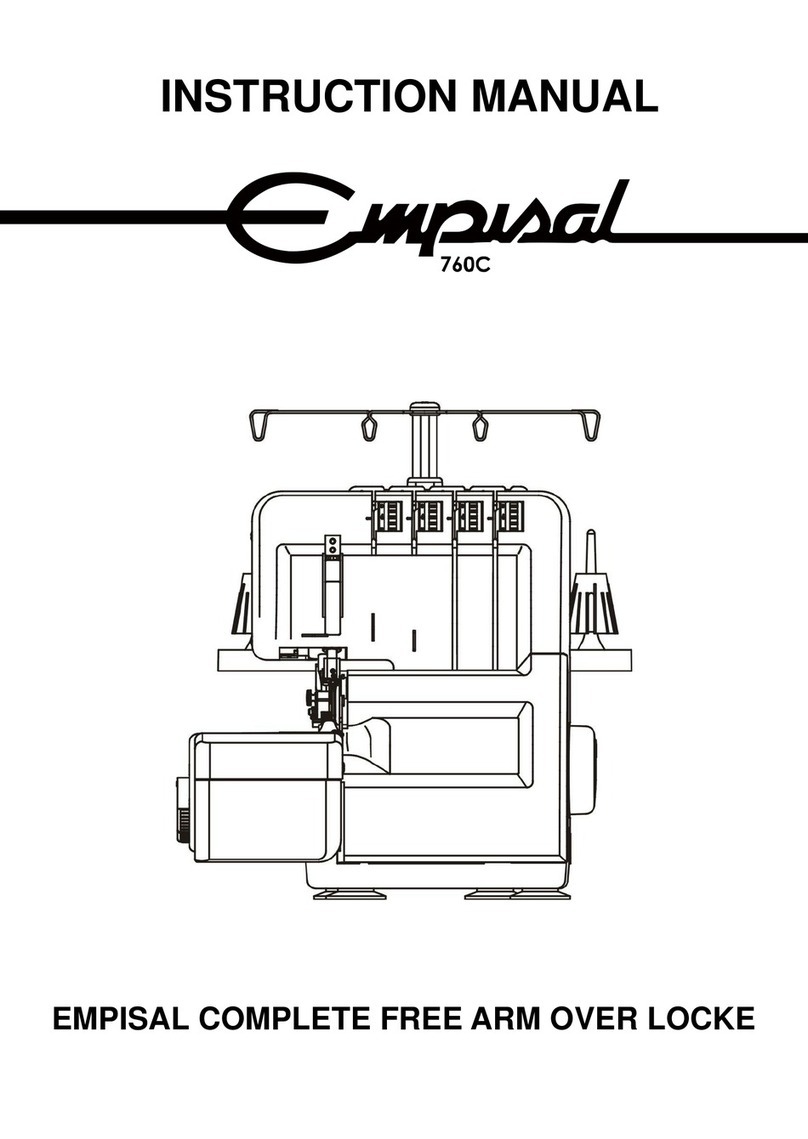

Empisal 760 User manual

- 0 -

MODEL: 760

INSTRUCTION MANUAL

EMPISAL COMPLETEFREE ARM OVER LOCKER

your creative assistant

- 1 -

Safety instructions

Like any other electrical device, a sewing machine can cause serious, even

life-threatening injuries. To avoid this, and in order to work safely:

• Before initial use of your sewing machine, read these operating instructions

thoroughly.

• Keep the operating instructions in a suitable place near the machine. When

passing the appliance on to others, always enclose the operating

instructions.

• Always disconnect the power supply when leaving the machine unattended.

This will prevent the risk of accidents if the machine is switched on

accidentally.

• First pull the power plug before changing the bulb or performing maintenance

work on the machine.

This will prevent possibly life-threatening electric shocks.

• Do not remove the plug from the socket by pulling on the cable. Always grip

the plug and not the cable when pulling out the power plug.

• Only use the sewing machine in dry rooms.

Don’t use the machine in wet condition and location.

