EMPERO EMP.KTE.70 User manual

1

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

CONTENTS

A GENERAL INFORMATION Page 2

A1 PRODUCT DESCRIPTION Page 3

A2 TECHNICAL INFORMATION Page 3

A3 TRANSPORTATION Page 4

A4 UNPACKING Page 4

B INSTALLATION Page 4

C SAFETY INSTRUCTIONS Page 5

D OPERATION Page 6

E CLEANING & MAINTENANCE Page 7

F TROUBLESHOOTING Page 8

G SPARE PART LIST- EXPLODING DRAWING Page 9

H ELECTRIC CIRCUIT SCHEMA Page 13

2

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

A GENERAL INFORMATION

Before installing the appliance, read operation and maintenance instructions

carefully.Wrong installation and part changing may damage the product or may cause

injury on people.These are not in our company’s responsibility to damage the

appliance intentionally,negligence,detriments because of disobeying instructions and

regulations,wrong connections.Unauthorized intervention to appliance invalidates the

warranty.

1. This instruction manual should be kept in a safe place for future reference.

2. Installation should be made in accordance with ordinances and security rules of

that country by a qualified service personnel.

3. This appliance has to be used by trained person.

4. Please turn off the appliance immediately in the event of malfunction or failure.The

appliance should be repaired only by authorized service personnel.Please demand

original spare part.

3

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

A1 PRODUCT DESCRIPTION

*The Professional Boiling Pan (Electrical) ,that provides high efficiency has been designed to

be used in industrial kitchens.

Product Code

Dimensions (mm)

Weight (kg)

Packaging

Dimensions (mm)

EMP.KTE.70

800x730x850

80

890x960x1150

EMP.KTE.150

800x900x850

100

1060x920x1180

EMP.KTE.250

1000x900x850

190

1310x1070x1140

A2 TECHNICAL INFORMATION

Product Code

Capacity

(lt)

Electric Inlet

(V)

Cable

(mm²)

Power

(KW)

EMP.KTE.70

70

380

5X4

12

EMP.KTE.150

150

380

5X6

18

EMP.KTE.250

250

380

5x10

30

4

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

A3 TRANSPORTATION

* This appliance can not be moved by hand from area to area. Therefore Use a hauling truck

(forklift or pallet jack) to move the appliance. ( The lifting arms of the of forklift or pallet jack

must reach up to more than half part of t appliance underneath.

A4 UNPACKING

*Please unpack the package according to the security codes and ordinances of current

country and get rid from the pack.Parts which contacts with food are produced by stainless

steel.All plastic parts are marked by material’s symbol.

*Please check that all the parts of appliance had come completely and if they are damaged or

not during the shipping.

B INSTALLATION

*Please place the product to straight and sturdy ground,please take necessary steps against

possibility of overturn.

*Technician who will serve for installation and service for the appliance must be professional

on this subject and must have installation and service licenses by the company.

*Connection to Electric Power Supply must be done by authorized person.

*Please be sure that the voltage connected to appliance must be equal with the voltage which

is on appliance’s label.

This appliance must be connected to an earthed outlet in accordance with safety rules

and standards.

*Appliance’s earthing must be connected to earthing line on panel which is nearest to

electric installation.

*Connection to the main fuse and leak current fuse must be done in accordance with the

current regulations.

*If the location where boiling pans (electrical) placed is covered with nonflammable heat

insulation material,the distance between them must be 5 cm.Otherwise it should be at least 20

cm.The appliance shouldn’t be operated under chimney hood.

!

5

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

C SAFETY INSTRUCTIONS

*Do not use the appliance in insufficient lighted place.

*Do not touch the moving attachments while the appliance operates.

*Do not install the appliance in the presence of flammable or explosive materials.

*Do not operate the appliance when the machine is empty.

*Do not load so less or more than appliance’s capacity.

*Do not attempt to use the appliance without suitable protective equipments.

*Because of any reason if there is a fire or flame flare where the appliance is

used,turn off all gas valves and electric contactor switch quickly and use fire

extinguisher .Never use water to extinguish the fire.

*All the damages because of not having earthing connection will not be on

warranty.

*Do not forget to evacuate the pressure air that is in paries.

!

!

!

!

!

!

!

