Parameter Definitions

:Input Type and Functions (Default=3)

0 :

1 :

(INC)

Down (DEC)

, Down

.(INC/DEC)

. (INC/INC)

Down (UP/DOWN)

x1 .(for Incremental Encoder)

x2 .(for Incremental Encoder )

x4 .(for Incremental Encoder )

2 :

3 :

4 :

5 :

6 :

7 :

Upcount on rising edge of Ch-Ainput.

count on rising edge of Ch-Ainput.

Upcount on rising edge of Ch-Ainput count on rising

edge of Ch-B input

Upcount on rising edge of Ch-Ainput,Upcount on rising edge of

Ch-B input

Upcount on rising edge of Ch-A input when Ch-B is at 0

count on rising edge of Ch-Awhen Ch-B is at 1.

Phase Shifting

Phase Shifting

Phase Shifting

: (Default=0)Filter time for Ch-A and Ch-B Inputs

It is used to protect against the electrical contact debounce or the

signal that is less than the determined pulse time.

It can be adjusted from to milisecond.

: (Default=50)Filter time for Reset and Pause Inputs

It is used to protect against the electrical contact debounce or the

signal that is less than the determined pulse time.

It can be adjusted from to milisecond.

:Count Direction (Default=0)

Downcount. ( Preset--> 0 )

Upcount. ( 0 -->Preset )

:Sensor Type Selection (Default=0)

PNP Sensor type is selected.

NPN Sensor type is selected.