• In case of any visible damage on the machine, the foot switch or the power

cable: Have the damage repaired by Customer Service before using the

sewing machine again.

• The supply cord cannot be replaced. If the supply cord connected with foot

controller is damaged the foot controller shall be scrapped.

• Never let children or elderly persons handle the machine unsupervised

because they may not properly appreciate the possible dangers. Keep

electrical appliances outside the reach of children.

• Never use the machine when the ventilation apertures are blocked. Keep the

ventilation apertures of the machine and the foot switch free from fluff, dust

and waste material.

• Don’t let children play with sewing machine.

• Never use the machines if the air went are blocked keep the air wends free

form dust, fusel and leftovers.

• Never place anything on the foot controller.

• This appliance can be used by children aged from 8 years and above and

persons with

reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they

have been given supervision or instruction concerning use of the appliance in

a safe way and

understand the hazards involved.

• Children shall not play with the appliance.

• Cleaning and user maintenance shall not be made by children without

supervision.

- 2 -

• Keep your work space tidy. An untidy workplace can lead to accidents.

• Provide adequate lighting when working!

• Do not wear loose clothing or jewelry, as these can be caught in the moving

parts. You should also wear a hair net if you have long hair.

• Avoid abnormal posture. Remain steady and in a well-balanced positionat all

times.

• Be alert! Pay attention to what you are doing. Always take a rational

approach to your work. Never work with the sewing machine if you are

unable to concentrate or if you are feeling unwell!

• If accidents occur as a result of handling the machine with insufficient care, or

failure to follow the safety instructions in this manual, then the manufacturer

cannot accept liability.

• Please use for your sewing machine the ZHEJIANG FOUNDER presser foot,

type KD-2902.

Power rating: 220 - 240V ~ , 50/60Hz

Current rating: 1.0A

Protection Class : II

• The sound pressure level under normal operating conditions is 78dB (A).

• If the supply cord that fixed with foot controller is damaged, it must be

replaced by the manufacturer or its service agent or a similar qualified person

in order to avoid a hazard.

- 3 -

INTRODUCTION

THANK YOU FOR CHOOSING OUR OVERLOCK MACHINE

This overlock machine can stitch dependable seams on all kinds offabric, both light and heavy,

includingcotton, wool, rayon, tricot, jersey, andknits.

You do not need a special table forthis portable machine.

We suggest that you read this instruction manual carefully before you start to operate the machine.

FOR YOUR SAFETY

1. Keep youreyes on the needles when operating the overlock machine. Do not touch the hand

wheel, the cutter or the needles when the machine is running.

2. Turn off the power switch, and pull out the plug from electric socket in the following cases:

*When you have finished your sewing.

*When you leave the over locker temporarily.

*When replacing the parts.

*When cleaning and adjusting the machine.

BEFORE YOU USE

1. Wipe dust and oil off the machine to avoid any stains on the sewing materials.

2. Test sew by using the same sewing materials you intend to sew.

3. Read this instruction manual thoroughly before replacing the cutters and the needles. Follow the

instructions for correct replacements and adjustments.

- 4 -

TABLE OF CONTENTS

NAME OF MAINCOMPONENTS ......................................................................................5-6

SETTING UP YOURMACHINE .........................................................................................7-9

The position of thread stand ...................................................................................7

Cotton holders .......................................................................................................7

Spool caps............................................................................................................7

Connecting the foot control......................................................................................8

Controlling sewing speed ........................................................................................8

Safety switch.........................................................................................................8

ACCESSORIES.................................................................................................................9

USING THE MACHINE...................................................................................................... 10

Hand wheel......................................................................................................... 10

Front cover.......................................................................................................... 10

Free arm............................................................................................................. 10

LOOPER THREADING.......................................................................................................11

NEEDLE THREADING .......................................................................................................12

TRIAL SEWING.................................................................................................................13

ADJUSTING THREAD TENSIONS..................................................................................14-15

Adjusting the needle thread tensions .......................................................................15

Adjusting the looper thread tensions........................................................................15