6

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

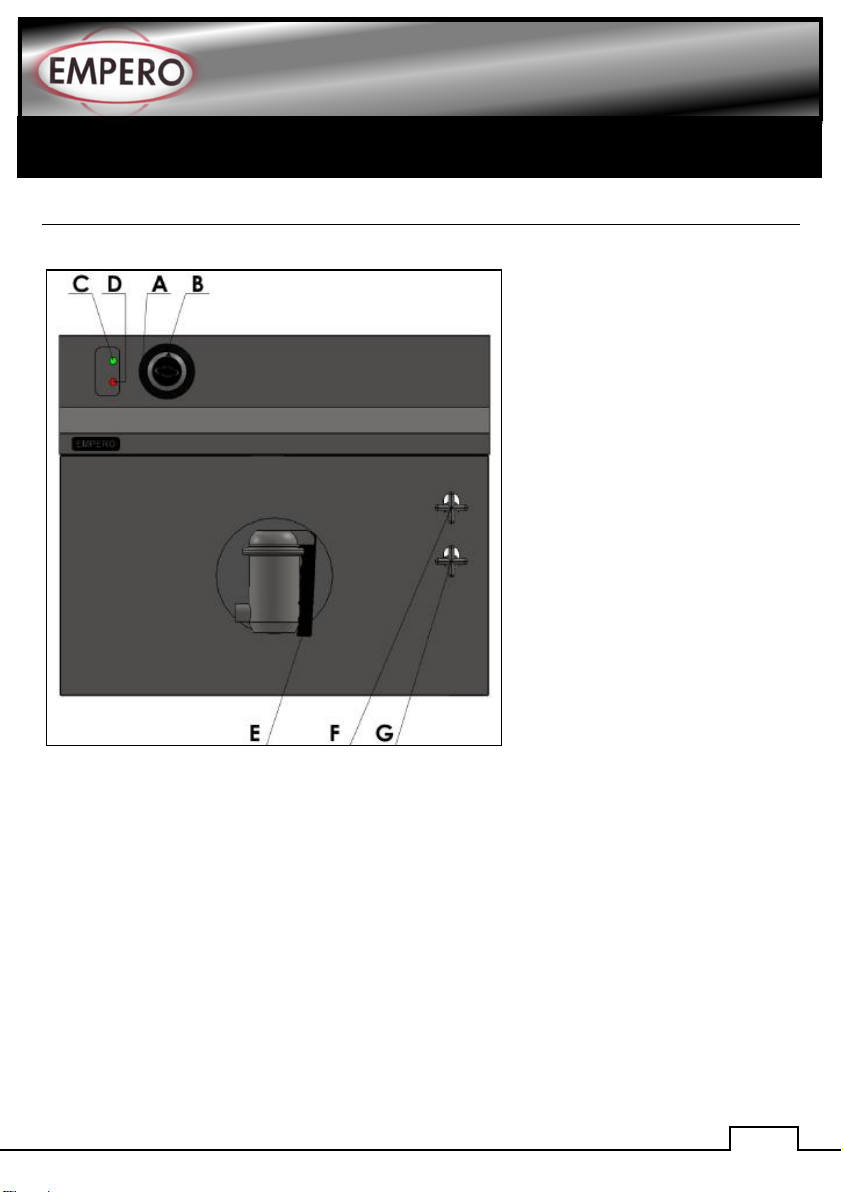

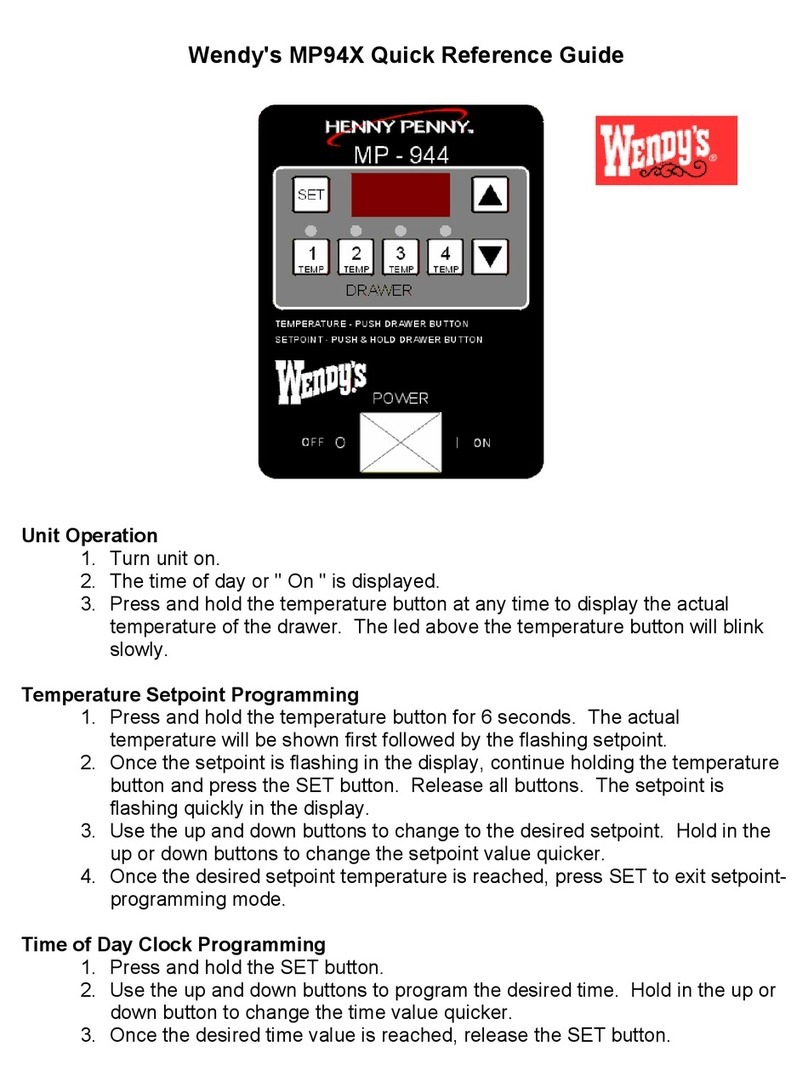

D OPERATION

*Control Panel;

A: ON position

B: OFF position

C: Indicator lamp

D: Signal lamp

E: Evacuation valve

F: Water outlet valve

G: Water inlet valve

*Operating;

•In order to operate the appliance,plug in.

•Turn on the tap in order to fill the paries that is under cooking tank with water.

•Adjust the heat setting.

•Be sure that materials that will be cooked had been prepared.

•Add water to pan through the tap at the top.

•Close the appliance’s lid.

•Check the manometer after cooking and remove the pressure from the paries.

•Take the cooked foods from evacuation tap.

•When the operation is completed,switch off the thermostat and unplug the appliance.

7

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

E CLEANING & MAINTENANCE

➢CLEANING AND MAINTENANCE AFTER EVERY USE

•Always turn off the appliance and disconnect from the power supply before cleaning.

•Clean the outer surface of the appliance,cooking pan and lid with moist cloth.

•Do not use abrasive cleaning chemicals as these can leave harmful residues

•Do not clean the appliance by spraying water directly,otherwise electric motor may

get damaged.

➢PERIODIC CLEANING AND MAINTENANCE

•Maintenance should be done by qualified person.

•Get the periodic maintenance of the appliance once in every 15 days.

•Maintenance of the appliance’s contactor should be done by compressed air

according to frequency of use.

•Check the pressure valve and manometer according to frequency of use.

8

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

F TROUBLESHOOTING

THE APPLIANCE DOESN’T OPERATE

1. Check if the appliance is plugged in.

2. Check the electrical connections and

voltage.

3. Check if the fuse is on or off.

THE APPLIANCE DOESN’T COOK WELL

1. Check the temperature adjustment that

is working in needed and correct degree

or not

2. Do not overload the pan.

THE APPLIANCE STOPPED

1. The appliance can stop due to low

voltage.In this situation check the

voltage.

•If cooking at boiling pans (electrical) is not done at suitable quality

•If any function of security doesn’t work

➢Do not use the appliance.

*If these problems are still going on,contact with our authorized services.

