TROUBLESHOOTING

Problem Solution

Window 01 always shows zero load,

even if the motor is running

- Check the connection of the current

transformer(s).

- Check that value of the rated motor power in

window 41 is the same as the rated motor power

on the motor plate.

- Check that window 03 shows a phase current

value in correspondents with the rated motor

current.

Window 03 shows an improper value

of the phase current

- Check that current transformer has been

selected according to the tables 1 and 2.

- Check that the number of windings is according

to table 1 and 2.

- Check that the value of the motor current in

window 42 is the same as the value of the motor

current on the motor plate.

The monitor never gives an alarm - Check that window 01 shows a value greater

than zero.

- Check the alarm levels in windows 11 to 14. If

not correct readjust the levels or per form an

AUTOSET.

The monitor always gives an alarm - Check the alarm levels in windows 11 to 14.

If not correct readjust the levels or per form an

AUTOSET.

- Check if the monitor is programmed for “latched

alarm” (window 61=on). If so reset the monitor

by pressing the reset key.

Window 00 shows “LU” or “OU”.

Under- or over voltage alarm.

Switch off the supply:

- Check that the supply voltage is corresponding

with the voltage range on the monitor type plate.

Window 01 shows “oor”. "Out Of

Range" alarm.

- The measured shaft power is higher than 125% of

the rated motor power programmed in window 41.

Window 03 shows “oor”. “Out Of

Range” alarm.

- The measured motor cur rent is higher than 125%

of the rated motor cur rent programmed in

window 42.

The alarm relays are not switching - Check that the wire links between terminals 6

and 7 are removed according to “Wiring”.

8

Continue

Dismantling and disposal

The housing is made of recyclable plastic, PC/ABS and the circuit

board contain small amount of tin and lead. When disposing, the

parts must be handled and recycled in accordance with local regula-

tions.

EU (European Union) specifications

EMC EN 50081-1, EN 50081-2,

EN 50082-1, EN 61000-6-2

Electrical safety IEC 947-5-1

Rated insulated voltage 690 V

Rated impulse withstand voltage 4000V

Pollution degree 2

Terminals 3, 4, 5, 6, 7 and 8 are basic insulated from the line.

Terminals 3 and 4 are basic insulated from terminals 5, 6, 7 and 8.

US specifications

FCC (Federal Communications Commission). This equipment has

been tested and found to comply with the limits for a class A digital

device pursuant to the Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interfer-

ence when the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruc-

tion manual, may cause harmful interference, in which case, the user

will be required to correct the interference at their own expense.

Canada specifications

DOC (Department of communications). This digital apparatus does

not exceed the Class A limits for radio noise emissions from digital

apparatus as set out in the Canadian interference-Causing Equipment

Regulations. Le présent appareil numérique n'ément pas de bruits

radio-électriques dépassant les limites applicables aux appareils

numériques de la Classe A prestite dans le Régelement sur le brouil-

lage radioélectrique édicté du Canada.

9

Window Function Range Default Custom Symbol

14 MIN Main Alarm

(relay R1)

0-125 0 %

0-745 0 kW

0-125 0 %

0-999 0

21 MAX Main Alarm

margin

0-100 16 %

22 MAX Pre-Alarm

margin

0-100 8 %

23 MIN Pre-Alarm

margin

0-100 8 %

24 MIN Main Alarm

margin

0-100 16 %

31 Star t delay 1-999 2 s

32 Response delay 0.1-90 0.5 s

33 Hysteresis 0-50 0 %

41 Rated motor power 0.10-745 2.2 kW

0.13-999 3

42 Rated current 0.01-999 5.6 A

43 Number of phases 1PH/3PH 3PH

61 Main alarm latch on/OFF OFF

62 Alarm at no motor

current

on/OFF OFF

63 Main Alarm relay R1 nc/no nc

64 Pre-Alarm relay R2 nc/no no

81 Digital input rES/AU/bLo rES

82 Block timer 0.0-90 0.0 s

91 Analog output 0.20/4.20/20.0/

20.4

0.20

99 Factor y defaults dEF/USr dEF

SERVICE

This manual is valid for the following model:

EL-FI M20

Document number: 01-2551-01

Document version: r1a

Date of release: 2002-02-26

Emotron AB reserves the right to alter product specifications without

prior notification. No part of this document may be reproduced with-

out permission from Emotron AB.