MACHINEADJUSTMENT CHART.......................................................................................16

CHANGING THE THREAD..................................................................................................17

BUILT-IN POCKETHANDLE...............................................................................................17

ADJUSTMENTOF STITICHSTITCH LENGTH.......................................................................18

Stitch length setting...............................................................................................18

CUTTING WIDTH ..............................................................................................................19

The proper cutting width.........................................................................................19

Adjust to a wider cutting width.................................................................................19

Adjust to a narrower cutting width............................................................................19

CHANGING THE NEEDLE..................................................................................................20

REPLACING THE BULB.....................................................................................................20

REPLACING THE CUTTERS...............................................................................................21

THREE THREAD NARROWANDWIDE OVERLOCK STITCH ................................................22

FREEARM SEWING.........................................................................................................23

CONVERTIBLE PRESSER FOOT.......................................................................................23

ROLLED ANDNARROW EDGE.....................................................................................24-25

Rolled edge..........................................................................................................24

Narrow edge.........................................................................................................24

Rolled hemming....................................................................................................25

Narrow hemming...................................................................................................25

DIFFERENTIAL FEED...................................................................................................26-27

Differential feed mechanism...................................................................................26

Adjusting the differential feed..................................................................................26

Wavy knits & Gathering .........................................................................................27

Stretching to prevent puckering...............................................................................27

TROUBLE SHOOTING GUIDE............................................................................................28

CLEANING ANDLUBRICATING ..........................................................................................29

SPECIFICATION OF MACHINE...........................................................................................29

- 5 -

NAME OF MAIN COMPONENTS

1. Thread stand

2. Lower looper thread tensiondial

3. Spool pin

4. Spool holder

5. Handwheel

6. Base

7. Machine socket

8. Power switch

9. Front cover

10. Support bed

11. Free arm

12. Needle plate

13. Left needle thread tension dial

14. Right needle thread tension dial

15. Upper looper thread tensiondial

16. Thread guide plate

1

2

3

4

5

6

7

8

9

10

11

12

13

16

14

15

Always disconnect the power supply when leaving the machine unattended. This will prevent the

risk ofaccidents ifthe machine is switched on accidentally.

- 6 -

1. Upper looper

2. Lower looper

3. Free arm

4. Lower knife

5. Cutting width adjustment knob

6. Presserfoot

7. Upper knife

2

3

4

5

6

7

1

- 7 -

SETTING UP YOUR MACHINE

Set your Overlock machine on asturdyflat

surface.

[ THE POSITION OF THREAD STAND ]

Pull up thread stand to its highest point before

threading.

Turn the thread stand so the thread guides

come right above the spool pins.

[ COTTON HOLDERS ]

Both industrial cones and domestic type thread

spools can be used on this machine.

For large diameterindustrial cones use the

cone holders with the large end at the top.

For small diametercones. useUse the same

cone holders with the small end at the top.

[ SPOOL CAPS ]

When using domestic type thread spools,

remove the spool holders and place spool

caps over the thread spools.

Normal

Positioning catches

Spool holder

Domestic type

thread spool

Spool cap

Notch

- 8 -

[ CONNECTING THE FOOT CONTROL ]

Push foot control plug into the machine socket and then into main socket.

Turn on the power switch. This power switch controls both the machine power and sewing light.

[ CONTROLLING SEWING SPEED ]

The foot control regulates the sewing speed.

The sewing speed can be adjusted by

increasing or decreasing the pressure on the

foot control.

[ SAFETY SWITCH ]

This machine is equipped with a micro safety

switch.

The machineis automaticallycut offfrom the

motor electricity supplyif front cover is open.

Close both free arm and front cover before

you start sewing.

Foot control

Safety switch

Foot control

Powerswitch

Machine plug

Powersupply plug

Powersupply

Machine socket

- 9 -

ACCESSORIES

Tweezers

Spare uppercutter

Needles

Machine cover

Screwdriver

Brush

Hexagon wrench key

Instruction manual

Spool caps

- 10 -

Open the free arm for threading.

1. Remove the support bed as arrow.

2a. Press and pull up the free arm release lever.

2b. Pull up free arm as arrow way, when hinge

be released from needle plate.

