XU] XU] YUZ ZU\ ZU\ ZU_ [UW ZU\ ZU_ [UW [UW

WU^ XUX XU^ XU^ XU_ YU_ ZU^ ZU^ [U^ [U^ ZU^ [U^ [U^ [U^

WUZ_ WU\X WU^\ WU^\ WU^\ XUX XUY XUY XU_ YUW XUY XU_ YUW YUW

WU]Z WU_` XUXY XUXY XUZ^ XU_\ YUZ[ YUZ[ ZU[ ZU[ YUZ[ ZU[ ZU[ ZU[

WU]Z WU_` XUXY XUXY XUZ^ XU_\ YUZ[ YUZ[ ZU[ ZU[ YUZ[ ZU[ ZU[ ZU[

WU[Y WU\Y WU` WU` WU` XUY XU\ XU\ XU_ YUW XU\ XU_ YUW YUW

WUZ_ WU\] WU^\ WU^\ WU^\ XUW] XUY XUY XU_ YUW XUY XU_ YUW YUW

WU] WU_ XUW\ XUW\ XUZ XU_ YUZ YUZ ZUZ ZUZ YUY\ ZUZ ZUZ ZUZ

WUX\ WUX_ WUZ WUZ WUZY WUZ[ WU[^ WU[^ WU^\ WU_\ WU[^ WU^\ WU_\ WU_\

WUZY WUZ] WU\` WU\` WU^[ WU^_ XUY[ XUY[ XU]_ XU]_ WU^_ XU]_ XU]_ XU]_

WUZY WUZ] WU\` WU\` WU^[ WU^_ XUY[ XUY[ XU]_ XU]_ WU^_ XU]_ XU]_ XU]_

WUZY WUZ] WU\` WU\` WU^[ WU^_ XUY[ XUY[ XU]_ XU]_ WU^_ XU]_ XU]_ XU]_

WUZY WUZ] WU\` WU\` WU^[

[UX [UX ]U] `U_ XZU_

WU^_ XUY[ XUY[ XU]_ XU]_ WU^_ XU]_ XU]_ XU]_

WUX\ WUX_ WUZ WUZ WUZY WUZ[ WU[^ WU[^ WU^\ WU_\ WU[^ WU^\ WU_\ WU_\

WUX\ WUX_ WUZ WUZ WUZY WUZ^ WU\] WU\] WU_\ WU` WU\] WU_\ WU` WU`

WUX\ WUX_ WUZ WUZ WUZ WUZY WU[] WU[] WU^\ WU` WU[] WU^\ WU` WU`

YU\ ZU\ [U\ [U\ ]U\

T

XW

T

XW

XUZ\ YUX YUX YUX YU` ZU^ [U` [U` ^U[\ ^U[\ [U` ^U[\ ^U[\ ^U[\

XUZ] YUX YUXZ YUXZ YU`] ZU^Y [U` [U` ^U\ ^U\ [U` ^U\ ^U\ ^U\

.PUJPOJODPOUSPMT

ξ

&YUFSJPS1BSUT*EBOUJGJDBUJPO

12

NA SERIES MANUAL

7-1

NA006, NA009, NA015, NA019,NA028,

NA038, NA050, NA060, NA080, NA100

▼

Window

▼

Top Cover

▼

Base

▼

Cable

Entries

▼

Body

Stopper Bolts

▼

▼

▼

Top Cover

Bolts

Handle

Handle Cover

▼

▼

Lever

▼

Drive Bushing

▼

9

13

Top Cover

Bolts

Handle

Drive Bushing Bolts

Gear Box

Stopper Bolt

Window

Top Cover

Lever

Base

Drive Bushing

Cable

Entries

Earth

Flange

p

7-2

NA150, NA150, NA200, NA250, NA300

.PUJPOJODPOUSPMT

ξ

*OUFSJPS1BSUT*EBOUJGJDBUJPO

14

NA SERIES MANUAL

8-1 NA006, NA009, NA015, NA019, NA028, NA038, NA050

NA060, NA080, NA100, NA150, NA200, NA250, NA300

Indicator

Limit Micro Switch

Open Limit Cam Switch

Close Limit Cam Switch

Terminal

Heater

t

Condenser

Torque Micro Switch

Open Torque Cam Switch

Close Torque Cam Switch

Auxiliary Open,

Close Limit Switch

9

15

Before installation or use, verify the nameplate information to insure that you have the correct

model number, torque, voltage and enclosure type.