For more information contact your local sales outlet or one of the

Emotron companies below or visit us at: www.emotron.com

Emotron AB, Headquater, Sweden

Mörsaregatan 12, Box 222 25

SE-250 24 Helsingborg, Sweden

Tel. +46 42 169900

Fax +46 42 169949

Emotron Antriebssysteme GmbH, Germany

Tel. +49 3943 92050

Fax +49 3943 92055

Emotron B.V., The Netherlands &Belgium

Tel. +31 497 389222

Fax +31 497 386275

Emotron Drives (UK) Ltd, Great Britain

Tel. +44 1270 879 440

Fax +44 1270 886 119

Emotron El-Fi SA, Spain

Tel. +34 93 209 14 99

Fax +34 93 209 12 45

Emotron Inc., USA

Tel. +1 (419) 841-7774

Fax +1 (419) 843-5816

K.K: El-Fi, Japan

Tel. +81 42 528 88 20

Fax +81 42 528 88 21

11

PARAMETER LIST

Window Function Range Default Custom Symbol

00 Alarm indication

01 Measured shaft

power in % rated

power

0-125 0-125 %

Measured shaft

power in kW

0-745 kW

Measured shaft

power in % rated

power

0-125 %

Measured shaft

power in HP

0-999

02 Measured line volt-

age

90-760 V V

03 Measured current 0.00-999 A A

04 Parameter lock 0-999 Ï

05 Monitor function OVER- and UNDER-

LOAD, OVERLOAD,

UNDERLOAD

OVERLOAD and

UNDERLOAD

11 MAX Main Alarm

(relay R1)

0-125 100 %

0-745 2.2 kW

0-125 100 %

0-999 3

12 MAX Pre-Alarm

(relay R2)

0-125 100 %

0-745 2.2 kW

0-125 100 %

0-999 3

13 MIN Pre-Alarm

(relay R2)