USING THE MACHINE

[ HAND WHEEL]

Always turnhandwheel towardyou, i.e. the

same direction as on a household sewing

machine.

[ FRONT COVER ]

To open front cover, slide the hollowto the

right as far as it will go then pull front cover

toward you.

The front cover won't close while the free arm

is open.

[ FREE ARM ]

○,2

○,1

Free arm

release lever

2a

Hinge

Support bed

Free arm

Needle plate

2b

1

- 11 -

LOOPER THREADING

Warning: Before contriving please adjust main control switch to (OFF).

Correct threading is important otherwise uneven stitches or thread breakage may result.

Aconvenient threading chart is placed on the front panel inside the front cover.

In addition, each thread guide is coloured for

threading indication.

To help in threading, tweezers can be found in

the accessory box.

Threading must be carried out in the following

sequence.

1. FIRST……...Upper looper

2. SECOND…..Lower looper

3. THIRD……...Right needle

4. FINALLY……Left needle

1. Open thefront cover and free arm.

2. Turn the handwheel toward you until. the

looper comes to best position for threading.

3. Pass the upper looper thread and lower

looper thread as illustrated.

Important: The thread must lie correctly

between the two discs inside the tension

dials.

4. Pull out the thread end about 10 cm (4")

long from the looper eyes. Raise the

presser foot and place threads under it,

then lower the presser foot.

Upper looper thread Lowerlooper thread

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

8

7

6

5

5

8

5

2

3

4

6

7

Lower looper

Upper looper

Error!

2

Error!

1

3 ○,3

Thread between two discs

- 12 -

NEEDLE THREADING

5. Turn the hand wheel toward you until

needles are fully raised.

6. Pass theright andleft needle threads as

illustrated.

Important: The threadmust lie correctly

between the two discs inside the tension

dials.

Pass through the needle eyes from front to

back as illustrated.

7. Pull out thethreadend about 10 cm (4")

long from the needle eyes. Raise the

presser foot and place threads under it,

then lower the presser foot.

Left needle thread Right needle thread

Error!

Error!

2

Error!

1

3

Error!

Error!

Error!

Error!

Error!

Error!

Error!

Error!

8

5

2

3

4

6

7

6

Error!

Error!

Error!

Error!

8

7

Error!

5

4

6

Error!

Error!

Error!

Thread between two discs

- 13 -

TRIAL SEWING

When the overlock has been threaded for the

first time orre-threaded because of thread

breakage during sewing, start sewing in the

following manner.

Holding the end of threads between your left

finger tips, turn the handwheel slowly toward

you two or three times and check the thread

chain.

Place fabric for trial sewing under the presser

foot and start sewing slowly.

The fabric will be automatically fed.

Guide the fabric as you sew.

When work is finished, continue sewing to

form about 5 cm (2") long thread chain from

the end of fabric.

Cut the threads with a scissor.

Cloth

- 14 -

ADJUSTING THREAD TENSIONS

Thread tensions will vary according to the type and thickness of both thread and fabric.

Adjust the thread tension ofthe machine accordingly while checking the seam.

Thread tension: Turn dial toward smaller numbers, tension becomes loose.

Turn dial toward larger numbers, tensionbecomes tight.

B: Right needle thread

tension dial

D: Lower looper thread

tension dial

C: Upper looper thread

tension dial

A: Left needle thread

tension dial

Correct thread tension

Right needle thread

Left needle thread

Lower looper thread

Back side

Upper looper thread

6 mm (0.24”)

- 15 -

It is necessary to adjust the thread tension for the seams shown below.

[ ADJUSTING THE NEEDLE THREAD TENSIONS ]

[ ADJUSTING THE LOOPER THREAD TENSIONS ]

The left needle thread tension is too loose.

The right needle thread tension is too loose.

The lower looper thread is tight and/or

the upper looper thread is loose.

The upper looper threadis tight and/or

the lower looper thread is loose.

Loosen the lower looper thread tension

and/or tighten the upper looper thread

tension.