9

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

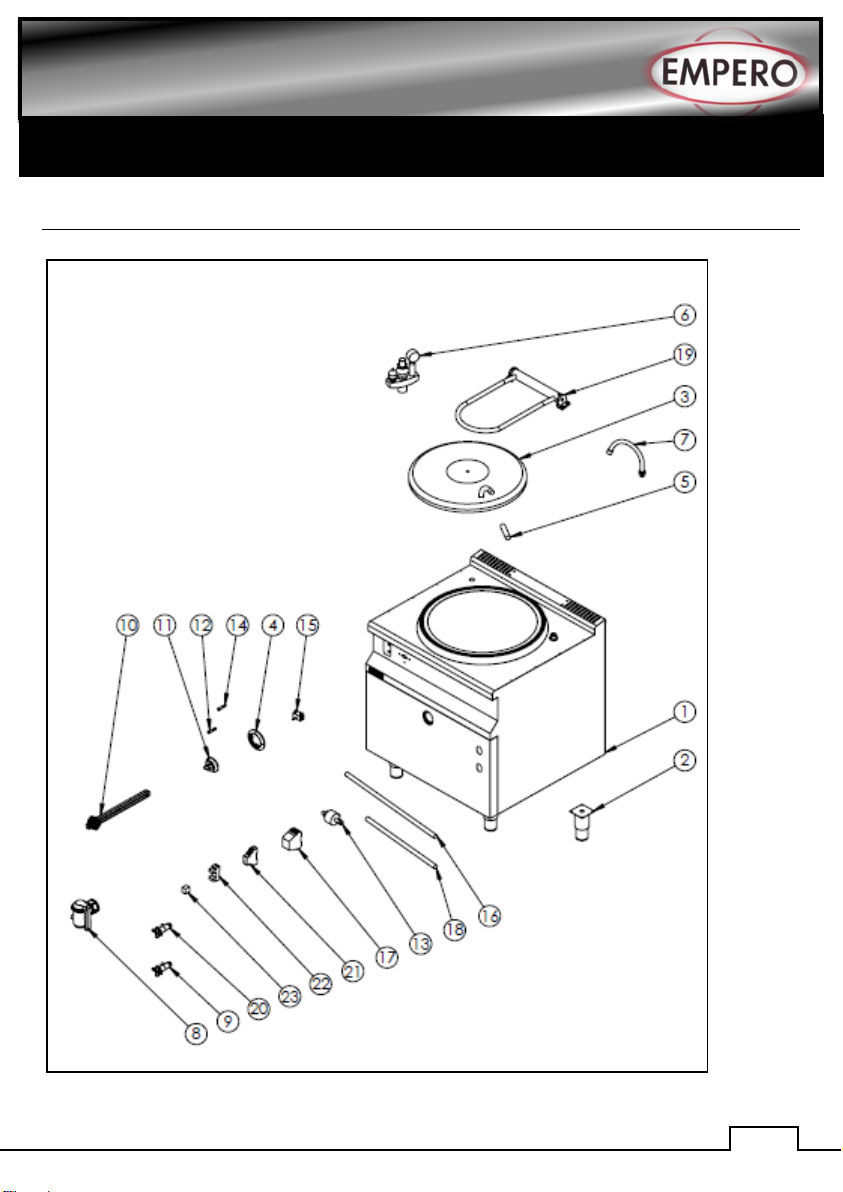

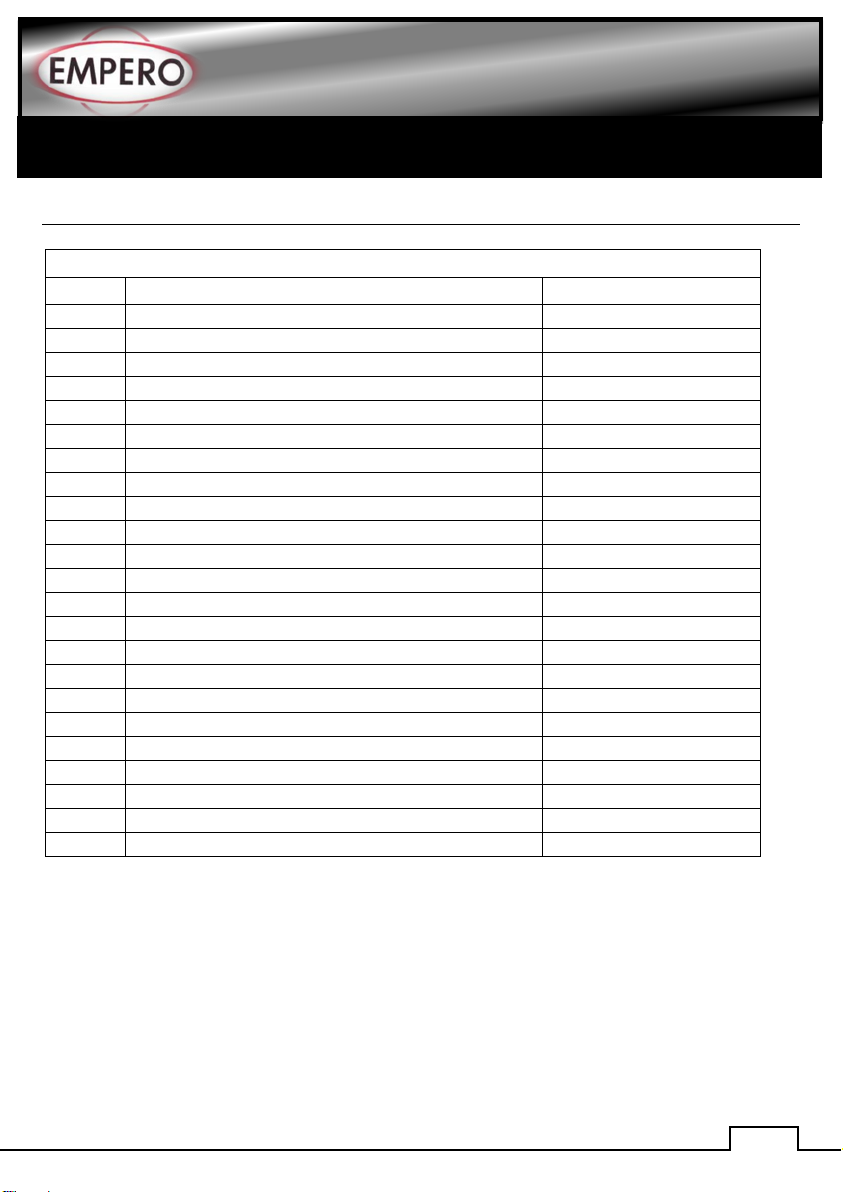

G SPARE PART LIST-EXPLODING DRAWING

10

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

G SPARE PART LIST-EXPLODING DRAWING

PRODUCT CODE: EMP.KTE.70

NO

PRODUCT NAME

P.CODE

1

BASE FRAME

Y.EMP.KTE.70.001

2

FEET

Y.EMP.KTE.70.002

3

LID

Y.EMP.KTE.70.003

4

BUTTON BUFFER

Y.EMP.KTE.70.004

5

HANDLE

Y.EMP.KTE.70.005

6

MANOMETER

Y.EMP.KTE.70.006

7

TAP

Y.EMP.KTE.70.007

8

DRAINAGE VALVE

Y.EMP.KTE.70.008

9

DRAINAGE VALVE (INTERNAL WALL)

Y.EMP.KTE.70.009

10

RESISITANCE

Y.EMP.KTE.70.010

11

BUTTON

Y.EMP.KTE.70.011

12

WARNING LAMP-RED

Y.EMP.KTE.70.012

13

SWITCH

Y.EMP.KTE.70.013

14

WARNING LAMP-GREEN

Y.EMP.KTE.70.014

15

SWITCH 0-1

Y.EMP.KTE.70.015

16

FLEX HOSE 100CM

Y.EMP.KTE.70.016

17

CONTACTOR 5,5 KW

Y.EMP.KTE.70.017

18

FLEX HOSE 50CM

Y.EMP.KTE.70.018

19

LID LIFTING MECHANISM

Y.EMP.KTE.70.019

20

VALVE (INTERNAL WALL)