0-125 0 %

0-745 0 kW

0-125 0 %

0-999 0

10

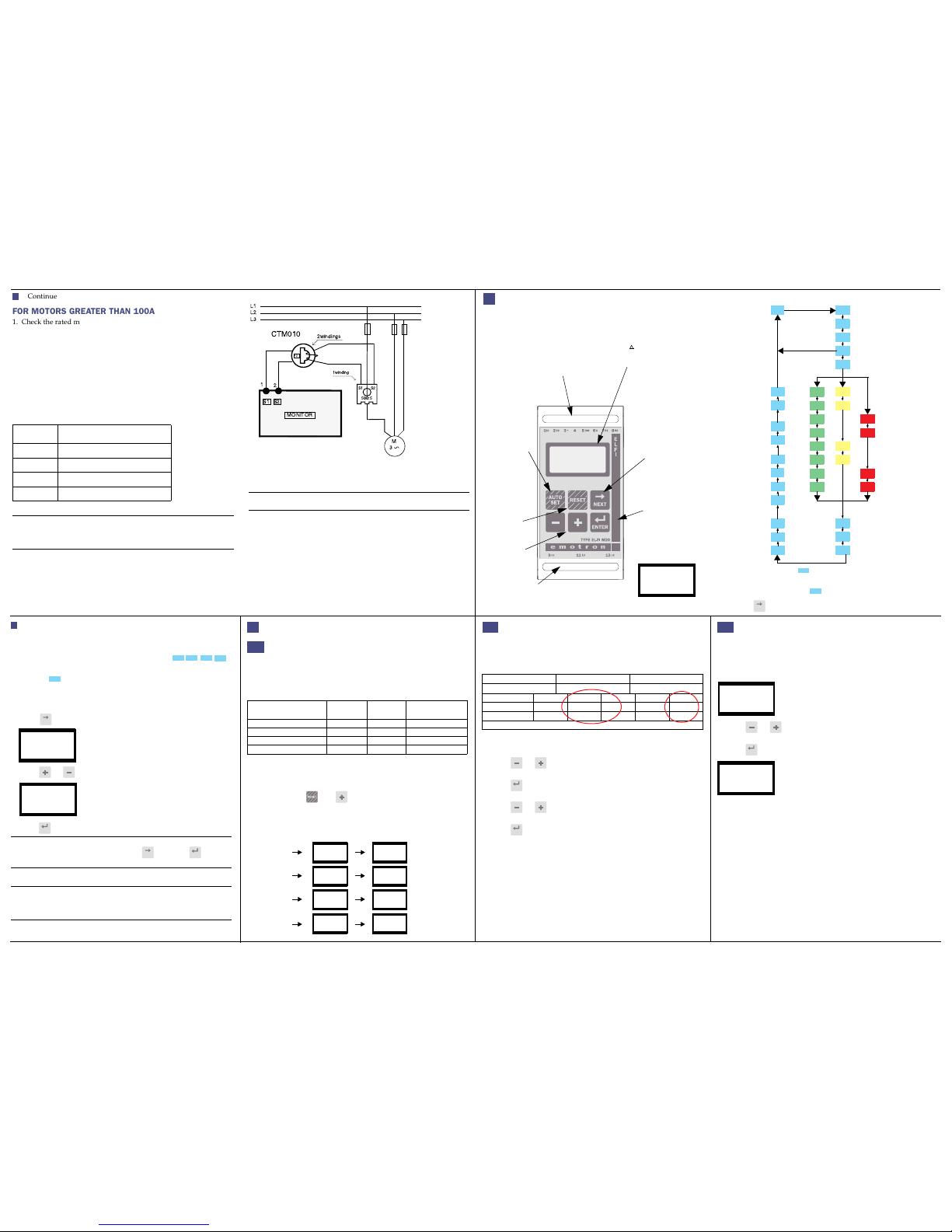

TECHNICAL DATA

Dimensions (WxHxD) 45x90x115 mm (1.77" x 3.54" x 4.53")

Mounting 35 mm DIN-rail 46277

Weight 0.30 kg (10.5 oz)

Supply voltage (±10%) 1x100-240 VAC, 3x100-240 VAC, 3x380-500 VAC, 3x525-

600 VAC, 3x600-690 VAC

Frequency 50 or 60 Hz

Current input Current transformer; CTM 010, 025, 050 and 100 (>100A

extra transformer needed)

Power consumption max 6 VA

Start-up delay 1-999 s

Hysteresis 0-50% of rated motor power

Response delay 0.1-90 s

Relay output 5 A/240 VAC Resistive, 1.5 A/240 VAC Pilot duty/AC12

Analog output max load 500 ohm

Digital input max 240 VAC or 48 VDC. High:>24 VAC/DC.

Low:<1 VAC/DC

Fuse max 10 A

Terminal wire size Use 75°C copper (CU) wire only. 0.2-4.0 mm2single core

(AWG12). 0.2-2.5 mm2flexible core (AWG14), stripped length

8 mm (0.32")

Terminal tightening torque 0.56-0.79 Nm (5-7 lb-in)

Accuracy ±2%, ±1 unit cos phi>0.5; excl. current transformer; +20°C

(+68°F)

Repeatability ±1 unit 24h; +20 °C (+68°F)

Temperature tolerance max 0.1%/°C

Operating temperature -20 to +50 °C (4°F to +122°F)

Storage temperate -30 to +80 °C (22°F to +176°F)

Protection class IP20

Approved to CE, cUL (UL and CSA up to 600 V)

9

115mm(4.53)

45mm (1.77)

26mm

(1.02) 35mm

(1.38)

90mm(3.54)

Reset to FACTORY DEFAULTS (Window 99)

The FACTORY DEFAULTS are reset by entering “dEF” in window 99.

If Window 99 shows “USr” it indicates that the settings have been

changed to user specific settings.

View ALARM MESSAGE (Window 00)

In an alarm condition, the window 00 appears automatically. The

window indicates the following Alarm conditions. Window 00 is

always blinking.

F

F^

LU

00

0U

00

F0

00

00

00

00

00

00

F_

FOOO

!

!

!

!

!!

!!

O

_Pre-Alarm MAX

level reached

Alarm MAX

level reached

Pre-Alarm MIN

level reached

Alarm MIN

level reached

Under voltage,

switch of f the

Over voltage,

switch of the

No motor current

Window 62=on

Out Of Range.

This message

appears only in

window 01 (actual

load) or 03 (actual

current)

supply!

supply!

Continue

Set ANALOG OUTPUT (Window 91)

The ANALOG OUTPUT provides an analog signal of either 0-20 mA

or 4-20 mA signal which represents the motor shaft power. The signal

can be inverted. Full scale: rated motor power.

Fig 12. Analog Output.

LOCK PARAMETERS (Window 04)

To avoid unintentional change of parameter settings the program-

ming can be locked by entering the code “369” in window 04. Now

only the motor variables LOAD [01], VOLTAGE [02] and CURRENT

[03] can be checked. Follow the same procedure to UNLOCK the

monitor. The AutoSet button is disabled when parameters are locked.

AutoSet via Digital Input is always active if window 81 is set to AU

(AutoSet).

Note!

The “Lock” symbol appears in all windows.

7

4.20

91

PSHAFT

100%

0%

0mA 4mA 20mA Output

20.4

20.0

0.20

4.20

24

%

01

Ï