Loosen the upper looper thread tension

and/or tighten the lower looper thread

tension.

Tighten the left needle thread tension.

Tighten the right needle thread tension.

Back side

Front side

Back side

Front side

Front side

Front side

Back side

Back side

- 16 -

MACHINE ADJUSTMENT CHART

The best tensionfor onefabric may not be correct foranother.

The required tensions depend upon stiffness and thickness offabric, thread size and type.

If necessary, readjust referring to the chart below.

Fabrics

Threads

Needle

Stitch length

Standard Setting

Light-weight

.Cotton

.Spun

polyester

.Polyester

continuous

No. 80 - 100

HA× 1

No. 11

130 / 705H

No. 80

2.0 - 3.5 mm

.Standard

2.5 mm

.Georgette

.Organdy

.Lawn

.Voile

.Crepe-de-chine

.Silk

etc.

Medium-weight

.Cotton

.Spun

polyester

.Polyester

continuous

No. 60 - 100

HA× 1

No.11-14

130 / 705H

No. 80 - 90

2.0 - 3.5 mm

.Standard

2.5 mm

.Cotton

.Poplin

.Gingham

.Corduroy

etc.

Heavy-weight

.Cotton

.Spun

polyester

.Polyester

continuous

No. 50 - 80

HA× 1

No. 14

130 / 705H

No. 90

2.5 - 4.0 mm

.Standard

3.0 mm

.Denim

.Tweed

.Velour

etc.

- 17 -

CHANGING THE THREAD (TYING ON)

It is simple to change the thread in the following

manner.

Cut the thread above the spool pin, and knot

ends of old and new threads together.

Set the tension dials to "O" and raise the

presserfoot.

Pull the other end of thread until knots come

under the presser foot. For needle threads, pull

theother ends of threads until knots come to

needle eyes and cut the threads at the both

sides ofthe knots. Then re-thread the needles.

BUILT-IN POCKET HANDLE

The Built in pocket handle is a convenient way

tocarry yourmachine.

Pocket handle

- 18 -

ADJUSTMENT OF STITCH LENGTH

There are nine setting adjustments which can be made from 1.0 to 5.0mm.

Most overlock work is done with a basic stitch length setting of2.5-3.5 mm.

[ STITCH LENGTH SETTING ]

Stitches

Stitch length

Regular seaming

Narrow seaming

Rolled edging

Picot edging

2.0 –4.5 mm

3.0 mm (Standard Setting)

1.0 - 2.0 mm

1.0 - 2.0 mm

3.0- 4.0 mm

Stitch length

adjustment knob (lnner dial)

- 19 -

CUTTING WIDTH

The proper cutting width differs with the type offabric. Check the seams each time, and adjust the

cutting width as follows.

1. Turn the hand wheel toward you until the needles are at the lowest position.

2. Open thefront cover and free arm.

3. Turn the cutting width adjustment knob until the looper threads lies along the edge ofthe fabric.

Adjust to a narrower cutting width if the fabric edges curl when sewing. Turn the cutting width

adjustment knob to the right.

Adjust to a wider cutting width ifthe thread loops off the edge of the fabric. Turn the cutting width

adjustment knob to the left.

[ THE PROPER CUTTING WIDTH ]

[ ADJUST TO A WIDER CUTTING

WIDTH ]

Needle plate

Cutting width

adjustment knob

Wide

Narrow

Stitch width

Cutting width

Front side

[ ADJUST TO A NARROWER

CUTTING WIDTH ]

Front side

Front side

Threads looping

off edge of fabric

Stitch curling

edge of fabric

Table of contents

Other Empisal Sewing Machine manuals

Empisal

Empisal Dress Maker 270D User manual

Empisal

Empisal Dress Maker 120A User manual

Empisal

Empisal creations User manual

Empisal

Empisal EES10 User manual

Empisal

Empisal EEM350 User manual

Empisal

Empisal Expression 889 User manual

Empisal

Empisal S4D User manual

Empisal

Empisal em-250 User manual

Empisal

Empisal Designer 800 User manual

Empisal

Empisal 760C User manual