Y.EMP.KTE.70.020

21

LIQUID LEVEL RELAY

Y.EMP.KTE.70.021

22

ABB RELAY SOCKET

Y.EMP.KTE.70.022

23

ABB RELAY

Y.EMP.KTE.70.023

11

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

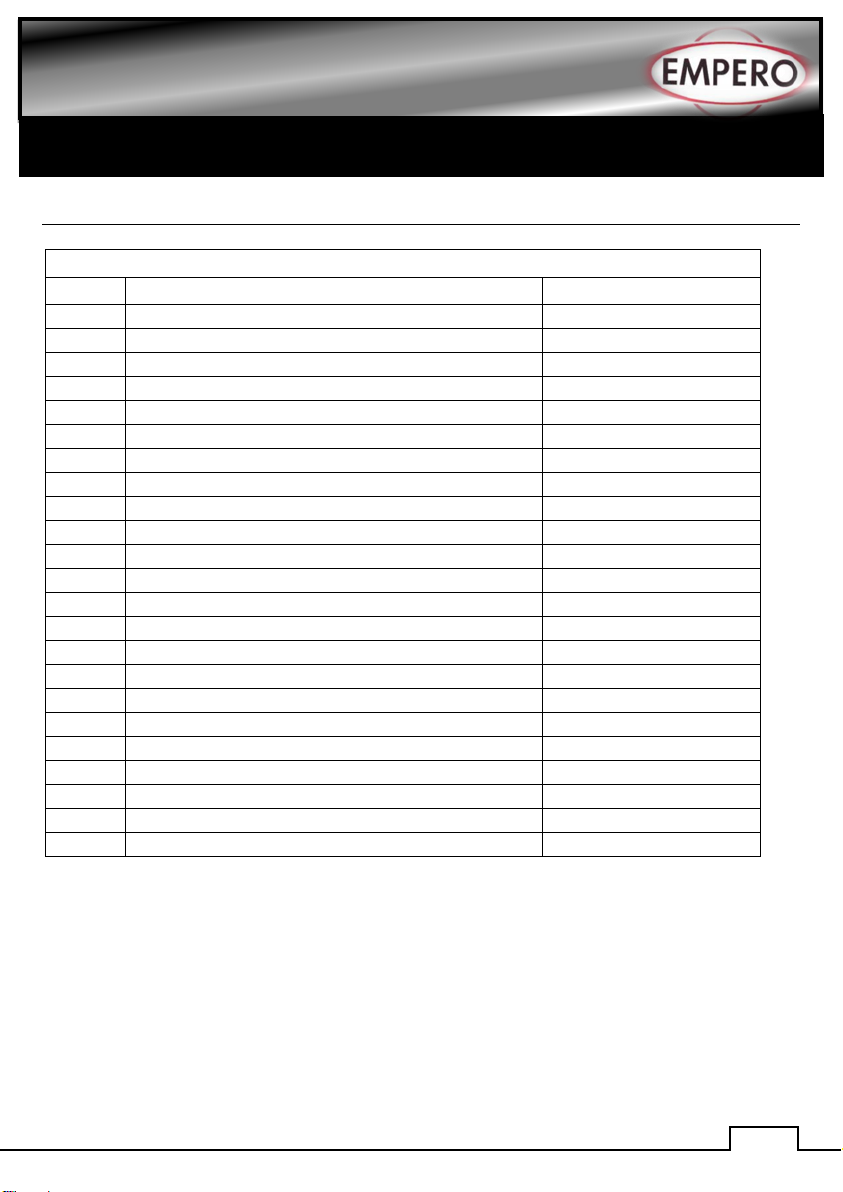

G SPARE PART LIST-EXPLODING DRAWING

PRODUCT CODE: EMP.KTE.150

NO

PRODUCT NAME

P.CODE

1

BASE FRAME

Y.EMP.KTE.150.001

2

FEET

Y.EMP.KTE.150.002

3

LID

Y.EMP.KTE.150.003

4

BUTTON BUFFER

Y.EMP.KTE.150.004

5

HANDLE

Y.EMP.KTE.150.005

6

MANOMETER

Y.EMP.KTE.150.006

7

TAP

Y.EMP.KTE.150.007

8

DRAINAGE VALVE

Y.EMP.KTE.150.008

9

DRAINAGE VALVE (INTERNAL WALL)

Y.EMP.KTE.150.009

10

RESISITANCE

Y.EMP.KTE.150.010

11

BUTTON

Y.EMP.KTE.150.011

12

WARNING LAMP-RED

Y.EMP.KTE.150.012

13

SWITCH

Y.EMP.KTE.150.013

14

WARNING LAMP-GREEN

Y.EMP.KTE.150.014

15

SWITCH 0-1

Y.EMP.KTE.150.015

16

FLEX HOSE 100CM

Y.EMP.KTE.150.016

17

CONTACTOR 5,5 KW

Y.EMP.KTE.150.017

18

FLEX HOSE 50CM

Y.EMP.KTE.150.018

19

LID LIFTING MECHANISM

Y.EMP.KTE.150.019

20

VALVE (INTERNAL WALL)

Y.EMP.KTE.150.020

21

LIQUID LEVEL RELAY

Y.EMP.KTE.150.021

22

ABB RELAY SOCKET

Y.EMP.KTE.150.022

23

ABB RELAY

Y.EMP.KTE.150.023

12

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

G SPARE PART LIST-EXPLODING DRAWING

PRODUCT CODE: EMP.KTE.250

NO

PRODUCT NAME

P.CODE

1

BASE FRAME

Y.EMP.KTE.250.001

2

FEET

Y.EMP.KTE.250.002

3

LID

Y.EMP.KTE.250.003

4

BUTTON BUFFER

Y.EMP.KTE.250.004

5

HANDLE

Y.EMP.KTE.250.005

6

MANOMETER

Y.EMP.KTE.250.006

7

TAP

Y.EMP.KTE.250.007

8

DRAINAGE VALVE

Y.EMP.KTE.250.008

9

DRAINAGE VALVE (INTERNAL WALL)

Y.EMP.KTE.250.009

10

RESISITANCE

Y.EMP.KTE.250.010

11

BUTTON

Y.EMP.KTE.250.011

12

WARNING LAMP-RED

Y.EMP.KTE.250.012

13

SWITCH

Y.EMP.KTE.250.013

14

WARNING LAMP-GREEN

Y.EMP.KTE.250.014

15

SWITCH 0-1

Y.EMP.KTE.250.015

16

FLEX HOSE 100CM

Y.EMP.KTE.250.016

17

CONTACTOR 5,5 KW

Y.EMP.KTE.250.017

18

FLEX HOSE 50CM

Y.EMP.KTE.250.018

19

LID LIFTING MECHANISM

Y.EMP.KTE.250.019

20

VALVE (INTERNAL WALL)