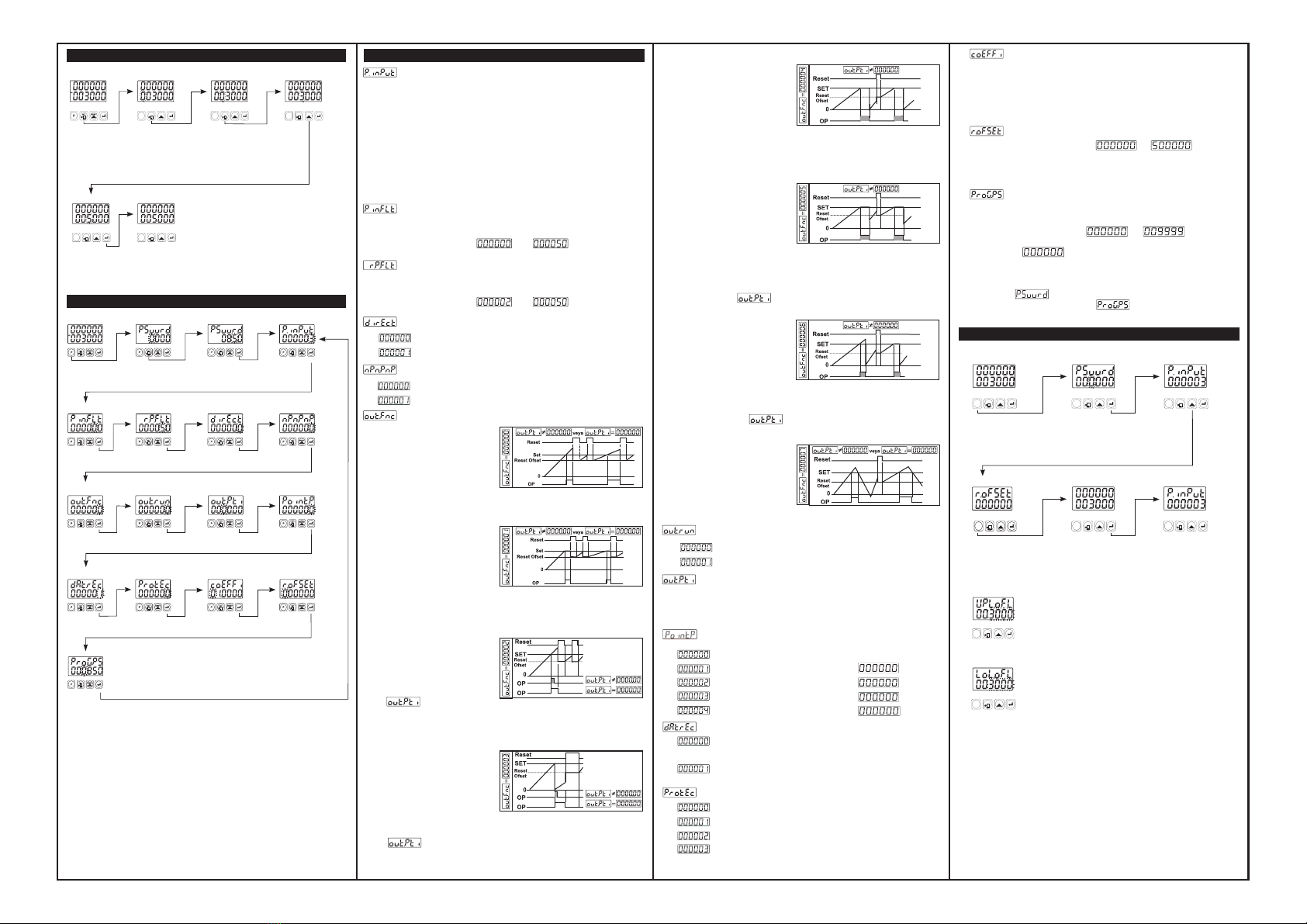

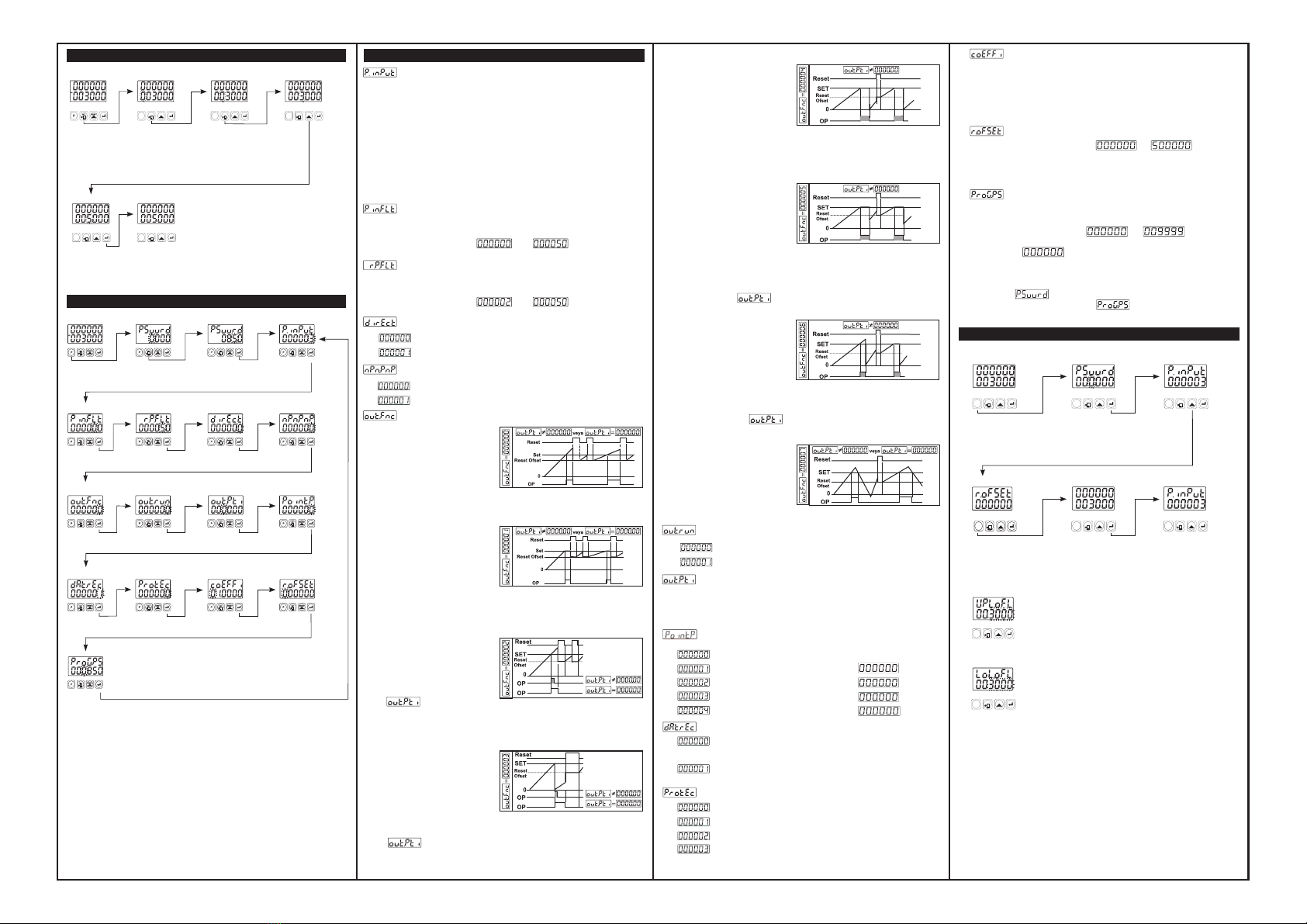

:Output Functions (Default=0)

0:

Manuel Reset-1: Process

counts,until manuel reset

happens.When count

value reaches the Set

value,Output Position is

changed.

Manuel Reset-2: Process

counts,until manuel reset

hap p e ns.W h e n coun t

value reaches the Set

value,Output Position is

changed.Counting doesn’t

change continue over Set

value.Outp ut P os it io n

doesn’t change ,until

manuel reset happens.

2:

Manuel Reset-3: Process

counts,until manuel reset

hap pens . Whe n c ount

value reaches the Set

value,Output Position is

changed.After the end of

the Output Pulse Time

output positions

changes the old position.

3:

Automatic Reset-1:When

count value reaches the

Set value,Output position

is changed.Process value

automatically and counting

will continue from “0”(up

cou nt) o r “ Set ”(do wn

count).After the end of

the Output Pulse Time

output positions

changes the old position.

4:

Automatic Reset-2: When

cou nt va lue r each es th e

Set value,Output position

is changed.Counting doesn’t

continue over the Set value.

P r o c e s s v a l u e i s r e s e t

a u t o m a t i c a l l y , c o u n t i n g

continue from “0” (upcount)

or “Set” (downcount) and

Output position changes the old

position at the end of the

output pulse time.

5:

Automatic Reset-3: When

count valu e r e a c h e s t h e

Se t v alu e,O utpu t pos itio n

i s c h a n g e d . C o u n t v a l u e

beco m e s z e ro.(F o r 0 - > P)

Counting restarts on “0” value,

but Set Value is showen on the

P r o c e s s v a l u e s c r e e n .