"DUVBUPS/BNFQMBUF*OGPSNBUJPO

5ZQF

Model Number

.PUPS

Motor Wattage

4FS/P

A unique serial number is issued for each ACTUATOR

4VQQMZ

Main Power supply voltage

8JS/P

Electrical diagram for ACTUATOR as built. The circuit diagram can be located inside top cover.

Contact your supplier if you cannot locate the diagram or it is different than the one listed on

the nameplate.

0QUJPO

Options installed will be listed here. For complete listing of options and descriptions

please refer to Selction 5. Optional Specification.

'MBNFQSPPG&YQMPTJPO1SPPG"$56"503&ODMPTVSF

If the application requires an explosion proof ACTUATOR, you must confirm

that the nameplate lists the explosion proof symbol or the certification body

number. If no symbol or certification is located on the nameplate, immediately

contact the supplier as the ACTUATOR is not manufactured for explosion

proof service.

Type Motor

Ser.No. Supply

Wir.No. Option

Manufacturer and Contact Info

※ Flameproof Enclosure Symbol : In the case of ATEX

“CE 0470 II 2G Ex d IIB T4 Nemko 03ATEX1342X”

.PUJPOJODPOUSPMT

ξ

"DUVBUPS.PVOUJOH'MBOHF

16

NA SERIES MANUAL

The NA-Series mounting flanges is manufactured to ISO5211 standards. If the ACTUATOR does not

mount directly to the valve, then a mounting kit will need to be manufactured.

Model NA006~NA009 Model NA015~NA050

Model NA060~NA100 Model NA150~NA300

B.C.D

TAP

ISO 5211

B.C.D

TAP

ISO 5211

B.C.D

TAP

ISO 5211

Ø70

4-M8

DP12

-

-

-

A

B

Option

Model

(mm)

Size

NA006

~NA009

NA015

~NA019

Ø70

Ø102

Ø82Ø82

4-M8

DP12

4-M8

DP12

4-M8

DP12

--

4-M10

DP15

F07F07

F10

NA028

~NA050

Ø102

Ø125

4-M10

DP15

-

-

-

-

--

4-M12

DP22

F10

NA060

~NA100

Ø125

Ø140

4-M12

DP22

F10

4-M10

DP15

Ø125

F14

4-M16

DP22

4-M16

DP22

F12

NA150

~NA300

Ø165

4-M20

DP22

F10

4-M16

DP22

Ø140

Ø140

F16

9

17

A removable blank drive bushing is supplied with each ACTUATOR that can machined to adapt

to the valve stem.

"DUVBUPS%SJWF#VTIJOH

Shaft Orientation when Butterfly Valve is in Full open Machined Drive Bushing Orientation and Type

