Prophi®6R

10

5.2. Manual programming (program menu)

LANGUAGE SELECTION: This selects the language of the operating menu

(German, English, Spanish, Portuguese, French, RU, Cz, NL, PL, TR)

1 I-CONVERTER PRIM: [ 5...13000]A

This selects the primary current of the current converter. Adjustment is

via the é / ê keys. Save and continue with ENTER

2 I-CONVERTER SEC: [ 5 or 1]A

This sets the secondary current of the current converter

Selection via é / ê. Save and continue with ENTER

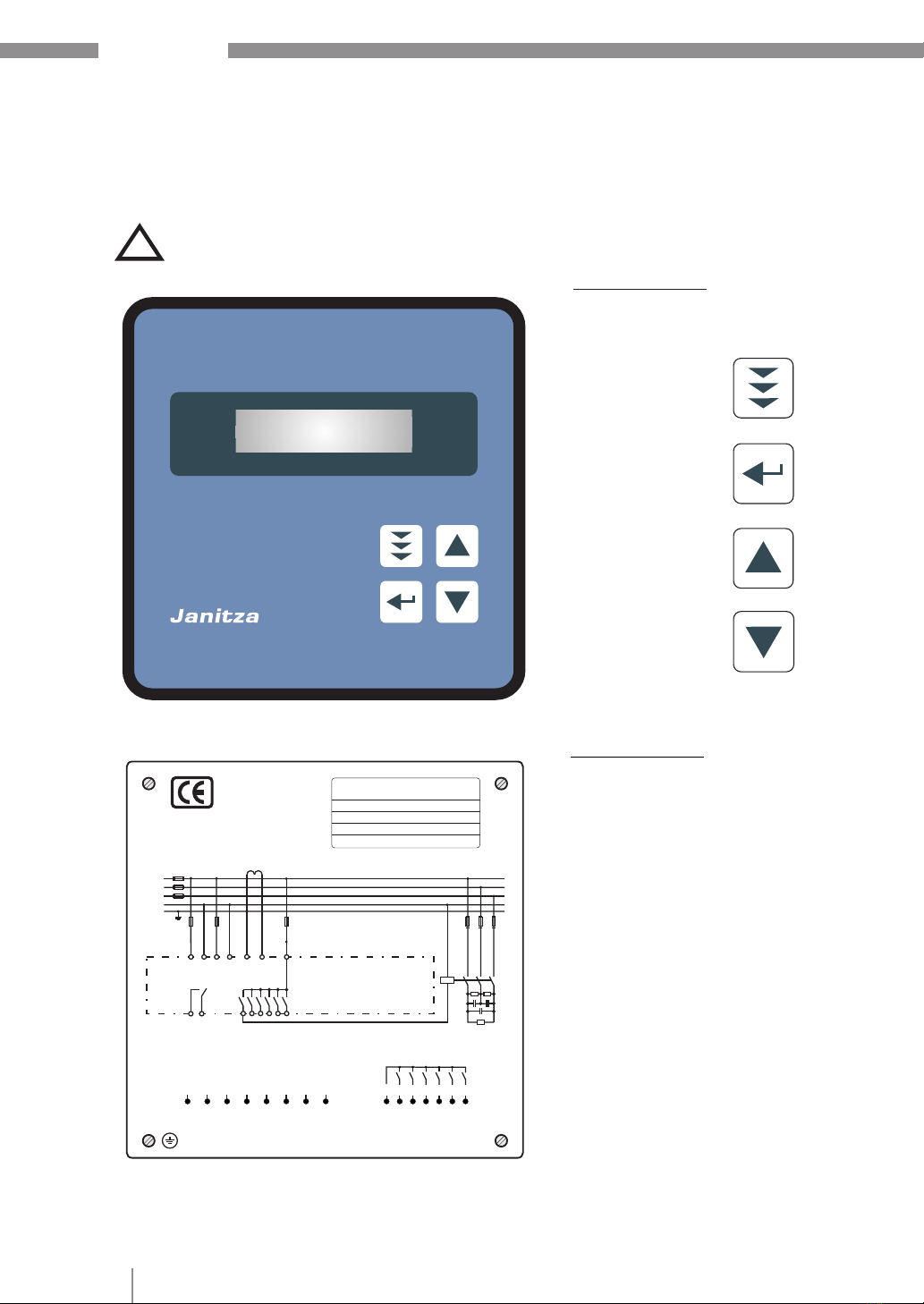

3 END STOPP: [ 6/7 ] switching to 7.stage in expert-mode 2

By setting the end stopp, the number of active capacitor branches is

matched to the respective capacitor bank. This is done via the é / ê

keys. The visible symbols of the capacitors correspond to the connected

outputs. The maximum possible number of capacitor branches is pre-

set at the works (6 branches). Save and continue with ENTER

4 CONTROL SERIES: [ 1...20 + E ]

The ratio of the capacitor branch power determines the control series,

the power of the first capacitor always being assigned the value 1. The

control series required for the compensation network is again selected

via the é/ê keys. If the required control series should exceptionally not

be present (Annex 1), the user may define a special one (control series

"E”).More on this point in the control-series editor in Annex 1.

5 CONTROL PRINCIPLE: The control preference may be selected here:

SEQUENTIAL connection

LOOP connection

INTELLIGENT loop connection (default setting)

COMBINED CHOKE

See Section 9 for an explanation of the various control modes.

Selection with é / ê keys. Save and continue with ENTER

6 POWER 1. STAGE: [ 0.01 ... 255.99 ] kvar

To determine the controller's response sensitivity, the dimensions of

the network's smallest capacitor (stage 1) must be known. They are

entered in two steps in kvar. The integral kvar values (before the

comma) are initially selected via the é / ê keys and saved with

ENTER. The positions after the comma are then selected, again via the

é / ê keys. If the response sensitivity is being undercut, a warning will

occur ( indication of “!” in the display )

Save and continue with ENTER

7 TARGET COS PHI: [ 0.1 ind ... 0.1 cap ]

By setting the target cos phi, the power factor to be attained via the PF

correction is defined. It is also set via the é / ê keys.