Output position becomes the old

and the Real count value

can be seen at the end of

output pulse time.

6:

Automatic Reset-4: When

count value reaches the

Set value,Output position

is changed.Count value is

automatically reset and

counting will continue ( for

0->P) and Output position

c h a n g e s t h e o l d

position at the end of the

output pulse time.

7:

:Output Run Type (Default=0)

Normally Energised.

Normally De-energised.

:Output Pulse Time (Default=0.00)

It determines how long Output will be active.It can be adjusted

from 00.00 to 99.99 seconds. If it is 00.00 second ,then it

operates indefinitely.

: Point Position (Default=0)

Between first and second digits.

No point.

Between second and third digits.

Between third and fourth digits.

Between fourth and fifth digits.

: Data Record (Default=1)

Count value is not saved to memory when power is

disconnected.

Count value is saved to memory when power is

disconnected and restored on power up.

:Reset and Set Protection (Default=0)

No Reset and Set protection.

Only Reset button protection is active.

Only Set button protection is active .

Full Protection.Reset and Set button protection is

active.

: Multiplication Coefficient (Default=01.0000)

The Count value that is read from Process input,is multiplied

with this value.Parameter value can be adjusted from

00.0000 to 99.9999.If this parameter is adjusted to

“01.0000” then this parameter has no effect on Process

input count,so Process value equal to the Process input

count.

: Reset Offset (Default=0)

It can be adjusted from to .When

Process is manually reset ,count process starts from this

value.