Y.EMP.KTE.250.020

21

LIQUID LEVEL RELAY

Y.EMP.KTE.250.021

22

ABB RELAY SOCKET

Y.EMP.KTE.250.022

23

ABB RELAY

Y.EMP.KTE.250.023

13

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

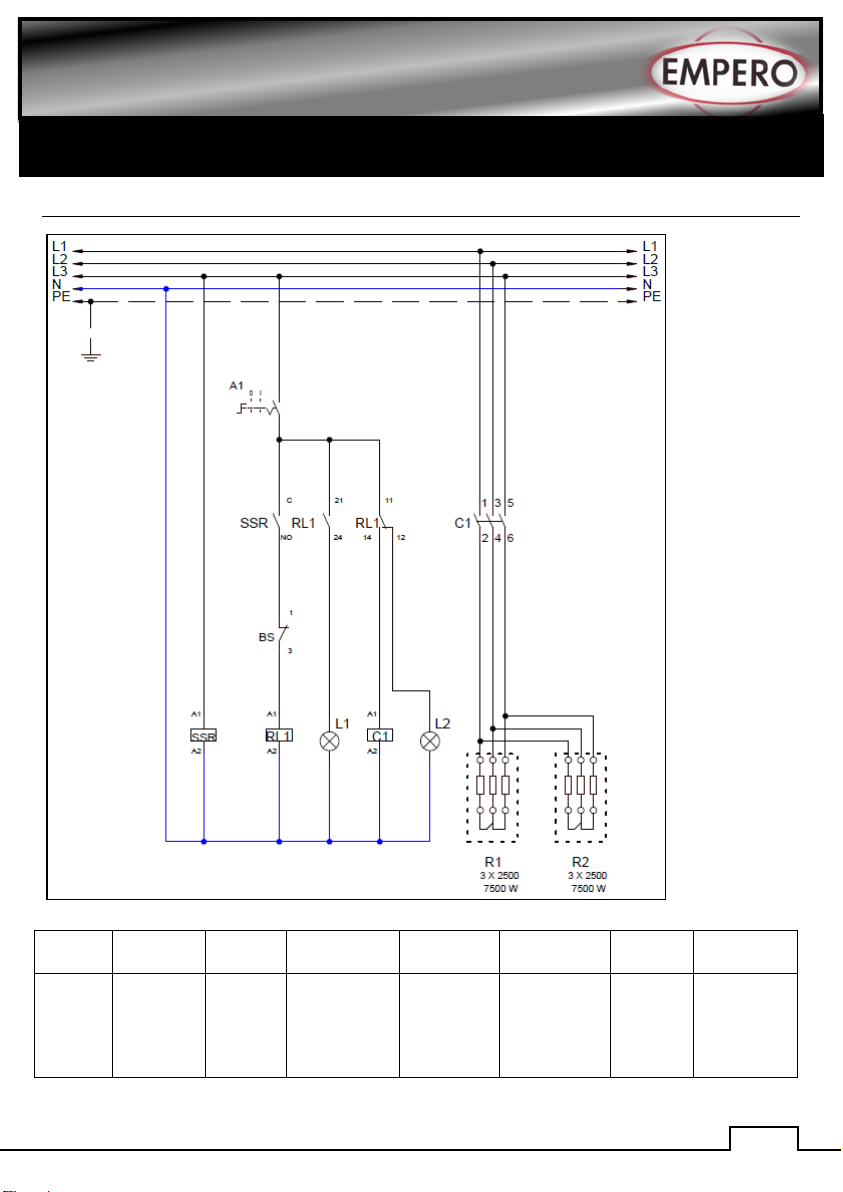

H ELECTRIC CIRCUIT SCHEMA

EMP.KTE.70

RL1

BS

SSR-

SSC

A1

C1

R1-R2

L1

L2

Small

Role

220 V.

Pressure

Switch

O4

Liquid

Level

Role

(0-1)