▼

▼

▼

Base

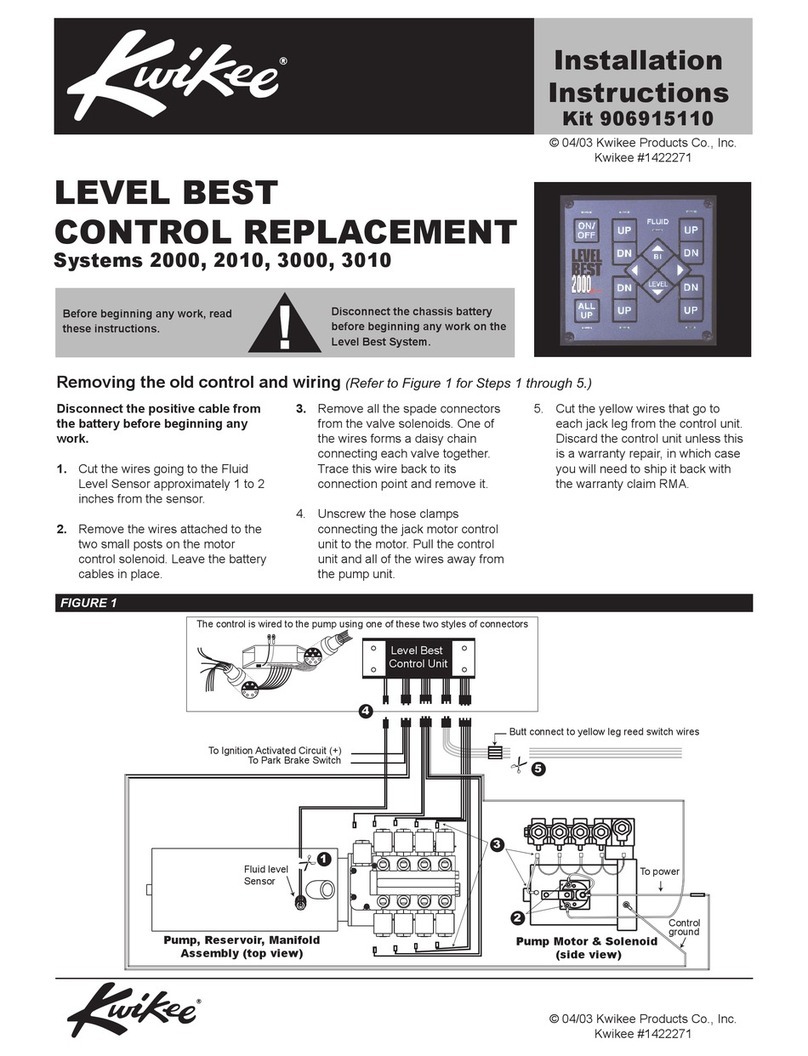

Remove the 4 bolts by using an L-wrench a

nd the separate drive bushing from ACTUATOR.

The drive bushing should be machined to match the valve stem dimensions

when the valve is in the full open or full closed position. The ACTUAOR

bushings can be provided machined and ready to mount to the valve if the

valve drawings are provided to the manufacture.

Drive Bushing

Bolts

%SJWF#VTIJOH4FQBSBUJPO

%SJWF#VTIJOH"EBQUJPO

.PUJPOJODPOUSPMT

ξ

18

NA SERIES MANUAL

%SJWF#VTIJOH."9.BDIJOFE#PSF4J[F

Model NA006~NA100

OP

Max "ØD" MAX E

" Squre"

NA006~009

MODEL

Ø22 20 43

Ø22

Ø32

Ø42

20 43

26 52

34 59

Ø75 65 100

NA028~050

NA015~019

NA060~100

Model NA150~NA300

(mm)

Max "ØD" MAX E

" Squre"

NA150~300

MODEL

Shaft Orientation when Butterfly Valve is in Full open Machined Drive Bushing Orientation and Type

9

19

※ EMICO mounts and cycles the valve assembly, and then calibrates the limit switch settings.

12-1-1

Confirm that the valve mounting dimensions match the ACTUATOR base and machined bushing

dimensions.

12-1-2

Pull lever to engage the handwheel, then rotate the ACTUATOR to the full clockwise/ closed

position turn the valve shaft to the full close position.

"DUVBUPSBOE7BMWF"TFFNCMZ

#VUUFSGMZ7BMWF"TTFNCMZ

Base

Drive Bushing

Valve

Bolt

Lever

Handle

.PUJPOJODPOUSPMT

ξ

20

NA SERIES MANUAL

Grease

Valve and Actuater add Up

Bolt

12-1-3

Apply a thin coat of grease to the drive bushing

and install in the ACTUATOR. Apply a thin coat

of grease to the valve stem and then mount the

ACTUATOR to the valve as shown.

12-1-4

Fasten the ACTUATOR and vavle together using stud bolts

and nuts or hex bolts. Firmly tighten the assembly and confirm

the there is no gap between the ACTUATOR and valve.

This manual suits for next models

14