: Program Password (Default=0)

It is used for accessing to the program parameters.

It can be adjusted from to .

If it is ; there is no password protection while

entering to the program parameters.

If operator accesses to the program parameters by entering

“0” to ,then the operator can only see the parameter

without changing,except

Failure Messages in EZM-XX30 Programmable Counter

Reset Offset Parameter

1- If Actual Value is flashing and counting is

stopped ;

It appears if any of the count value is bigger

than the maximum count value.

To remove this warning and reset the count

value press button.RESET

2- If Actual Value is flashing and counting is

stopped ;

It appears if any of the count value is lower than

the minimum count value.

To remove this warning and reset the count

value press button.RESET

W h e n

button is pressed,

password entering

screen will appear.

P R O G The most

Significant digit

of the parameter

(4th digit for

this parameter)

Flashes.

Press ENTER

Button without

entering the

password.

No digit

flashes.

By pressing

ENTER

button, user

can see all

parameters

except for

program

password.

Press PROG button to exit

from programming mode.

Continue to

press

b u t t o n f o r

scanning the

parameters.

ENTER

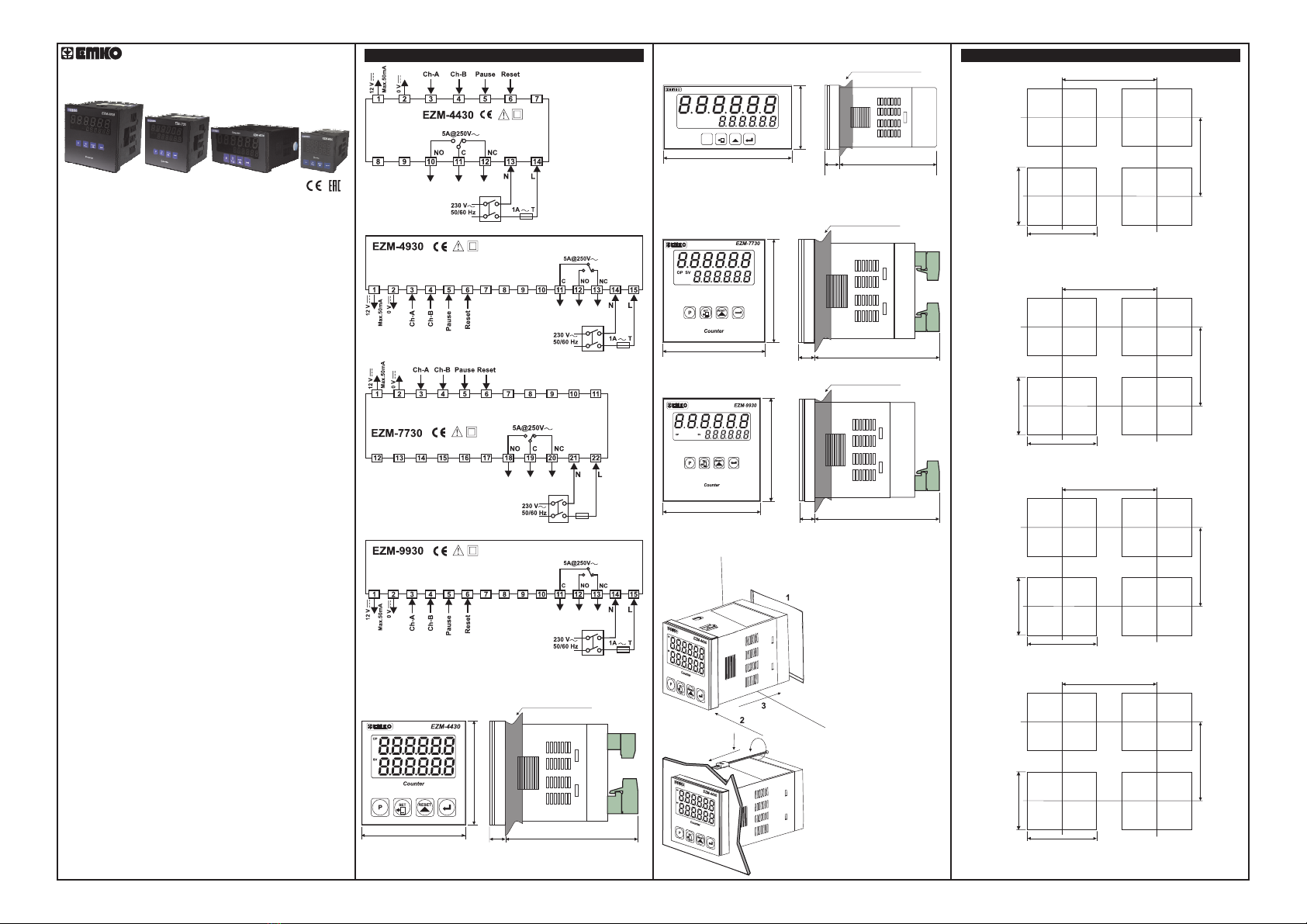

Accessing and Changing the Set Values

Main Operation

Screen

Shift button is

pressed,6th digit

of S e t Val u e

starts to flash.

SET Screen

Press Shift

Button again.

5th digit of the

SET value

starts to flash.

4th digit of

the SET

value starts

to flash.

Increase the

flashing digit

with pressing

the Increment

Button.

Save the SET

v a l u e w i t h

pr e ssi n g th e

ENTER Button.

Main Operation

Screen

Accessing to the Program Parameters

Program Password

Press Enter button to access to

the first program (Input Type

and Function) parameter.

Press Enter Button to

access to following

parameter.

When Button

is pressed,password

must be entered for

accessing the program

parameter.

Prog 4th digit of the password

parameter flashes.Enter the

password with using Shift

and Increment Button.

After entered the

Password, press

Enter Button.

Main Operation