Single

Phase

Circuit

Breaker

Heater

Contactor

Heater

Resistance

Heater

Open

Signal

Lamp

Heater

Off Signal

Lamp

14

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

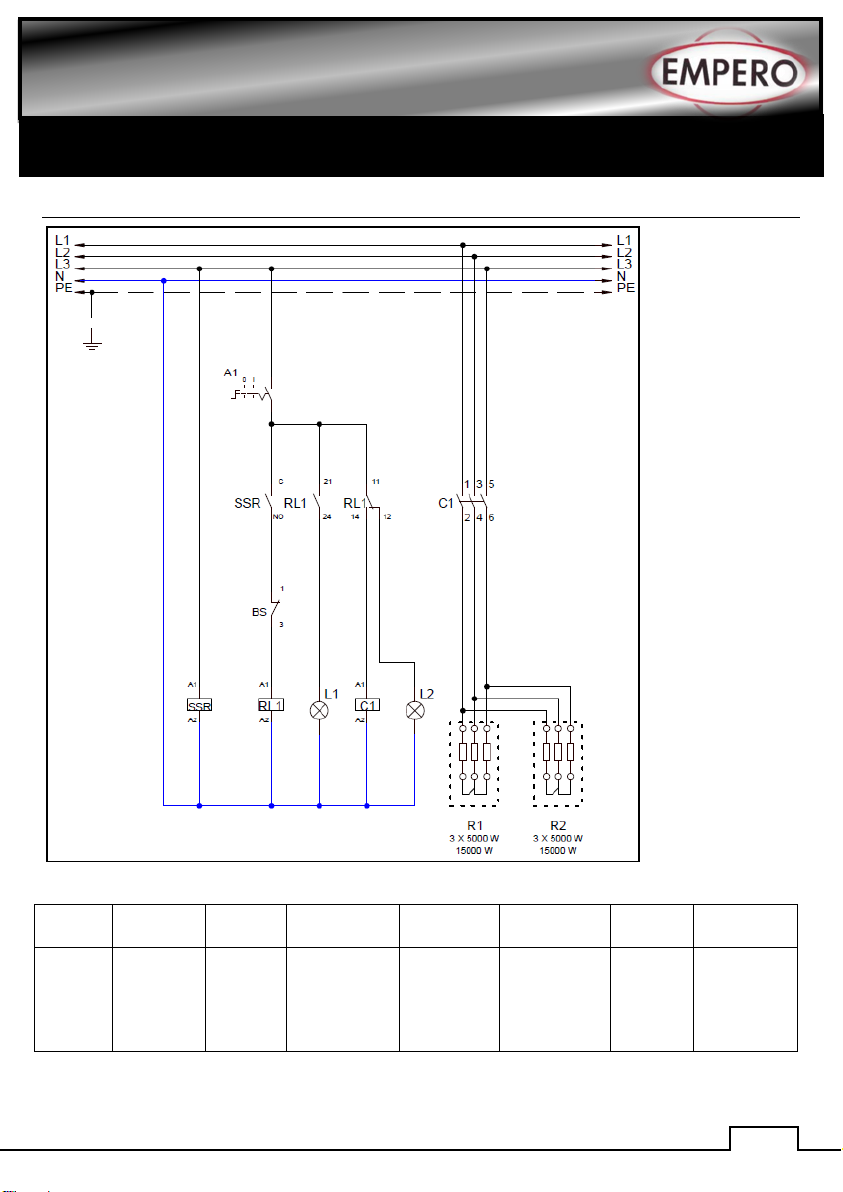

H ELECTRIC CIRCUIT SCHEMA

EMP.KTE.150

RL1

BS

SSR-

SSC

A1

C1

R1-R2

L1

L2

Small

Role

220 V.

Pressure

Switch

O4

Liquid

Level

Role

(0-1)

Single

Phase

Circuit

Breaker

Heater

Contactor

Heater

Resistance

Heater

Open

Signal

Lamp

Heater

Off Signal

Lamp

15

BOILING PAN (ELECTRICAL)

Kasap Tip Dik Buzdolapları

H ELECTRIC CIRCUIT SCHEMA

EMP.KTE.250

RL1

BS

SSR-

SSC

A1

C1

R1-R2

L1

L2

Small

Role

220 V.

Pressure

Switch

O4

Liquid

Level

Role

(0-1)

Single

Phase

Circuit

Breaker

Heater

Contactor

Heater

Resistance

Heater

Open

Signal

Lamp

Heater

Off Signal

Lamp

This manual suits for next models

2

Table of contents

Other EMPERO Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Hatco

Hatco TOASTMAX TM3-5 Series Installation and operating manual

Rational

Rational TC 61/101 E Operator and installation manual

Henny Penny

Henny Penny Wendy's MP94 Series Quick reference guide

Flavor Burst

Flavor Burst TS 80FCB manual

Hendi

Hendi Grillsystem 1020 User instructions

Waldorf

Waldorf Bold PCB8140E-7 Installation and operating manual