Screen Password Screen Password Screen Input Type and Functions

Process Input

Filter

Reset and Pause

Input Filter Count Direction Sensor Type

Selection

Output

Functions

Output Run

Type Output Pulse

Time

Decimal Point

Position

Data

Record

Reset and Set

Protection

Multiplication

Coefficient Reset Offset

Note-1

Note-1

Note-1

Note-1

Note-1

Note 1- Parameter value can be changed with Incrament button.

When the Enter button is pressed,parameter value will be saved

and following parameter is accessed.

Note 2- Press “P” button is exit without saving the parameter

value.Thus Main Operation Screen is appeared.

Counter Counter Counter

Counter Counter Counter

Note-1

Note-1

Press Shift

Button again.

SET Screen

SET Screen SET Screen

Press Enter Button to

access to following

parameter.

Press Enter Button to

access to following

parameter.

Press Enter Button to

access to following

parameter.

Press Enter Button to

access to following

parameter.

Press Enter Button to

access to following

parameter.

Press Enter Button to

access to following

parameter.

Press Enter Button to

access to following

parameter.

Press Enter Button to

access to following

parameter.

Press Enter Button to

access to following

parameter.

Press Enter Button to

access to following

parameter.

Press Enter Button to

access to following

parameter.

Press Enter Button to

access to following

parameter.

1:

Password Screen

Main Operation

Screen Input Type and Functions

Main Operation

Screen Input Type and Functions

Note-1

Note-1

Note-1

Note-1 Note-1

Note-1

Note-1

Automatic Reset-5:Process

counts,until manuel reset

happens.Output pulse time

does not take into considera

tion.This function can be

prefered on systems that,

upcounts or downcounts at

the same time.

O1

O2

SV

S2

RESET

PSET

O1

O2

SV

S2

RESET

PSET

O1

O2

SV

S2

RESET

PSET

O1

O2

SV

S2

RESET

PSET

O1

O2

SV

S2

RESET

PSET

OV

O2

SV

S2

RESET

PSET

OV

O2

SV

S2

RESET

PSET

Counter

Counter

Counter

O1

O2

SV

S2

RESET

PSET

O1

O2

S1

S2

RESET

PSET

O1

O2

S1

S2

RESET

PSET

O1

O2

S1

S2

RESET

PSET

O1

O2

SV

S2

RESET

PSET

O1

O2

S1

S2

RESET

PSET

RESET

PSET

Counter Counter Counter

Counter Counter